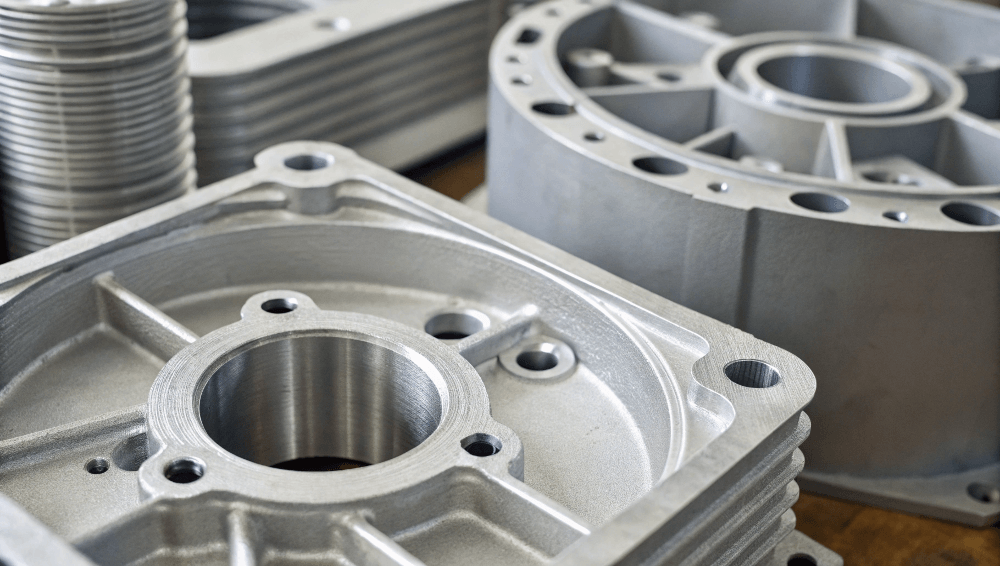

Aluminum die casting alloys are crucial for manufacturing high-precision parts in industries like automotive, aerospace, and electronics. If you’re looking for the best material for your project, selecting the right alloy is a decision that will directly impact the quality, cost, and efficiency of production.

So, which aluminum die casting alloy is best suited for your project? The answer depends on your specific requirements, such as strength, corrosion resistance, and the intended application. In this article, we will explore the different types of aluminum die casting alloys, their characteristics, and how to choose the best one for your needs.

Understanding the intricacies of aluminum alloys and their applications is key to making an informed choice. This article will provide you with a detailed overview, breaking down the factors to consider and offering insights into selecting the right alloy for your project.

1. What Are Aluminum Die Casting Alloys?

Aluminum die casting alloys are a combination of aluminum and other elements such as copper, magnesium, silicon, and zinc. These alloys are designed for the die casting process, which involves injecting molten metal into a mold to produce complex parts with high precision.

What exactly makes these alloys ideal for die casting? The answer lies in their ability to withstand high pressures and temperatures, their lightweight nature, and their ability to form intricate shapes with excellent dimensional accuracy.

The Role of Alloying Elements

- Silicon helps improve fluidity during casting and provides better casting ability.

- Magnesium increases strength, hardness, and corrosion resistance.

- Copper enhances strength at high temperatures.

How Different Alloys Are Used

| Alloy Type | Primary Use | Benefits |

|---|---|---|

| A380 | Automotive, Electronics | High strength, good fluidity, and corrosion resistance |

| A360 | Aerospace, Medical | Excellent corrosion resistance, good castability |

| ADC12 | Automotive, Consumer | High strength, lightweight, good wear resistance |

2. Why Do Aluminum Die Casting Alloys Matter in Manufacturing?

Choosing the right aluminum die casting alloy is vital for producing parts that meet specific requirements like strength, precision, and durability. The correct alloy ensures that the final product performs well under stress and environmental conditions, making it essential for applications in critical industries.

What makes aluminum die casting alloys so important? These alloys offer the perfect combination of properties that can withstand high stress, harsh environments, and high temperatures, making them the preferred choice for many industries.

