Introduction

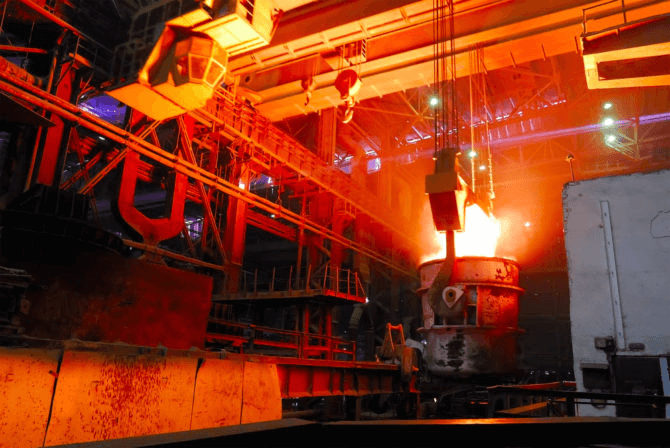

The casting industry, often underappreciated by those outside the manufacturing sector, is a cornerstone of modern industry. Castings play an essential role in the production of countless products that form the backbone of various sectors, ranging from automotive and aerospace to construction and machinery. This intricate process involves pouring liquid material, usually metal, into a mold where it solidifies into the desired shape. The result is a casting—an indispensable component used in everything from engine blocks to architectural structures.

Globally, the casting industry is vast and multifaceted, driven by a network of manufacturers and suppliers who specialize in different types of castings. These range from intricate investment castings used in aerospace components to large-scale sand castings for industrial machinery. Given the widespread application and economic significance of castings, it’s no surprise that the industry is dominated by a few key players on the global stage.

In this article, we will delve into the intricacies of the global casting industry, exploring who the largest producer of castings in the world is. We will examine the factors that have contributed to the rise of this leader, the role of technological advancements, and the future prospects for the global casting market. Whether you’re a procurement officer searching for the best carbon steel casting factories or an industry insider looking to deepen your understanding of the market, this comprehensive guide will provide you with valuable insights.

Understanding Castings

What Are Castings?

At its core, casting is a manufacturing process where a liquid material—typically molten metal—is poured into a mold containing a hollow cavity of the desired shape. The material is then allowed to cool and solidify, after which the part is removed from the mold. The result is a casting, which can be further processed or finished depending on its intended use.

There are several types of casting processes, each with its unique advantages and applications:

- Sand Casting: One of the most widely used methods, sand casting involves creating a mold from a sand mixture. It’s particularly useful for producing large parts, such as engine blocks or industrial machine parts. The process is cost-effective and flexible, allowing for the casting of both ferrous and non-ferrous metals.

- Investment Casting: Also known as lost-wax casting, this process involves creating a wax pattern, which is then coated with a ceramic material. Once the ceramic hardens, the wax is melted away, leaving a mold into which the metal is poured. Investment casting is renowned for its precision and is often used for complex shapes and high-precision components, particularly in the aerospace and medical industries.

- Die Casting: This process involves forcing molten metal into a mold cavity under high pressure. Die casting is typically used for mass production of small to medium-sized parts that require a high level of detail, such as automotive components. It’s a fast and efficient process but is usually limited to non-ferrous metals like aluminum, zinc, and magnesium.

- Continuous Casting: Unlike other methods that produce discrete parts, continuous casting produces long sections of metal, which are then cut into smaller pieces. This method is commonly used in the production of steel and other metals, providing a cost-effective solution for high-volume production.

These methods underline the versatility of casting as a manufacturing process, capable of producing everything from large structural components to intricate mechanical parts. The choice of casting method depends on factors such as the material used, the complexity of the part, and the desired production volume.

The Importance of Castings in Modern Industry

The significance of castings cannot be overstated. They are integral to the production of a vast array of products across multiple industries. For instance, in the automotive sector, castings are used to manufacture engine blocks, cylinder heads, and transmission components. In the aerospace industry, precision castings are vital for producing turbine blades, engine components, and structural parts. The construction industry relies heavily on castings for building materials, such as pipes, valves, and heavy machinery parts.

From an economic perspective, the casting industry contributes significantly to global GDP. The industry provides raw materials for numerous other sectors, creating a ripple effect throughout the global economy. Moreover, advancements in casting technology have led to improvements in product quality, production efficiency, and cost-effectiveness, further enhancing the industry’s impact.

The casting industry also plays a crucial role in innovation. As new materials and technologies emerge, casting processes have evolved to accommodate these changes. For example, the development of advanced alloys and composite materials has expanded the possibilities of casting, enabling the production of stronger, lighter, and more durable components. Similarly, innovations in casting methods, such as additive manufacturing (3D printing), have opened up new avenues for customization and precision in casting.

