High pressure aluminum die casting is a manufacturing process used to create precise, durable metal parts. This method involves injecting molten aluminum into a steel mold under high pressure, which ensures the aluminum flows into intricate designs and takes shape once cooled. It’s a process that is widely used across industries like automotive, aerospace, and electronics. But how does this process work exactly? How does it compare to other methods, and what makes it so popular? In this article, we will explore the ins and outs of high pressure aluminum die casting, its benefits, challenges, and applications.

1. What is High Pressure Aluminum Die Casting?

High pressure aluminum die casting is a process that involves forcing molten aluminum into a metal mold under high pressure. The mold, typically made of steel, allows the aluminum to take on intricate shapes, which makes it suitable for producing complex parts with high dimensional accuracy.

Ready for the good part? This process has been used for decades and continues to grow in importance. It enables the production of parts that require little to no additional finishing after the casting process. By using high pressure, manufacturers can create parts with excellent surface finishes and tight tolerances. Aluminum is a popular choice due to its lightweight, corrosion resistance, and strength.

Applications of High Pressure Aluminum Die Casting are numerous and can be found across a variety of industries. From the automotive industry, where parts like engine blocks and transmission cases are produced, to the electronics industry, where enclosures for devices are cast. But what are the advantages of using aluminum over other metals? Let’s dive into the benefits next.

| Application | Industry | Part Type |

|---|---|---|

| Automotive | Automotive | Engine blocks, transmissions |

| Aerospace | Aerospace | Aircraft parts, structural components |

| Electronics | Electronics | Device housings, enclosures |

2. How Does High Pressure Aluminum Die Casting Work?

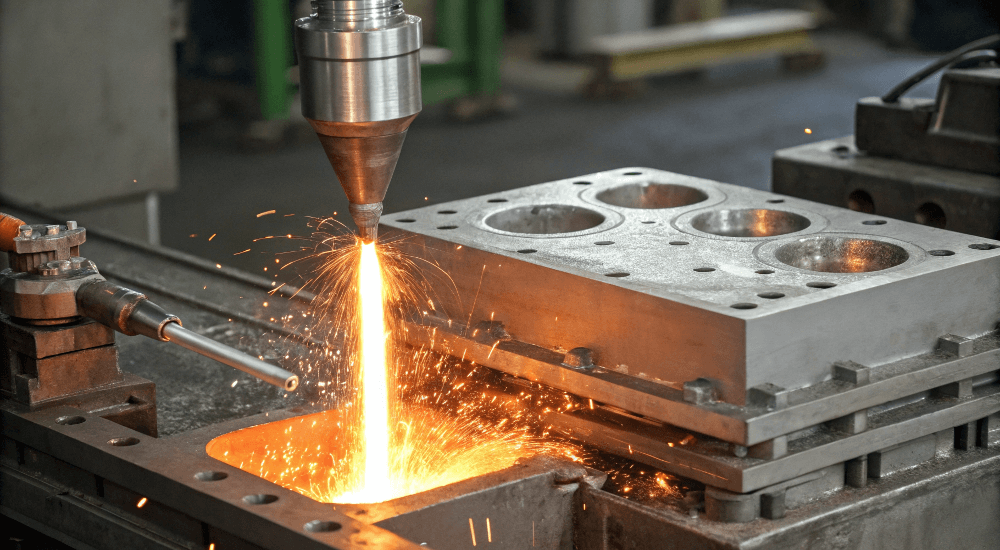

So, how does this entire process actually unfold? High pressure aluminum die casting involves several steps. First, the die is preheated to the appropriate temperature. Molten aluminum is then poured into a chamber where it is injected into the die under immense pressure, typically around 1,000 to 2,000 tons.

But here’s the kicker – once the aluminum has been injected into the die, the pressure is maintained for a short period to ensure the metal fills all parts of the mold. The cooling process follows, which solidifies the aluminum into the shape of the mold. Once solid, the mold is opened, and the part is ejected. The result is a highly detailed part with minimal surface defects.