Key Benefits

- Lightweight: Aluminum is lighter than other metals, making it ideal for parts where weight reduction is crucial, such as in automotive and aerospace applications.

- Strength: Aluminum alloys, especially those reinforced with magnesium or copper, offer enhanced strength, enabling them to support heavy loads.

- Corrosion Resistance: Aluminum naturally resists corrosion, making it perfect for outdoor or high-moisture environments.

| Benefit | Alloy Example | Industry Application |

|---|---|---|

| Corrosion Resistance | A360 | Aerospace |

| High Strength | A380 | Automotive |

| Lightweight | ADC12 | Consumer Electronics |

3. How Do Different Aluminum Die Casting Alloys Compare?

Each aluminum die casting alloy has distinct advantages and trade-offs. It’s essential to understand how they differ in terms of performance, cost, and suitability for specific applications.

How do these alloys compare in real-world use? While some alloys are ideal for high-temperature applications, others excel in corrosion resistance or high-strength applications. Understanding these differences helps you make the best decision for your project.

Strength vs. Cost

- A380 Alloy: Offers high strength and precision but comes at a higher cost due to its complexity.

- A360 Alloy: More cost-effective with excellent corrosion resistance, ideal for parts exposed to harsh environments.

| Alloy Type | Strength | Cost | Best For |

|---|---|---|---|

| A380 | High | High | Automotive, Aerospace |

| A360 | Moderate | Low | Corrosion-resistant parts |

| ADC12 | Moderate | Moderate | Consumer goods, Machinery |

4. What Factors Should You Consider When Choosing an Aluminum Alloy for Die Casting?

When selecting an aluminum die casting alloy, there are several factors you must consider, such as mechanical properties, environmental conditions, and the specific application.

What factors should influence your alloy choice? You need to assess the required strength, weight, and corrosion resistance based on the part’s end use. You should also consider whether the alloy is compatible with the casting process.

Key Considerations for Selection

- Strength and Hardness: Ensure the alloy can withstand the mechanical demands of your application.

- Corrosion Resistance: For parts exposed to moisture, like automotive or marine applications, select alloys with higher corrosion resistance.

- Casting Process Compatibility: Some alloys are easier to cast than others, so ensure your chosen alloy fits the die casting process.

| Consideration | Alloy Example | Impact on Final Product |

|---|---|---|

| Strength & Hardness | A380 | Suitable for load-bearing applications |

| Corrosion Resistance | A360 | Best for harsh environments |

| Casting Compatibility | ADC12 | High casting ability for intricate shapes |

5. What Are the Main Alloy Types Used in Aluminum Die Casting?

The main alloy types in aluminum die casting include the 100, 200, 300, and 400 series, each offering different properties depending on the elements used in the composition.

What are the most common alloy types? The 100 and 200 series alloys are known for their high strength and good fluidity, while the 300 series alloys excel in corrosion resistance, and the 400 series are best for high-temperature applications.

Common Alloys and Their Applications

| Alloy Type | Key Features | Best Applications |

|---|---|---|

| 100 Series | High purity, good fluidity | Automotive parts, engine components |

| 200 Series | Good strength, moderate corrosion resistance | Aerospace, industrial machinery |

| 300 Series | Excellent corrosion resistance | Marine, chemical industries |

| 400 Series | High temperature resistance | Aerospace, heavy-duty machinery |

6. How Does the Chemical Composition Affect Aluminum Die Casting Alloys?

The chemical composition of an aluminum die casting alloy is crucial because it directly influences the material’s mechanical properties, fluidity, strength, and corrosion resistance. By adjusting the proportions of alloying elements like copper, magnesium, and silicon, manufacturers can tailor the alloy’s performance to meet specific requirements.

How does the chemical composition affect the alloy’s characteristics? The addition of elements such as copper improves strength, while magnesium enhances corrosion resistance. Silicon, on the other hand, improves the fluidity of the molten aluminum, making it easier to cast into intricate shapes.

