Material Testing

Chemical composition is the basic property of metal castings, which will directly affect the mechanical properties of the products. Therefore, in the process of investment casting, material testing is an important step to obtain qualified products.

Why metal casting requires material testing?

Precise Material Verification: Advanced Chemical Analysis for Investment Castings

At Precisionvast Foundry, material integrity begins with scientific validation. We utilize high-precision Optical Emission Spectroscopy (OES) to conduct rigorous chemical analysis on every heat of metal. This ensures that every investment casting we produce adheres strictly to international material standards (ASTM, AISI, DIN, or JIS).

How Our Spectrometric Testing Works

Our in-house laboratory is equipped with state-of-the-art spectrometers that analyze the elemental “fingerprint” of the alloy.

Full Elemental Detection: The spectrometer accurately measures the exact percentage of every element—from base metals like Iron (Fe) and Nickel (Ni) to critical trace elements like Chromium (Cr), Molybdenum (Mo), and Carbon (C).

Standards Comparison: Our software instantly compares the live melt data against a database of global material specifications.

Pass/Fail Validation: A “Pass” is only granted if every single element falls within the strict tolerance range of the required chemical composition.

Multi-Stage Material Testing & Traceability at Precisionvast

At Precisionvast, we implement a rigorous, three-tier material verification process to guarantee that every investment casting meets exact metallurgical specifications. Our “Zero-Error” protocol ensures total chemical integrity from the raw ingot to the finished component.

Stage 1: Pre-Stocking Verification (Raw Material Audit)

Before any alloy ingot enters our inventory, we perform a mandatory dual-validation:

Certificate of Conformity (CoC): We review the original mill test reports provided by our material suppliers.

Spectrochemical Analysis: To ensure the authenticity of the supplier’s data, our lab technicians cut a sample from each batch for independent testing. Only “Qualified” materials that pass our internal spectrometer benchmarks are admitted into stock.

Stage 2: In-Process Melt Analysis (Pre-Pouring Check)

Chemical composition can shift during the melting process. To prevent casting errors:

Real-Time Molten Metal Inspection: We perform a final chemical scan of the molten metal immediately before pouring.

Strict Correction Protocols: If the elemental balance (such as Carbon, Chromium, or Nickel levels) deviates from the target range, pouring is halted. The melt is adjusted or scrapped to ensure the final casting’s mechanical properties are never compromised.

Stage 3: Final Product Validation (Post-Casting Audit)

Our quality control doesn’t end at the furnace. Once the casting is complete:

Sample Destructive/Non-Destructive Testing: We conduct a final spectrochemical analysis on the finished sample.

Full Traceability: This final data point is logged, providing our clients with a complete Heat Traceability record, linking the finished part directly back to the original melt batch.

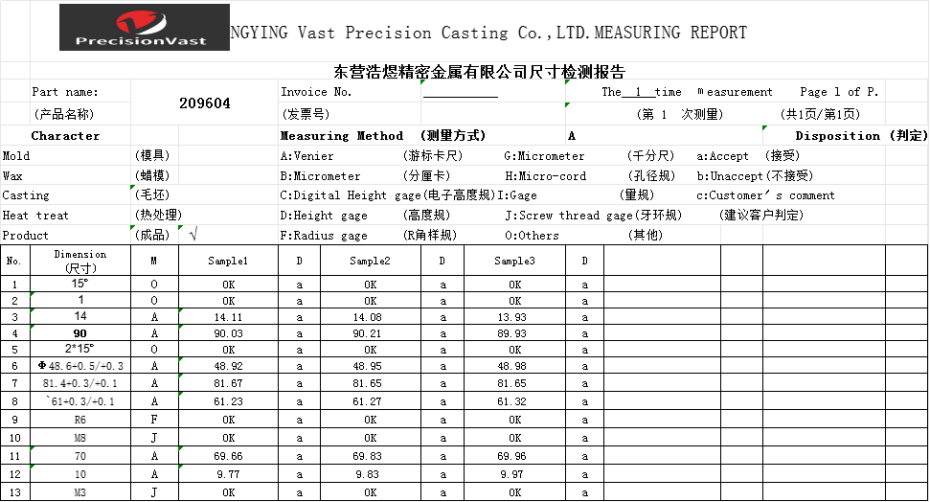

Precisionvast Material Report:

Detailed Material Test Reports (MTR) & Batch Traceability

At Precisionvast, transparency is the foundation of our quality control. We provide comprehensive Material Test Reports (MTR) for every project, ensuring that our clients have documented proof that their investment castings meet every metallurgical requirement.

What is Included in a Precisionvast Material Report?

Our reports are designed for clarity and technical accuracy, allowing engineers to verify quality at a glance:

Standard vs. Actual Comparison: Every report lists the Required Material Specifications (e.g., ASTM A351 for Stainless Steel) side-by-side with the Actual Tested Values from our spectrometer.

Elemental Breakdown: Clear data on critical alloying elements such as Chromium, Nickel, Molybdenum, and Carbon.

Pass/Fail Validation: A definitive statement confirming whether the batch is “Qualified” based on international standards.

Quality Assurance: From Prototypes to Series Production

We maintain the same rigorous standards regardless of order size:

Sample Development: A detailed chemical analysis report accompanies your initial samples, providing a technical baseline for approval.

High-Volume Series Production: For mass production, we perform chemical analysis on every single batch. This ensures 100% consistency across long production runs.

Batch Summary Reports: These single-page summaries provide a “clear picture” of the specific alloying elements in a particular production lot, ensuring your supply chain remains compliant and risk-free.

Digital Traceability & Comprehensive Quality Assurance Protocols

At Precisionvast, our quality control is backed by a robust digital infrastructure. By integrating advanced Spectrometric Analysis with automated data logging, we provide our clients with an unbreakable chain of traceability for every investment casting produced.

Advanced Data Archiving & 3-Year Traceability

We go beyond immediate testing by ensuring long-term data accessibility:

Network-Integrated Testing: Our spectrometers are directly connected to a secure central network. This ensures that every chemical analysis report is instantly digitized and stored without the risk of manual entry errors.

Spectral Block Retention: We archive all physical spectral blocks and digital records for a minimum of three years.

Audit-Ready Accessibility: These records are available for inspection at any time, providing our partners with the data security needed for rigorous industrial audits and safety compliance.

Tools for material testing

We have a full range of material testing tools to ensure that we deliver high quality products at the source, so feel free to contact us if you need anything.