The key advantage of using high pressure during this process is that it helps the molten aluminum to fill the mold faster and more thoroughly, reducing the chance of defects and ensuring a smooth finish. But here’s where it gets interesting – how do manufacturers ensure consistent quality throughout this process? Let’s move on to that.

| Step | Process Description |

|---|---|

| Preheating the Die | Die is heated to ensure smooth metal flow |

| Injection of Aluminum | Molten aluminum is injected under high pressure |

| Cooling | Metal is allowed to cool and solidify in the die |

| Ejection | Mold is opened and the part is ejected |

3. What Are the Advantages of High Pressure Aluminum Die Casting?

Why should manufacturers choose high pressure aluminum die casting over other processes? The advantages are clear. One of the biggest benefits is speed. Since molten aluminum is injected under pressure, it fills the mold quickly, allowing for rapid production of parts. This makes it perfect for industries that need large quantities of parts in a short amount of time.

Another advantage is precision. High pressure ensures that even the most intricate designs are captured in the mold, with tight tolerances and smooth finishes. Parts produced by high pressure die casting typically require little to no further machining, which can reduce labor costs and lead time. The accuracy of the process also reduces material waste, making it a more efficient and cost-effective option.

What’s the real story here? High pressure aluminum die casting is a highly efficient and versatile process that can produce a wide range of parts, from small components to large, complex structures. It’s a go-to method for industries that require speed, precision, and durability. But every process comes with its challenges. Let’s explore them in the next section.

| Advantage | Description |

|---|---|

| Speed | Quick production times |

| Precision | High accuracy with tight tolerances |

| Cost Efficiency | Reduced need for additional machining and material waste |

4. What Are the Key Challenges in High Pressure Aluminum Die Casting?

While high pressure aluminum die casting has its advantages, it’s not without its challenges. One common issue is the high initial cost of the mold. The dies used in this process are typically made of hardened steel, which can be expensive to produce. This initial cost may be a deterrent for smaller manufacturers or for businesses looking to produce low volumes of parts.

Another challenge lies in the material selection. Not all aluminum alloys are suitable for the high pressure casting process. Some alloys may not flow properly, or they might not withstand the high temperatures involved in the casting process. It’s crucial to choose the right alloy for the job to avoid defects.

Additionally, issues like porosity and surface imperfections can sometimes arise, which can require additional post-processing to fix. So, while the process is efficient, maintaining quality throughout production is critical. Ready for the good part? Let’s see how you can mitigate these challenges in the next section.

| Challenge | Impact | Solution |

|---|---|---|

| High mold cost | Expensive for low-volume production | Invest in durable, reusable molds |

| Material compatibility | Some alloys may not flow properly | Choose appropriate aluminum alloys |

| Porosity issues | Can lead to surface defects | Implement strict quality control |

5. What Are the Applications of High Pressure Aluminum Die Casting?

High pressure aluminum die casting has diverse applications across a wide range of industries. In the automotive sector, for example, it is used to create engine blocks, transmission cases, and even small parts like brackets and housings. These parts benefit from the process’s ability to produce strong, lightweight components with complex geometries.

But what’s the real story here? High pressure aluminum die casting isn’t just confined to the automotive industry. It’s also widely used in aerospace for structural components, where strength and precision are paramount. In electronics, die-cast aluminum parts are used in devices like mobile phones, laptops, and televisions, offering durability and sleek design.

The versatility of high pressure aluminum die casting makes it a popular choice for any industry that requires precision parts in high volumes. But which industries benefit the most from this process? Let’s break it down further.

| Industry | Common Applications |

|---|---|

| Automotive | Engine blocks, transmission cases, brackets |

| Aerospace | Structural components, aircraft parts |

| Electronics | Device housings, mobile phone frames |

6. What Are the Different Types of Die Casting?

Die casting is a versatile manufacturing method with several variations. While high pressure die casting is the most widely used method, there are other forms like low pressure die casting and gravity die casting.