Chemical Composition and Its Impact

| Alloy Element | Impact on Properties | Common Alloys |

|---|---|---|

| Silicon | Improves fluidity, reduces shrinkage | A380, ADC12 |

| Magnesium | Increases strength and corrosion resistance | A360, A380 |

| Copper | Improves strength at high temperatures | A380, A383 |

| Zinc | Improves fluidity, enhances casting ability | A383, ADC12 |

By optimizing the chemical composition, manufacturers can produce alloys that are ideal for specific applications. For example, A380 alloy, which has a higher percentage of copper, is commonly used in automotive and aerospace industries where high strength is required.

7. What Role Does Heat Treatment Play in Aluminum Die Casting Alloys?

Heat treatment is a crucial step in the production of aluminum die casting alloys. It is used to modify the alloy’s properties, enhancing characteristics such as hardness, strength, and resistance to wear. The heat treatment process involves heating the alloy to a specific temperature and then cooling it at a controlled rate.

Why is heat treatment important for aluminum die casting alloys? Heat treatment helps improve the material’s mechanical properties, making it stronger and more durable. In particular, alloys like A360 benefit significantly from heat treatment, enhancing their corrosion resistance and fatigue strength.

Effects of Heat Treatment on Properties

| Alloy Type | Heat Treatment Effect | Resulting Properties |

|---|---|---|

| A360 | Solution heat treated, aged | Increased corrosion resistance and strength |

| A380 | Solution heat treated | Enhanced tensile strength, better performance under high stress |

| A413 | Age hardened | Higher resistance to wear and cracking |

| ADC12 | As-cast, some heat treatment | Good balance of strength and casting ability |

This heat treatment process ensures that the parts produced from aluminum die casting alloys can withstand the stresses of their intended applications. By properly treating the alloys, manufacturers can significantly improve the performance and longevity of the parts.

8. How Does the Die Casting Process Work with Aluminum Alloys?

The die casting process for aluminum alloys involves injecting molten aluminum into a metal mold, known as a die, under high pressure. The mold is precisely crafted to ensure that the molten aluminum fills all cavities, creating parts with high dimensional accuracy. Once the part cools and solidifies, it is removed from the mold and further processed.

What makes die casting so effective for aluminum alloys? The high pressure used in the die casting process allows aluminum alloys to be molded into highly intricate shapes while maintaining strength and precision. This makes aluminum die casting ideal for applications that require complex geometries and tight tolerances.

Die Casting Process Overview

| Process Step | Description | Importance for Aluminum Alloys |

|---|---|---|

| Injection | Molten aluminum is injected into a die under high pressure | Ensures accurate and precise shapes |

| Cooling | Part is cooled in the mold before removal | Solidifies the part, ensuring dimensional accuracy |

| Ejection | Solidified part is removed from the die | Allows for the creation of complex shapes with high detail |

| Finishing | Parts may undergo secondary processes like machining or coating | Improves surface finish and quality |

Aluminum die casting alloys work well in this process because they have good fluidity and can be easily cast into intricate molds. This is particularly beneficial for industries that require highly detailed parts, such as automotive and electronics.

9. What Are the Benefits of Using Aluminum Die Casting Alloys Over Other Materials?

Aluminum die casting alloys offer several advantages over other materials, such as zinc, magnesium, and steel. The primary benefits of using aluminum die casting alloys include their lightweight nature, strength, corrosion resistance, and ability to be cast into complex shapes. These advantages make aluminum alloys the material of choice for industries like automotive, aerospace, and electronics.

What makes aluminum die casting alloys stand out? They offer the perfect balance of lightweight design and high strength, making them ideal for parts that must perform well under high stress while also minimizing weight. Additionally, their superior corrosion resistance ensures long-lasting performance, even in harsh environments.

Aluminum vs. Other Materials

| Material Type | Strength | Weight | Corrosion Resistance | Best Use |

|---|---|---|---|---|

| Aluminum | High | Lightweight | Excellent | Automotive, Aerospace |

| Zinc | Moderate | Heavy | Good | Consumer Electronics |

| Magnesium | Moderate | Very lightweight | Poor | Automotive, Military |

| Steel | Very High | Heavy | Moderate | Heavy-duty machinery |

The combination of lightweight, high strength, and corrosion resistance makes aluminum die casting alloys the best option in situations where precision and durability are key.