In summary, castings are the backbone of modern manufacturing, supporting a wide range of industries and driving economic growth. As we move forward, the continued evolution of the casting industry will be essential in meeting the demands of an increasingly complex and interconnected world.

The Global Casting Market

Overview of Global Casting Production

The global casting industry has undergone significant growth and transformation over the past few decades. Historically, casting has been a critical manufacturing process, with roots dating back thousands of years. However, it is the industrial revolution and subsequent technological advancements that have truly shaped the modern casting industry as we know it today. The industry’s development can be traced through the evolution of production techniques, materials used, and the expansion of market applications.

Globally, casting production is dominated by a few key regions, each with its unique strengths and specializations. Asia, in particular, has emerged as a powerhouse in the casting industry, with countries like China and India leading the charge. Europe and North America also play significant roles, contributing to high-quality castings used in specialized industries such as aerospace, automotive, and heavy machinery.

The market share distribution among top casting-producing countries reflects the broader economic and industrial landscape. Asia’s dominance, led by China, is attributed to several factors, including abundant raw materials, a skilled labor force, and supportive government policies. Europe and North America, while not as dominant in terms of sheer volume, excel in producing high-precision and specialized castings, catering to industries that demand the highest quality standards.

Over the years, the global casting market has seen a steady increase in production volumes, driven by growing demand from emerging markets and technological advancements. This growth is expected to continue as the world economy expands and new industries emerge, further solidifying the casting industry’s role as a vital component of global manufacturing.

Top Countries in Casting Production

When examining the top countries in casting production, China stands out as the undisputed leader. With an annual production volume that far surpasses any other nation, China has established itself as the global hub for casting manufacturing. The country’s dominance can be attributed to several key factors, including its vast industrial base, access to raw materials, and a highly skilled workforce. Moreover, China’s government has played an instrumental role in fostering the growth of the casting industry, providing incentives and support to manufacturers.

India follows closely behind, with a robust casting industry that caters to both domestic and international markets. India’s strength lies in its ability to produce a wide range of castings, from basic iron and steel castings to more complex and specialized components. The country’s competitive advantage is further bolstered by its cost-effective production methods and a large pool of skilled labor.

The United States remains a significant player in the global casting market, particularly in high-value and precision castings. The U.S. casting industry is characterized by its focus on quality and innovation, with many manufacturers investing heavily in research and development to produce cutting-edge casting solutions. The country’s advanced infrastructure and access to high-grade materials also contribute to its standing as a leader in the production of specialized castings, particularly in the aerospace and defense sectors.

Germany and Japan are also noteworthy contributors to the global casting market, known for their engineering excellence and high-quality production standards. Both countries have a strong tradition of precision manufacturing, and their casting industries are well-regarded for producing components that meet the stringent requirements of industries such as automotive, machinery, and electronics.

In summary, while China leads in terms of production volume, other countries like India, the United States, Germany, and Japan excel in specific areas of the casting industry, particularly in high-precision and specialized applications. The global casting market is thus a diverse and dynamic landscape, shaped by the strengths and capabilities of these leading nations.

The Largest Producer of Castings in the World

Identifying the Leading Producer

As of 2024, China remains the largest producer of castings in the world, a position it has held for several decades. China’s dominance in the casting industry is not just a recent phenomenon but the result of a sustained and strategic effort to build and expand its manufacturing capabilities. The country’s rise to the top of the casting industry can be traced back to the late 20th century when China’s economic reforms and opening up to global trade created the conditions for rapid industrial growth.

China’s casting industry is supported by a vast network of manufacturers, ranging from small family-owned businesses to large state-owned enterprises. These companies produce a wide variety of castings, including iron, steel, aluminum, and non-ferrous metal castings, catering to both domestic and international markets. The sheer scale of China’s production capacity is unmatched, with the country producing more castings annually than the next several largest producers combined.

One of the key factors behind China’s dominance is its access to abundant raw materials, particularly iron ore and coal, which are essential for casting production. Additionally, China’s government has implemented policies that encourage investment in the manufacturing sector, including subsidies for energy costs, tax incentives for export-oriented businesses, and investment in infrastructure projects that support industrial growth.

Major casting companies in China, such as the China Foundry Association (CFA), have played a crucial role in driving the industry’s development. These companies are responsible for a significant portion of the country’s casting output and have established themselves as leaders in both domestic and international markets. The CFA, in particular, has been instrumental in promoting the adoption of advanced casting technologies and improving production standards across the industry.

