3D printing technology in the field of precision casting applications

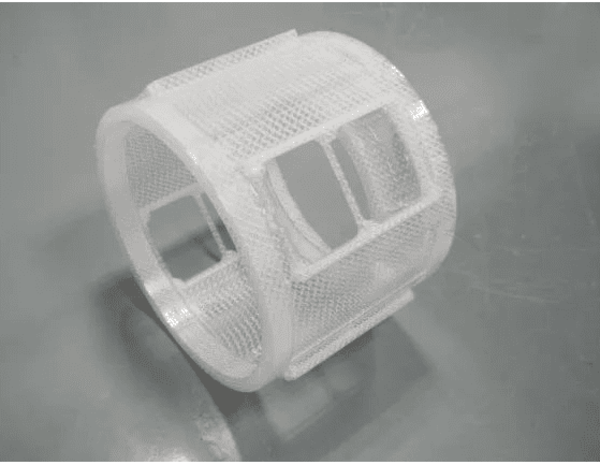

3D printing technology as an advanced intelligent application can be said to be popular in many fields! One of the application in the field of investment casting is to let the audience applaud! The use of three-dimensional graphics in the computer for sampling molding, so that it gets rid of the traditional casting process of cumbersome and inefficient, and greatly promote the efficiency of the refined production, so that the die casting more efficient and environmentally friendly! And its flexibility, applicability of the advantages of a wide range to better meet the current manufacturing on the casting of complex structures, fine details of the stringent requirements, is to realize the metal parts of a single piece or small batch agile manufacturing effective method, widely used in aerospace, automotive motorcycle and other fields.

What areas of investment casting can 3D printing technology be used for?

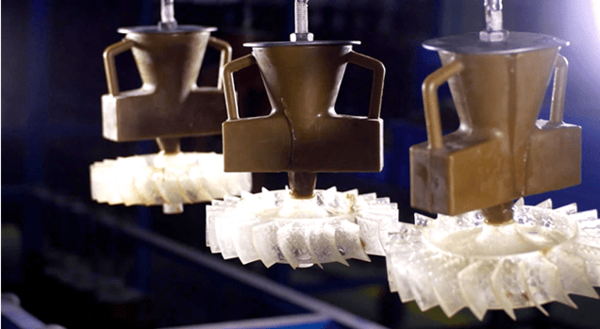

3D Printed Castings – Mold Preprocessing and Assembly Group Tree

3D Printed Castings – Dewaxing

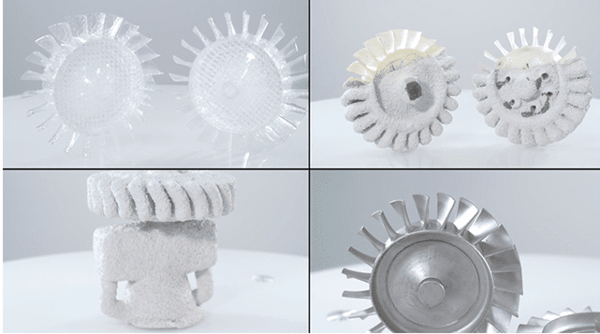

3D printed castings – shell making

3D Printed Castings – Pouring

3D Printed Castings – Roasting

Finished 3D printed castings

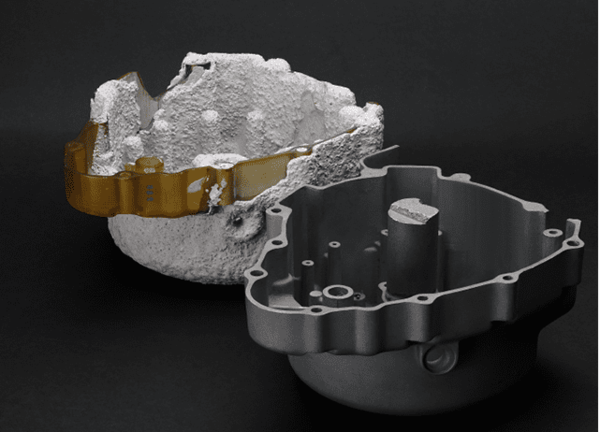

3D printed investment castings

3D printing of precision automotive castings

The intervention of 3D printing technology has successfully solved the problems of high cost and long cycle time of traditional precision casting, and has greatly driven the efficiency of industrialized production, making the detail processing more delicate while taking into account the concept of environmental protection. Overall, 3D printing technology has led the precision casting field for new innovative reforms, become an integral part of its production closed loop, in the future, 3D printing will also explore more exciting applications in the precision casting!