Carbon steel casting has long been a staple in manufacturing processes across various industries, providing durable, high-strength components at a cost-effective price. The versatility and performance of carbon steel make it an ideal material for numerous applications, from automotive parts to industrial machinery. But what makes carbon steel casting such a valuable choice for your projects? This article explores the key benefits of using carbon steel castings, shedding light on how it can provide significant advantages for your business needs. Whether you’re involved in heavy machinery production or looking to improve the reliability of your products, understanding these benefits can help you make an informed decision.

1. What is Carbon Steel Casting?

Carbon steel casting is a manufacturing process where molten carbon steel is poured into a mold to create various components. The process has been used for centuries to produce durable and strong parts. But what exactly is carbon steel, and why is it so widely used in casting?

Carbon steel is primarily composed of iron and carbon, with small amounts of other elements like manganese, sulfur, and phosphorus. The carbon content in steel can range from 0.05% to 2%, affecting the material’s hardness, strength, and ductility. Carbon steel casting is known for its ability to produce parts that are both strong and tough, which is why it’s often used in industries requiring high-performance components.

What’s the real story behind its effectiveness? The casting process itself allows manufacturers to produce parts of complex shapes with high precision. From automotive components to heavy industrial machinery, carbon steel castings are used in countless applications due to their ability to withstand wear, resist impact, and maintain performance even under extreme conditions.

This is where it gets interesting… Carbon steel castings can be tailored for different purposes by adjusting the alloy composition, making it suitable for both structural and functional components. It offers a blend of strength and malleability, providing the perfect balance for high-demand industries.

| Process Step | Description |

|---|---|

| Step 1: Mold Creation | A mold is designed based on the part specifications. |

| Step 2: Pouring Molten Steel | Molten carbon steel is poured into the mold, taking its shape. |

| Step 3: Cooling and Solidification | The metal cools and hardens, forming the casting. |

| Step 4: Finishing | Post-casting processes, including cleaning and machining, refine the product. |

2. Advantages of Carbon Steel Casting

Carbon steel casting brings several benefits to the table, especially when compared to other materials used for manufacturing components. It’s a cost-effective option that doesn’t compromise on strength or durability. But here’s the kicker—carbon steel casting is also highly versatile. Let’s break it down further.

One of the most prominent advantages of carbon steel casting is its strength and durability. Carbon steel, with its relatively high carbon content, creates a material that’s capable of handling immense stress and pressure. This makes it perfect for applications that require robust and long-lasting components.

But there’s more! Carbon steel castings also offer excellent machinability. Whether you need precise drilling, cutting, or threading, carbon steel components can be easily shaped without sacrificing their mechanical properties. This is particularly useful in industries such as automotive and aerospace, where complex parts with tight tolerances are common.

Another advantage is cost-effectiveness. While high-performance materials like stainless steel or titanium offer superior properties, they come with a higher price tag. Carbon steel provides similar benefits at a fraction of the cost, making it an excellent choice for businesses looking to keep costs low without compromising on quality.

| Advantage | Key Benefit |

|---|---|

| Strength and Durability | Withstands extreme conditions and impacts. |

| Machinability | Can be easily processed without loss of integrity. |

| Cost-Effectiveness | High performance at a lower cost than other materials. |

3. Key Benefits of Carbon Steel Casting

Carbon steel casting has some notable advantages that make it stand out from other manufacturing methods. Ready for the good part? Here’s how carbon steel casting can elevate your projects.

1. High Mechanical Properties: Carbon steel castings offer outstanding mechanical properties, including high tensile strength and hardness. These qualities ensure that carbon steel castings perform well even in harsh environments.

2. Versatility in Applications: From valves and pumps to heavy machinery components, carbon steel castings are suitable for a wide range of applications. The versatility of carbon steel makes it a go-to option for different industries, including automotive, aerospace, and construction.

3. High-Temperature Resistance: Carbon steel castings can endure high-temperature environments without losing their structural integrity. This makes them ideal for industries where heat resistance is essential, such as in the production of engine parts, turbines, and power plants.

