In the world of manufacturing, precision and quality are crucial. One method that stands out for producing high-quality aluminum castings is permanent mold aluminum casting. But is it right for your project? This process allows manufacturers to produce complex shapes with high dimensional accuracy, making it ideal for various industries, especially when durability and surface finish matter. In this article, we will explore the ins and outs of permanent mold aluminum casting, helping you determine if it’s the right fit for your needs.

1. What is Permanent Mold Aluminum Casting?

Permanent mold aluminum casting is a manufacturing process where molten aluminum is poured into reusable molds to produce metal parts. Unlike expendable molds used in sand casting or other processes, permanent molds are designed to last for many casting cycles, making the process both efficient and cost-effective for high-volume production. The process is popular in industries like automotive, aerospace, and electronics due to the high precision and durability of the castings it produces.

But here’s the kicker—the use of permanent molds allows manufacturers to achieve exceptional surface finishes, which is a significant advantage over other casting methods like sand casting. This is achieved through the cooling process, where the molten aluminum is allowed to solidify slowly, helping to minimize defects like porosity. The result is a clean, smooth finish that doesn’t require much post-processing.

Permanent mold aluminum casting typically involves a gravity-fed system or low-pressure techniques. Molten aluminum is poured into the mold and then cooled, where it takes the shape of the cavity inside the mold. The cooling time and mold material play a crucial role in determining the overall quality of the casting.

Ready for the good part? Permanent molds can be made from a variety of materials, including steel, which adds to their durability and longevity. This process is ideal for high-volume production where precision and repeatability are essential.

