A356 Aluminum Castings: Understanding Its Properties and Industrial Uses

Introduction

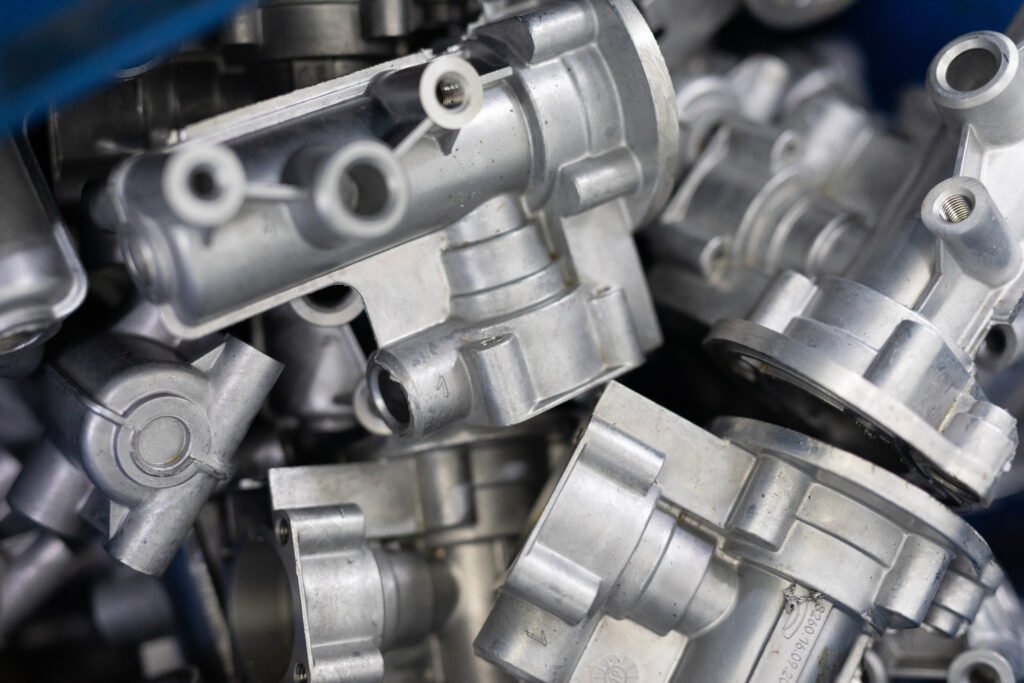

A356 aluminum alloy is an icon in the casting industry, revered for its exceptional combination of strength, durability, and corrosion resistance. Consisting mostly of aluminum, silicon, and magnesium elements, A356 makes itself available as an efficient material suitable for precision casting applications requiring both weight reduction and improved performance.

This article delves deeply into A356 aluminum castings, exploring their properties and applications across industries. From automotive parts to aerospace structures, A356 aluminum alloy plays an essential role in shaping modern industry landscape. We seek to offer a comprehensive insight into this alloy; explaining why its characteristics align perfectly with advanced manufacturing techniques.

As we examine A356 aluminum, we will focus not only on its physical and mechanical properties but also how these attributes translate to practical applications in industries that prioritize precision, efficiency, and durability.

Characteristics of A356 Aluminum Alloy

A356 aluminum alloy stands as a paragon in the world of precision casting, especially at PrecisionVast, where we prioritize materials that deliver both quality and efficiency. Renowned for its impeccable blend of components, A356 has carved a niche in the casting industry owing to its robust properties. Let’s dissect the composition and mechanical prowess of this alloy:

A356 Aluminum Alloy Composition:

| Component | Percentage (%) |

| Silicon | 6.5 – 7.5 |

| Magnesium | 0.2 – 0.4 |

| Iron | Max 0.2 |

| Copper | Max 0.2 |

| Manganese | Max 0.1 |

| Zinc | Max 0.1 |

| Titanium | Max 0.2 |

| Others | Each Max 0.05; Total Max 0.15 |

This alloy is a blend that is meticulously formulated to achieve the best in casting performance. The high silicon content significantly enhances fluidity and reduces shrinkage, making it ideal for intricate designs.

Mechanical Properties

At PrecisionVast, we value the mechanical properties of A356 due to its high tensile strength and excellent durability. It exhibits an ultimate tensile strength of about 231 MPa (33,000 psi) and a yield strength of 165 MPa (24,000 psi). This strength-to-weight ratio is pivotal in industries where both durability and lightweight characteristics are crucial.

Lightweight Nature and Corrosion Resistance

One of the standout features of A356 aluminum alloy is its remarkably lightweight nature without compromising on strength. This quality makes it a go-to material for automotive and aerospace applications where weight reduction is a key concern. Furthermore, its innate corrosion resistance is another attribute that makes it a preferred choice, especially in environments prone to corrosive elements.

In summary, A356 aluminum alloy is more than just a material; it’s a solution that aligns with PrecisionVast’s commitment to delivering exceptional quality and performance in our precision casting projects. Its balanced composition, coupled with superior mechanical properties, positions it as an ideal choice for a range of demanding applications.

Industrial Applications of A356 Aluminum Castings

Automotive Industry:

Lightweight Strength in Motion A356 aluminum alloy has found great use in the automotive industry as it provides an ideal balance of strength and lightness, which makes it especially valuable in components like wheels and engine parts where weight reduction significantly enhances fuel economy and performance. Furthermore, A356’s ability to cast intricate shapes while maintaining structural integrity make it an indispensable material in modern automotive design.

Soaring High: A356 in Aerospace

In the aerospace sector, A356 aluminum’s outstanding strength-to-weight ratio makes an impactful statement about its capabilities in withstanding flight stresses while contributing to weight reduction – an ideal combination for various aircraft structures. Furthermore, its properties facilitate production of parts which not only are lighter in weight but are robust enough to meet rigorous safety standards in aerospace.

Engineering Applications

A356 aluminum has become a go-to material in general engineering applications due to its versatility and casting properties, enabling precision parts casting of complex machinery and equipment parts. Furthermore, its versatility across a variety of engineering applications underscores its significance as an adaptable material that can meet different requirements, from heavy machinery to intricate mechanical components.

The Impact of A356 Aluminum in Modern Manufacturing

PrecisionVast’s use of A356 aluminum alloy serves as a prime example of innovation and versatility in modern manufacturing and engineering sectors. It is distinguished by its combination of strength, durability, and lightweight nature which has proven crucial in developing components with improved strength, weight reduction, performance, and cost effectiveness. A356’s widespread industrial applications in various fields such as the automotive and aerospace sectors underlines its role as an invaluable material; meeting diverse manufacturing demands while still meeting quality and cost requirements makes this material an attractive option across various industries.

PrecisionVast, with its vast expertise in precision casting, understands the role A356 aluminum plays in pushing forward modern manufacturing capabilities. We recognize this material’s immense potential as part of our dedication to innovation and excellence by offering clients solutions that exceed expectations within an ever-evolving industrial landscape.