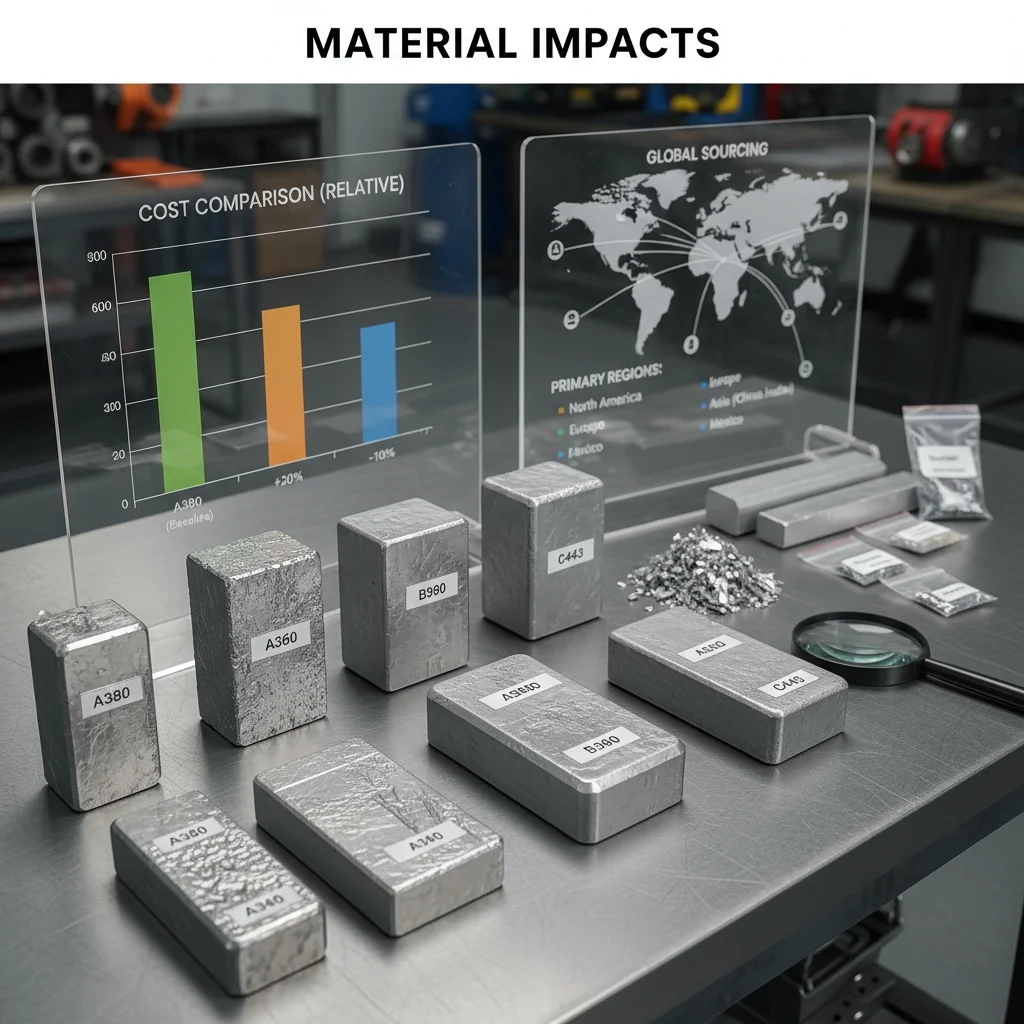

How to Accurately Estimate Aluminum Die Casting Cost for Your Project

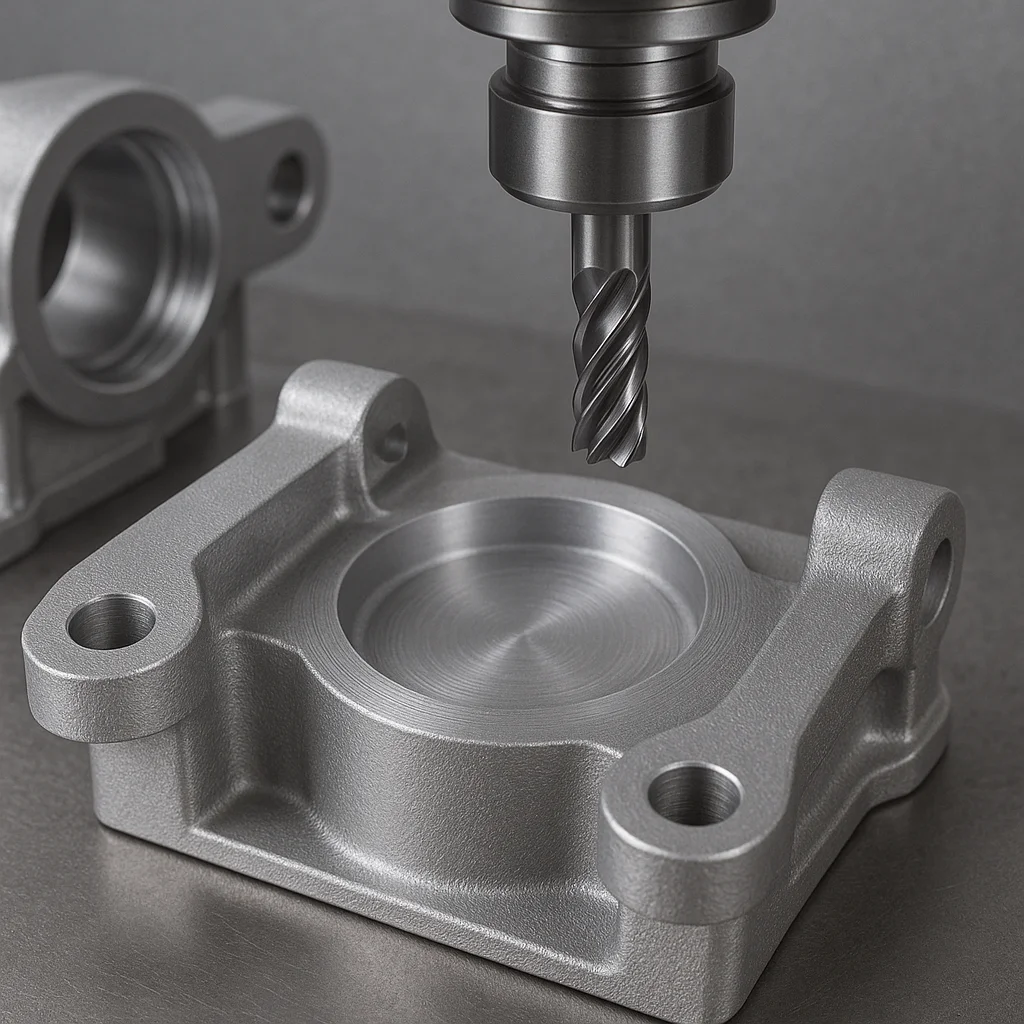

Struggling to predict die casting costs for your aluminum parts leads to budget overruns and delayed projects. This uncertainty can inflate expenses by 20-30% due to overlooked factors like material waste and tooling errors. Discover a step-by-step guide to accurately calculate die casting costs, empowering your manufacturing decisions with proven strategies from over 20 years […]

