Aluminum castings play a critical role in modern structural applications, offering strength and versatility. Whether you’re constructing bridges, building frameworks, or designing machinery, understanding aluminum castings’ benefits and applications can enhance your design process.

Aluminum castings provide significant advantages in structural design, including lightweight properties and durability. This article explores their benefits, types, and applications, helping you make informed decisions for your next project.

In the world of structural engineering, choosing the right materials is essential for durability and cost-efficiency. Let’s dive deeper into why aluminum castings are increasingly preferred in various industries, and how they can solve common challenges in structural design.

1. What are Aluminum Castings for Structural Applications?

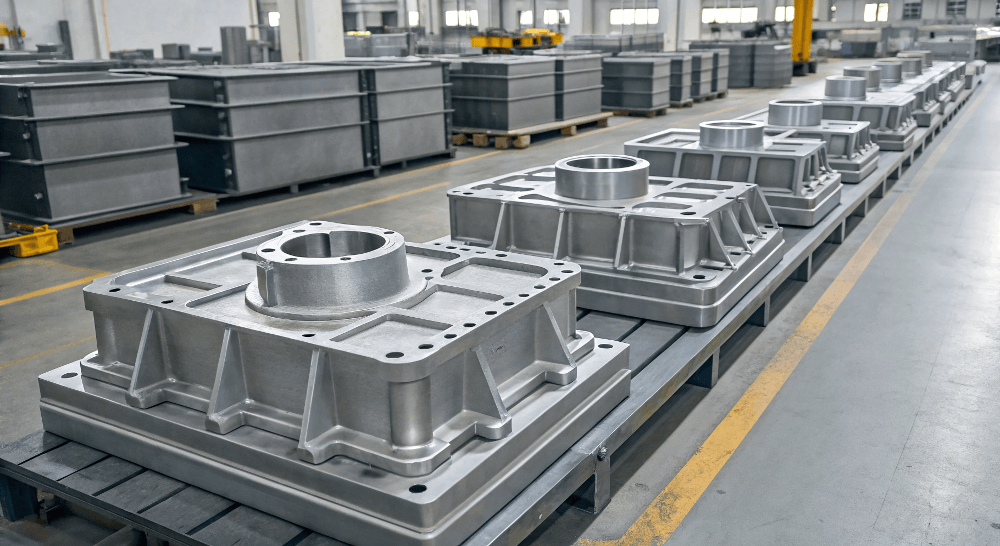

Aluminum castings are used widely in structural engineering due to their ability to combine strength, lightness, and flexibility. This section will provide a breakdown of what aluminum castings are and why they are so valuable in structural applications.

Aluminum castings refer to aluminum alloys that are melted, poured into molds, and solidified to create durable components for various uses, especially in structural applications. These components are widely used because of their strength-to-weight ratio, resistance to corrosion, and overall structural integrity.

What Makes Aluminum Castings Ideal for Structural Applications? Aluminum castings offer an ideal balance between lightness and strength, making them suitable for various structural needs. The corrosion resistance is another reason aluminum is favored, particularly in outdoor and marine environments. It also provides a high strength-to-weight ratio, making it an excellent choice for aerospace and automotive industries.

| Property | Aluminum Castings |

|---|---|

| Strength-to-weight ratio | High |

| Corrosion resistance | Excellent |

| Durability | Long-lasting |

| Cost efficiency | Good |

| Versatility | Highly versatile |

2. Why are Aluminum Castings Important in Structural Design?

Aluminum castings are integral to structural design for several reasons. Their ability to offer both lightweight strength and durability contributes to the efficiency and safety of the structures they support.

Aluminum castings are crucial because they ensure a strong yet lightweight framework that is resistant to wear and tear. With many industries relying on these castings for both small and large-scale projects, their role in structural design continues to grow. These castings help engineers balance performance and cost, which is why they remain popular in construction.

Key Benefits of Aluminum in Structural Design The lightweight nature of aluminum is perhaps the most beneficial property, particularly when weight is a critical factor in a design. Additionally, aluminum castings maintain their integrity over time without requiring heavy maintenance. These castings are also recyclable, contributing to sustainability in structural projects.

| Key Benefit | Explanation |

|---|---|

| Lightweight | Reduces material weight in construction |

| Durability | Long lifespan even in harsh environments |

| Recyclability | Environmentally friendly solution |

| Cost-effectiveness | Low cost for high performance |

3. What Types of Aluminum Are Used for Castings?

Aluminum alloys come in several grades, each with its unique set of characteristics. In structural applications, choosing the right type of aluminum is vital to ensuring optimal performance.

Aluminum alloys are categorized based on their composition. Some alloys are more suited for high-strength applications, while others are used for their lightweight or corrosion-resistant properties. Each type of aluminum offers unique advantages, and selecting the right alloy depends on the specific requirements of the structural application.

