High pressure aluminum die casting is a widely used manufacturing process in industries ranging from automotive to aerospace. This technique offers an efficient way to produce high-quality parts with exceptional precision and strength. But what exactly does high pressure aluminum die casting entail? In this article, we’ll explore the process, advantages, key applications, and much more. If you’re considering aluminum die casting for your next project, you’re in the right place to learn everything you need to know.

1. Introduction to High Pressure Aluminum Die Casting

High pressure aluminum die casting is one of the most effective ways to create complex, lightweight, and durable parts. It involves injecting molten aluminum into a metal mold at high pressure, typically between 1,000 and 2,000 psi. This method is highly favored for its ability to produce parts with high dimensional accuracy and surface quality, especially when compared to other casting methods.

But here’s the kicker: aluminum’s properties make it an excellent choice for casting. Aluminum alloys are lightweight yet incredibly strong and resistant to corrosion, which makes them ideal for demanding industries like automotive and aerospace. What’s the real story? The high pressure casting process allows manufacturers to create intricate shapes and complex designs with minimal waste, optimizing the overall production process.

In this section, we’ll delve deeper into what high pressure aluminum die casting is, how it works, and why it is so important in modern manufacturing. You’ll also get an overview of its key benefits, which set it apart from other casting techniques.

| Property | High Pressure Aluminum Die Casting | Sand Casting | Investment Casting |

|---|---|---|---|

| Precision | High | Low | High |

| Surface Finish | Smooth | Rough | Smooth |

| Production Speed | Fast | Slow | Medium |

| Material Strength | High | Medium | High |

| Cost for Low Quantities | Higher | Lower | Higher |

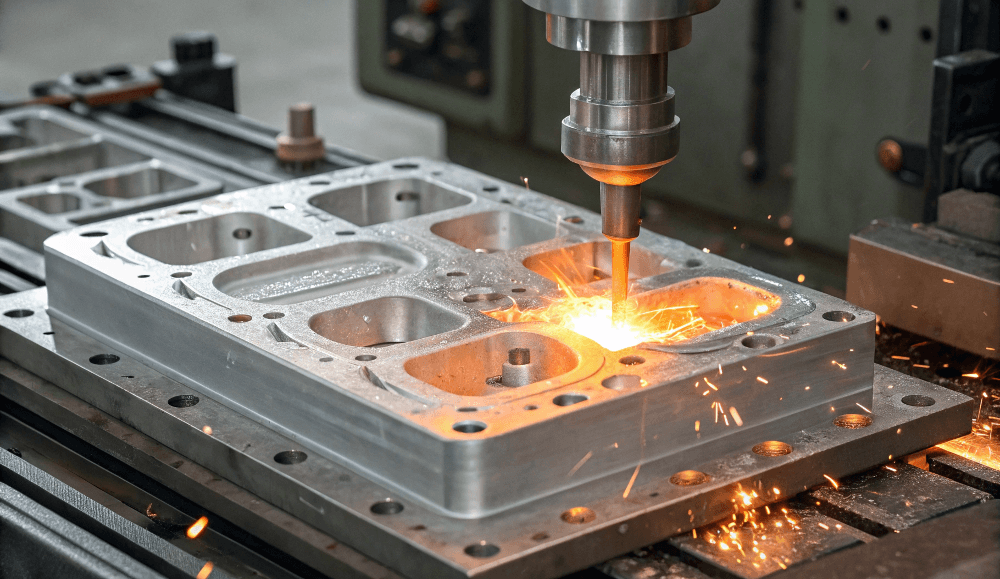

2. The High Pressure Die Casting Process

The high pressure die casting process is a precise and repeatable method that produces high-quality components. Here’s how it works:

First, molten aluminum is poured into a cold chamber. Then, a plunger forces the aluminum into a mold under high pressure. The pressure helps the molten metal fill the mold quickly, ensuring that even the most complex shapes are captured. After the metal solidifies, the mold opens, and the finished part is ejected.

Ready for the good part? The real beauty of high pressure die casting lies in its efficiency. The process is fast, and the parts produced have smooth surfaces, reducing the need for post-production processing. It’s ideal for producing large quantities of parts with consistent quality, making it cost-effective for mass production.