China’s Dominance in the Casting Industry

China’s position as the largest producer of castings is the result of a combination of factors, including its vast industrial base, government support, and strategic investments in technology. The country’s manufacturing sector is one of the most advanced and diverse in the world, with casting production playing a central role in its industrial ecosystem.

One of the key drivers of China’s success in the casting industry is its large-scale manufacturing capabilities. China has invested heavily in developing large industrial complexes and production facilities that are capable of producing castings in massive quantities. These facilities are equipped with state-of-the-art technology and are supported by a highly skilled workforce, enabling Chinese manufacturers to produce castings quickly and efficiently.

Another factor contributing to China’s dominance is its strategic approach to innovation and technology adoption. The Chinese government has prioritized the development of advanced manufacturing technologies, including automation, robotics, and digitalization, which have significantly improved the efficiency and quality of casting production. By integrating these technologies into their production processes, Chinese manufacturers have been able to reduce costs, increase output, and improve the quality of their products.

China’s casting industry also benefits from a well-developed supply chain and infrastructure. The country has invested heavily in building transportation networks, logistics hubs, and industrial parks that support the efficient movement of raw materials and finished products. This infrastructure, combined with China’s extensive network of suppliers and distributors, ensures that casting manufacturers have easy access to the resources they need to maintain high levels of production.

In addition to its domestic market, China is a major exporter of castings, supplying products to countries around the world. Chinese castings are used in a wide range of industries, including automotive, aerospace, construction, and machinery, making the country a key player in the global supply chain. China’s ability to produce high-quality castings at competitive prices has made it the supplier of choice for many international companies, further cementing its position as the largest producer of castings in the world.

Comparison with Other Leading Countries

While China is the largest producer of castings by a significant margin, other countries also play important roles in the global casting industry. India, for example, is the second-largest producer of castings and has a growing presence in the global market. India’s casting industry is known for its cost-effectiveness and versatility, with the country producing a wide range of castings for various applications.

The United States, although not as dominant in terms of production volume, excels in producing high-precision and specialized castings. The U.S. casting industry is characterized by its focus on innovation and quality, with many manufacturers investing in research and development to create cutting-edge casting solutions. The U.S. is also a major exporter of castings, particularly to markets in Europe and Asia, where there is a high demand for high-quality components.

Germany and Japan are also key players in the global casting market, known for their engineering excellence and high production standards. Both countries have a strong tradition of precision manufacturing, and their casting industries are well-regarded for producing components that meet the stringent requirements of industries such as automotive, machinery, and electronics. Germany, in particular, is known for its advanced foundry technologies and high-quality iron and steel castings.

In comparison to China, these countries have smaller production volumes but are leaders in specific areas of the casting industry. Their strengths lie in producing high-value, specialized castings that are used in critical applications where quality and precision are paramount. As the global casting market continues to evolve, these countries are likely to maintain their positions as leaders in the production of specialized castings, even as China continues to dominate in terms of overall production volume.

Key Factors Behind the Success of the Largest Producer

Technological Advancements

One of the primary factors behind China’s success as the largest producer of castings is its rapid adoption of technological advancements. Over the past few decades, China has invested heavily in modernizing its manufacturing sector, with a particular focus on incorporating advanced technologies into its production processes. This commitment to innovation has allowed Chinese casting manufacturers to improve efficiency, reduce costs, and produce higher-quality products.

Automation has been a significant driver of productivity gains in China’s casting industry. By integrating automated systems into their production lines, Chinese manufacturers have been able to streamline operations, reduce labor costs, and minimize errors. This has been particularly beneficial in high-volume production environments, where automation can significantly increase output without compromising quality.

In addition to automation, Chinese manufacturers have also embraced digitalization, using advanced software and data analytics to optimize their production processes. Digital tools allow manufacturers to monitor and control every aspect of the casting process in real-time, from material handling to mold design to quality control. This level of precision and control has resulted in higher-quality castings and reduced waste, further enhancing the competitiveness of China’s casting industry.

Another area where China has made significant strides is in the development of new materials and alloys. Chinese researchers and manufacturers have been at the forefront of developing advanced materials that offer superior performance characteristics, such as increased strength, durability, and resistance to corrosion. These materials have opened up new possibilities for casting applications, particularly in industries such as aerospace and automotive, where high-performance components are critical.

Furthermore, China has invested in the development of environmentally friendly casting technologies. As environmental concerns have become increasingly important, Chinese manufacturers have sought to reduce the environmental impact of their operations by adopting cleaner production methods and more sustainable practices. This includes the use of energy-efficient furnaces, recycling of waste materials, and the implementation of stringent emissions controls.

