Does your production line suffer from heavy components and sky-high machining costs? You are not alone in this struggle. Engineers constantly battle the tradeoff between structural integrity and manufacturing expenses. Here is the deal. High-performance manufacturing demands a solution that delivers complex geometries without destroying the budget. Aluminum precision casting stands as that solution. It transforms raw molten metal into sophisticated, near-net-shape parts that drive modern machinery. This article analyzes the technical nuances, economic benefits, and operational realities of this foundational manufacturing method.

1. What Is Aluminum Precision Casting?

Defining the Manufacturing Process

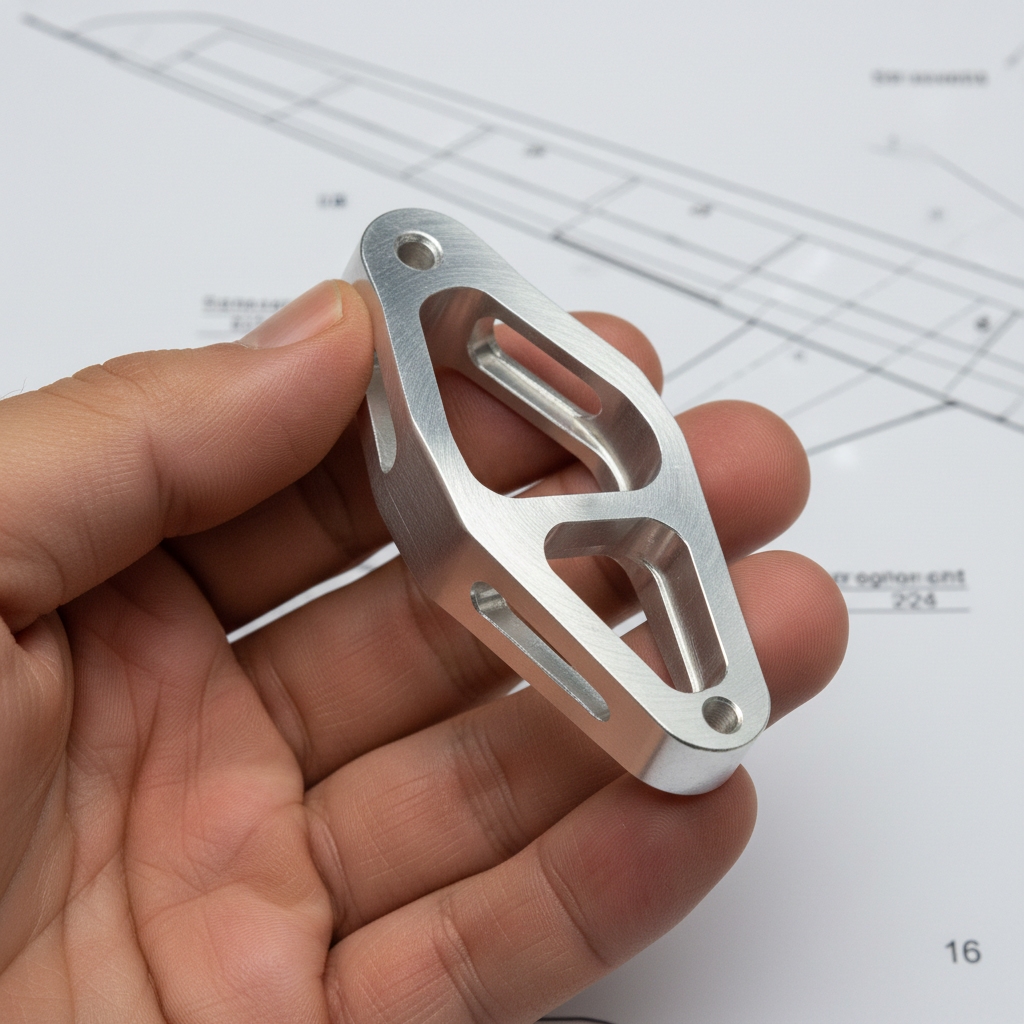

Aluminum precision casting is a specialized fabrication technique. It creates metal parts holding tight dimensional tolerances. Unlike rough forming methods, this approach prioritizes exactitude. It creates components that require minimal machining. The process starts with a detailed pattern. Manufacturers use this pattern to create a mold. This mold dictates the final geometry of the piece. Industry leaders rely on aluminum precision casting for intricate shapes. Machining such forms from solid blocks proves impossible or too costly. It represents a direct path from design to physical reality.