How to Select the Best Aluminum Casting Alloy for Your Project

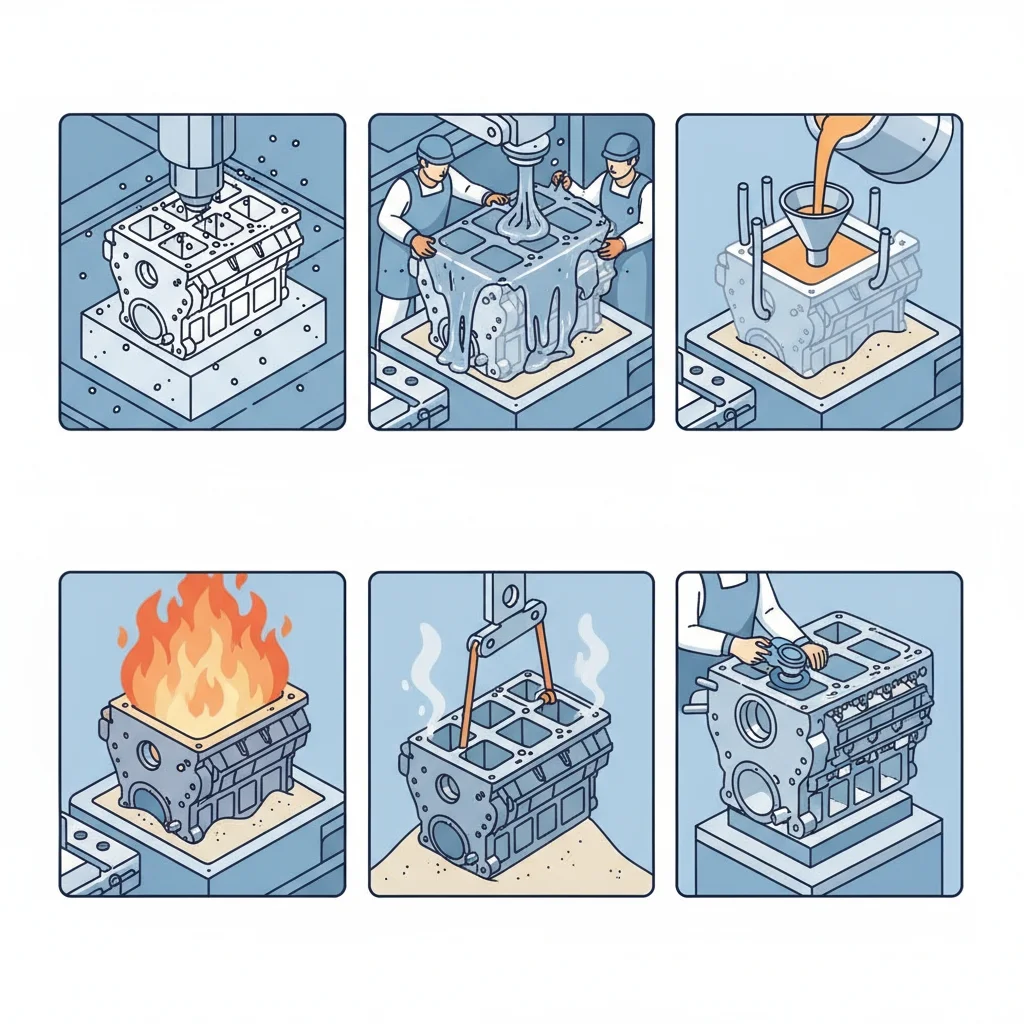

Struggling to produce intricate metal parts without excessive machining costs or defects? Engineers often face challenges with traditional casting methods that limit design freedom and drive up production expenses. You might be wondering how to streamline manufacturing for complex components in automotive or aerospace sectors. The answer lies in mastering the lost foam casting process—a […]

How to Control Casting Temperature of Aluminum for Defect-Free Parts

Introduction In aluminum casting operations, inconsistent temperatures can lead to defects like porous spots or incomplete fills, resulting in scrapped parts, delayed shipments, and reduced efficiency. Proper casting temperatures ensure smooth fluidity and solid components that meet specifications. This guide covers essentials from melting basics to optimization techniques, providing practical steps to improve the process. […]

How to Choose the Right Aluminum Alloy for Casting Without Costly Defects

You face tight deadlines in manufacturing, but picking the wrong aluminum alloy leads to casting defects, wasted materials, and unreliable parts that fail under stress. These missteps escalate quickly, inflating costs by up to 20%, delaying shipments, and eroding trust with clients who demand precision in high-stakes industries like automotive and aerospace. This guide breaks […]

How to Leverage the Aluminum Die Casting Industry for High-Volume Production

Imagine you’re overseeing a production line for automotive parts, where delays from inconsistent molding push back shipments and inflate costs by 20-30%. These pain points—erratic quality, excess scrap, and prolonged lead times—can jeopardize your deadlines and bottom line in a competitive market. Enter aluminum die casting: a high-pressure process that delivers precise, lightweight components quickly, […]