| Type of Mold | Material Used | Advantages |

|---|---|---|

| Permanent | Steel, Cast Iron | Long lifespan, High precision |

| Expendable | Sand, Shell | Low cost, Versatility |

2. How Does Permanent Mold Aluminum Casting Work?

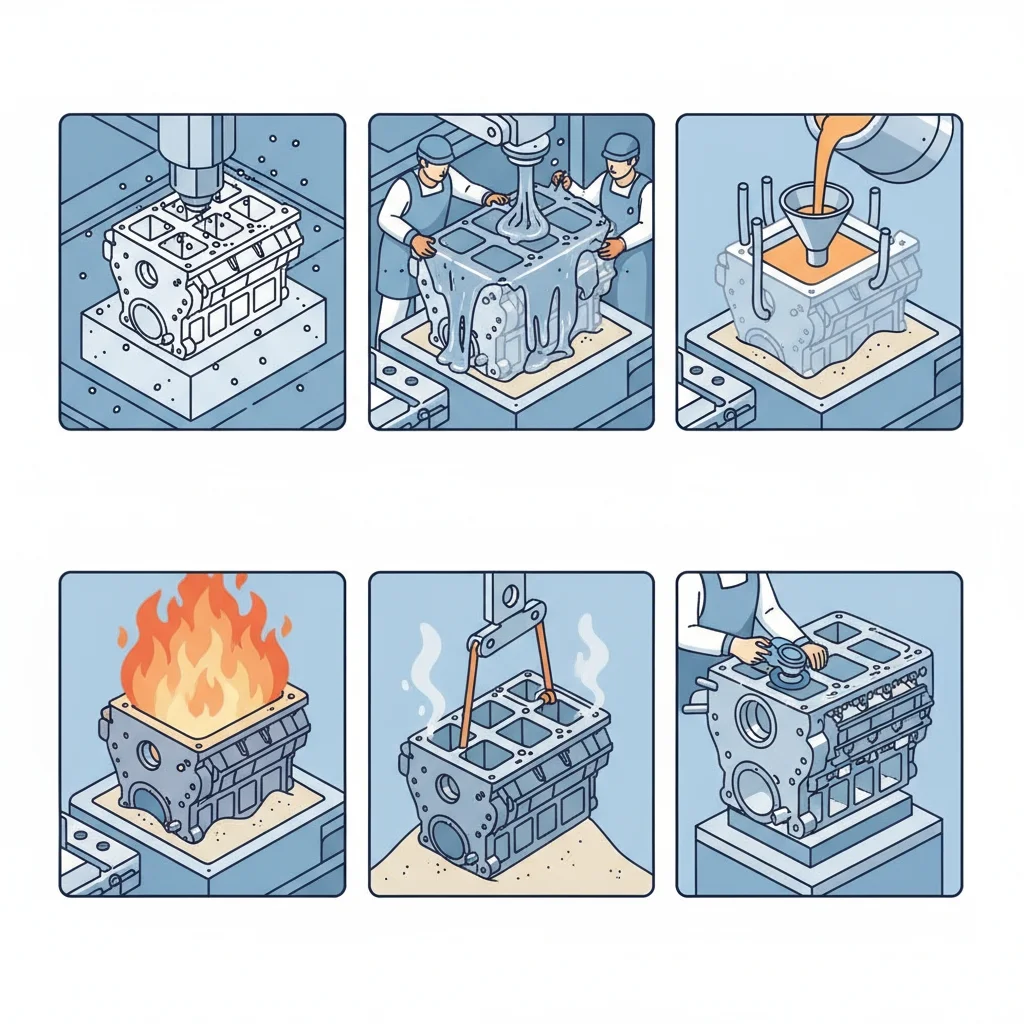

The process of permanent mold aluminum casting involves several critical steps, each designed to ensure high-quality results. First, the mold is preheated to a specific temperature. This step is essential because the mold material must be capable of withstanding the heat from the molten aluminum. Once preheated, molten aluminum is poured into the mold cavity.

What’s the real story? The aluminum stays in the mold until it cools and solidifies. The cooling process can take anywhere from several minutes to hours, depending on the size and thickness of the part being cast. During cooling, the aluminum forms a solid shape that mirrors the interior of the mold. Once the aluminum has solidified, the mold is removed, and the casting is inspected for defects like porosity or cracks.

An interesting aspect of permanent mold aluminum casting is that it allows for a more controlled cooling rate compared to sand casting. This control is crucial for producing castings with minimal defects and a smooth surface. This is where it gets interesting—the cooling rate is often influenced by the mold’s material and design, which can have a significant impact on the final quality of the casting.

Moreover, the design of the mold is key to ensuring that the casting process runs smoothly. Proper venting, mold wall thickness, and gating system are all factors that need to be considered. These design aspects help to guide the molten aluminum in the right direction and prevent issues like air pockets or trapped gases.

| Step | Description |

|---|---|

| Preheating the Mold | Mold is heated to specific temperature |

| Pouring Molten Aluminum | Aluminum is poured into the mold cavity |

| Cooling and Solidification | Aluminum cools and solidifies to form the desired shape |

| Mold Removal | Mold is removed, and the casting is inspected |

3. Why Choose Permanent Mold Aluminum Casting?

Permanent mold aluminum casting is a favored method in many industries due to its numerous advantages. But here’s the kicker—its ability to produce high-quality, durable parts makes it a go-to option for critical applications where precision and repeatability are paramount.

One of the main advantages of this casting process is the high dimensional accuracy. Because the molds are reusable, the consistency from one part to the next is much higher than with sand or shell casting methods. This accuracy makes it suitable for industries like aerospace and automotive, where exact specifications are a must. What’s the real story? The process also results in fewer defects like porosity, which can affect the strength and functionality of the casting.

Another benefit is the reduced need for post-processing. Due to the excellent surface finish achieved through permanent mold casting, many parts do not require additional machining or finishing steps. This can save significant time and cost in the overall production process.

In terms of material use, permanent mold aluminum casting is versatile. It allows for the use of various aluminum alloys, each with different properties suited for specific applications. Whether it’s for lightweight automotive parts or high-strength aerospace components, this method can be customized to meet the exact needs of the industry.

| Advantage | Explanation |

|---|---|

| High Dimensional Accuracy | Precision parts with minimal variations |

| Reduced Post-Processing | Excellent surface finish with little to no machining |

| Versatility | Suitable for a wide range of aluminum alloys |

4. What Are the Types of Permanent Mold Aluminum Casting?

Permanent mold aluminum casting can be classified into two main types: gravity casting and low-pressure casting. Both methods have distinct characteristics and applications, and choosing the right one depends on the specific needs of the part being produced.

Ready for the good part? Gravity casting is the most commonly used method. In this process, the molten aluminum flows into the mold cavity under the influence of gravity. While this method is simple and cost-effective, it may not be suitable for parts requiring extreme precision or structural integrity.

On the other hand, low-pressure casting involves applying a controlled amount of pressure to force the molten aluminum into the mold cavity. This method is ideal for producing parts with more complex geometries or greater material strength. What’s the real story? Low-pressure casting ensures better material flow, reduces the likelihood of air pockets, and improves the overall quality of the cast part.

