Stainless steel investment casting is one of the most advanced methods for producing precise, complex, and durable metal components. It’s used across various industries, from aerospace to medical devices, because of its outstanding performance. If you are considering stainless steel for your next project, investment casting offers a multitude of advantages.

Stainless steel investment casting provides unparalleled precision, strength, and durability. But why is it considered the best method for certain applications? Let’s explore the key benefits and see how it works.

Stainless steel investment casting has a proven track record for producing complex, durable parts with exceptional quality. The method allows for highly intricate designs and tight tolerances, which makes it ideal for industries where reliability and performance are crucial.

1. What is Stainless Steel Investment Casting?

Stainless steel investment casting may sound like a complex process, but it is an incredibly efficient and effective method for creating high-precision parts. So, what exactly does it involve?

Investment casting starts with a pattern, usually made of wax or a similar material, which is then covered with a heat-resistant ceramic shell. The pattern is heated, the wax is removed, and molten stainless steel is poured into the mold. The resulting part can be complex, durable, and precise.

The process is known for producing parts with minimal material waste, high dimensional accuracy, and a wide range of material options, making it suitable for many industries. It’s especially favored for creating parts with intricate shapes that would be difficult or impossible to manufacture with other methods.

Types of Stainless Steel Used for Investment Casting

| Type of Stainless Steel | Properties | Common Applications |

|---|---|---|

| Austenitic Stainless Steel | High corrosion resistance, excellent welding properties | Aerospace, chemical processing |

| Ferritic Stainless Steel | Magnetic, better oxidation resistance at high temperatures | Automotive, heating applications |

| Martensitic Stainless Steel | High hardness, good strength | Tooling, turbine blades |

2. How Does Stainless Steel Investment Casting Work?

So, how does the process work? Let’s break it down step by step.

Investment casting begins with creating a pattern of the part. This pattern is typically made of a wax material. Once the pattern is formed, it is coated in a layer of fine sand or ceramic to create a mold. After the mold hardens, the wax is melted out of the mold, leaving a hollow space for the molten stainless steel.

Molten stainless steel is then poured into the mold, filling the cavity where the wax was. Once the metal has cooled, the mold is broken away, revealing the cast part. The result is an extremely precise part with minimal need for post-casting machining.

Advantages of Stainless Steel Investment Casting

| Advantage | Description |

|---|---|

| High Precision | Can produce parts with intricate designs and tight tolerances. |

| Material Efficiency | Minimizes waste compared to other casting methods. |

| Versatility | Can be used to create a wide variety of shapes, sizes, and types of parts. |

3. What Are the Key Benefits of Stainless Steel Investment Casting?

Stainless steel investment casting offers numerous advantages, making it one of the preferred methods for producing parts that require high precision and durability.

High Precision

Investment casting provides unparalleled accuracy, ensuring that parts fit and function as designed without needing extensive post-production modifications. This precision is crucial for industries like aerospace and medical device manufacturing.

Complex Geometries

One of the standout features of stainless steel investment casting is its ability to produce complex parts that would be nearly impossible with other methods like die casting or forging. Whether it’s fine details or complicated internal structures, investment casting can handle it.

Reduced Material Waste

Compared to other methods like machining or stamping, investment casting minimizes material waste. The process produces parts directly from the mold without the need to trim excess material, which can lead to significant savings.

Durability and Strength

Stainless steel is known for its strength and corrosion resistance, and when used in investment casting, it results in parts that are both durable and capable of performing in harsh environments. This makes it perfect for industries like automotive, aerospace, and energy.

Cost-Effectiveness in High-Volume Production

While the initial setup for investment casting can be more expensive than other methods, it is highly cost-effective when producing large quantities of parts. The consistency and minimal material waste make it ideal for mass production.

| Benefit | Description |

|---|---|

| High Precision | High accuracy and reduced need for additional machining. |

| Complex Geometries | Can create parts with complex shapes and details. |

| Reduced Material Waste | Produces minimal waste, reducing production costs. |

| Durability and Strength | Stainless steel offers strength and corrosion resistance. |

| Cost-Effectiveness | Ideal for high-volume production, minimizing cost per part. |

4. Why Choose Stainless Steel for Investment Casting?

Stainless steel is the material of choice for investment casting due to its excellent properties, which make it highly reliable and durable in various applications.

Corrosion Resistance

Stainless steel is resistant to rust and corrosion, making it ideal for applications in industries such as oil and gas, chemical processing, and food processing. Parts made from stainless steel can withstand harsh environments and remain intact for long periods.

Strength and Durability

In addition to being corrosion-resistant, stainless steel is incredibly strong, making it perfect for parts that need to endure stress and wear. The material’s strength ensures that parts can perform reliably over long periods.