10. How Do Aluminum Die Casting Alloys Perform in High-Stress Environments?

Aluminum die casting alloys are known for their high-performance capabilities in high-stress environments, such as those found in automotive, aerospace, and industrial applications. These alloys can withstand extreme temperatures, mechanical stresses, and exposure to harsh chemicals without degrading in performance.

What makes aluminum die casting alloys suitable for high-stress environments? Alloys like A380 and A360 are specifically designed to resist wear, fatigue, and corrosion under demanding conditions. This makes them ideal for use in parts that require both strength and long-term durability.

Performance in Stressful Conditions

| Alloy Type | High Temperature Resistance | Fatigue Resistance | Corrosion Resistance |

|---|---|---|---|

| A380 | Good | Excellent | Excellent |

| A360 | Excellent | Good | Excellent |

| A413 | Moderate | Excellent | Good |

| ADC12 | Good | Moderate | Good |

These alloys perform exceptionally well in harsh environments, such as under high mechanical stress or exposure to chemicals, making them indispensable in industries like aerospace and automotive.

11. How Are Aluminum Die Casting Alloys Used in the Automotive Industry?

The automotive industry relies heavily on aluminum die casting alloys for the production of lightweight, high-strength, and durable parts. Aluminum alloys are used in various components such as engine blocks, transmission cases, wheels, and structural parts. These alloys offer significant weight reduction compared to other materials, contributing to improved fuel efficiency and reduced emissions.

Why are aluminum die casting alloys preferred in the automotive industry? The need for lightweight materials without compromising strength and durability has made aluminum alloys the go-to material for automotive manufacturers. They offer superior performance in both safety-critical parts and aesthetic components.

Common Automotive Applications

| Alloy Type | Automotive Application | Benefits |

|---|---|---|

| A380 | Engine blocks, transmission housings | High strength, durability, good fluidity |

| A360 | Wheels, structural components | Lightweight, corrosion resistant |

| ADC12 | Chassis, engine parts | Cost-effective, high strength-to-weight ratio |

| A413 | Structural parts, brake components | Excellent fatigue resistance, good thermal conductivity |

By choosing the right aluminum alloy, automotive manufacturers can produce parts that meet stringent performance standards while also contributing to overall vehicle efficiency and safety.

12. What Are the Most Common Industries That Use Aluminum Die Casting Alloys?

Aluminum die casting alloys are widely used across various industries due to their versatility, strength, and precision. Key industries that rely on these alloys include aerospace, electronics, automotive, and industrial machinery.

Which industries benefit the most from aluminum die casting alloys? These alloys are ideal for producing complex parts with tight tolerances, making them essential in industries that require high precision, durability, and lightweight materials for critical applications.

Key Industries Using Aluminum Die Casting

| Industry | Application Examples | Alloy Benefits |

|---|---|---|

| Aerospace | Aircraft components, landing gear | Lightweight, high strength, heat resistance |

| Electronics | Computer housings, mobile phone parts | Precision, durability, corrosion resistance |

| Automotive | Engine blocks, wheels, transmissions | Strength, lightweight, cost-effective |

| Industrial | Pumps, valves, machinery parts | Durability, high precision, resistance to wear |

Aluminum die casting alloys are crucial in producing parts that must withstand extreme conditions and maintain high performance over time, making them an indispensable material in these industries.

13. How Do Aluminum Die Casting Alloys Perform in Extreme Conditions?

Aluminum die casting alloys excel in high-stress and extreme environmental conditions, including exposure to extreme temperatures, mechanical wear, and aggressive chemicals. Their ability to withstand such conditions makes them ideal for applications in harsh environments such as aerospace, automotive, and industrial machinery.

How do these alloys perform under extreme conditions? With the right alloy composition, aluminum die casting alloys can resist high temperatures, corrosion, and physical stress, making them a reliable choice for critical applications where performance and safety are paramount.