Understanding the differences between these two methods can help manufacturers make the best choice based on the complexity, volume, and material properties required. It’s essential to know when gravity casting is sufficient and when low-pressure casting is needed for optimal results.

| Casting Method | Advantages | Applications |

|---|---|---|

| Gravity Casting | Simple, cost-effective, suitable for large parts | Automotive, General manufacturing |

| Low-Pressure Casting | Better material flow, complex geometries, stronger parts | Aerospace, Heavy machinery |

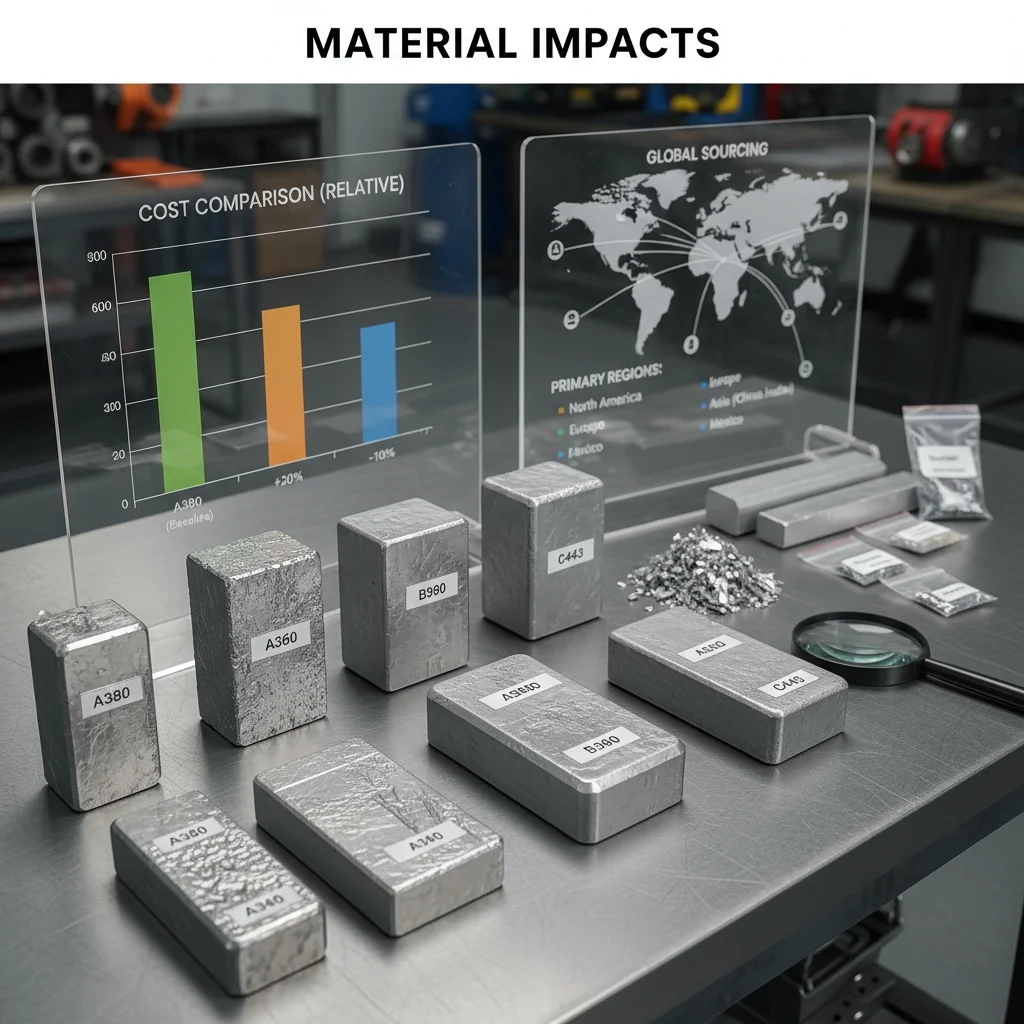

5. What Materials Are Used in Permanent Mold Aluminum Casting?

The choice of material for the permanent mold is crucial to the overall success of the casting process. But here’s the kicker—the material needs to withstand high temperatures and repeated cycles without losing its integrity. Typically, permanent molds are made from metals like steel or cast iron, which are capable of withstanding the heat from molten aluminum.

