When sourcing precision castings, especially carbon steel precision castings, China is often a top choice due to its vast manufacturing capabilities, cost-effectiveness, and expertise in this field. However, finding a reliable manufacturer can be a daunting task given the number of suppliers available and the complexities involved in precision casting. This comprehensive guide aims to provide in-depth insights into identifying and collaborating with trustworthy carbon steel precision casting manufacturers in China, ensuring you receive high-quality products and a smooth business experience.

Understanding Different Types of Precision Casting

What is Precision Casting?

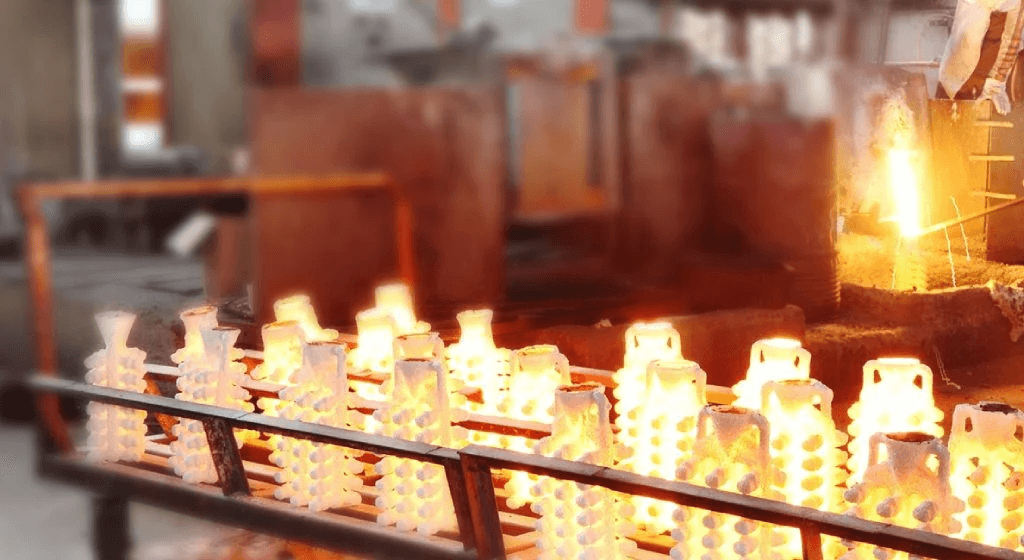

Precision casting, also known as investment casting, is a manufacturing process used to create complex metal parts with high accuracy and excellent surface finish. This process involves creating a wax model of the desired part, which is then coated with a ceramic material. Once the ceramic material hardens, the wax is melted away, leaving a mold that is filled with molten metal. Once the metal solidifies, the ceramic shell is broken away, revealing a precise metal part that requires minimal finishing.

Precision casting is favored in various industries, including automotive, aerospace, and machinery, due to its ability to produce parts with intricate designs and tight tolerances. The process is highly versatile and can be used with a variety of metals, including carbon steel and stainless steel, making it suitable for different applications depending on the properties required.

Benefits of Different Casting Materials

Carbon Steel Casting: Carbon steel is a widely used material in precision casting due to its excellent mechanical properties and cost-effectiveness. Carbon steel castings are known for their strength, toughness, and wear resistance, making them ideal for applications where durability and strength are paramount, such as in construction, mining, and heavy machinery. Moreover, carbon steel is relatively easy to work with, allowing for the production of complex shapes and designs with precision.

Stainless Steel Casting: Stainless steel, another popular material in precision casting, offers superior corrosion resistance and strength compared to carbon steel. This makes stainless steel castings ideal for applications in harsh environments or where hygiene is crucial, such as in the food and beverage industry, chemical processing, and medical equipment. While stainless steel is generally more expensive than carbon steel, its long-term durability and low maintenance requirements often justify the higher upfront cost.

Investment Casting: The investment casting process, regardless of the material used, provides several benefits over other manufacturing methods. These include high dimensional accuracy, excellent surface finish, and the ability to cast complex geometries that would be difficult or impossible to achieve through other processes like machining or forging. Additionally, investment casting can be more economical for small to medium production runs, especially when considering the reduced need for secondary machining and finishing.

Why Choose China for Precision Casting?