What’s the takeaway? The benefits of carbon steel castings can significantly improve your product performance and operational efficiency. Whether you’re producing small components or large-scale industrial parts, carbon steel casting provides the durability, versatility, and performance needed for long-term success.

| Benefit | Description |

|---|---|

| Mechanical Properties | High strength and hardness for robust performance. |

| Versatility | Suitable for diverse applications across industries. |

| Temperature Resistance | Handles high temperatures without compromising strength. |

4. Industries that Use Carbon Steel Casting

Carbon steel castings are used in a variety of industries, each benefiting from their unique properties. Here’s where it gets exciting. These castings play a key role in industries that demand high-performance materials.

Automotive Industry: Carbon steel castings are used extensively in the automotive sector for producing engine blocks, transmission components, and other parts. These components need to withstand extreme conditions, including heat, pressure, and friction, making carbon steel the ideal choice.

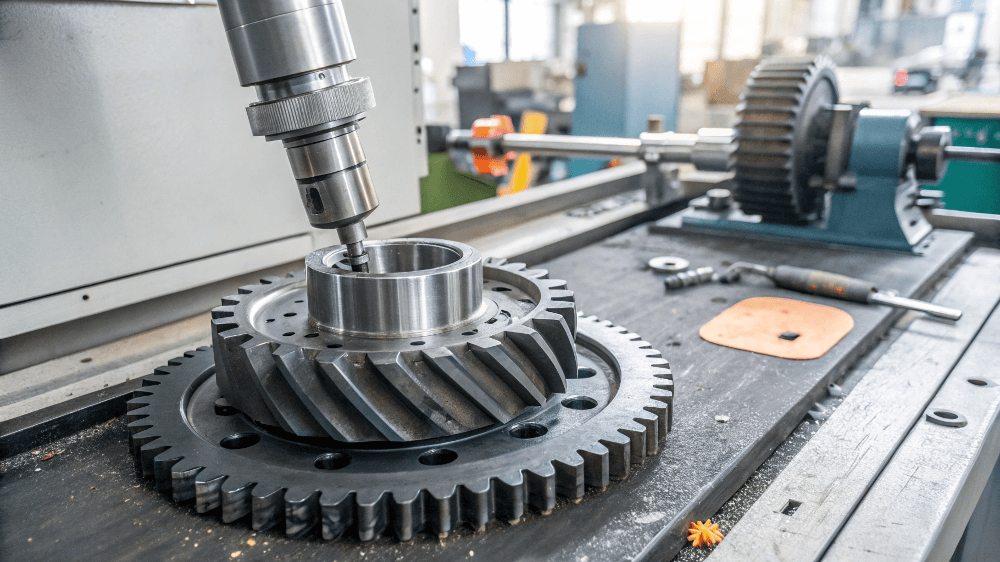

Heavy Machinery and Construction: Components such as gears, shafts, and heavy-duty valves are often made from carbon steel. These parts must handle heavy loads and resist wear, which is where carbon steel shines.

Oil and Gas Sector: The oil and gas industry relies on carbon steel castings for parts such as valves, pumps, and pressure vessels. These components must endure high pressure and corrosion, making carbon steel an excellent material choice.

Carbon steel castings are also used in aerospace, marine, and defense sectors. With each industry requiring specific characteristics, carbon steel offers the perfect balance of strength, durability, and cost-efficiency.

| Industry | Common Applications |

|---|---|

| Automotive | Engine blocks, transmission components. |

| Heavy Machinery | Gears, shafts, heavy-duty valves. |

| Oil and Gas | Valves, pumps, pressure vessels. |

| Aerospace | Aircraft parts, engine components. |

5. The Carbon Steel Casting Process

Understanding the casting process itself can help you appreciate why carbon steel is so effective. But here’s the kicker—casting provides incredible precision while maintaining cost-efficiency.

The process begins with mold creation, where a detailed mold of the part is designed. After the mold is prepared, molten carbon steel is poured into it, filling all cavities to form the part. The molten steel is allowed to cool and solidify, creating the casting.