Consider the complexity of a turbocharger impeller. The curved blades must direct airflow efficiently. Machining these curves from a solid cylinder takes hours. Casting forms them in seconds. This efficiency defines the modern foundry.

The Role of Molten Aluminum

Liquid metal acts as the lifeblood of this operation. Technicians heat aluminum ingots until they reach a fluid state, typically around 1200°F. This molten aluminum must flow smoothly into every crevice of the mold. Fluidity is key. If the metal cools too fast, it creates defects. Operators carefully control temperature and pouring rate. They ensure the liquid aluminum fills the cavity completely. Once inside, the metal solidifies. It captures the finest details of the mold surface. This phase determines the ultimate surface finish.

Achieving Net-Shape Components

You might be wondering. Why is “net-shape” such a big deal? It means the part comes out of the mold looking almost exactly like the final drawing. You do not need to shave off layers of metal. You save material. You save time. Traditional machining turns expensive metal into scrap chips. Aluminum precision casting minimizes this waste. The part emerges with holes, slots, and complex contours already formed. This efficiency makes it the preferred method for mass production. It excels where geometry is complex and tolerance is tight.

2. Why Is This Method Crucial for Industry?

Bridging Material and Function

Engineers constantly seek the sweet spot between weight and strength. Steel is strong but heavy. Plastic is light but weak. Aluminum sits perfectly in the middle. Aluminum precision casting allows designers to utilize this material’s full potential. They can place material exactly where stress loads are high. They remove it where it is unnecessary. This results in optimized topology. A cast part functions as a unified structure. There are no welds to fail. There are no bolts to loosen. It creates a seamless bridge between raw material properties and functional requirements.

Driving Economic Efficiency

Think about it for a moment. Every minute a machine runs costs money. Various aluminum casting methods offer different cost structures. Precision casting shines in high-volume scenarios. While initial tooling cost might be significant, unit price drops drastically as volume increases. A single mold can produce thousands of identical parts. Labor costs per unit decrease. Material waste is virtually non-existent compared to subtractive manufacturing. Companies that switch to various aluminum casting methods often see their return on investment soar. It happens within the first year of production. It is a volume game, and casting wins it.

Consider a manufacturer producing 50,000 automotive brackets. Machining each from billet costs

45.Castingthemmightcost45. Casting them might cost 45.Castingthemmightcost

8 per unit after paying for a $20,000 mold. The savings are astronomical.

Versatility in Part Design

Design freedom is perhaps the biggest advantage. Machining has limits. A CNC tool cannot reach around corners. Casting has no such restriction. If you can mold it, you can cast it. Designers can integrate features like internal cooling channels or complex ribbing patterns. These features increase stiffness without adding mass. Aluminum precision casting empowers engineers to think outside the box. They can combine multiple assembled parts into a single casting. This consolidation simplifies the supply chain. It reduces assembly errors.

3. What Properties Make Aluminum Alloys Unique?

Exploring Strength-to-Weight Ratios

Aluminum is roughly one-third the density of steel. Yet, modern alloys offer surprising strength. This high strength-to-weight ratio is vital for anything that moves. Cars consume less fuel. Planes carry more payload. Robots move faster. Aluminum precision casting preserves these ratios by maintaining a dense, uniform grain structure. This process ensures the metal solidifies properly. It maximizes mechanical properties. You get a lightweight part that can take a beating.

Corrosion Resistance Factors

But wait, there is more. Aluminum naturally forms a protective oxide layer when exposed to air. This microscopic shield prevents rust. It makes aluminum castings ideal for harsh environments. Marine applications rely on this. Outdoor telecommunications gear depends on it. Unlike iron which flakes away, aluminum heals itself. If you scratch the surface, the oxide layer reforms instantly. This self-protecting characteristic reduces maintenance costs for the end-user.

Thermal and Electrical Conductivity

Heat management is a major challenge in electronics. Aluminum is an excellent conductor of heat. Cast aluminum heat sinks are ubiquitous in computers and LED lighting. They pull heat away from sensitive components efficiently. Electrical conductivity is also a key factor. While not as conductive as copper, aluminum is far lighter and cheaper. Power transmission components frequently utilize aluminum precision casting. They balance weight and electrical performance.