Steel is the most common material used because of its durability, strength, and resistance to wear and tear. It’s ideal for high-volume production, where the mold must endure many casting cycles without degrading. This is where it gets interesting—cast iron can also be used for smaller runs, as it’s less expensive than steel, though it may wear out faster.

In addition to steel and cast iron, other materials like copper-based alloys are sometimes used for molds that need to dissipate heat more quickly. These materials help maintain the temperature consistency during the cooling process, which is crucial for producing high-quality castings.

| Mold Material | Characteristics | Advantages |

|---|---|---|

| Steel | Strong, durable, resists wear and tear | Long lifespan, high precision |

| Cast Iron | More affordable, but less durable | Lower initial cost |

| Copper-based Alloys | Excellent heat dissipation | Ideal for quick cooling |

6. What Are the Advantages of Permanent Mold Aluminum Casting?

Permanent mold aluminum casting offers several distinct advantages over other casting methods. What’s the real story? First, it delivers superior dimensional accuracy, which is critical when producing parts that require tight tolerances. This is achieved due to the rigid structure of the permanent mold, which doesn’t deform under pressure like sand molds can.

Another benefit is the reduced porosity. In many casting processes, air pockets can form inside the part, weakening its structure. However, with permanent mold casting, the mold’s rigid material and controlled cooling help eliminate these defects, resulting in stronger and more durable parts.

Finally, the excellent surface finish that comes with permanent mold aluminum casting is another key advantage. Because the mold can withstand high temperatures and is highly polished, the surface of the cast part is smooth, reducing the need for post-casting finishing.

| Advantage | Explanation |

|---|---|

| Dimensional Accuracy | High precision with minimal variation |

| Reduced Porosity | Fewer defects, leading to stronger parts |

| Excellent Surface Finish | Smooth finish, reducing the need for post-processing |

7. What Are the Limitations of Permanent Mold Aluminum Casting?

Despite its many advantages, permanent mold aluminum casting has some limitations. This is where it gets interesting—the process is best suited for parts that are relatively simple in shape. While it can handle moderately complex geometries, extremely intricate designs may be better suited for other methods, such as die-casting.

Another limitation is the initial cost of the mold. Permanent molds, especially those made from steel, are costly to produce. This is a consideration for manufacturers who may not need high-volume production runs. However, this cost is offset by the longevity of the mold, which can be reused for thousands of cycles.

Additionally, permanent mold casting isn’t ideal for all aluminum alloys. Some alloys, particularly those with high levels of silicon, may not perform well in permanent mold casting due to the risk of crystallization during cooling. In such cases, other casting methods might be a better fit.

| Limitation | Explanation |

|---|---|

| Complexity of Shape | Not suitable for highly intricate designs |

| Initial Mold Cost | High upfront cost for durable molds |

| Alloy Compatibility | Not ideal for all aluminum alloys |

8. How to Design for Permanent Mold Aluminum Casting?

Designing parts for permanent mold aluminum casting requires careful consideration of several factors. But here’s the kicker—a poorly designed part can lead to defects, high scrap rates, and increased costs. To avoid this, it’s crucial to pay attention to factors such as wall thickness, draft angles, and venting.

First, wall thickness should be uniform throughout the part to ensure even cooling. Parts with varying wall thicknesses can lead to uneven solidification, causing defects like cracks or warping. What’s the real story? Draft angles are also important, as they allow the mold to be removed without damaging the casting. Typically, a draft angle of 2-5 degrees is ideal for most parts.

Additionally, venting is crucial to avoid air pockets. Proper venting ensures that gas can escape during the pouring and cooling process, preventing defects like porosity. Mold designers must consider where air pockets may form and incorporate vents to release trapped gas.

| Design Factor | Ideal Specifications | Impact on Casting |

|---|---|---|

| Wall Thickness | Uniform throughout the part | Prevents defects and ensures even cooling |