Key equipment used in this process includes die casting machines, molds (or dies), and furnaces. The dies themselves are typically made of steel, as it can withstand the repeated stress of the casting process. The temperature control during casting is also crucial, as it ensures that the aluminum solidifies properly, preventing defects like porosity and cracks.

| Step | Description |

|---|---|

| 1. Melting the Metal | Aluminum is melted at high temperatures. |

| 2. Injection | Molten aluminum is injected into the die under high pressure. |

| 3. Cooling | The part cools and solidifies inside the mold. |

| 4. Ejection | The mold opens, and the cast part is ejected. |

3. Types of High Pressure Die Casting

There are two main types of high pressure die casting: cold chamber and hot chamber. Both processes involve injecting molten metal into a mold at high pressure, but the way the molten metal is fed into the die differs.

- Cold Chamber Die Casting: In this method, molten metal is poured into the chamber before being injected into the mold. Cold chamber die casting is typically used for materials with high melting points, such as aluminum, brass, and bronze. It’s commonly used in automotive and industrial applications.

- Hot Chamber Die Casting: In hot chamber die casting, the molten metal is kept inside a chamber and is injected directly into the mold. This method is best suited for metals with lower melting points, such as zinc and magnesium.

What’s the real story? The choice between cold chamber and hot chamber die casting depends on the type of material being used and the specific requirements of the part. Both methods have their advantages, but understanding when and why to use each one can help manufacturers save time and reduce costs.

| Type of Die Casting | Molten Metal Feeding Method | Ideal For |

|---|---|---|

| Cold Chamber | Metal poured into the chamber | High melting point alloys (aluminum, brass) |

| Hot Chamber | Metal injected directly into the mold | Low melting point alloys (zinc, magnesium) |

4. Advantages of High Pressure Aluminum Die Casting

High pressure aluminum die casting offers several key advantages that make it a preferred choice for many industries. Let’s break them down:

- Precision and Accuracy: The high pressure ensures that even the smallest and most intricate details of the design are captured, making it perfect for complex geometries.

- Durability and Strength: Aluminum parts produced by this process are incredibly strong and resistant to corrosion, making them ideal for automotive, aerospace, and electronics applications.

- Cost-Effective for Mass Production: The fast turnaround times, minimal waste, and ability to create multiple parts at once make this process highly cost-efficient for large production runs.

- Minimal Post-Processing: The smooth surface finish of parts created via high pressure die casting reduces the need for additional finishing processes like machining or polishing.

This is where it gets interesting: Many industries rely on high pressure aluminum die casting for its ability to produce high-quality, lightweight parts in large quantities, saving both time and money. Whether you’re in automotive, aerospace, or industrial manufacturing, this casting method delivers consistent results that meet the toughest standards.

| Advantage | Description |

|---|---|

| Precision | Parts have high dimensional accuracy and detailed designs. |

| Durability | Parts are resistant to wear, corrosion, and high stress. |

| Cost-Effectiveness | Faster production cycles and reduced material waste. |

| Surface Quality | Requires little to no post-processing due to smooth surface finish. |

5. Materials Used in High Pressure Aluminum Die Casting

While aluminum is the primary material used in high pressure die casting, there are several other materials that can be used depending on the application. Here’s a quick rundown of the most commonly used materials:

- Aluminum Alloys: The most popular material for die casting due to its lightweight nature, corrosion resistance, and excellent thermal properties. Aluminum alloys such as A380 and A360 are commonly used for high pressure die casting.

- Magnesium: Magnesium alloys are another excellent choice, especially for lightweight components. However, they require more careful handling due to their high flammability.

- Zinc: Zinc die casting is used for parts that require high strength and corrosion resistance, although it’s typically used for smaller components.

- Copper: Copper-based alloys, such as brass, are used in die casting for parts requiring high thermal and electrical conductivity.