Next, the casting undergoes finishing processes. This can involve cutting, grinding, or polishing the product to ensure it meets the required specifications. This step is crucial for removing any imperfections and ensuring the part is fit for use.

What’s interesting here? The entire process allows manufacturers to produce parts that are incredibly complex, offering the freedom to design components with high precision and detailed features.

| Process Step | Description |

|---|---|

| Mold Creation | A detailed mold is designed based on part specifications. |

| Pouring Molten Steel | Molten steel is poured into the mold to create the part. |

| Cooling and Solidification | The steel cools and hardens, forming the casting. |

| Finishing | Post-casting processes refine the part for use. |

6. Applications of Carbon Steel Castings

From automotive parts to heavy machinery, carbon steel castings are used in a wide variety of applications. But what’s the real story behind its extensive use?

Engine Components: Carbon steel castings are perfect for engine components that need to endure extreme conditions. Engine blocks, cylinder heads, and crankshafts are just a few examples of parts made from carbon steel.

Industrial Machinery: Heavy-duty machinery components, including gears, bearings, and pumps, often rely on carbon steel castings for their strength and wear resistance.

Construction and Infrastructure: Carbon steel is also widely used in the construction of bridges, tunnels, and other infrastructure components that require high durability.

Carbon steel’s applications continue to grow as industries increasingly rely on durable, cost-effective materials for their manufacturing needs. The variety of parts it can be used for ensures it remains a valuable material choice.

| Application | Common Uses |

|---|---|

| Automotive | Engine components, crankshafts, cylinder heads. |

| Industrial Machinery | Gears, bearings, pumps. |

| Construction & Infrastructure | Bridges, tunnels, heavy-duty components. |

7. Choosing the Right Carbon Steel Grade for Casting

Selecting the correct carbon steel grade for your casting project is critical. But here’s where it gets interesting… not all carbon steel grades are created equal.

Grades like AISI 1020 and AISI 1045 are commonly used in carbon steel castings. The grade you choose depends on the specific demands of your application, such as the required strength, hardness, and corrosion resistance.

What matters most when selecting a grade? The key is understanding how the material will be used in your project. For example, AISI 1020, with its lower carbon content, is better for parts that don’t require extreme strength, while AISI 1045, with a higher carbon content, provides greater strength for more demanding applications.

| Steel Grade | Characteristics | Common Uses |

|---|---|---|

| AISI 1020 | Low carbon content, easy to machine | Automotive parts, light-duty components |

| AISI 1045 | Higher carbon content, stronger and tougher | Heavy-duty components, gears, shafts |

8. Common Issues in Carbon Steel Casting

While carbon steel casting offers numerous benefits, it’s not without its challenges. But don’t worry! Here are some common issues you might face during the process and how to address them.

Shrinkage: As molten metal cools, it tends to shrink. This can result in voids or gaps within the casting. To prevent this, careful attention must be given to the mold design to account for shrinkage.

Porosity: Small holes or voids can form in the casting, weakening the final product. Proper venting and degassing of the molten steel can help eliminate porosity.

Inconsistent Quality: If the carbon steel casting process isn’t monitored carefully, it can lead to inconsistent product quality. This can be avoided by using high-quality raw materials and maintaining strict control over the casting process.

| Issue | Solution |

|---|---|

| Shrinkage | Adjust mold design to account for shrinkage. |

| Porosity | Use proper venting and degassing techniques. |

| Inconsistent Quality | Monitor the casting process and use quality raw materials. |

9. Carbon Steel Casting vs. Other Casting Materials

What’s the real story here? Carbon steel casting holds its own when compared to other casting materials like stainless steel and aluminum.

Stainless steel is known for its corrosion resistance, but it can be more expensive and less malleable than carbon steel. On the other hand, aluminum is lighter and easier to cast, but it doesn’t offer the same strength and durability as carbon steel.