| Draft Angles | 2-5 degrees | Ensures easy mold removal |

| Venting | Adequate venting in key areas | Prevents porosity and gas pockets |

9. What Industries Use Permanent Mold Aluminum Casting?

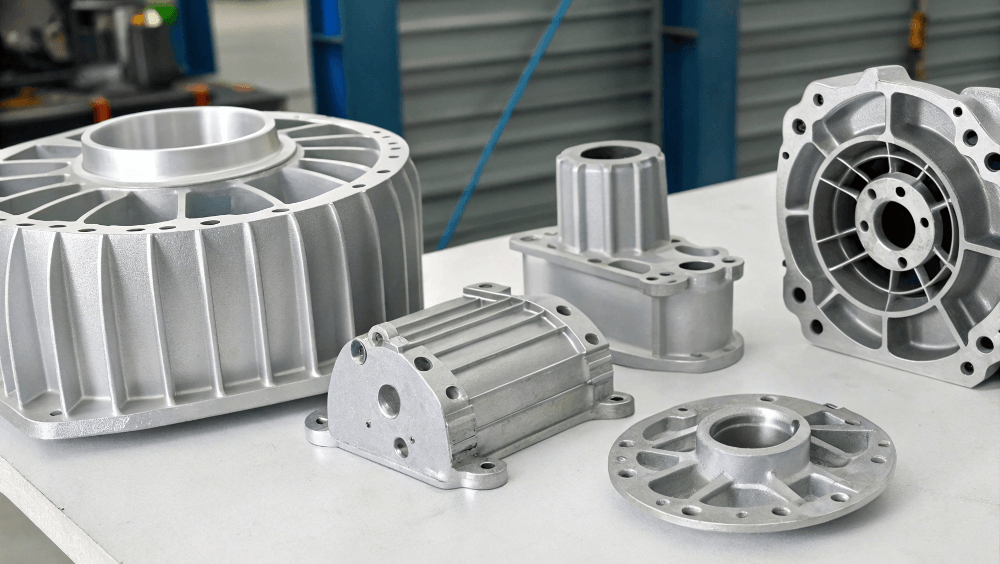

Permanent mold aluminum casting is used across a wide range of industries. This is where it gets interesting—its versatility makes it ideal for everything from automotive to aerospace. In the automotive industry, permanent mold casting is used to make engine blocks, wheels, and transmission components, where strength and precision are critical.

In aerospace, the demand for lightweight, high-strength parts makes aluminum an ideal material. Ready for the good part? Permanent mold aluminum casting helps produce components like turbine housings and structural parts, which must meet strict performance standards.

Finally, in electronics, this casting method is used for enclosures, connectors, and heat sinks, ensuring that parts can handle heat dissipation and environmental conditions.

| Industry | Applications | Benefits |

|---|---|---|

| Automotive | Engine blocks, wheels, transmission components | Strength, precision |

| Aerospace | Turbine housings, structural components | Lightweight, high-strength parts |

| Electronics | Enclosures, connectors, heat sinks | Heat dissipation, durability |

10. How Much Does Permanent Mold Aluminum Casting Cost?

The cost of permanent mold aluminum casting varies depending on several factors. What’s the real story? The initial cost of the mold is one of the most significant expenses, especially if steel molds are used. However, the cost per part decreases significantly with higher production volumes due to the reusability of the mold.

The complexity of the part and the type of aluminum alloy used also influence the overall cost. But here’s the kicker—simple parts made from common aluminum alloys will be less expensive than highly complex parts made from specialty alloys. When calculating the cost, it’s important to consider both the initial mold cost and the ongoing production costs.

| Factor | Impact on Cost |

|---|---|

| Initial Mold Cost | Significant upfront investment |

| Part Complexity | More complex designs increase the cost |

| Aluminum Alloy | Specialty alloys cost more to process |

11. How to Maintain Permanent Mold Aluminum Casting Molds?

Proper mold maintenance is essential to ensure the longevity of permanent molds. Ready for the good part? Regular cleaning is necessary to remove any aluminum buildup, which can affect the quality of future castings. After each use, the mold should be cleaned thoroughly to remove any residue and prevent wear from aluminum buildup.

Mold inspection is also critical. This is where it gets interesting—checking for cracks or other damage will help identify potential issues before they affect the casting process. Keeping molds well-maintained ensures that they last for many cycles and continue to produce high-quality parts.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Cleaning | Remove aluminum buildup | After each use |

| Inspection | Check for cracks, wear, and other damage | Regularly |

| Repairing | Fix any cracks or damage | As needed |

12. What Are Common Defects in Permanent Mold Aluminum Casting?

Despite its many advantages, permanent mold aluminum casting can still result in defects. But here’s the kicker—defects like porosity, cracks, and shrinkage can occur if the process isn’t carefully controlled. What’s the real story? Porosity, in particular, is a common defect that occurs when gas is trapped in the molten aluminum during casting.