Workforce and Skill Development

The success of China’s casting industry is also closely tied to the development of a skilled and capable workforce. China has a large pool of labor, and the government has made significant investments in education and training programs to ensure that workers have the skills needed to operate advanced manufacturing equipment and meet the demands of modern production environments.

Technical education and vocational training programs have been a key focus in China, with many institutions offering specialized courses in casting and foundry technology. These programs provide students with the knowledge and practical experience needed to work in the casting industry, including training in areas such as mold design, metallurgy, and quality control. This emphasis on education and training has helped to create a highly skilled workforce that is capable of producing high-quality castings with precision and efficiency.

In addition to formal education, many Chinese casting manufacturers also invest in on-the-job training and continuous professional development for their employees. This ensures that workers stay up-to-date with the latest technologies and best practices in the industry. By fostering a culture of continuous improvement, Chinese companies are able to maintain high standards of quality and productivity, even as production volumes increase.

The availability of a skilled workforce is a major advantage for China’s casting industry, allowing it to produce complex and high-value castings that require a high level of expertise. This has been particularly important in industries such as aerospace and automotive, where the demand for precision and quality is paramount. As China’s economy continues to grow, the development of a skilled workforce will remain a critical factor in sustaining the country’s leadership in the global casting market.

Infrastructure and Industrial Ecosystem

China’s dominance in the casting industry is also supported by a well-developed infrastructure and a robust industrial ecosystem. The country’s extensive transportation network, which includes highways, railways, ports, and airports, facilitates the efficient movement of raw materials and finished products. This infrastructure is crucial for supporting the high-volume production and distribution that characterizes China’s casting industry.

In addition to physical infrastructure, China has developed a comprehensive industrial ecosystem that supports the entire casting supply chain. This ecosystem includes suppliers of raw materials, manufacturers of casting equipment, and service providers that offer specialized support in areas such as mold design, quality testing, and logistics. The close proximity of these suppliers and service providers to casting manufacturers creates a highly efficient and integrated production environment, where resources can be quickly and easily accessed.

China’s government has played a key role in fostering this industrial ecosystem by creating industrial parks and special economic zones that are specifically designed to support the manufacturing sector. These zones offer a range of incentives, including tax breaks, reduced land costs, and access to advanced infrastructure, which have attracted a large number of casting manufacturers. The concentration of casting companies in these zones has created a cluster effect, where companies benefit from close collaboration, shared resources, and access to a skilled labor pool.

The industrial ecosystem in China also benefits from strong linkages with other sectors of the economy. For example, the automotive and construction industries, which are major consumers of castings, are closely integrated with the casting industry. This integration ensures a steady demand for castings and encourages continuous innovation and improvement in production processes.

Government Policies and Support

The Chinese government’s role in the growth of the casting industry cannot be overstated. Over the years, the government has implemented a range of policies and initiatives aimed at supporting the development of the manufacturing sector, including the casting industry. These policies have provided a favorable environment for investment, innovation, and growth, helping to establish China as the largest producer of castings in the world.

One of the key policy measures has been the provision of financial incentives to casting manufacturers. These incentives include subsidies for energy costs, tax breaks for export-oriented businesses, and low-interest loans for companies investing in new technology and equipment. By reducing the cost of production, these incentives have made it easier for Chinese casting manufacturers to compete on the global stage.

In addition to financial incentives, the Chinese government has also invested heavily in infrastructure development, creating the physical and logistical foundations needed to support large-scale manufacturing. This includes the construction of industrial parks, transportation networks, and energy facilities, all of which are critical for supporting the high-volume production required by the casting industry.

The government has also prioritized research and development (R\&D) as a key driver of growth in the casting industry. Through various funding programs and partnerships with academic institutions, the government has encouraged innovation and the development of new technologies that enhance the efficiency and quality of casting production. This focus on R\&D has helped Chinese manufacturers stay at the forefront of technological advancements in the casting industry, further solidifying the country’s leadership position.

Finally, the Chinese government has actively promoted international trade and export opportunities for casting manufacturers. Through trade agreements, participation in global trade organizations, and the establishment of export processing zones, the government has created a conducive environment for Chinese castings to reach international markets. This has allowed Chinese manufacturers to expand their customer base and increase their share of the global casting market.

Challenges and Opportunities in the Casting Industry

Environmental Concerns

As with many industrial processes, the casting industry faces significant environmental challenges. The production of castings is energy-intensive and generates a considerable amount of waste, including emissions of greenhouse gases, particulate matter, and other pollutants. The environmental impact of casting production has become a growing concern, particularly in countries like China, where large-scale industrial activities have led to serious air and water pollution.