| Alloy Series | Primary Element | Key Characteristic | Typical Application | |

|---|---|---|---|---|

| 3xx.x | Silicon/Copper | High Fluidity, Good Strength | Engine Blocks, Die Casting | |

| 4xx.x | Silicon | Excellent Corrosion Resistance | Marine Parts, Cookware | |

| 5xx.x | Magnesium | High Tensile Strength | Structural Brackets | |

| 7xx.x | Zinc | Highest Strength | Aerospace Frames | |

| 2xx.x | Copper | High Heat Strength | Cylinder Heads |

4. Which Casting Processes Work Best?

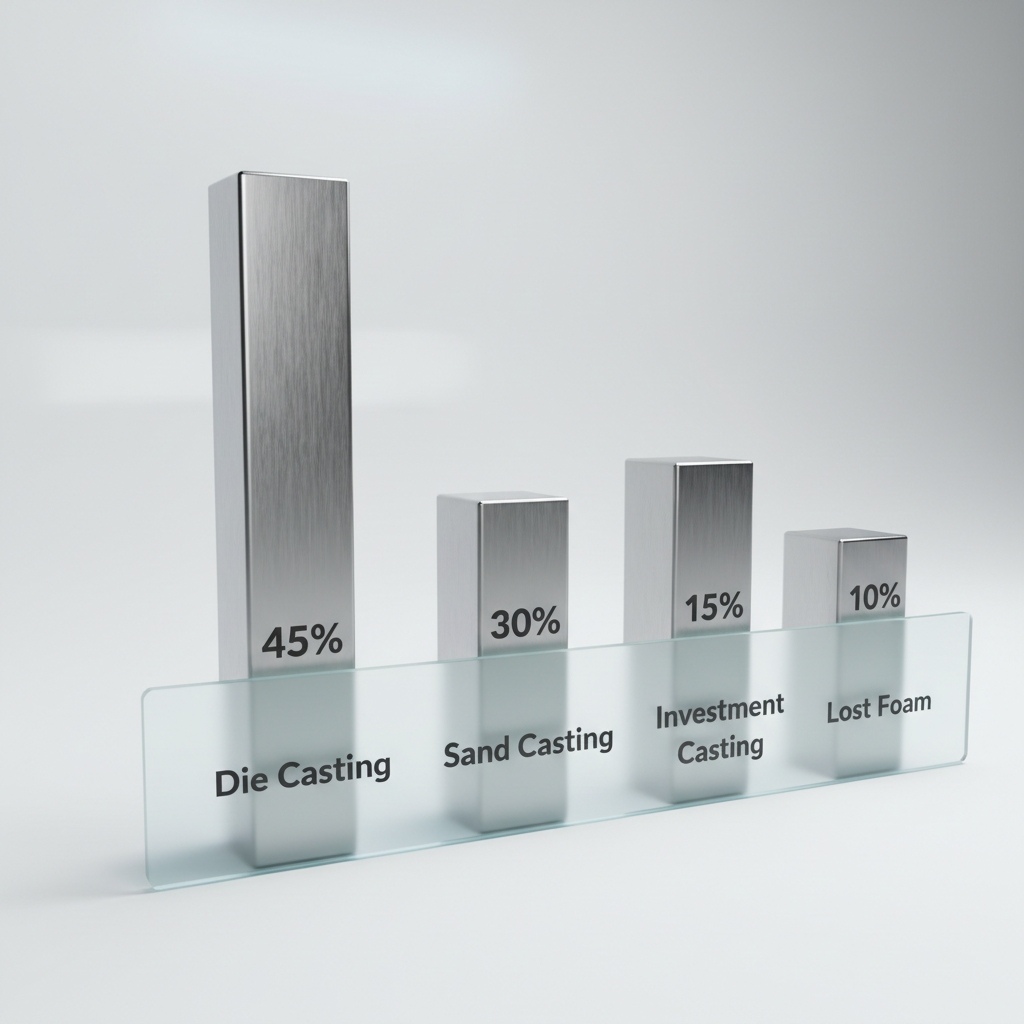

Overview of Common Methods

Not all castings are created equal. The industry uses several distinct methods depending on need. Aluminum precision casting covers techniques like die casting, investment casting, and permanent mold casting. Each has a specific niche. Sand casting is great for prototypes. Die casting rules mass production. Selecting the right method determines project success. It involves matching process capabilities with product requirements.

Comparing Sand and Die Casting

Let’s break it down. Sand casting is the old-school method. It uses sand to form the mold. It is cheap for low volumes but finish is rough. Dimensions vary. Die casting production is the modern powerhouse. It forces metal into steel molds under high pressure. The surface comes out smooth. Dimensions are exact. If you need 50 parts, use sand. If you need 50,000, you must use die casting production . Tooling for die casting is expensive, but speed is unmatched.