China has emerged as a global leader in precision casting, particularly in carbon steel and stainless steel castings, due to several competitive advantages:

- Low Cost: One of the primary reasons companies choose to source precision castings from China is the cost advantage. Chinese manufacturers benefit from lower labor costs, lower raw material costs, and a highly developed supply chain, all of which contribute to the overall cost-effectiveness of their products.

- Complete Supply Chain: China has a comprehensive and well-established supply chain for precision casting. This includes everything from raw material suppliers to advanced foundries and finishing facilities, allowing manufacturers to offer one-stop solutions and streamline the production process.

- Advanced Techniques and Equipment: Over the years, Chinese manufacturers have invested heavily in modernizing their equipment and adopting advanced casting techniques. This has led to significant improvements in the quality and precision of castings produced in China, making them comparable to, if not better than, those produced in other countries.

- High Efficiency: Chinese manufacturers are known for their high production capacity and efficiency. This allows them to meet tight deadlines and deliver large orders on time, making them a reliable choice for businesses that require a steady supply of high-quality castings.

Understanding these aspects of precision casting and why China is a preferred destination for sourcing these products lays the foundation for selecting the right manufacturer. In the next sections, we will delve deeper into the key criteria for choosing a reliable carbon steel precision casting manufacturer in China and how to effectively evaluate potential suppliers.

Key Criteria for Selecting a Reliable Manufacturer

Choosing a reliable carbon steel precision casting manufacturer in China requires careful consideration of several critical factors. This ensures that you receive high-quality products that meet your specifications and that the manufacturer can be a long-term partner for your business. Here’s a detailed look at the essential criteria to evaluate when selecting a manufacturer.

Quality Standards and Certifications

Quality should be at the forefront of your considerations when selecting a carbon steel precision casting manufacturer in China. High-quality castings are crucial for the performance and safety of the final products, especially in industries such as automotive, aerospace, and heavy machinery.

- ISO and Other Relevant Certifications: ISO certifications, such as ISO 9001 for quality management systems, are globally recognized standards that indicate a manufacturer’s commitment to maintaining consistent quality. Other certifications, like IATF 16949 for automotive quality management or AS9100 for aerospace, may also be relevant depending on your industry. These certifications ensure that the manufacturer adheres to strict quality control processes and continually improves their practices.

- Quality Control Processes: Beyond certifications, you should also inquire about the manufacturer’s internal quality control processes. This includes how they inspect incoming raw materials, monitor production, and perform final inspections before shipping. A reliable manufacturer should have robust quality control measures in place at every stage of production to ensure that each casting meets the required specifications.

- Third-Party Audits: Consider whether the manufacturer is open to third-party audits or inspections. Third-party audits can provide an unbiased assessment of the manufacturer’s quality management system and help identify any potential issues that may affect product quality.

Experience and Expertise

Experience is another critical factor to consider when selecting a carbon steel precision casting manufacturer. A manufacturer with a proven track record is more likely to have the expertise and know-how to handle your specific needs.

- Industry Experience: Look for manufacturers with extensive experience in producing carbon steel precision castings, particularly for your industry. This experience is often reflected in their understanding of industry-specific requirements and standards, which can be crucial for ensuring that your castings meet all necessary specifications.

- Technical Expertise: The complexity of precision casting requires technical expertise in areas such as mold design, material selection, and casting processes. A manufacturer with a skilled engineering team and knowledgeable staff will be better equipped to handle complex designs and provide valuable insights into optimizing your products for manufacturing.

- Past Projects and Case Studies: Ask potential manufacturers for examples of past projects or case studies that demonstrate their capabilities. Reviewing these examples can give you a better understanding of the manufacturer’s experience and expertise in producing high-quality carbon steel precision castings.

Manufacturing Capabilities

Understanding a manufacturer’s capabilities is essential to ensure they can meet your production requirements and deliver high-quality castings.

- Production Capacity: Evaluate the manufacturer’s production capacity to ensure they can handle your order volume, whether it’s a small batch or a large production run. This includes understanding their equipment and machinery, as well as their ability to scale production if needed.

- Technology and Machinery: Advanced technology and machinery play a significant role in the precision and quality of castings. Look for manufacturers that use modern equipment, such as CNC machines for mold making and advanced furnaces for metal melting. Manufacturers with state-of-the-art facilities are more likely to produce high-quality castings with tight tolerances and excellent surface finishes.