When it comes to cost-effectiveness and performance, carbon steel often emerges as the best choice for heavy-duty applications. It offers a perfect balance of strength, durability, and cost-efficiency.

| Material | Strength | Durability | Cost | Corrosion Resistance |

|---|---|---|---|---|

| Carbon Steel | High | Very High | Low | Moderate |

| Stainless Steel | Moderate | High | High | High |

| Aluminum | Low | Moderate | Moderate | Low |

10. The Future of Carbon Steel Casting

The future of carbon steel casting looks bright, with continuous advancements in manufacturing technology and growing demand in emerging markets. But here’s the kicker—technology is making it possible to cast even more complex shapes and components with carbon steel, expanding its applications even further.

As industries continue to evolve, the demand for high-strength, cost-effective materials like carbon steel will only increase. Carbon steel casting is expected to play an even larger role in manufacturing over the coming years, especially as new innovations improve its performance and sustainability.

| Trend | Description |

|---|---|

| Technological Advances | More complex and precise castings will become possible. |

| Increasing Demand | Industries in emerging markets will increase their reliance on carbon steel. |

| Sustainability Focus | More sustainable manufacturing methods will be developed. |

11. How to Select a Reliable Carbon Steel Casting Supplier

When sourcing carbon steel castings, it’s crucial to choose the right supplier. Here’s what you need to look out for.

First, verify that the supplier has the necessary certifications, such as ISO 9001, to ensure product quality. Second, inquire about their lead times and production capabilities to avoid delays. Finally, assess their customer service and after-sales support to ensure smooth communication throughout the process.

| Criteria | Description |

|---|---|

| Certifications | Ensure supplier meets quality standards like ISO 9001. |

| Lead Times | Assess production capabilities and lead time reliability. |

| Customer Service | Evaluate communication and after-sales support. |

12. Cost Considerations for Carbon Steel Casting

When it comes to cost, carbon steel casting is one of the most cost-effective options available. However, various factors can influence the final price.

Material quality, mold design, and post-casting processes all play a role in determining the overall cost of carbon steel casting. Despite this, the material’s ability to provide high strength at a lower cost makes it an attractive option for many industries.

| Cost Factor | Description |

|---|---|

| Material Quality | Higher-grade carbon steel can increase costs but improve performance. |

| Mold Design | Complex molds increase costs, but improve precision. |

| Post-Casting Processes | Additional processing like machining can raise costs. |

13. Tips for Optimizing Your Carbon Steel Casting Projects

Want to get the most out of your carbon steel casting projects? Here are some tips for ensuring success.

First, carefully design your molds to minimize defects and ensure efficient use of materials. Second, invest in high-quality carbon steel and work with reputable suppliers. Finally, don’t skimp on post-casting processes—ensure proper finishing and quality control.

| Tip | Description |

|---|---|

| Mold Design | Optimize designs to minimize defects and waste. |

| Material Selection | Choose high-quality steel for better performance. |

| Post-Casting Processes | Prioritize proper finishing to maintain quality. |

14. Conclusion

In conclusion, carbon steel casting is an invaluable option for businesses looking to produce durable, cost-effective components. With its wide range of benefits, from high strength to versatility, carbon steel castings offer superior performance for various industries. By choosing the right suppliers and optimizing your processes, you can maximize the benefits of this material, ensuring the success of your projects. The key takeaway? Carbon steel casting remains one of the best choices for businesses in need of high-performance, reliable, and affordable materials.

FAQ Section

Q1: What is carbon steel casting?

Carbon steel casting is a manufacturing process where molten carbon steel is poured into a mold to create components, which cool and harden to form a strong, durable product.

Q2: How does the carbon steel casting process work?

The process begins with mold creation, followed by pouring molten steel into the mold. The steel cools and solidifies into the casting, which undergoes finishing processes for final refinement.

Q3: What are the main benefits of carbon steel casting?

The main benefits of carbon steel casting include high strength, durability, cost-effectiveness, excellent machinability, and versatility across a range of industries.

Q4: Which industries benefit from carbon steel castings?

Carbon steel castings are used in industries such as automotive, heavy machinery, aerospace, and oil and gas, where high-performance, durable components are required.

Q5: How do I choose the right carbon steel grade for casting?

The right grade depends on the strength, hardness, and corrosion resistance required for the application. Higher carbon content grades offer greater strength, while lower content grades are more ductile.