Titanium has long been known for its strength, lightweight nature, and corrosion resistance. But is titanium an alloy? This question may seem simple, yet it holds the key to understanding the unique properties and applications of titanium and its alloys in various industries. In this article, we’ll dive into the specifics of titanium, including its composition, how it is used, and why titanium alloys are integral to industries like aerospace, medicine, and manufacturing.

1. Introduction

Titanium is a versatile metal widely used in multiple industries, thanks to its strength, lightweight nature, and resistance to corrosion. However, a common misconception arises when asking, “Is titanium an alloy?” Pure titanium, while exceptional in its properties, is not considered an alloy. It becomes an alloy when combined with other metals to improve specific characteristics like strength or temperature resistance. In this article, we will explore the composition of titanium, the different types of titanium alloys, their properties, and their practical uses. From its role in aerospace technology to its increasing importance in medical implants, titanium alloys offer significant advantages over other materials. Let’s break down the complex world of titanium alloys, so you can understand their uses, benefits, and limitations.

2. What is Titanium?

Titanium is a transition metal that is both strong and lightweight, with a density much lower than that of steel. This makes titanium an ideal material for industries where strength-to-weight ratios are crucial, such as aerospace, military, and sports. Naturally, titanium is extracted from minerals like rutile and ilmenite, which are abundant in the earth’s crust. Titanium’s strength is comparable to steel, but it is nearly 45% lighter. It is also highly resistant to corrosion, even in extreme environments such as saltwater. Titanium’s unique combination of lightness, strength, and corrosion resistance makes it suitable for a variety of applications. Pure titanium is often used in marine, medical, and aerospace applications.

But here’s the kicker—while titanium in its pure form is beneficial for many applications, it’s titanium alloys that truly shine when it comes to meeting the demands of more specific industries, thanks to their enhanced properties. These alloys are formed by combining titanium with various other metals, such as aluminum, vanadium, or molybdenum, to alter the physical properties to suit particular needs. So, if you’re considering titanium for an upcoming project, understanding both its pure form and alloy versions will help you make the right decision.

3. Is Titanium an Alloy?

Many people ask the question, “Is titanium an alloy?” To answer this, it’s important to understand what constitutes an alloy. An alloy is a mixture of two or more elements, where at least one of them is a metal. Pure titanium is not an alloy because it consists only of the element titanium. However, when titanium is mixed with other metals, such as aluminum, vanadium, or iron, it forms a titanium alloy. These titanium alloys have improved characteristics like better strength, increased temperature resistance, or greater corrosion resistance. For example, titanium alloys like Ti-6Al-4V (which includes aluminum and vanadium) are used in aerospace applications because of their lightweight and strength properties.

What’s the real story? While pure titanium is useful in some situations, the creation of titanium alloys opens up a whole new world of applications. These alloys are not only stronger but are also tailored for specific applications, making them more effective in demanding environments. From medical devices to aircraft parts, titanium alloys are indispensable in modern engineering.

4. Understanding Titanium Alloys

Titanium alloys are produced by mixing pure titanium with other metals to achieve specific material properties. These properties can include increased strength, improved corrosion resistance, or the ability to withstand higher temperatures. Titanium alloys are typically categorized into three primary types: alpha alloys, beta alloys, and alpha-beta alloys. Each type has distinct advantages based on the metals used and the desired outcome for the alloy.

Alpha alloys, which contain small amounts of aluminum and tin, are typically used in applications requiring high strength and resistance to corrosion. Beta alloys, which contain elements like vanadium and molybdenum, are stronger than alpha alloys but have lower temperature resistance. Alpha-beta alloys, which are a combination of the two, offer the best of both worlds: high strength, good formability, and excellent corrosion resistance.

But here’s where it gets interesting—titanium alloys also come in specialized forms such as titanium aluminides, which are used in advanced aerospace and automotive applications. The properties of these alloys, such as high heat resistance, make them suitable for extremely high-performance engines and structural components. Understanding the differences between titanium alloy types can help you choose the best material for your specific needs.