- Specialized Services: Some projects may require specialized services, such as heat treatment, machining, or surface finishing. It’s important to select a manufacturer that can provide these services in-house or has reliable partners to ensure a seamless production process and reduce the risk of delays or quality issues.

Reputation and Reviews

A manufacturer’s reputation can provide valuable insights into their reliability and the quality of their products.

- Customer Feedback and Reviews: Online reviews, testimonials, and feedback from previous customers can provide a glimpse into the manufacturer’s strengths and weaknesses. Look for patterns in customer feedback, such as consistent praise for quality and service or repeated complaints about delays or quality issues.

- Case Studies and References: Request case studies or references from the manufacturer to learn more about their past projects and how they have met the needs of other customers. Speaking with references can provide firsthand insights into the manufacturer’s reliability, communication, and problem-solving abilities.

- Industry Recognition and Awards: Consider any industry recognition or awards the manufacturer has received. These accolades can indicate a strong reputation within the industry and a commitment to excellence.

Communication and Customer Service

Effective communication and strong customer service are essential for a successful partnership with a carbon steel precision casting manufacturer.

- Responsiveness: Pay attention to how quickly and clearly the manufacturer responds to your inquiries. Prompt and transparent communication is crucial for addressing any concerns or changes in requirements that may arise during the production process.

- Understanding and Support: A good manufacturer should take the time to understand your specific needs and provide support throughout the project. This includes offering technical advice, providing updates on production progress, and being proactive in addressing any potential issues.

- After-Sales Service: Evaluate the manufacturer’s after-sales service and support policies. Reliable manufacturers should offer comprehensive after-sales support, including handling any quality issues, providing replacement parts, and offering ongoing technical assistance.

Cost and Pricing Structures

While cost should not be the sole determining factor when selecting a manufacturer, it is an important consideration, especially for projects with tight budgets.

- Understanding Pricing: Request detailed quotes from potential manufacturers and compare their pricing structures. This includes understanding the costs associated with raw materials, labor, tooling, and any additional services such as machining or surface finishing.

- Negotiating Terms: Be open to negotiating terms and pricing with the manufacturer. In some cases, larger order volumes or long-term partnerships may result in more favorable pricing. However, it’s important to ensure that cost savings do not come at the expense of quality.

- Evaluating Cost-Saving Opportunities: Look for opportunities to reduce costs without compromising quality. This may include selecting alternative materials, optimizing designs for manufacturing, or taking advantage of the manufacturer’s production efficiencies.

By carefully considering these criteria, you can identify and select a reliable carbon steel precision casting manufacturer in China that meets your specific needs and ensures a successful partnership.

Researching Potential Manufacturers

Finding the right carbon steel precision casting manufacturer in China begins with thorough research. This step is critical to narrowing down your options and identifying manufacturers that have the potential to meet your needs. Here are several methods to effectively research potential manufacturers.

Online Research and Directories

The internet is a valuable resource for finding manufacturers and gathering initial information about their capabilities.

- Industry-Specific Directories: Websites like Alibaba, Made-in-China, and Global Sources provide extensive listings of manufacturers in various industries, including precision casting. These directories allow you to search for manufacturers based on specific criteria, such as material type, production capabilities, and certifications.

- Manufacturer Websites: Visit the websites of potential manufacturers to learn more about their capabilities, equipment, and experience. A well-maintained website can provide insights into the manufacturer’s professionalism and commitment to quality. Look for detailed information about their processes, facilities, and past projects.

- Online Reviews and Forums: Online reviews and industry forums can provide valuable insights into a manufacturer’s reputation and reliability. Look for feedback from other businesses that have worked with the manufacturer, paying attention to any recurring positive or negative comments.

Industry Trade Shows and Expos

Attending industry trade shows and expos is an excellent way to meet manufacturers face-to-face and gain a better understanding of their capabilities.

- Networking Opportunities: Trade shows provide opportunities to network with manufacturers, suppliers, and industry experts. This can help you build relationships and gain insights into the latest trends and technologies in precision casting.