Cost-Effectiveness

Stainless steel is a relatively affordable material compared to other metals like titanium or specialized alloys. This makes it a cost-effective solution for industries that need durable parts without the high material costs.

| Advantage | Description |

|---|---|

| Corrosion Resistance | Ideal for harsh environments where other materials would corrode. |

| Strength and Durability | Stainless steel is strong and able to endure wear and stress. |

| Cost-Effectiveness | More affordable than other materials like titanium or specialized alloys. |

5. How Does Stainless Steel Investment Casting Compare to Other Methods?

Stainless steel investment casting competes with other casting methods like sand casting and die casting. Each method has its strengths, and understanding these differences can help you determine the best option for your project.

Investment Casting vs Sand Casting

Investment casting offers much higher precision than sand casting, which makes it ideal for parts that require tight tolerances. However, sand casting is typically more cost-effective for larger parts where precision is not as critical.

Investment Casting vs Die Casting

Die casting is faster and typically better for producing high-volume, small to medium parts. However, investment casting can handle more intricate designs, making it better suited for highly detailed or complex parts.

| Method | Investment Casting | Sand Casting | Die Casting |

|---|---|---|---|

| Precision | High | Moderate | Moderate |

| Complexity | High | Low | Moderate |

| Material Waste | Low | High | Low |

| Cost for Large Parts | High | Low | Moderate |

| Best for | Detailed, complex parts | Large parts | Medium, high-volume parts |

6. What Are the Common Applications of Stainless Steel Investment Casting?

Stainless steel investment casting is used in many industries that demand high precision and durability. From aerospace to medical applications, this method offers unparalleled performance and versatility.

Aerospace Industry

In the aerospace industry, stainless steel investment casting is critical for producing parts like turbine blades, landing gear components, and engine parts. These parts require high strength, heat resistance, and the ability to withstand extreme conditions, which stainless steel can deliver.

Medical Devices and Equipment

For medical device manufacturers, precision is key. Stainless steel investment casting is used for making surgical tools, implants, and devices that must meet strict quality and safety standards.

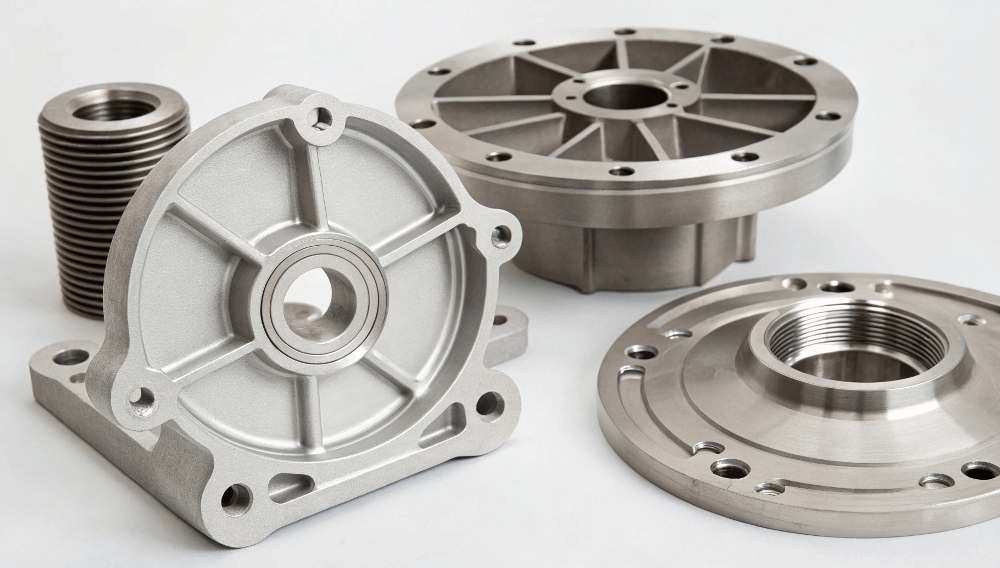

Industrial Machinery and Parts

Stainless steel investment casting is widely used in the industrial machinery sector for creating components like pumps, valves, and gears. These parts must withstand high pressure and corrosive environments, making stainless steel the ideal material.

| Industry | Application Example | Requirements |

|---|---|---|

| Aerospace | Turbine blades, landing gear | High strength, heat resistance, precision |

| Medical Devices | Surgical tools, implants | High precision, reliability, safety standards |

| Industrial Machinery | Pumps, valves, gears | Durability, resistance to wear and corrosion |

7. What Materials Are Best Suited for Investment Casting?

While stainless steel is the most commonly used material in investment casting, various alloys can be used depending on the specific requirements of the part.