5. Types of Titanium Alloys

Titanium alloys are classified into several types, depending on the combination of elements in the alloy and the resulting properties. The three main types of titanium alloys are alpha alloys, beta alloys, and alpha-beta alloys.

- Alpha Alloys: These alloys are generally used in applications that require high strength and excellent corrosion resistance. They are highly resistant to high temperatures and have a good fatigue resistance. Common elements added to titanium in alpha alloys include aluminum and tin. These alloys are often used in the aerospace and medical industries, especially for parts that require stability in extreme environments.

- Beta Alloys: Beta titanium alloys have higher strength than alpha alloys, thanks to the addition of elements such as vanadium, molybdenum, and chromium. These alloys are often used in structural components for aerospace and automotive applications. They are especially useful for parts that need to withstand high temperatures and stresses.

- Alpha-Beta Alloys: The combination of both alpha and beta elements provides a balance between strength and formability. These alloys are used in a wide range of industries, including aerospace, automotive, and marine applications, where high strength, formability, and corrosion resistance are needed.

What’s the catch? Not all titanium alloys are the same. Understanding which type suits your needs is essential when selecting the material for a specific project. By choosing the right titanium alloy, you can ensure that your parts will perform optimally in their respective environments.

6. Titanium Alloy Grades

Titanium alloys come in different grades, each designed for specific applications based on the material’s strength, corrosion resistance, and other factors. The grading system for titanium alloys is standardized by the International Organization for Standardization (ISO). Titanium grades are typically numbered from Grade 1 to Grade 5, with the higher-grade alloys offering better mechanical properties.

- Grade 1: This is the most commercially pure titanium, offering excellent corrosion resistance but relatively lower strength. It’s typically used in marine, chemical, and food processing industries.

- Grade 2: This is another commercially pure titanium alloy, offering slightly better strength than Grade 1. It is often used in applications that require a balance between strength and corrosion resistance.

- Grade 5 (Ti-6Al-4V): This is one of the most widely used titanium alloys, consisting of 90% titanium, 6% aluminum, and 4% vanadium. It is strong, lightweight, and highly resistant to corrosion. It’s used in aerospace, medical, and military applications.

Ready for the good part? The strength and versatility of Grade 5 titanium make it a popular choice for high-stress environments, where other materials would not perform as well. Understanding titanium alloy grades is crucial for making the right material selection for demanding projects.

7. Properties of Titanium Alloys

Titanium alloys offer numerous properties that make them highly desirable for a wide range of industrial applications. Some of the key properties of titanium alloys include:

- Strength and Durability: Titanium alloys are incredibly strong, with a high tensile strength-to-weight ratio. This makes them ideal for applications where strength is crucial, yet weight must be minimized.

- Corrosion Resistance: One of the primary reasons titanium alloys are so popular is their resistance to corrosion. They can withstand extreme conditions, including exposure to harsh chemicals, high temperatures, and saltwater environments.

- High-Temperature Resistance: Titanium alloys can operate at high temperatures without losing their strength. This makes them perfect for use in aerospace engines, gas turbines, and other high-performance applications.

- Light Weight: Despite their strength, titanium alloys are lightweight, which makes them ideal for use in the aerospace and automotive industries where minimizing weight is a critical factor.

But here’s the twist—titanium alloys also offer excellent biocompatibility, making them essential in the medical field, particularly in surgical implants and prosthetics. Their ability to integrate seamlessly with human tissue is a game-changer for medical technology.

8. Uses and Applications of Titanium Alloys

Titanium alloys are used across numerous industries due to their exceptional properties. One of the most well-known applications is in the aerospace sector, where their lightweight and strength-to-weight ratio are essential for aircraft and spacecraft. Titanium alloys are used for aircraft frames, engine parts, and even landing gears. The automotive industry has also embraced titanium alloys for high-performance components such as exhaust systems, turbochargers, and suspension components.