- Direct Assessment: Meeting manufacturers in person allows you to directly assess their professionalism, communication skills, and technical knowledge. It also provides an opportunity to see samples of their work and discuss your specific needs in detail.

- Notable Trade Shows in China: Some of the key trade shows for precision casting in China include the China International Foundry Expo (Metal China) and the China International Hardware Show. These events attract numerous manufacturers and provide a comprehensive overview of the industry.

Networking and Referrals

Leveraging your professional network can be an effective way to find reputable manufacturers.

- Industry Contacts: Reach out to colleagues, industry associations, and other contacts to ask for recommendations. Referrals from trusted sources can be invaluable in finding reliable manufacturers.

- Word-of-Mouth Recommendations: Word-of-mouth recommendations can provide insights into a manufacturer’s reliability and quality that may not be available through other channels. These recommendations can help you identify manufacturers that have a proven track record of success.

- Previous Partnerships: If you have previously worked with a reliable manufacturer or supplier, consider asking them for recommendations. They may have established relationships with other manufacturers that could meet your needs.

By utilizing these research methods, you can create a shortlist of potential carbon steel precision casting manufacturers in China. The next step is to evaluate these manufacturers more closely through on-site visits, audits, and detailed assessments of their capabilities and reputation. This will ensure that you choose a manufacturer that can deliver high-quality castings and meet your specific requirements.

Evaluating Manufacturers: On-Site Visits and Audits

After conducting initial research and creating a shortlist of potential carbon steel precision casting manufacturers in China, the next step is to evaluate them more thoroughly. This evaluation typically involves on-site visits and audits, which provide valuable insights into the manufacturer’s capabilities, quality control processes, and overall reliability. Here’s a detailed guide on how to effectively conduct these evaluations.

Planning an On-Site Visit

Visiting a manufacturer’s facility in person is one of the most effective ways to assess their capabilities and ensure they are a good fit for your needs. An on-site visit allows you to see the production process firsthand, meet the team, and evaluate the overall environment of the facility.

- Scheduling and Preparation: Contact the manufacturer to schedule your visit in advance, ensuring they have enough time to prepare and allocate the necessary resources. Before the visit, create a checklist of key areas you want to inspect, such as production lines, quality control stations, storage areas, and shipping facilities.

- Key Areas to Observe: During the visit, pay close attention to the cleanliness and organization of the facility, the condition of the equipment, and the workflow of the production process. Evaluate whether the manufacturer follows best practices in manufacturing and quality control, such as maintaining a clean environment, using well-maintained equipment, and ensuring that employees follow safety protocols.

- Assessing Workforce and Management: Take the time to interact with the workforce and management team. This provides an opportunity to gauge their expertise, experience, and commitment to quality. Ask questions about their experience in carbon steel precision casting, their understanding of your specific requirements, and how they handle challenges that arise during production.

Conducting Audits

Audits are a more formal evaluation process that involves a comprehensive assessment of the manufacturer’s operations, quality management system, and compliance with industry standards. Conducting an audit can help identify any potential issues that may affect the quality or reliability of the castings.

- Importance of Audits: Audits provide an unbiased and thorough assessment of a manufacturer’s capabilities and processes. They help verify that the manufacturer has the necessary infrastructure, technology, and quality control measures in place to consistently produce high-quality castings.

- Checklist for Audits: Prepare a detailed checklist for the audit that includes key areas such as raw material sourcing, production processes, quality control measures, and employee training. Pay special attention to how the manufacturer handles critical aspects of the casting process, such as mold making, metal pouring, and finishing.

- Evaluating Compliance and Standards: During the audit, ensure that the manufacturer complies with relevant industry standards and certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. Also, evaluate their adherence to safety protocols and their ability to trace and manage materials throughout the production process.

Understanding Cultural and Language Differences

When evaluating manufacturers in China, it’s important to be mindful of cultural and language differences that may impact communication and understanding.

- Navigating Cultural Differences: Understanding Chinese business culture can help facilitate better communication and build stronger relationships with manufacturers. For example, Chinese business culture often places a strong emphasis on building relationships and trust, which may require more time and effort compared to Western cultures.

- Overcoming Language Barriers: Language barriers can pose challenges during on-site visits and audits, especially if technical terms and specifications are involved. Consider bringing a translator or working with a bilingual consultant who understands both technical language and cultural nuances to ensure clear communication.