Cracks can form during the cooling process if the mold doesn’t provide even cooling or if the aluminum solidifies too quickly. Shrinkage is another common issue that happens when the aluminum contracts as it cools. This is where it gets interesting—ensuring proper venting, cooling, and mold design can help minimize these defects and improve the quality of the final product.

| Defect | Cause | Prevention Methods |

|---|---|---|

| Porosity | Trapped gas in molten aluminum | Proper venting and degassing |

| Cracks | Uneven cooling, rapid solidification | Controlled cooling rate, mold design |

| Shrinkage | Aluminum contraction during cooling | Use of risers and proper mold design |

13. How to Improve Quality in Permanent Mold Aluminum Casting?

Improving the quality of permanent mold aluminum castings requires careful attention to each step of the process. What’s the real story? One of the most effective ways to enhance quality is through rigorous quality control measures, such as using advanced inspection tools to detect defects early.

Advanced techniques like ultrasonic testing and x-ray inspection can identify internal flaws that might not be visible on the surface. This is where it gets interesting—investing in high-tech inspection equipment can significantly reduce defect rates and improve overall casting quality.

Another way to improve quality is by optimizing the mold design. Using computer simulations and modeling can help identify potential issues before the mold is even created, ensuring that the final casting meets the required specifications.

| Improvement Method | Description | Benefit |

|---|---|---|

| Rigorous Quality Control | Use of inspection tools and testing | Detect defects early |

| Mold Design Optimization | Use of simulations and modeling | Prevent issues before casting begins |

| Advanced Techniques | Ultrasonic, x-ray testing | Improve defect detection |

14. How Do Technological Advancements Affect Permanent Mold Aluminum Casting?

Technological advancements have significantly impacted the permanent mold aluminum casting process. But here’s the kicker—automation and robotics have made it possible to increase production speed while maintaining high precision. This means manufacturers can produce larger quantities of high-quality castings in less time.

What’s the real story? 3D printing is also playing a role in mold design. Manufacturers can now quickly prototype and test mold designs, reducing the lead time for new projects. This is where it gets interesting—simulations are also helping mold designers predict how molten aluminum will behave during casting, allowing them to optimize the process and reduce defects.

| Technology | Impact on Casting Process | Benefit |

|---|---|---|

| Automation | Increases speed, maintains precision | Faster production, higher efficiency |

| 3D Printing | Enables rapid prototyping of mold designs | Reduced lead times for new designs |

| Simulations | Optimizes mold design and casting process | Fewer defects, better quality |

15. How to Choose a Permanent Mold Aluminum Casting Supplier?

Choosing the right supplier for permanent mold aluminum casting is a crucial decision. What’s the real story? The best suppliers are those with experience and a strong reputation for delivering high-quality products. Start by checking their customer reviews and testimonials—this gives you an idea of their reliability and quality standards.

It’s also important to evaluate the supplier’s ability to meet deadlines. Timely delivery is crucial in manufacturing, especially for industries that rely on tight production schedules. Ready for the good part? Choosing a supplier with state-of-the-art equipment and quality control processes will ensure that your castings meet your expectations.

| Selection Criteria | Considerations | Importance |

|---|---|---|

| Reputation | Check reviews and customer testimonials | Ensures quality and reliability |

| Ability to Meet Deadlines | Evaluate delivery performance | Critical for manufacturing timelines |

| Equipment & Technology | Assess the supplier’s equipment and processes | Guarantees precision and consistency |

FAQ Section

Q1: What is permanent mold aluminum casting?

Permanent mold aluminum casting is a manufacturing process where molten aluminum is poured into reusable molds to create high-precision, durable parts with excellent surface finishes.

Q2: How does permanent mold aluminum casting work?

In permanent mold aluminum casting, molten aluminum is poured into a metal mold, where it cools and solidifies to form a part with minimal defects and a smooth finish.

Q3: What are the advantages of permanent mold aluminum casting?

Permanent mold aluminum casting offers high dimensional accuracy, reduced porosity, and excellent surface finishes, making it ideal for industries that require precision and durability.

Q4: What industries use permanent mold aluminum casting?

Permanent mold aluminum casting is used in industries like automotive, aerospace, and electronics for parts that need high strength, light weight, and dimensional accuracy.

Q5: What are common defects in permanent mold aluminum casting?

Common defects include porosity, cracks, and shrinkage, but these can be minimized with proper mold design, cooling control, and inspection techniques.