Stainless Steel Alloys

Austenitic, ferritic, and martensitic stainless steel alloys are commonly used for investment casting, offering a wide range of properties like corrosion resistance, high strength, and hardness.

Superalloys

In high-performance applications, such as gas turbine engines, superalloys are used for investment casting. These alloys can withstand high temperatures and provide excellent resistance to oxidation and corrosion.

Other Materials

While stainless steel is the most common, other materials like carbon steel, aluminum, and brass can also be used in investment casting depending on the application.

| Material Type | Advantages | Common Uses |

|---|---|---|

| Stainless Steel | Corrosion-resistant, strong, durable | Aerospace, automotive, medical |

| Superalloys | High-temperature resistance, strong | Turbine engines, high-performance parts |

| Carbon Steel | Affordable, good strength | General engineering applications |

| Aluminum | Lightweight, good thermal conductivity | Automotive, electronics |

8. How Does Stainless Steel Investment Casting Impact Design Flexibility?

One of the main advantages of stainless steel investment casting is its ability to produce highly intricate and complex designs that would be difficult or impossible to achieve with other manufacturing methods.

Design Freedom

Investment casting allows for nearly limitless design flexibility. Whether it’s thin walls, complex shapes, or intricate internal passages, this method can accommodate it all without the need for additional machining.

Reducing Post-Casting Work

With traditional casting methods, parts often require extensive post-casting work, such as machining to remove excess material. Investment casting minimizes or eliminates the need for post-casting machining by creating parts close to their final form.

Producing Small, Lightweight Parts

Investment casting is also great for producing small, lightweight parts with fine features. This is especially beneficial for industries like aerospace, where weight reduction is crucial.

| Design Feature | Investment Casting | Traditional Casting |

|---|---|---|

| Complexity | High | Low |

| Post-Casting Machining | Minimal or none | Extensive |

| Weight | Low (lightweight parts) | Heavier parts |

9. How Is Stainless Steel Investment Casting Beneficial for High-Volume Production?

Stainless steel investment casting offers a range of benefits that make it a great choice for high-volume production. While the initial setup costs can be higher than some other methods, it becomes more cost-effective as production volumes increase.

Efficiency in Mass Production

Once the molds and patterns are established, investment casting can produce large numbers of parts quickly and efficiently. The process is highly repeatable, ensuring that each part is identical, which is crucial for large-scale manufacturing.

Cost Reduction in Long-Term Production

In high-volume production, the cost per part decreases significantly. The ability to produce complex parts without the need for extensive machining reduces labor costs, making it an economical choice for large-scale production.

| Benefit | Description |

|---|---|

| Efficiency | High repeatability and fast production times for large volumes. |

| Cost Reduction | Decreased cost per part in high-volume production. |

| Minimal Waste | Reduced material waste compared to traditional methods. |

10. What Are the Cost Considerations for Stainless Steel Investment Casting?

Cost is an important factor when considering any manufacturing method, and stainless steel investment casting is no exception.

Initial Setup Costs

The cost of tooling, mold creation, and pattern production can be high. This upfront investment can make the process more expensive for small production runs. However, for large orders, these costs are distributed over more units, making the per-part cost lower.

Production Efficiency

While the initial cost may be higher, the process becomes more cost-effective as production volume increases. The reduced need for post-casting work also cuts costs in the long run.

Additional Costs

Additional costs to consider include labor, material expenses, and quality control measures to ensure that each part meets the required specifications.

| Cost Factor | Impact on Total Cost |

|---|---|

| Initial Setup | High upfront investment |

| Production Volume | Lower cost per unit in high volumes |

| Material Waste | Minimal waste, contributing to cost savings |

| Labor and Machining | Reduced labor and machining costs in high-volume production |

11. How Do Stainless Steel Investment Castings Contribute to Sustainability?

Sustainability is an increasing concern across all industries, and stainless steel investment casting offers several advantages in this area.

Reduced Waste

Investment casting minimizes material waste compared to other casting methods like sand casting. The precision of the process ensures that minimal material is lost, which helps reduce the overall environmental footprint of the production.

Recyclability

Stainless steel is highly recyclable, which contributes to the sustainability of the process. Scraps and unused materials can be collected and reused, reducing the need for raw materials.

Energy Efficiency

The energy requirements for investment casting can be relatively low compared to other manufacturing methods, especially in high-volume production. This helps reduce the carbon footprint of the manufacturing process.

| Sustainability Factor | Investment Casting Impact |

|---|---|

| Material Waste | Minimal waste due to precision |

| Recyclability | Stainless steel can be easily recycled |

| Energy Consumption | Lower energy usage in high-volume production |

12. What Are the Challenges of Stainless Steel Investment Casting?

While stainless steel investment casting offers numerous benefits, it is not without its challenges.