Imagine needing a rough prototype for a pump housing. Sand casting delivers this in days for a few hundred dollars. Die casting would require months and thousands of dollars for tooling.

Specialized Casting Techniques

There are also niche methods for specific needs. Squeeze casting combines casting and forging to create incredibly dense parts. Plaster mold casting offers surface finishes that rival die casting. It does so with lower tooling costs. Vacuum casting removes air from the mold. This prevents bubbles. These specialized forms of aluminum precision casting solve unique problems. They allow engineers to tackle challenges standard methods cannot handle.

| Feature | Sand Casting | Die Casting | Investment Casting | |

|---|---|---|---|---|

| Volume | Low to Medium | High to Very High | Low to Medium | |

| Tolerance | Low | Very High | High | |

| Surface Finish | Rough | Smooth | Very Smooth | |

| Tooling Cost | Low | High | Medium | |

| Part Complexity | High | Medium | Very High |

5. How Does Die Casting Optimize Production?

The High-Pressure Advantage

Pressure changes everything. In gravity casting, metal simply flows in. In high-pressure die casting, a piston slams metal into the mold. This pressure ensures aluminum fills every microscopic detail. It compresses the metal. This reduces internal porosity. Aluminum precision casting via the die cast method produces parts with thinner walls. You can create lightweight housings that are still rigid. It unlocks designs previously thought impossible.

Die casting machines exert clamping forces ranging from 400 to over 4,000 tons. This immense power holds the mold closed against the injection pressure. It creates flash-free parts.

Cold Chamber vs. Hot Chamber

It gets even better. Engineers have optimized the machinery itself. Hot chamber machines are fast but injection mechanisms sit in molten metal. Aluminum attacks steel, so it damages hot chamber machines. Therefore, aluminum precision casting typically uses cold chamber machines. Here, metal is ladled into a shot sleeve for each cycle. It separates the melting pot from the injection ram. This extends machine life. It ensures consistent part quality.

