Discover the Different Stainless Steel Materials in Precision Casting

Introduction

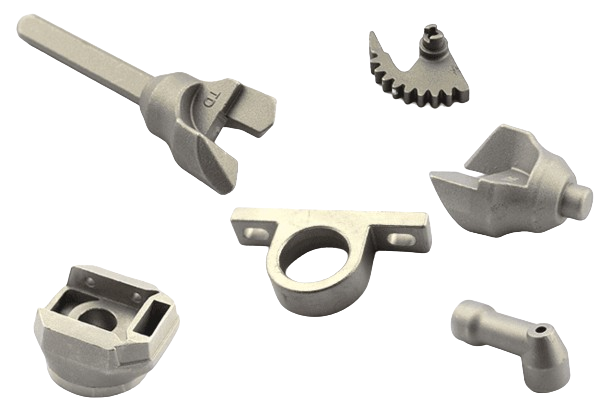

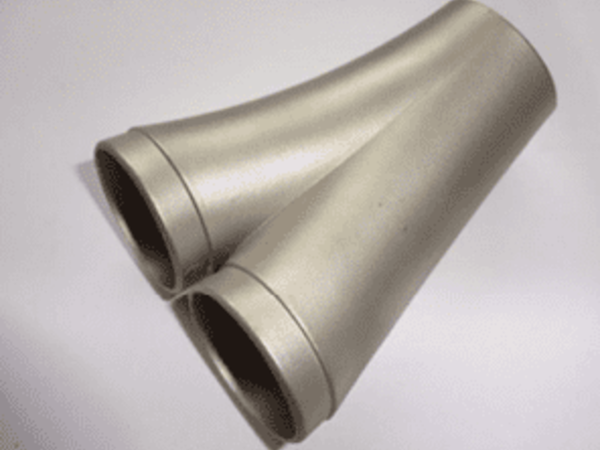

Welcome to the world of precision casting, a domain where meticulous detail meets industrial strength. This is a field not just about melting and molding metals, but about creating components with such precision that they become the backbone of countless industries – from the intricacies of aerospace to the robust demands of automotive manufacturing.

In this arena, stainless steel plays a starring role. It’s not just any metal; it’s a family of alloys known for their corrosion resistance and strength, making them ideal for precision casting. Each variety of stainless steel brings its own set of unique properties to the table, enabling custom solutions for diverse applications.

At PrecisionVast, we’ve honed our expertise over two decades, specializing in the art and science of precision casting. Our journey has led us to work extensively with various grades of stainless steel – 304, 321, 316, 410, 8620, 4140, duplex 2205, and 17-4, to name a few. These aren’t just numbers and names; they’re materials that we’ve mastered, enabling us to deliver products that stand the test of time and performance.

As we delve into the world of stainless steel in precision casting, remember that each type has a story, a set of capabilities, and a place in the vast puzzle of industrial applications. And at PrecisionVast, we’re not just casting metals; we’re crafting legacies.

In-Depth Analysis of Stainless Steel Materials Commonly Used by PrecisionVast

304 Stainless Steel: Versatility and Characteristics

Corrosion Resistance: Exceptional, particularly against environmental factors.

Processability: Highly workable, making it suitable for a wide range of applications.

321 and 316 Stainless Steel: Specialized Applications

321 Stainless Steel:

Specific Use: Optimal for aerospace components due to its resistance to high temperatures.

Titanium Addition: Reduces the risk of weld decay.

316 Stainless Steel:

Medical Applications: Ideal for surgical instruments due to its excellent corrosion resistance.

Molybdenum Presence: Enhances corrosion resistance, particularly against chlorides.

410, 8620, and 4140 Stainless Steel: Martensitic and Ferritic Qualities

410 Stainless Steel:

Hardness and Wear Resistance: High, suitable for cutlery and other applications requiring sharp edges.

8620 and 4140 Stainless Steel:

Application: Often used in the automotive industry due to their combination of toughness, strength, and ductility.

Duplex 2205 and 17-4 Stainless Steel: Strength and Corrosion Resistance

Duplex 2205:

Characteristics: Combines excellent strength with superior corrosion resistance.

Use: Commonly used in chemical processing and marine environments.

17-4 Stainless Steel:

High Strength: Ideal for applications requiring both strength and corrosion resistance.

Aging Treatment: Can be heat treated to enhance strength further.

| Stainless Steel Type | Key Properties | Ideal Applications |

| 304 | Versatile, corrosion-resistant, highly workable | General purpose, kitchenware, construction |

| 321 | High temperature resistance, reduced weld decay | Aerospace components |

| 316 | Superior corrosion resistance, contains molybdenum | Medical instruments, marine applications |

| 410 | High hardness, wear-resistant | Cutlery, tools |

| 8620 and 4140 | Tough, strong, ductile | Automotive parts, gears |

| Duplex 2205 | Strong, excellent corrosion resistance | Chemical processing, marine environments |

| 17-4 | High strength, heat-treatable | Aerospace, chemical processing |

In summary, each stainless steel variant offers unique properties, making them suitable for specific applications. At PrecisionVast, understanding these materials helps us tailor our precision casting solutions to meet diverse industry requirements effectively.

Selecting the right stainless steel material

In the precision casting world, choosing the right stainless steel material is critical to ensuring the quality and performance of the final product. At PrecisionVast, our team of experts determines the most appropriate type of stainless steel by thoroughly analyzing project requirements, while finding the optimal balance between cost-effectiveness and performance.

Project Requirements Analysis

Every casting project has unique needs and challenges that dictate the type of stainless steel required. For example, if a project requires extremely high corrosion resistance and strength, we might choose 316 stainless steel, which gains superior corrosion resistance from the addition of molybdenum. For applications requiring higher hardness and wear resistance, such as certain industrial tools, 410 or 4140 stainless steel may be more suitable.

When analyzing project requirements, the following factors need to be considered:

- Corrosion resistance requirements

- Strength and hardness requirements

- Machinability

- Environment of use (e.g., high temperatures, chemical exposure, etc.)

- Life expectancy of the product

By carefully considering these elements, we are able to select the most appropriate stainless steel material for each project.

Cost versus performance trade-offs

When selecting a stainless steel material, a balance needs to be found between cost-effectiveness and performance. While some high-end stainless steels (such as duplex 2205 or 17-4 stainless) offer superior performance, they also come at a relatively high cost. This constitutes an important consideration when choosing a material, especially when budgets are limited.

Our experts weigh the following factors:

- Material cost and total project cost

- Required performance versus cost

- Durability and maintenance costs in long-term use

- Sustainability and environmental impact

By thoroughly evaluating these factors, we provide our customers with the most cost-effective solution without sacrificing performance.

At PrecisionVast, we understand that selecting the right stainless steel material is critical to the success of a casting project. Our expertise and years of experience ensure that we are able to provide the best material selection for each project, not only to meet technical requirements, but also to take into account economic benefits.

Future Trends and the PrecisionVast Advantage

The future of stainless steel materials is full of potential as technology advances and market demands change. Research and development of new stainless steel alloys and processing technologies is advancing, and these innovations are expected to provide higher performance and a wider range of applications. For example, alloys that are more corrosion resistant and stronger are being developed to meet the demands of more demanding industrial applications.

PrecisionVast draws on its expertise in stainless steel material selection and use and more than two decades of industry experience to be a trusted partner in this evolving field. Not only do we keep abreast of the latest advances in material science, but we also ensure that we provide our customers with the best casting solutions through continuous technological innovation and quality control. At PrecisionVast, we are committed to utilizing these emerging materials and technologies to further enhance the performance and quality of our products to meet the growing needs of our customers.