Common Aluminum Alloys for Castings Some of the most commonly used aluminum alloys in structural casting include the 200, 300, 400, and 500 series. Each alloy is chosen based on the specific performance needs of a project, whether it’s for heavy-duty applications or corrosion resistance in marine environments.

| Alloy Type | Characteristics | Best Used For |

|---|---|---|

| 200 Series | High strength, easy to weld | Aerospace components |

| 300 Series | Corrosion resistant | Marine applications |

| 400 Series | Cost-effective, good casting properties | Structural frames and supports |

| 500 Series | Excellent corrosion resistance | Marine and industrial applications |

4. How are Aluminum Castings Manufactured?

The process of manufacturing aluminum castings involves several key steps that ensure the final product is both durable and precise.

Aluminum castings are made through a process known as casting, where aluminum is melted and poured into molds to form specific shapes. This process may vary depending on the type of casting being used, such as sand casting, die casting, or permanent mold casting.

Casting Techniques for Structural Applications The sand casting method is commonly used for aluminum castings in structural applications. The process involves pouring molten aluminum into sand molds, which are then removed after cooling. Die casting, on the other hand, involves injecting molten aluminum into a metal mold under pressure for precise components.

| Casting Method | Key Advantage | Best For |

|---|---|---|

| Sand Casting | Cost-effective, flexible | Large structural components |

| Die Casting | Precision, repeatability | High-volume, precise parts for machinery |

| Permanent Mold | Strength, precision | High-strength structural components |

5. What Makes Aluminum Castings Suitable for Structural Applications?

Aluminum castings are especially well-suited for structural applications due to their unique combination of properties.

The material’s strength, combined with its lightweight nature, makes aluminum castings ideal for use in heavy structures like bridges, supports, and frames. Aluminum castings can handle large loads while remaining relatively light, which is essential in reducing the overall weight of the structure.

Strength and Durability Aluminum’s mechanical properties—such as its tensile strength, fatigue resistance, and corrosion resistance—make it one of the best materials for use in structural applications. The ability to maintain these properties under high-stress conditions ensures the reliability and safety of the structures.

| Property | Performance in Structural Use |

|---|---|

| Tensile Strength | Excellent for supporting loads |

| Fatigue Resistance | High, ideal for heavy-duty applications |

| Corrosion Resistance | Ideal for outdoor use and marine environments |

6. What Are the Advantages of Aluminum Castings Over Other Materials?

Aluminum castings offer several key advantages when compared to other traditional construction materials such as steel, concrete, and wood. Understanding these benefits can help you choose the most cost-effective and durable option for your structural application.

Aluminum is favored over other materials due to its remarkable combination of strength, lightness, and resistance to corrosion. Unlike steel, aluminum does not rust, which makes it ideal for use in environments with exposure to moisture. Moreover, aluminum castings are much lighter than steel, which reduces the overall weight of a structure and lowers transportation and handling costs.

Comparison with Steel, Concrete, and Wood When comparing aluminum to steel, one of the key differentiators is weight. Aluminum offers a much higher strength-to-weight ratio, allowing for lighter and more efficient structures. Additionally, aluminum is more resistant to corrosion than steel and can perform better in extreme conditions.

| Property | Aluminum Castings | Steel | Concrete | Wood |

|---|---|---|---|---|

| Weight | Light | Heavy | Heavy | Light |

| Corrosion Resistance | Excellent | Poor | Good | Poor |

| Strength-to-Weight Ratio | High | Moderate | Low | Low |

| Durability | Long-lasting | Long-lasting | Long-lasting | Moderate |

| Cost-effectiveness | Moderate | High | Low | Low |

7. How Do Aluminum Castings Contribute to Sustainable Design?

In an era where sustainability is becoming increasingly important, aluminum castings provide a significant advantage. Their environmental benefits stem from their recyclability, energy efficiency in manufacturing, and the long life cycle they offer to structures.

Aluminum is one of the most recycled materials in the world, and using aluminum castings supports a circular economy. Recycling aluminum uses only about 5% of the energy required to produce new aluminum, which drastically reduces carbon emissions.

Recycling and Reducing Carbon Footprint Aluminum’s ability to be recycled without losing its quality is a critical factor in sustainable design. Using aluminum castings not only reduces the demand for new raw materials but also minimizes waste and energy consumption.

| Sustainability Factor | Aluminum Castings |

|---|---|

| Recyclability | 100% recyclable |

| Energy Savings in Recycling | 95% energy saved |

| Carbon Emissions Reduction | Significant |

| Impact on Circular Economy | High |

| Reuse Potential | High |

8. What Are the Challenges of Using Aluminum Castings in Structural Applications?

While aluminum castings offer several advantages, there are also some challenges associated with their use in structural applications. These challenges primarily relate to handling, processing, and the limitations in specific high-stress applications.