- Ensuring Mutual Understanding: To avoid misunderstandings, be clear and specific about your requirements and expectations. Use visual aids, such as diagrams and samples, to illustrate your points, and ask the manufacturer to confirm their understanding to ensure that everyone is on the same page.

By conducting thorough on-site visits and audits, and by being mindful of cultural and language differences, you can gain a comprehensive understanding of a manufacturer’s capabilities and reliability. This will help you make an informed decision when selecting a carbon steel precision casting manufacturer in China.

Steps to Select a Good Investment Casting or Stainless Steel Casting Supplier

Selecting a reliable supplier for investment casting or stainless steel casting involves several steps that ensure the supplier can meet your specific needs and deliver high-quality products. While these steps are similar to those for selecting a carbon steel precision casting manufacturer, there are some additional considerations to keep in mind.

Verify Supplier Authenticity

Before entering into a partnership with a supplier, it’s important to verify their authenticity and ensure they are a legitimate business.

- Differentiate Between Factory, Trader, and Agent: In China, it’s common to encounter not only factories but also traders and agents who act as intermediaries between buyers and manufacturers. While traders and agents can provide valuable services, such as sourcing and quality control, it’s important to understand their role and the added costs they may introduce. Verify whether the supplier is a factory, trader, or agent, and choose the option that best aligns with your needs.

- Check Business Licenses and Registration: Request copies of the supplier’s business licenses and registration documents to verify their legitimacy. This can help you confirm that the supplier is a registered business in China and operates in compliance with local regulations.

- Use Online Verification Tools: Utilize online verification tools and platforms that provide information about Chinese businesses. Websites like China Checkup and the National Enterprise Credit Information Publicity System can help you verify the supplier’s business status and identify any potential red flags.

Evaluate Workshops and Equipment

Assessing the supplier’s workshops and equipment is crucial to ensuring they have the necessary capabilities to produce high-quality castings.

- Inspect Facilities: During your on-site visit, inspect the supplier’s facilities to evaluate the condition of their workshops and equipment. A well-maintained facility with modern equipment is often an indicator of a supplier’s commitment to quality and their ability to produce precision castings.

- Assess Equipment Capabilities: Review the supplier’s equipment capabilities to ensure they can handle the specific requirements of your project. This includes evaluating the types of furnaces, molds, and machining equipment they use, as well as their ability to perform specialized processes such as heat treatment and surface finishing.

- Consider Technology and Innovation: Look for suppliers that embrace new technologies and innovation in their processes. Advanced technologies, such as automated casting systems and 3D printing for mold making, can enhance the precision and quality of castings while reducing lead times and costs.

Understand Suitable Casting Processes

Understanding the casting processes used by the supplier is essential to ensuring they are capable of producing castings that meet your specific needs.

- Different Casting Methods: Different casting methods, such as lost wax casting, sand casting, and shell molding, have their own advantages and limitations. Ensure the supplier uses the appropriate casting method for your project and has experience with similar products.

- Match Capabilities with Requirements: Align the supplier’s capabilities with your specific requirements, such as material type, size, complexity, and tolerances. A supplier with expertise in producing similar products is more likely to deliver high-quality castings that meet your specifications.

- Review Process Flow: Request a detailed overview of the supplier’s process flow, from mold making to finishing. Understanding each step of the process can help you identify potential areas for improvement and ensure the supplier follows best practices in precision casting.

Start with Small Orders

Starting with small orders is a prudent approach to minimize risk and evaluate the supplier’s capabilities before committing to larger production runs.

- Pilot Runs and Sample Orders: Begin with a pilot run or sample order to assess the supplier’s quality and consistency. This allows you to identify any issues early on and address them before scaling up production.

- Evaluate Quality and Performance: Use the small orders to evaluate the quality of the castings, including their dimensional accuracy, surface finish, and material properties. Also, assess the supplier’s ability to meet delivery timelines and their responsiveness to any issues that arise.

- Build Trust and Confidence: Starting with small orders helps build trust and confidence between you and the supplier. It provides an opportunity to establish clear communication, set expectations, and develop a strong working relationship.

Check Supplier’s Performance History

A supplier’s performance history can provide valuable insights into their reliability and ability to deliver high-quality castings.