Complexity in Design

Although the process allows for great design freedom, highly complex designs can sometimes pose challenges. For instance, intricate internal structures might require careful consideration to avoid casting defects.

Risk of Defects

Potential defects like porosity, cracks, or inclusions can occur, especially if the process is not carefully monitored. These defects can compromise the integrity of the part and may require reworking or replacement.

Labor Requirements

Investment casting requires skilled labor to ensure high-quality output. The process can be labor-intensive, especially for parts that need to meet stringent quality standards.

| Challenge | Impact |

|---|---|

| Complex Design | Risk of defects in highly intricate parts |

| Defects | Porosity, cracks, or inclusions can affect part quality |

| Labor Requirements | Skilled labor needed for precise casting |

13. How Do You Ensure Quality in Stainless Steel Investment Casting?

Ensuring quality in stainless steel investment casting is crucial for achieving optimal results.

Quality Control Techniques

Common techniques for ensuring quality include visual inspections, ultrasonic testing, and X-ray inspection to detect internal flaws. These methods help ensure that each part meets the required specifications.

Experienced Technicians

Experienced technicians play a critical role in the casting process. Their expertise ensures that the process is carried out correctly, and any potential issues are addressed early.

Industry Standards

Following industry standards and obtaining certifications, such as ISO 9001, is essential for maintaining quality and consistency in stainless steel investment casting.

| Quality Control Method | Description |

|---|---|

| Visual Inspection | Check for surface imperfections |

| Ultrasonic Testing | Detect internal flaws and voids |

| X-ray Inspection | Inspect for porosity and cracks |

| Certification | Adhere to ISO 9001 standards for quality |

14. What Are the Future Trends in Stainless Steel Investment Casting?

The future of stainless steel investment casting is promising, with several exciting trends on the horizon.

Advancements in Materials

New stainless steel alloys with enhanced properties are being developed to meet the needs of advanced industries like aerospace and medical manufacturing.

Automation and Technology

Automation in the casting process is improving speed, reducing human error, and increasing precision. The integration of artificial intelligence and machine learning into quality control is also expected to grow.

Sustainability Trends

As environmental concerns grow, investment casting is expected to become even more sustainable. With innovations in recycling methods and energy-efficient practices, this method will continue to be a more eco-friendly option.

| Trend | Impact |

|---|---|

| Advanced Materials | Development of new, high-performance alloys |

| Automation | Improved efficiency and precision |

| Sustainability | Reduced environmental impact through energy efficiency and recycling |

15. How Can You Choose the Right Supplier for Stainless Steel Investment Casting?

Choosing the right supplier is critical to ensuring the success of your investment casting project.

Factors to Consider

Key factors include the supplier’s experience, certifications, and ability to meet quality standards. It’s also important to evaluate their customer service, lead times, and the ability to handle large-scale production.

Evaluating Quality

Requesting samples or prototypes can help you assess the quality of the supplier’s work. It’s also essential to check their track record for delivering parts on time and meeting specifications.

| Evaluation Criteria | Importance |

|---|---|

| Experience | Ensure the supplier has the necessary expertise |

| Certifications | ISO and other relevant certifications |

| Customer Service | Timely communication and support |

| Lead Times | Ability to meet deadlines for production |

Conclusion

Stainless steel investment casting is a game-changer for industries requiring high-quality, precise, and durable parts. Whether you’re in aerospace, medical, or automotive industries, this method offers unparalleled benefits in terms of material efficiency, strength, and design flexibility. If you are considering using investment casting for your next project, understanding these key benefits will help you make the right choice.

FAQ

Q1: What is stainless steel investment casting?

Stainless steel investment casting is a manufacturing process where molten stainless steel is poured into a mold made from a heat-resistant material, creating precise and complex parts used across various industries.

Q2: How does stainless steel investment casting work?

The process begins with creating a pattern, often from wax, which is coated in a mold material. After melting the wax away, molten stainless steel fills the mold, creating the desired part.

Q3: What industries use stainless steel investment casting?

It’s used in aerospace, automotive, medical, energy, and industrial machinery sectors for high-precision parts that require strength and durability.

Q4: What are the main benefits of stainless steel investment casting?

Key benefits include high precision, ability to create complex geometries, reduced material waste, and strong, durable parts suitable for various industries.

Q5: What are the challenges of stainless steel investment casting?

Challenges include high initial setup costs, potential defects like porosity, and the need for skilled labor to ensure high-quality outputs.