In the medical field, titanium alloys are used for surgical implants, including joint replacements, dental implants, and pacemakers. Their resistance to corrosion and biocompatibility make them the material of choice for implants that need to be durable and integrate with the human body.

Ready for the good part? Titanium alloys are also essential in marine applications, where their resistance to saltwater corrosion ensures that they perform well in ships, submarines, and offshore drilling platforms. Their strength and resistance to high temperatures make them perfect for industrial applications like chemical processing, power generation, and even desalination plants.

9. Why Titanium Alloys Are Preferred in Certain Industries

Titanium alloys are preferred in specific industries due to their unmatched combination of strength, weight, and durability. For example, in the aerospace industry, reducing weight is a top priority, and titanium alloys offer an excellent strength-to-weight ratio. The automotive industry also uses titanium alloys for components that must withstand high temperatures and wear, such as engine parts.

But here’s the kicker—titanium alloys are highly resistant to corrosion, making them the material of choice in industries that deal with harsh environments, such as the marine and chemical industries. In these sectors, titanium alloys ensure that equipment and machinery remain functional for longer periods, saving businesses money on replacements and repairs.

10. Advantages of Titanium Alloys

Titanium alloys offer several distinct advantages that make them an attractive choice for manufacturers and engineers. One of the primary benefits is their strength-to-weight ratio, which allows for lightweight components without compromising on strength. This is particularly important in aerospace and automotive industries where every gram counts.

Titanium alloys also offer corrosion resistance, making them ideal for use in harsh environments like saltwater, acids, and high temperatures. This property ensures that titanium components last longer and require less maintenance, reducing the cost of ownership over time.

But wait, there’s more—titanium alloys are biocompatible, which is why they are widely used in the medical field for implants and prosthetics. Their non-reactivity with human tissue ensures that titanium implants integrate seamlessly with the body, offering longer-lasting solutions for patients.

11. Challenges and Disadvantages of Titanium Alloys

Despite their many benefits, titanium alloys are not without their challenges. One of the main drawbacks is their high cost. Titanium itself is more expensive to mine and refine than other metals, and the alloys require complex manufacturing processes. This can make titanium alloys less cost-effective compared to other materials, especially for applications where high performance is not as critical.

Additionally, titanium alloys can be difficult to machine due to their hardness, which increases manufacturing costs. The alloys also tend to be more prone to galling (the sticking of metal surfaces) during processing, which can complicate the fabrication of intricate parts.

But here’s the catch—while the challenges of titanium alloys are real, their benefits often outweigh the costs, especially when performance is the primary concern. In industries where strength, corrosion resistance, and weight are critical, titanium alloys are often the best choice.