In response to these concerns, there has been a growing emphasis on developing more environmentally friendly casting technologies. Chinese manufacturers, for example, have adopted a range of measures to reduce the environmental footprint of their operations. This includes the use of energy-efficient furnaces, the implementation of waste recycling programs, and the adoption of cleaner production methods that minimize emissions.

One of the most promising developments in this area is the use of alternative materials and processes that have a lower environmental impact. For instance, the development of bio-based and recycled materials for use in molds and cores has the potential to reduce waste and emissions. Additionally, advancements in digitalization and automation have made it possible to optimize production processes, reducing energy consumption and waste generation.

Despite these efforts, the casting industry still faces significant challenges in achieving sustainability. The transition to more environmentally friendly production methods requires substantial investment in new technology and infrastructure, which can be a barrier for many manufacturers. Moreover, there is a need for greater regulatory oversight and enforcement to ensure that environmental standards are met across the industry.

Economic and Trade Challenges

The global casting industry is also subject to a range of economic and trade challenges. One of the most significant issues is the volatility of raw material prices, particularly for key inputs such as iron ore, coal, and non-ferrous metals. Fluctuations in the prices of these materials can have a direct impact on the cost of production, making it difficult for manufacturers to maintain stable pricing for their products.

Trade tensions and protectionist policies have also created challenges for the casting industry. In recent years, there has been an increase in tariffs and trade barriers, particularly between major economies such as the United States and China. These measures have disrupted global supply chains, leading to increased costs and uncertainty for casting manufacturers. Additionally, trade restrictions can limit access to key markets, reducing opportunities for export growth.

To mitigate these challenges, many casting manufacturers have sought to diversify their supply chains and reduce their reliance on any single market. This includes sourcing raw materials from multiple suppliers, exploring new markets for exports, and investing in production facilities in different regions. By adopting a more flexible and resilient approach to supply chain management, manufacturers can better navigate the economic and trade challenges facing the industry.

Future Opportunities

Despite the challenges, the global casting industry also presents significant opportunities for growth and innovation. One of the most promising areas is the development of new casting technologies that offer greater efficiency, precision, and sustainability. Advances in additive manufacturing, for example, have the potential to revolutionize the casting industry by enabling the production of complex and customized parts with minimal waste.

Emerging markets also offer new opportunities for growth. As economies in regions such as Southeast Asia, Africa, and South America continue to develop, the demand for castings in industries such as construction, automotive, and infrastructure is expected to increase. These markets represent a significant opportunity for casting manufacturers to expand their customer base and increase their global presence.

Another area of opportunity is the increasing demand for high-performance materials in industries such as aerospace, automotive, and energy. As these industries continue to push the boundaries of what is possible, there is a growing need for castings that can withstand extreme conditions and offer superior performance. Manufacturers that can develop and produce these advanced castings will be well-positioned to capitalize on the growing demand for high-value components.

In conclusion, while the global casting industry faces a range of challenges, it also presents numerous opportunities for growth and innovation. By adopting new technologies, exploring emerging markets, and investing in sustainable practices, casting manufacturers can continue to thrive in an increasingly complex and competitive global landscape.

Conclusion

Summary of Key Insights

The casting industry is a vital component of global manufacturing, playing a crucial role in the production of a wide range of products used in industries such as automotive, aerospace, construction, and machinery. As the largest producer of castings in the world, China has established itself as a dominant force in the industry, thanks to its large-scale manufacturing capabilities, strategic investments in technology, and supportive government policies.

China’s success in the casting industry is supported by a skilled workforce, a well-developed infrastructure, and a robust industrial ecosystem. The country’s commitment to innovation and sustainability has allowed it to maintain its leadership position in the global market, producing high-quality castings that are used in critical applications around the world.

Looking Forward

As the global casting industry continues to evolve, new challenges and opportunities will emerge. Environmental concerns, economic volatility, and trade tensions will require manufacturers to adopt more flexible and sustainable practices. At the same time, advances in technology and the growth of emerging markets offer exciting opportunities for innovation and expansion.

For companies looking to source the best carbon steel casting factories, understanding the dynamics of the global casting market is essential. By choosing suppliers that are leaders in technology, quality, and sustainability, businesses can ensure that they are getting the best products at competitive prices.

In the years ahead, the casting industry will remain a critical part of the global manufacturing landscape, driving economic growth and supporting the development of new technologies and industries. As China continues to lead the way, other countries will also play important roles in shaping the future of the casting industry, ensuring that it remains a vibrant and dynamic sector for years to come.