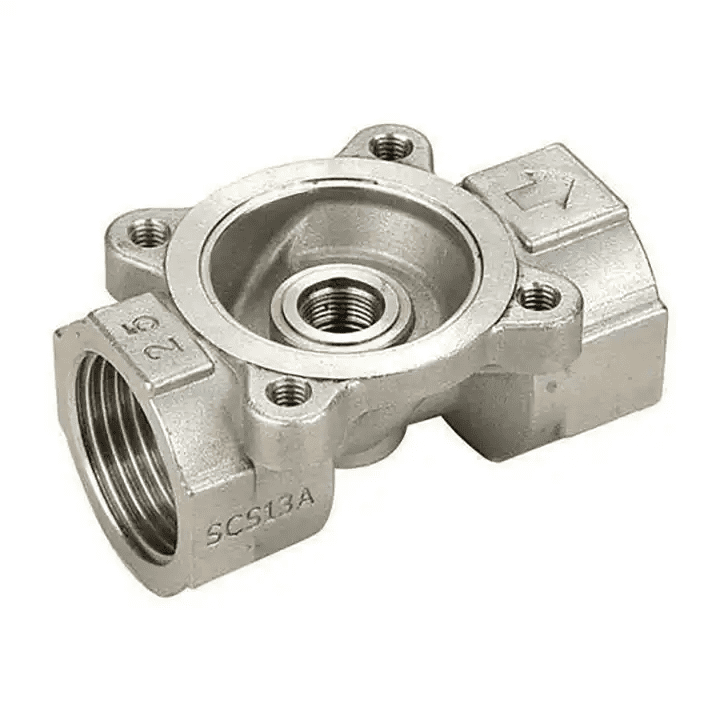

Investment Casting Tooling

We specialize in precision manufacturing of investment casting tools. Our tools are designed to accurately capture complex part geometries, ensuring that each casting meets strict dimensional and quality standards. Our advanced toolmaking techniques are key to ensuring casting quality and efficiency!

What is Investment casting tooling?

Investment casting tooling, also known as wax pattern tooling, plays a critical role in the investment casting process, renowned for its precision and versatility. This technique is essential for creating complex and high-quality metal components. Tooling in investment casting involves the creation of detailed molds and patterns, crucial for shaping the final cast product. The process requires meticulous attention to detail, as the quality of the tool directly impacts the accuracy and integrity of the cast component.

In the design phase of tooling for investment casting, precision is paramount. Every tool is crafted to replicate the final product’s exact specifications, taking into account dimensions, tolerances, and surface finish. The design must also consider the peculiarities of the casting process, including the flow of molten metal and the need for vents and risers to ensure quality casting

The Challenge of Abrasive Design

Addressing design challenges is a significant aspect of tooling design. One major challenge is accommodating the shrinkage that occurs when metal cools and solidifies. Designers must predict and compensate for this shrinkage to ensure that the final product meets the desired dimensions. Another challenge lies in designing tools that can be easily removed from the final cast without damaging it, requiring careful planning of the parting lines and draft angles.

The choice of materials for creating tooling is crucial. Typically, tooling is made from durable materials such as steel or aluminum, capable of withstanding repeated use and the thermal stresses of the casting process. The material selection depends on factors like the number of parts to be produced, the complexity of the design, and the type of metal being cast.

Aluminum Material

Steel Material

About Investment Casting Tooling Cost

For new investment cast parts, you will receive a quote covering both the piece price and the tooling charge. Typically, foundries itemize tooling costs separately, often a one-off expense. It’s advisable to clarify the type of tooling quoted, such as manual, automatic, single, or multi-cavity. Tooling generally becomes the customer’s property once all payments are complete, with the foundry responsible for its storage and maintenance. Clarity on ownership and upkeep is crucial from the start. Tooling costs usually range between $800 and $2,000, depending on size and complexity. Note that modifying tooling for design improvements incurs additional costs, payable by the buyer.

Precision Vast's Tools and Casting Capabilities

At Precisionvast, with over 20 years of experience, we’ve produced and supplied over 5,000 custom castings for diverse applications, ranging from prototypes to high-volume production. Our in-house tooling workshop, equipped with vertical machining centers and other equipment, and our experienced engineers enable us to create precise tooling for your investment casting projects. Our control over tooling design and manufacturing, including cost and delivery, enhances our competitiveness. We offer comprehensive services, including machining, heat treatment, and surface finishing, ensuring top-quality custom molds and toolings, tailored to your specifications and designed with CAD files in various formats. For unique requirements, we provide accurate quotes based on your 2D and 3D drawings, factoring in casting tolerances.

we’re committed to providing top-tier investment casting and tooling services tailored to your specific needs. Our experienced team and advanced facilities are ready to transform your concepts into reality with precision and efficiency. If you have any custom requirements or need a detailed consultation, please don’t hesitate to contact us. We’re here to offer solutions and assist you every step of the way