But here’s the kicker: The selection of material depends heavily on the specific requirements of the part. Factors like strength, weight, and corrosion resistance must all be considered when choosing the right material for casting.

| Material Type | Common Uses | Key Advantages |

|---|---|---|

| Aluminum | Automotive, aerospace, electronics | Lightweight, corrosion-resistant |

| Magnesium | Automotive, aerospace | Lightweight, high strength-to-weight ratio |

| Zinc | Small components like gears | High strength and corrosion resistance |

| Copper | Electrical components | High thermal and electrical conductivity |

6. Key Applications of High Pressure Aluminum Die Casting

High pressure aluminum die casting is used across various industries due to its numerous benefits. Here are some of the key applications:

- Automotive Industry: Aluminum die casting is heavily used for producing engine blocks, transmission cases, and other engine components. These parts benefit from aluminum’s lightweight and durable properties, improving fuel efficiency and performance.

- Aerospace: The aerospace industry uses high pressure die casting for lightweight yet strong components that can withstand harsh environmental conditions.

- Electronics and Appliances: Aluminum die casting is used to make housings for electronic devices and appliances, ensuring they remain lightweight yet robust enough to protect sensitive internal components.

- Industrial Machinery: Valves, gears, and housings for machinery are often made using aluminum die casting, ensuring they are both durable and cost-effective.

Ready for the good part? With applications in such critical industries, it’s clear that high pressure aluminum die casting is essential for creating parts that need to withstand high stress while maintaining a lightweight profile. The ability to produce complex shapes and intricate details makes it indispensable in many fields.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Engine blocks, transmission cases | Lightweight, durable, improves efficiency |

| Aerospace | Aircraft parts, turbine components | High strength-to-weight ratio |

| Electronics | Housing for devices, appliance parts | Durable and protective for components |

| Industrial | Valves, gears, housings | Cost-effective and high-performance |

7. Common Challenges in High Pressure Aluminum Die Casting

While high pressure aluminum die casting offers many advantages, it is not without its challenges. Here are some of the most common issues that manufacturers face:

- Porosity and Shrinkage: These defects occur when gas gets trapped in the mold or when the aluminum cools too quickly, causing holes or voids in the final product.

- Tool Wear: Due to the high pressure involved, the dies can wear out faster, requiring regular maintenance or replacement.

- Material Handling: The handling of aluminum alloys can be tricky, as the temperature must be carefully controlled to avoid issues like oxidation or contamination.

- Complexity in Molding: Some complex geometries may require specially designed dies or additional processing steps to ensure proper casting.

This is where it gets interesting: By addressing these challenges with careful process control, material selection, and mold design, manufacturers can significantly improve the quality of their die-cast parts. Though challenges exist, many of these issues can be mitigated with the right techniques.

| Challenge | Description | Solutions |

|---|---|---|

| Porosity | Gas trapped inside the mold creates voids. | Use of degassing agents, optimal pressure settings |

| Tool Wear | Repeated use leads to die degradation. | Regular maintenance, use of harder materials |

| Material Handling | High temperatures can cause oxidation. | Proper temperature control, clean environments |

| Complex Geometries | Detailed molds may require extra processing. | Custom die design, advanced cooling systems |

8. High Pressure Die Casting vs. Other Casting Methods

High pressure die casting offers several advantages over other casting methods, but it’s not always the best choice for every situation. Let’s compare it to other common casting methods:

- Sand Casting: This method is cheaper and more flexible but produces lower-quality parts with rougher surfaces and less precision. It’s generally used for larger, less intricate parts.

- Investment Casting: This method is highly accurate but can be more expensive and time-consuming than high pressure die casting.

- Die Casting: Traditional die casting methods like cold chamber die casting are slower and less efficient compared to high pressure casting.

What’s the real story? High pressure die casting is often the best choice when you need high-quality, precise parts quickly and in large quantities. However, depending on the part’s requirements, methods like sand casting or investment casting might be more appropriate in some cases.

| Casting Method | Advantages | Disadvantages |

|---|---|---|

| High Pressure | High precision, fast production | High tooling costs |

| Sand Casting | Flexible, lower costs | Rough surface, lower accuracy |

| Investment Casting | Highly accurate, fine detail | Expensive, slow process |

9. Innovations in High Pressure Aluminum Die Casting

The world of high pressure aluminum die casting continues to evolve, driven by new technologies and innovations that improve the process. Here are some of the key advancements:

- Robotics and Automation: Automated machines and robotic systems are increasingly being used to handle the casting process, improving efficiency and consistency.