Aluminum castings can sometimes be prone to defects, such as porosity, if the casting process is not closely controlled. Additionally, while aluminum is a strong material, it may not always provide the same load-bearing capacity as steel in some high-stress applications.

Addressing Defects and Material Limitations To mitigate these issues, it is important to ensure strict quality control measures during the casting process, such as pressure testing and non-destructive testing. In certain applications, combining aluminum with other materials can enhance its performance.

| Challenge | Impact on Structural Application | Solution |

|---|---|---|

| Defects (e.g., porosity) | Affects material strength | Ensure strict quality control |

| Load-bearing limitations | Limited for very high-stress applications | Combine with stronger materials |

| Processing issues | Can lead to casting defects | Use advanced casting techniques |

9. How Are Aluminum Castings Tested for Quality Assurance?

Ensuring the quality of aluminum castings is essential for the reliability of the final product. Various testing methods are employed to check for mechanical strength, durability, and overall quality of the castings before they are used in structural applications.

Common testing methods include tensile testing, which evaluates the strength of the casting under stress, and non-destructive testing (NDT), such as ultrasonic and X-ray testing, which ensures there are no internal flaws.

Non-Destructive Testing Methods NDT techniques are used to assess the integrity of aluminum castings without damaging the material. These tests can detect issues such as cracks, voids, or inconsistencies in the material structure.

| Test Method | Purpose | Advantages |

|---|---|---|

| Tensile Testing | Measures material strength | Determines maximum load capacity |

| Ultrasonic Testing | Detects internal defects | Non-invasive and precise |

| X-ray Testing | Identifies internal voids and cracks | High accuracy for detecting hidden flaws |

| Hardness Testing | Measures surface hardness | Ensures durability of the material |

10. What Industries Benefit Most from Aluminum Castings?

Aluminum castings are used across a wide range of industries, owing to their strength, durability, and versatility. The industries that benefit most from aluminum castings include construction, aerospace, automotive, and machinery, among others.

In the construction industry, aluminum castings are used for structural components such as beams and frames. In aerospace, aluminum castings are favored for lightweight, high-strength components that are essential for aircraft design. Automotive manufacturers also rely on aluminum castings for engine parts, frames, and wheels.

Key Industries Utilizing Aluminum Castings Aluminum castings are versatile and essential in many sectors. Their use in critical applications, from automotive to aerospace, highlights the value they bring to modern manufacturing processes.

| Industry | Application | Benefit |

|---|---|---|

| Construction | Beams, frames, structural supports | Lightweight and durable solutions |

| Aerospace | Aircraft parts, engine components | High-strength, lightweight designs |

| Automotive | Engine parts, wheels, chassis components | Fuel efficiency, strength-to-weight ratio |

| Machinery and Equipment | Structural frames, machine components | Long-lasting and reliable |

11. How Do You Select the Right Aluminum Casting for Your Project?

Selecting the right aluminum casting for your project involves a careful evaluation of several factors. The material you choose will largely depend on the specific needs of your project, such as load-bearing capacity, environmental conditions, and cost considerations.

When choosing an aluminum casting, you should consider factors such as the application requirements (e.g., strength, weight, and corrosion resistance), the alloy type, and whether the casting process suits your needs. For heavy-duty applications, you may opt for higher-strength alloys, while lighter alloys are ideal for applications where weight is a critical factor.

Factors to Consider in Selecting Aluminum Castings Consider factors such as stress loads, corrosion exposure, and the shape of the casting. These elements influence the type of alloy, the casting process, and the overall durability of the material in specific applications.

| Factor | Impact on Selection | Recommended Solution |

|---|---|---|

| Stress Load | Determines the strength required | Choose high-strength aluminum alloys |

| Corrosion Exposure | Determines corrosion resistance needed | Select alloys with excellent corrosion resistance |

| Shape and Design | Impacts the casting method | Choose the appropriate casting technique |

| Environmental Conditions | Exposure to heat, moisture, or chemicals | Use corrosion-resistant alloys like 500-series |

12. What Are the Different Applications of Aluminum Castings in Structural Engineering?

Aluminum castings are widely used in various applications within structural engineering, providing key solutions in building, infrastructure, and mechanical applications. They can be used to create structural frames, supports, and even detailed decorative elements.

In construction, aluminum castings are commonly used for large-scale projects such as bridges, high-rise buildings, and highways. They are also used for creating durable components in industrial applications, such as in machinery, pumps, and engines.