12. Titanium Alloy Manufacturing Processes

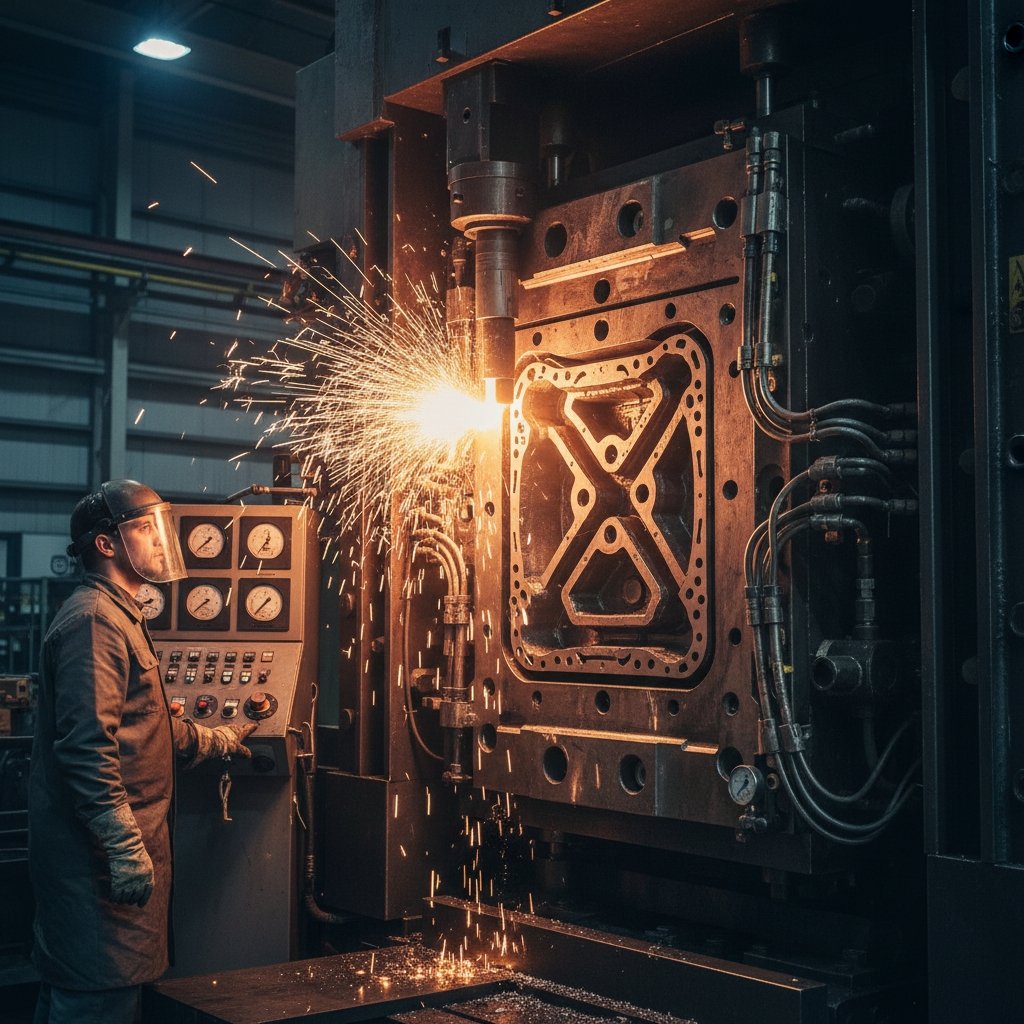

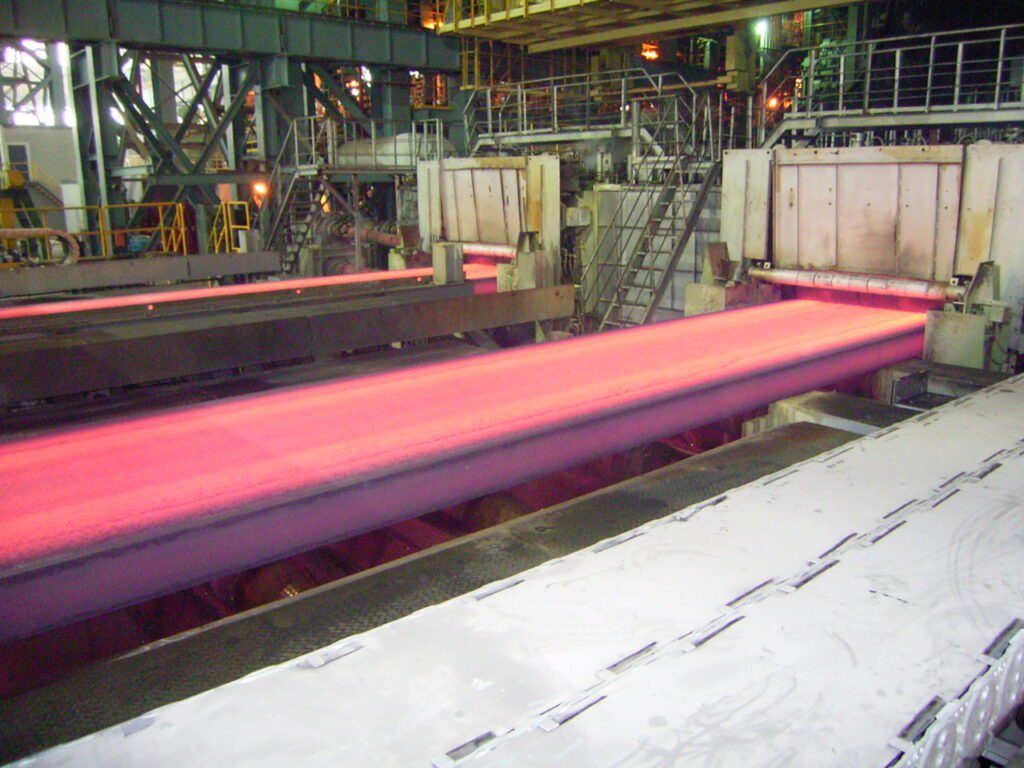

The manufacturing processes used to create titanium alloys are specialized and vary depending on the specific alloy being produced. The most common processes include casting, forging, and welding. Each method has its own advantages and disadvantages, depending on the application.

Titanium alloys are often cast into molds to create parts for various industries, but this process can be challenging due to the metal’s high melting point. Forging is another common method, which involves shaping the alloy by applying heat and pressure. This process improves the material’s strength and eliminates defects. Welding titanium alloys is complex, requiring specialized equipment and expertise, but it can create strong, reliable joints in titanium components.

13. Future Trends in Titanium Alloys

As technology advances, the use of titanium alloys continues to grow. New developments in titanium alloy formulations aim to improve the material’s strength, flexibility, and resistance to wear and corrosion. Emerging applications, such as in robotics and biomedical implants, are pushing the boundaries of what titanium alloys can achieve. Researchers are working on developing greener, more sustainable manufacturing methods for titanium alloys, which could lower production costs and increase the material’s accessibility.

14. How to Choose the Right Titanium Alloy for Your Project

Choosing the right titanium alloy depends on a variety of factors, including the application’s requirements for strength, weight, temperature resistance, and corrosion resistance. For example, if you are working on a project that involves extreme temperatures, a beta titanium alloy would be the best choice. Conversely, for a project that needs a balance of strength and formability, an alpha-beta alloy may be a better option.