- Review Past Projects: Ask the supplier for a portfolio of past projects or case studies that demonstrate their experience and capabilities. Reviewing these examples can help you gauge the supplier’s ability to handle similar projects and deliver quality results.

- Request References: Request references from other customers who have worked with the supplier. Speaking with these references can provide firsthand insights into the supplier’s reliability, communication, and problem-solving abilities.

- Evaluate Consistency: Consistency is key to maintaining a reliable supply chain. Evaluate the supplier’s track record for delivering consistent quality over time and their ability to meet deadlines and fulfill orders.

By following these steps, you can select a good investment casting or stainless steel casting supplier in China that meets your specific needs and ensures a successful partnership.

Negotiating Terms and Agreements

Once you have identified a reliable manufacturer or supplier, the next step is to negotiate terms and agreements that protect your interests and ensure a smooth collaboration. This involves understanding pricing structures, setting clear contractual terms, and ensuring legal compliance.

Understanding Pricing and Cost Structures

Understanding the pricing and cost structures of the manufacturer is essential to negotiating favorable terms and ensuring that you get the best value for your investment.

- Breakdown of Costs: Request a detailed breakdown of all costs associated with the casting project, including raw materials, labor, tooling, machining, and finishing. Understanding these costs can help you identify any hidden fees and negotiate better pricing.

- Volume-Based Pricing: Manufacturers often offer discounts for larger order volumes. If you anticipate placing large orders, negotiate volume-based pricing to reduce costs. However, be cautious about committing to large volumes without first verifying the quality of the castings.

- Payment Terms: Discuss payment terms with the manufacturer, including the deposit amount, payment schedule, and any penalties for late payments. Aim to negotiate terms that align with your cash flow needs while providing incentives for the manufacturer to deliver on time.

Setting Clear Contractual Terms

Setting clear contractual terms is crucial to ensuring that both parties understand their obligations and expectations. A well-drafted contract can help prevent disputes and protect your interests in case of any issues.

- Essential Contract Elements: Include essential elements in the contract, such as product specifications, quality standards, delivery timelines, payment terms, and penalties for non-compliance. Be as detailed as possible to avoid ambiguities and ensure that all aspects of the project are covered.

- Quality Standards and Inspections: Specify the quality standards that the castings must meet, as well as the inspection and testing requirements. Include provisions for third-party inspections and audits, and outline the process for handling quality issues or defects.

- Intellectual Property Protection: If your project involves proprietary designs or technology, include clauses to protect your intellectual property rights. This may include confidentiality agreements, non-disclosure agreements, and restrictions on the use of your designs.

Ensuring Legal Compliance

Ensuring that your contract complies with local laws and regulations is essential to protecting your interests and avoiding legal disputes.

- Understanding Chinese Laws: Familiarize yourself with Chinese laws and regulations related to manufacturing, contracts, and intellectual property. This can help you identify any legal requirements that must be met and ensure that your contract is enforceable in China.

- Using Legal Expertise: Consider hiring a lawyer with experience in international trade and Chinese law to review the contract and provide legal advice. A lawyer can help you identify any potential issues and ensure that your contract is legally binding.

- Enforceability: Make sure that the contract is enforceable in both your country and China. This may involve including provisions for arbitration or dispute resolution in a neutral jurisdiction.

By understanding pricing structures, setting clear contractual terms, and ensuring legal compliance, you can negotiate favorable terms and agreements that protect your interests and ensure a successful partnership with a carbon steel precision casting manufacturer in China.

Managing Quality Control and Production Monitoring

Ensuring the quality of your castings and monitoring production progress are critical to maintaining a reliable supply chain and meeting your project requirements. Effective quality control and production monitoring can help prevent issues, reduce costs, and ensure timely delivery.

Establishing Quality Control Processes

Establishing robust quality control processes is essential to ensuring that your castings meet the required specifications and standards.

- Key Quality Control Measures: Implement key quality control measures at every stage of the production process, from raw material sourcing to final inspection. This may include incoming material inspections, in-process inspections, and final inspections to verify that the castings meet all specifications.

- Third-Party Inspections: Consider hiring third-party inspectors to conduct independent quality checks. Third-party inspections provide an unbiased assessment of the castings and can help identify any issues before they reach your facility.