Examples of Aluminum Castings in Structural Engineering Aluminum castings are used in critical structural applications due to their strength, lightness, and durability. For example, aluminum castings are used in bridges and other infrastructure projects where the material’s lightweight nature can reduce the strain on supporting structures.

| Application | Examples of Use | Benefits |

|---|---|---|

| Bridges | Structural supports, beams, frames | Lightweight, corrosion-resistant |

| Buildings and High-Rise | Frames, support beams, window frames | Strong, easy to assemble, durable |

| Infrastructure Projects | Highway supports, pillars | Long-lasting and lightweight |

| Industrial Machinery | Pumps, machine components, valves | High strength and low weight |

13. How Can You Optimize the Design of Aluminum Castings for Structural Applications?

Optimizing the design of aluminum castings involves leveraging the material’s unique properties while ensuring that it meets structural requirements. By using modern design techniques and technology, engineers can make the most out of aluminum castings.

Design optimization is achieved by focusing on reducing material waste, improving the strength-to-weight ratio, and enhancing the casting process to minimize defects. Techniques like simulation software and casting simulation tools can predict potential weaknesses and help fine-tune designs before manufacturing.

Best Practices for Aluminum Casting Design Incorporating design features that minimize unnecessary material usage and maximize strength is essential. Additionally, optimizing the design for manufacturing, such as simplifying mold shapes and considering the flow of molten aluminum, can improve efficiency and reduce costs.

| Design Consideration | Benefit | Optimization Technique |

|---|---|---|

| Strength-to-Weight Ratio | Maximizes structural efficiency | Use lightweight, high-strength alloys |

| Material Waste Reduction | Reduces cost and environmental impact | Optimize casting shape and design |

| Manufacturing Process | Improves efficiency and cost-effectiveness | Use casting simulation and optimization tools |

14. What Are the Future Trends in Aluminum Castings for Structural Use?

The future of aluminum castings in structural applications is marked by technological advancements that improve manufacturing techniques, material properties, and sustainability. These trends are helping engineers and manufacturers meet the demands of modern structural engineering.

Emerging trends include the use of 3D printing for aluminum casting molds, the development of new aluminum alloys with enhanced properties, and automated manufacturing processes. These innovations will not only reduce costs but also improve the precision and quality of aluminum castings.

Emerging Trends in Aluminum Castings Advancements in casting technologies and material science will continue to push the boundaries of aluminum casting applications. Furthermore, the growing trend towards green building and sustainability will drive the demand for recyclable and energy-efficient materials like aluminum.

| Trend | Impact | Example |

|---|---|---|

| 3D Printing for Molds | Faster, more precise casting processes | Reduced lead times and improved accuracy |

| Advanced Alloys | Stronger, more durable materials | Improved performance in extreme conditions |

| Automation in Manufacturing | More efficient production | Lower costs and increased production rates |

15. How Do Aluminum Castings Compare in Terms of Cost and Performance?

Aluminum castings strike a balance between cost and performance, offering a cost-effective solution for many structural applications while providing superior performance.

While aluminum castings are not always the cheapest material available, their long-term durability, lightweight nature, and versatility make them an economical choice in the long run. The performance benefits often outweigh initial costs, especially in projects requiring high strength and resistance to environmental factors.

Cost vs. Performance When considering the cost of aluminum castings, it is important to account for both the initial cost and the long-term benefits. The ability to recycle aluminum also contributes to its overall cost-effectiveness in the construction and manufacturing industries.

| Cost Factor | Aluminum Castings | Other Materials (e.g., Steel) |

|---|---|---|

| Initial Material Cost | Moderate | High |

| Longevity | Long-lasting | Moderate to High |

| Maintenance Costs | Low | High |

| Environmental Impact | Low (due to recyclability) | High (especially with steel) |

Conclusion

Aluminum castings for structural applications provide significant advantages, including strength, durability, and versatility. These castings are integral in numerous industries, offering an ideal solution to reduce material weight while maintaining integrity. By understanding the types, processes, and benefits of aluminum castings, you can ensure the success of your next structural project.

FAQ Section

Q1: What is an aluminum casting?

Aluminum casting is the process of shaping molten aluminum into a mold to create components used in structural applications.

Q2: How does aluminum casting work?

Aluminum is melted, poured into molds, and allowed to cool and solidify into the desired shape. Various techniques, such as sand casting and die casting, are used for different types of applications.

Q3: What are the benefits of using aluminum castings in structural applications?

Aluminum castings are lightweight, durable, corrosion-resistant, and cost-effective, making them ideal for use in structural design.

Q4: How do you choose the right aluminum casting for your project?

The choice of aluminum alloy depends on the specific application, load requirements, and environmental factors. Consulting with an expert can help ensure the best choice.

Q5: Are aluminum castings sustainable?

Yes, aluminum is highly recyclable, making aluminum castings an environmentally friendly option in structural applications.