Shandong, China(Mainland)

No.183 Xisan Rd, Dongying,

Have Any Question

+86 13345064499

No.183 Xisan Rd, Dongying,

+86 13345064499

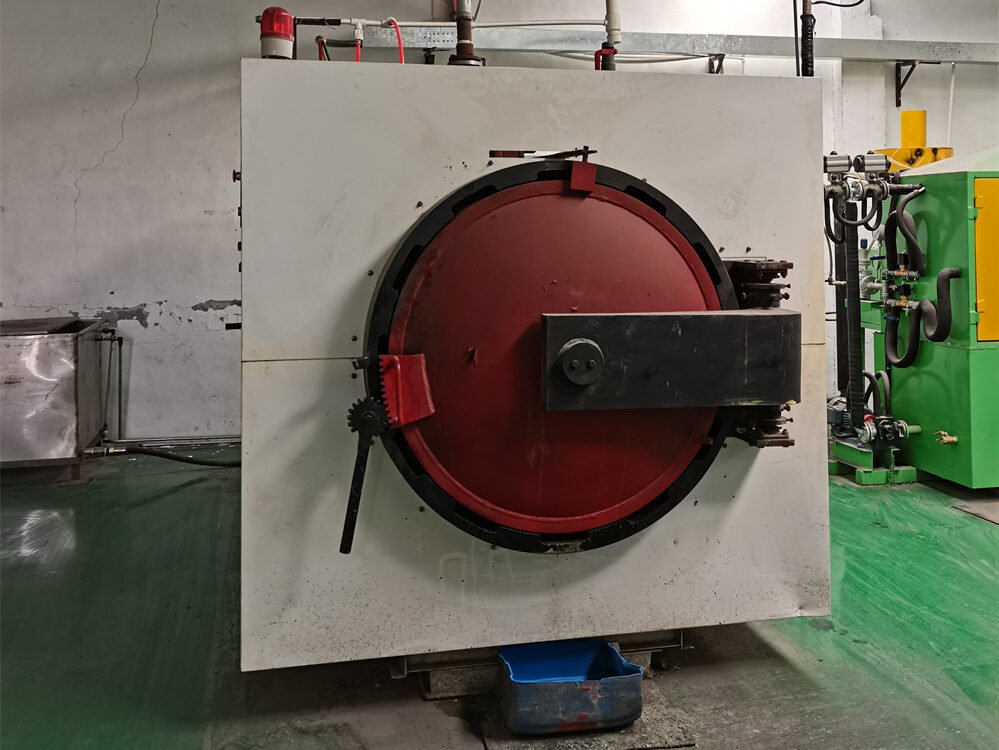

Explore the pinnacle of precision in casting technologies with Dongying Vast. Specializing in aluminum, high-temperature, titanium alloys, and stainless steel, we transform your most intricate designs into reality. Experience unparalleled quality and innovation in every cast

(Year)Professional Experience

(m2)Area

Employee Size

(Tons) Annual Production

Established in 2003 in Dongying City, Shandong Province, Dongying Vast spans over 4,000 square meters and employs over 200 staff, producing 700 tons annually of titanium, aluminum, and stainless steel alloys, among others. The company integrates advanced CAE casting simulation, ERP management software, and precision machinery, adhering to ISO9001 standards. It ensures quality through rigorous testing, adhering to international material and tolerance standards, and provides comprehensive testing reports for customer assurance. Serving over 800 customers across 50 industries globally, Dongying Vast excels in custom metal part manufacturing, offering one-stop solutions and striving to add value for its clients.

Dongying Vast boasts a comprehensive manufacturing capability, featuring rapid prototyping through SLA (Stereolithography) printing combined with precision casting. Our expertise extends to mold design and manufacturing, ensuring high-quality and efficient production processes. Specializing in precision casting, we handle a variety of materials including aluminum alloy, high-temperature alloy, titanium alloy, and stainless steel. In addition to our casting capabilities, we offer advanced mechanical processing and a range of surface treatments, enhancing the quality and durability of our products. Our one-stop solution approach streamlines the entire manufacturing process, from initial design to final product, ensuring a seamless experience for our clients.

Rapid prototyping with SLA printing and precision casting

Expert mold design and manufacturing

Specialized in aluminum, titanium, and steel alloy casting

Advanced mechanical processing capabilities

Comprehensive range of surface treatments

Seamless one-stop manufacturing solutions

Precise and intricate, the process of precision casting involves several key steps to transform raw materials into finely detailed components; let’s delve into each of these stages for a deeper understanding

Dongying Vast is highly regarded by our global clients for our quality, precision, and efficient one-stop solutions in casting and manufacturing.

As a project manager for shipbuilding projects, I’ve found Dongying Vast’s aluminum and titanium alloy castings indispensable. Their ability to deliver precise and high-quality components on schedule has significantly contributed to our project’s success. The professionalism and attention to detail in their work is something we’ve come to rely on.

In the demanding field of pump and valve manufacturing, we require components that meet exacting standards. Dongying Vast has consistently provided us with superior stainless steel castings that stand up to the rigors of our applications. Their commitment to quality and ability to customize to our specifications make them an invaluable partner.

As a wholesaler of industrial products, my experience with Dongying Vast has been exceptional. Their efficient processing and delivery of bulk orders, coupled with their consistent product quality, has greatly benefited our supply chain. Their wide range of alloys and precision in manufacturing have made them a preferred supplier for us.

Our FAQ section is designed to provide quick, clear answers to common questions about Dongying Vast’s products, services, and processes. It’s a helpful resource for understanding our capabilities, specifications, and how we can meet your specific needs in casting and manufacturing.

Dongying Vast can certainly accommodate your needs. We specialize in handling challenging parts with our advanced lost-wax casting process, ensuring precision and quality.

Our precision casting tolerances typically range within industry standards, offering high accuracy for various alloy castings.

Yes, investment casting is ideal for replacement parts due to its ability to produce complex shapes with excellent surface finishes and dimensional accuracy.

Absolutely. Our investment casting process excels in creating intricate and complex shapes, meeting diverse design requirements.

Yes, we can accommodate unique alloy requirements, thanks to our versatile casting capabilities and extensive material expertise.

Dongying Vast is equipped to handle both large and small-scale production runs, ensuring flexibility and efficiency for various project sizes.

Investment casting, also known as lost-wax casting, is a precision casting process used to create detailed and accurate metal parts from various alloys.

Investment casting offers high dimensional accuracy, excellent surface finish, the ability to cast complex shapes, and suitability for a wide range of materials.

Investment casting is suitable for a wide range of materials, including stainless steel, aluminum alloys, titanium, and high-temperature alloys.

Upon submitting your inquiry through our form, you can expect a prompt and detailed response from Dongying Vast within 8 hours. We value your questions and are committed to providing quick, efficient, and personalized assistance to address your specific needs and concerns.

Submit your inquiry and expect a detailed response from Dongying Vast within 8 hours.

Submit your inquiry and expect a detailed response from Dongying Vast within 8 hours.