In low pressure die casting, molten metal is introduced into the die under lower pressures, which makes it ideal for producing larger, thicker parts. Gravity die casting, on the other hand, relies on gravity to pull molten metal into the mold, making it suitable for simpler, lower-volume parts.

So, what’s the difference? High pressure die casting is the fastest and most accurate of these methods, making it the go-to choice for mass production. However, for larger parts or less intricate designs, low pressure and gravity die casting can be more cost-effective. Let’s now look at how these methods stack up against each other.

| Casting Type | Advantages | Applications |

|---|---|---|

| High Pressure Die Casting | High precision, fast production, minimal waste | Complex, high-volume parts |

| Low Pressure Die Casting | Suitable for larger parts, lower pressure | Large parts, such as automotive components |

| Gravity Die Casting | Simple, cost-effective for small parts | Low-volume production, simpler designs |

7. How Does High Pressure Aluminum Die Casting Compare to Other Manufacturing Methods?

When comparing high pressure aluminum die casting to other manufacturing methods, such as sand casting and investment casting, it’s clear that each method has its pros and cons.

High pressure die casting is the fastest method for producing complex, high-precision parts. In contrast, sand casting, while versatile, typically takes longer and doesn’t offer the same level of precision. Investment casting is better suited for very intricate parts but can be more expensive due to the labor-intensive mold creation process.

What’s the takeaway here? High pressure aluminum die casting excels in producing large quantities of detailed parts quickly, but other methods may be preferable for lower volumes or more complex designs. Let’s compare these methods in more detail.

| Casting Method | Advantages | Disadvantages |

|---|---|---|

| High Pressure Die Casting | Fast, precise, high volume production | High mold cost, requires high-pressure equipment |

| Sand Casting | Versatile, cost-effective for small runs | Lower precision, slower production |

| Investment Casting | High precision, ideal for complex parts | High cost, labor-intensive molds |

8. What is the Impact of High Pressure Aluminum Die Casting on the Environment?

As industries focus more on sustainability, it’s important to consider the environmental impact of manufacturing processes. High pressure aluminum die casting is often seen as an eco-friendly option because aluminum is a highly recyclable material. The die casting process also generates less waste compared to other methods, reducing overall environmental impact.

However, like any manufacturing process, high pressure die casting does have some environmental concerns. The use of energy to heat and melt aluminum is one area where improvements can be made. Some manufacturers are looking into more energy-efficient methods of production, which could further reduce the process’s carbon footprint.

So, what’s the bottom line? While high pressure aluminum die casting is already a more sustainable option, ongoing advancements in technology can help make it even more environmentally friendly.

| Environmental Factor | Impact | Solution |

|---|---|---|

| Energy Consumption | High energy use for heating aluminum | Adoption of energy-efficient methods |

| Waste Generation | Some scrap metal during the casting process | Recycling and waste reduction efforts |

| Material Recyclability | Aluminum is highly recyclable | Increase in recycling rates |

9. What Equipment is Needed for High Pressure Aluminum Die Casting?

High pressure aluminum die casting requires specialized equipment, including die casting machines, molds, and furnaces. The die casting machine injects molten aluminum into the mold under high pressure, while the mold itself is made of steel to withstand the pressure and temperature of the molten metal.

What’s the real story here? The equipment needed for this process can be costly, but it’s a worthwhile investment for manufacturers who produce high volumes of parts. Proper maintenance of the die casting machines and molds is crucial to ensure consistent quality. Let’s look at what these machines look like in more detail.

| Equipment | Function |

|---|---|

| Die Casting Machine | Injects molten aluminum into molds |

| Mold | Holds the molten aluminum until it solidifies |

| Furnace | Melts aluminum to the appropriate temperature |

10. How Do Manufacturers Ensure Consistent High-Quality Outputs?

To ensure the high quality of parts produced via high pressure aluminum die casting, manufacturers must implement strict quality control measures. This includes checking the material for defects, inspecting the final parts for dimensional accuracy, and conducting tests to ensure they meet industry standards.