- 3D Printing for Die Design: The use of 3D printing to design and prototype molds has revolutionized the casting industry, making it easier to test and refine die designs before actual production.

- Eco-friendly Practices: Manufacturers are now incorporating sustainable practices into the casting process, such as using recyclable aluminum and reducing waste.

- Advanced Materials: New, higher-performing aluminum alloys and other materials are being developed to improve the strength and durability of die-cast parts.

But here’s the kicker: These innovations are not just about improving the quality of the casting, but also about reducing environmental impact and increasing production efficiency. With advancements like these, high pressure aluminum die casting is becoming an even more powerful tool in manufacturing.

| Innovation | Description | Benefits |

|---|---|---|

| Robotics | Automated machines for casting control | Improves efficiency and consistency |

| 3D Printing | 3D printing for prototype die designs | Faster iteration, cost reduction |

| Eco-friendly Practices | Use of recyclable aluminum, reduced waste | Sustainability and cost savings |

| Advanced Materials | New aluminum alloys with enhanced properties | Improved durability and performance |

10. Quality Control in High Pressure Aluminum Die Casting

Quality control is paramount in high pressure aluminum die casting to ensure that the parts produced meet the required specifications. Here are the key methods used to ensure high-quality parts:

- Visual Inspections: Regular checks of the surface for cracks, porosity, or other defects.

- Non-Destructive Testing (NDT): Methods like X-ray or ultrasound are used to detect internal defects that are not visible to the naked eye.

- Dimensional Checks: Parts are measured to ensure that they meet tight tolerances and design specifications.

- Tensile Testing: This test ensures that the cast parts can withstand the forces they will experience in use.

This is where it gets interesting: The accuracy and reliability of the high pressure die casting process make it one of the best options for industries where quality cannot be compromised. Manufacturers who prioritize stringent quality control can ensure that their parts meet both customer requirements and industry standards.

| Quality Control Method | Description | Key Benefits |

|---|---|---|

| Visual Inspection | Checking for surface defects | Quick, cost-effective |

| X-ray Testing | Detecting internal defects | High precision, non-invasive |

| Dimensional Check | Measuring part size and tolerances | Ensures parts meet design specifications |

| Tensile Testing | Assessing material strength | Ensures parts can handle stress |

11. The Future of High Pressure Aluminum Die Casting

The future of high pressure aluminum die casting looks bright as new technologies and trends continue to shape the industry. Here are some of the key trends driving the future of casting:

- Increased Demand for Lightweight Parts: As industries like automotive and aerospace focus on reducing weight to improve fuel efficiency, the demand for lightweight aluminum components will continue to rise.

- Smart Manufacturing: The incorporation of sensors and data analytics into die casting processes will enable real-time monitoring, predictive maintenance, and further improvements in efficiency.

- Sustainability: The move towards greener, more sustainable manufacturing processes is driving innovations in recycling and reducing energy consumption in die casting.

What’s the real story? High pressure aluminum die casting will remain at the forefront of manufacturing, especially as industries look for ways to innovate and stay competitive. With continued advancements in materials, technology, and sustainability, this casting method is well-positioned for the future.

| Future Trend | Description | Impact on Industry |

|---|---|---|

| Lightweight Parts | Demand for lightweight components grows | Increased use in automotive and aerospace |

| Smart Manufacturing | Use of sensors and data for real-time monitoring | Efficiency and predictive maintenance |

| Sustainability | Adoption of greener practices in casting | Lower environmental impact, cost savings |

12. Cost Factors in High Pressure Aluminum Die Casting

The cost of high pressure aluminum die casting is influenced by several factors, including:

- Material Costs: Aluminum alloys can vary in price depending on the alloy used and market conditions.

- Die Costs: Molds and dies can be expensive to manufacture, especially for complex parts.

- Labor Costs: Skilled labor is needed to operate die casting machines, and labor costs can vary depending on the location and the scale of production.

- Production Time: While die casting is a fast process, setup times for new dies can add to the overall cost.