Performance in Extreme Conditions

| Condition | Alloy Type | Performance Impact |

|---|---|---|

| High Temperature | A380 | Excellent resistance to thermal stress |

| Corrosion Exposure | A360 | High corrosion resistance, ideal for marine environments |

| Mechanical Stress | A413 | Excellent fatigue resistance, high strength-to-weight ratio |

| Chemical Exposure | ADC12 | Moderate resistance to chemicals, suitable for industrial use |

These alloys maintain their strength and functionality even in the most demanding environments, offering consistent performance under extreme conditions.

14. How Do Advances in Technology Impact Aluminum Die Casting Alloys?

Advancements in material science and casting technology have led to the development of more advanced aluminum die casting alloys with improved performance characteristics. These advancements allow manufacturers to produce more efficient, durable, and lightweight components for a variety of industries.

What are the latest technological advancements in aluminum die casting alloys? Innovations in alloy composition, casting processes, and heat treatment have resulted in alloys that offer better performance at lower costs. For example, the use of advanced simulation software allows for more precise control over the casting process, reducing defects and improving part quality.

Technological Advancements

| Advancement | Impact on Alloy Performance | Example Alloys |

|---|---|---|

| Advanced Alloying | Improved strength, corrosion resistance | A380, A413 |

| Simulation Software | Enhanced casting accuracy, reduced defects | A360, ADC12 |

| Innovative Heat Treatment | Higher fatigue and wear resistance | A413, A360 |

| Additive Manufacturing | More complex geometries, better material properties | Custom alloys for aerospace |

These innovations help manufacturers meet increasingly stringent requirements for performance, reducing production costs while maintaining high-quality standards.

15. What Are the Cost and Production Considerations for Aluminum Die Casting Alloys?

When selecting aluminum die casting alloys, cost and production efficiency are essential factors to consider. While aluminum alloys tend to be more expensive than other materials, their benefits in terms of performance, weight reduction, and durability often justify the higher initial investment. Understanding the cost drivers and production considerations can help manufacturers make cost-effective decisions.

How do cost and production considerations affect alloy selection? While aluminum die casting alloys may have a higher upfront cost, their long-term benefits in terms of durability, performance, and reduced maintenance costs make them a sound investment. Production considerations, such as material availability and casting complexity, also play a significant role in the final decision.

Cost vs. Production Efficiency

| Alloy Type | Production Cost | Performance Benefits | Best For |

|---|---|---|---|

| A380 | High | High strength, excellent casting ability | Automotive, Aerospace |

| A360 | Moderate | Excellent corrosion resistance, good fluidity | Marine, Aerospace |

| A413 | Moderate | High fatigue resistance, wear resistance | Automotive, Heavy-duty machinery |

| ADC12 | Low | Good casting ability, moderate strength | Consumer products, Industrial machinery |

By balancing the cost of the alloys with the long-term benefits of using them in high-performance applications, manufacturers can make informed decisions that maximize the value of their investment.

Conclusion

Selecting the right aluminum die casting alloy is essential for ensuring your parts meet performance standards and industry requirements. By understanding the differences between the various alloys and carefully considering the specific needs of your project, you can make an informed decision that will save time, reduce costs, and enhance the overall quality of your product. Choosing wisely ensures you get the right balance of strength, precision, and durability.

FAQ

Q1: What are aluminum die casting alloys used for?

Aluminum die casting alloys are used in industries like automotive, aerospace, and electronics for creating lightweight, high-strength parts with excellent precision.

Q2: How does aluminum die casting work?

Aluminum die casting involves injecting molten aluminum into a mold under high pressure to form parts that meet specific dimensions and strength requirements.

Q3: Which aluminum alloy is best for automotive parts?

A380 is commonly used in automotive die casting due to its strength, precision, and ability to resist corrosion.

Q4: What is the difference between the 100 and 200 series alloys?

The 100 series alloys are high-purity, offering better fluidity, while the 200 series alloys provide a higher strength-to-weight ratio for more demanding applications.

Q5: Can aluminum die casting alloys withstand extreme temperatures?

Yes, alloys like A380 and A360 can withstand high temperatures, making them suitable for industries that require high-heat resistance, such as aerospace and automotive.