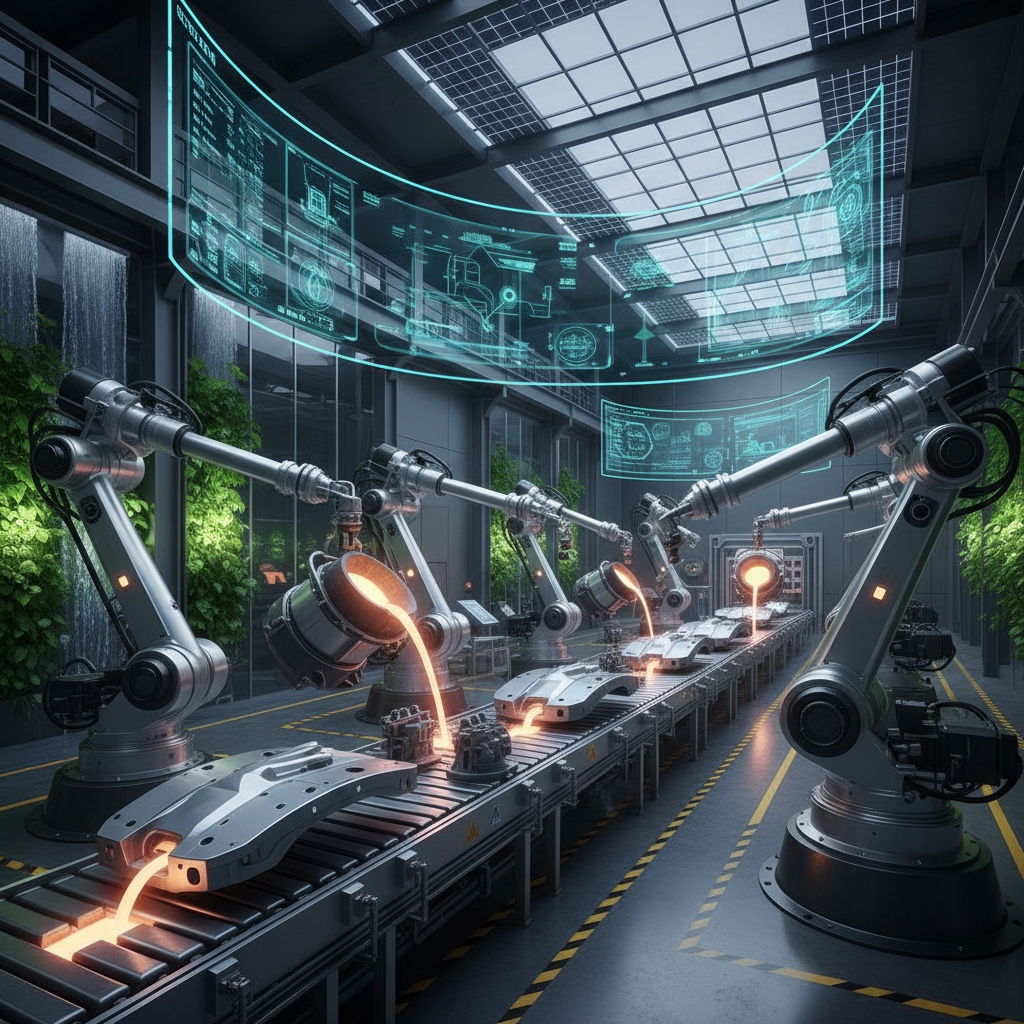

Ideal for High-Volume Runs

Speed is the name of the game. A die casting machine can cycle in seconds. Molten metal enters, solidifies, and ejects in a blink. Automation creates a rhythm. Robots spray lubricant, pour metal, and extract parts. They do this without stopping. This consistency reduces human error. It guarantees that the ten-thousandth part is identical to the first. For automotive and consumer electronics, this throughput is non-negotiable.

6. When Should You Choose Investment Casting?

Achieving Intricate Geometries

Sometimes, a shape is impossible to pull out of a rigid steel mold. Imagine a part with internal twists or undercuts. This is where the investment casting process shines. It creates a pattern out of wax. A ceramic shell forms around the wax. When you melt wax out, you leave a perfect cavity. There is no parting line. There is no draft angle required. Aluminum precision casting using this method allows for geometries that defy conventional manufacturing logic.

Medical implants often require this level of detail. A titanium or aluminum knee replacement prototype must match organic bone structures perfectly. Only investment casting can achieve this without machining marks.

The Lost Wax Technique

This ancient technique has gone high-tech. Manufacturers now 3D print wax patterns. This eliminates the need for expensive tooling for prototypes. You can go from CAD to cast part in days. The ceramic shell is extremely stable. It does not expand or contract much with heat. This stability ensures the investment casting process holds incredibly tight tolerances. It is the go-to method for aerospace components. Every micron counts there.

Surface Finish Superiority

Ready for the good part? Investment castings look beautiful. The ceramic mold produces a surface that is silky smooth. Often, no polishing is required. Textures, logos, and fine details reproduce perfectly. For parts visible to end users, this aesthetic quality is a major selling point. It reduces the need for secondary finishing operations. You get a functional part that looks like art.

7. What Are the Strength and Durability Metrics?

Understanding Tensile Strength

Engineers live by numbers. Tensile strength measures how much pulling force a part can take. Aluminum precision casting alloys like A380 or A356 offer impressive tensile data. They can withstand significant loads. However, casting quality matters. A casting full of bubbles is weak. A dense casting is strong. Process control directly correlates to structural performance. Rigorous testing ensures these parts meet safety standards.

Impact of Heat Treatment

You can change metal’s personality after casting. Casting heat treatment rearranges internal crystal structures. Processes like T6 involve heating the part. Then you quench it. This significantly boosts hardness and strength. It turns a relatively soft casting into a structural component. Aluminum precision casting often relies on casting heat treatment to meet demanding specs. It is a vital step in the manufacturing chain.

Fatigue Resistance in Alloys

You might be asking yourself. What happens after a million cycles? Fatigue is the silent killer of metal parts. Repeated stress causes microscopic cracks. Aluminum alloys vary in fatigue resistance. Silicon content helps. Manufacturing defects hurt. A smooth surface finish improves fatigue life. Cracks have nowhere to start. Precision casting methods producing smooth surfaces inherently offer better fatigue resistance. This is vital for reciprocating engine parts.

| Temper Code | Description | Effect on Property | |

|---|---|---|---|

| F | As Fabricated | No change, baseline properties | |

| T4 | Solution Heat Treated | Improved ductility, natural aging | |

| T5 | Cooled & Artificially Aged | Good hardness, minimal distortion | |

| T6 | Solution & Artificially Aged | Maximum strength and hardness | |

| O | Annealed | Softest state, highest ductility |

8. Where Are Aluminum Castings Used Today?

Aerospace and Defense Solutions

Gravity is the enemy of flight. Every gram saved on an airplane saves thousands of dollars in fuel. Industry applications in aerospace utilize aluminum investment casting extensively. They make brackets, housing for avionics, and cabin components. These parts must be fail-safe. Aluminum precision casting delivers necessary reliability. Defense contractors use it for missile guidance systems. The material performs well at high altitudes. It resists atmospheric corrosion.