Knowing the specific properties of different alloys is essential to making the right choice. By working closely with materials experts and understanding the demands of your project, you can ensure that the titanium alloy you select will perform optimally.

15. Conclusion

Titanium alloys are essential to a wide range of industries, offering unparalleled benefits such as strength, lightweight, and corrosion resistance. While pure titanium is useful in some situations, titanium alloys provide significant advantages, particularly when tailored to specific applications. Whether you’re designing components for aerospace, automotive, or medical applications, understanding the differences between pure titanium and its alloys is crucial to choosing the best material for the job.

FAQ Section

Q1: What is titanium?

Titanium is a strong, lightweight metal known for its corrosion resistance. It is used in various industries including aerospace, medical, and consumer goods due to its durability and high strength-to-weight ratio.

Q2: How does titanium alloy differ from pure titanium?

Pure titanium is a single metal element, while titanium alloys are mixtures of titanium and other metals. Titanium alloys have improved characteristics such as increased strength, heat resistance, and corrosion resistance.

Q3: Why are titanium alloys so expensive?

Titanium alloys are expensive because titanium itself is costly to extract and refine. Additionally, the complex processes involved in alloying and manufacturing titanium products contribute to its high price.

Q4: What are the most common applications of titanium alloys?

Titanium alloys are commonly used in aerospace (aircraft and rockets), medical (implants and prosthetics), marine (ship hulls), and automotive industries, as well as in chemical processing equipment and high-end consumer goods.

Q5: Can titanium alloys be recycled?

Yes, titanium alloys can be recycled, although the process is more challenging compared to other metals. The growing focus on sustainability is leading to improvements in recycling processes for titanium alloys.