But here’s the kicker – technology plays a significant role in quality control. Automated inspection systems can identify defects such as porosity or surface imperfections before the parts leave the factory, ensuring consistent quality.

| Quality Control Measure | Purpose |

|---|---|

| Dimensional Inspection | Ensures accuracy of part measurements |

| Material Testing | Verifies the integrity of the aluminum alloy |

| Automated Inspection | Identifies defects early in the process |

11. What Are the Costs Associated with High Pressure Aluminum Die Casting?

High pressure aluminum die casting can be expensive upfront, especially when considering the cost of molds and machinery. However, it offers a long-term cost advantage because of its speed and precision, which reduces the need for additional machining or rework. The cost per part tends to decrease as the production volume increases.

So, is it worth the investment? Absolutely, especially if you’re producing high quantities of parts that require precision. The benefits of reduced labor costs and material waste make high pressure die casting a cost-effective solution in the long run.

| Cost Factor | Estimated Cost Impact |

|---|---|

| Mold Production | High initial cost, but reusable |

| Machine Setup | Initial setup cost can be significant |

| Production Volume | Lower cost per part with higher production volume |

12. What are the Latest Innovations in High Pressure Aluminum Die Casting?

The die casting industry is always evolving, and new innovations are pushing the boundaries of what’s possible. One significant development is the use of advanced alloys that improve strength and thermal conductivity. Manufacturers are also exploring 3D printing technology to create more complex molds faster and cheaper.

What’s the real story here? These innovations make it possible to create even more detailed parts while reducing costs and production times. For manufacturers looking to stay competitive, keeping up with these advancements is essential.

| Innovation | Benefit |

|---|---|

| Advanced Alloys | Improved strength and thermal conductivity |

| 3D Printed Molds | Faster, cheaper mold creation |

| Automation | Increased efficiency and reduced defects |

13. How Can You Choose the Right High Pressure Aluminum Die Casting Supplier?

Choosing the right supplier for your high pressure aluminum die casting needs is critical for ensuring product quality and timely delivery. Look for suppliers with a proven track record, advanced equipment, and strong quality control processes.

What’s the kicker? Establishing a good relationship with your supplier can help you resolve issues quickly and keep your production process running smoothly.

| Supplier Criterion | Why It Matters |

|---|---|

| Experience | Experienced suppliers know the ins and outs of die casting |

| Equipment | Modern equipment ensures better precision |

| Customer Service | Quick response times and reliable support |

14. What Are the Benefits of High Pressure Aluminum Die Casting?

The benefits of high pressure aluminum die casting are numerous, making it a go-to method for manufacturers looking to produce high-precision, durable parts quickly and efficiently. From its speed and cost-effectiveness to its ability to create complex designs, this process continues to play a key role in many industries.

Conclusion

In conclusion, high pressure aluminum die casting is a vital manufacturing process that provides efficiency, precision, and cost savings. While it comes with its challenges, the benefits far outweigh the drawbacks, particularly for industries that need to produce large quantities of durable, intricate parts. Whether you’re in automotive, aerospace, or electronics, high pressure aluminum die casting can help streamline your production process and deliver superior results.

FAQ

Q1: What is High Pressure Aluminum Die Casting?

High Pressure Aluminum Die Casting is a manufacturing process that involves injecting molten aluminum into a steel mold under high pressure, producing high-precision parts.

Q2: How does High Pressure Aluminum Die Casting work?

The process involves injecting molten aluminum into a preheated die under high pressure, ensuring that the metal fills the mold completely before cooling.

Q3: What are the advantages of High Pressure Aluminum Die Casting?

The main advantages include speed, precision, and cost-efficiency, particularly in high-volume production.

Q4: What are the challenges in High Pressure Aluminum Die Casting?

Challenges include the high cost of molds, potential material incompatibility, and issues like porosity or surface imperfections.

Q5: What types of industries use High Pressure Aluminum Die Casting?

Industries like automotive, aerospace, and electronics commonly use this process for producing complex, durable parts.