- Quality Assurance Documentation: Require the manufacturer to provide detailed quality assurance documentation, including inspection reports, material certifications, and test results. This documentation can help you verify that the castings meet the required standards and provide traceability in case of any issues.

Production Monitoring

Monitoring production progress is essential to ensuring that your project stays on track and that any potential issues are addressed promptly.

- Regular Updates and Communication: Maintain regular communication with the manufacturer to receive updates on production progress. This includes weekly or bi-weekly reports on the status of your order, any delays or issues, and the expected completion date.

- Remote Monitoring Tools: Use remote monitoring tools, such as video calls or digital dashboards, to monitor production progress from afar. These tools allow you to stay informed about the status of your order and ensure that the manufacturer is meeting your requirements.

- On-Site Visits and Inspections: Consider conducting periodic on-site visits or inspections to monitor production progress in person. This provides an opportunity to address any issues early on and ensure that the manufacturer is following the agreed-upon processes and standards.

By establishing effective quality control processes and monitoring production progress, you can ensure that your castings meet the required specifications and are delivered on time.

Case Studies and Success Stories

Learning from case studies and success stories can provide valuable insights into best practices and potential pitfalls when working with carbon steel precision casting manufacturers in China. These examples can help you understand what has worked well for other companies and apply those lessons to your own projects.

Examples of Successful Partnerships

Examining successful partnerships with Chinese manufacturers can provide inspiration and guidance for your own sourcing efforts.

- Case Study: Automotive Industry: A leading automotive company partnered with a Chinese carbon steel precision casting manufacturer to produce high-quality engine components. The manufacturer’s advanced casting techniques and strict quality control measures ensured that the components met the required specifications and were delivered on time. The partnership resulted in cost savings and improved product performance, making it a win-win for both parties.

- Case Study: Aerospace Industry: An aerospace company worked with a Chinese manufacturer to produce complex stainless steel castings for aircraft engines. The manufacturer’s expertise in stainless steel casting and their ability to meet tight tolerances and quality standards were key factors in the success of the partnership. The company also benefited from the manufacturer’s ability to provide one-stop solutions, including design, engineering, and testing.

- Lessons Learned: These case studies highlight the importance of selecting a manufacturer with the right expertise and capabilities, establishing clear communication and quality control processes, and building strong relationships based on trust and mutual benefit.

Common Pitfalls and How to Avoid Them

While there are many success stories, there are also common pitfalls that companies can encounter when sourcing from China. Understanding these challenges can help you avoid them and ensure a successful partnership.

- Quality Issues: One of the most common pitfalls is quality issues, which can result from inadequate quality control processes, lack of experience, or poor communication. To avoid this, conduct thorough audits, establish clear quality standards, and maintain regular communication with the manufacturer.

- Delivery Delays: Delays in delivery can occur due to various reasons, such as production bottlenecks, supply chain disruptions, or inadequate planning. To mitigate this risk, work with manufacturers that have a proven track record of on-time delivery, and include penalties for late deliveries in your contract.

- Cultural and Language Barriers: Misunderstandings due to cultural and language differences can lead to miscommunication and errors. To avoid this, invest in building strong relationships with your manufacturer, use clear and concise language, and consider hiring a translator or bilingual consultant.

By learning from success stories and understanding common pitfalls, you can develop strategies to ensure a successful partnership with a carbon steel precision casting manufacturer in China.

Conclusion

Finding reliable carbon steel precision casting manufacturers in China requires thorough research, careful evaluation, and clear communication. By understanding the different types of precision casting, evaluating key criteria for selecting a manufacturer, and conducting on-site visits and audits, you can identify manufacturers that meet your specific needs and ensure a successful partnership.

By following the steps outlined in this guide, you can navigate the complexities of sourcing from China and build strong relationships with manufacturers that deliver high-quality castings and reliable service. Whether you are looking for carbon steel, stainless steel, or investment casting, this comprehensive guide provides the tools and knowledge needed to make informed decisions and achieve success in your sourcing efforts.

If you’re ready to start your journey to find a reliable carbon steel precision casting manufacturer in China, don’t hesitate to reach out for further guidance and support. With the right approach and careful planning, you can find the perfect partner to help you achieve your business goals and deliver high-quality products to your customers.