But here’s the kicker: Despite the initial costs, high pressure aluminum die casting is still one of the most cost-effective methods for producing high-quality, complex parts in large quantities. Understanding these cost factors can help manufacturers make informed decisions about which casting method to use.

| Cost Factor | Description | Impact on Total Cost |

|---|---|---|

| Material Costs | Price of aluminum alloys varies | Significant for large runs |

| Die Costs | Expensive for custom or complex molds | High initial investment |

| Labor Costs | Skilled labor is required for operation and setup | Varies by location |

| Production Time | Setup and turnaround times | Affects overall cost-efficiency |

13. Environmental Considerations in High Pressure Die Casting

As the industry moves towards more sustainable practices, high pressure die casting is increasingly being scrutinized for its environmental impact. Key considerations include:

- Energy Consumption: The casting process requires significant energy to melt aluminum and maintain high temperatures, contributing to the carbon footprint.

- Waste Management: While die casting produces minimal waste compared to other methods, managing scrap and recycling the material is important.

- Emissions: Proper ventilation and emissions control are necessary to prevent harmful gases from being released during the casting process.

Ready for the good part? Manufacturers are now working to reduce their environmental impact by adopting energy-efficient machines, improving waste management practices, and recycling aluminum scrap to reduce their overall carbon footprint.

| Environmental Concern | Description | Mitigation Strategy |

|---|---|---|

| Energy Consumption | High energy needed for melting and casting | Use energy-efficient equipment |

| Waste Management | Material scrap can accumulate | Recycle aluminum and reduce waste |

| Emissions | Potential for harmful gases during the process | Implement ventilation and filtration systems |

14. Selecting the Right Die Casting Manufacturer

Choosing the right die casting manufacturer is critical to ensuring the success of your project. Here’s what to look for:

- Experience and Expertise: Look for manufacturers with extensive experience in high pressure die casting, particularly for the type of components you need.

- Quality Control Systems: Ensure that the manufacturer has a robust quality control system in place to meet your specifications.

- Customer Service: Choose a manufacturer that offers strong communication and support throughout the production process.

- Certifications: Look for manufacturers with industry certifications, such as ISO 9001, to ensure they meet quality and safety standards.

What’s the real story? By selecting the right manufacturer, you can ensure that your high pressure aluminum die casting project is completed on time, within budget, and to the highest standards.

| Criteria | Description | Importance |

|---|---|---|

| Experience | Manufacturer’s track record in die casting | Ensures quality and reliability |

| Quality Control | Certifications and processes for ensuring accuracy | Critical for high standards |

| Customer Service | Communication and support during production | Ensures smooth project execution |

| Certifications | ISO 9001 or other relevant certifications | Guarantees quality assurance |

15. Conclusion and Final Thoughts

High pressure aluminum die casting is an essential manufacturing method used across many industries. With its ability to produce precise, durable, and lightweight parts, it’s no wonder that it’s the go-to method for high-performance components.

By understanding the process, advantages, materials, and applications of high pressure aluminum die casting, manufacturers can make more informed decisions that help optimize production and reduce costs. Whether you’re in automotive, aerospace, or electronics, high pressure aluminum die casting offers a reliable, cost-effective solution for producing high-quality parts.

FAQ Section

Q1: What is high pressure aluminum die casting?

High pressure aluminum die casting is a manufacturing process where molten aluminum is injected into a mold at high pressure to create intricate, durable, and precise components.

Q2: How does the high pressure aluminum die casting process work?

The process involves injecting molten aluminum into a steel mold under high pressure, allowing for rapid solidification and producing parts with smooth surfaces and high dimensional accuracy.

Q3: What are the main benefits of using aluminum in die casting?

Aluminum is lightweight, durable, corrosion-resistant, and has excellent thermal properties, making it an ideal material for producing complex parts that can withstand harsh conditions.

Q4: What industries use high pressure aluminum die casting?

High pressure aluminum die casting is used in industries such as automotive, aerospace, electronics, and industrial machinery to produce lightweight, high-strength components.

Q5: How can I avoid defects in high pressure aluminum die casting?

Proper temperature control, high-quality molds, and careful material handling can help prevent defects like porosity and shrinkage in high pressure aluminum die casting.