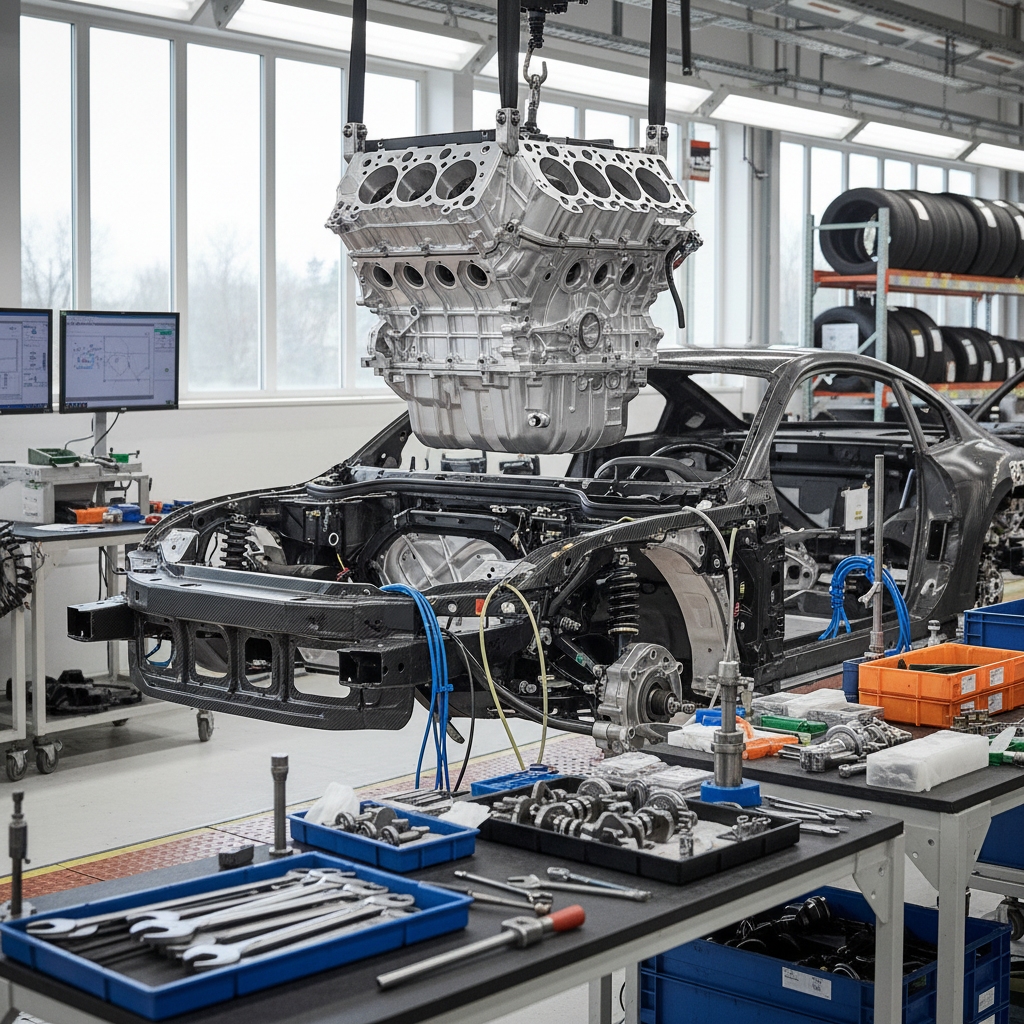

Revolutionizing the Auto Industry

Picture this. A modern car engine is almost entirely aluminum. Blocks, heads, transmission cases—they are all cast. This shift has reduced vehicle weight drastically. Lighter cars accelerate faster. They pollute less. Electric vehicles use large aluminum castings for battery trays. The trend is moving towards “gigacasting”. Massive sections of car frames are cast as a single piece. This innovation relies heavily on advanced industry applications of die casting technology.

Ford, Tesla, and Toyota all invest heavily in aluminum foundries. They recognize that lightweighting is the only path to meeting strict emission standards.

Medical and Consumer Goods

Your dentist’s chair? Likely has cast aluminum parts. High-end camera bodies? Magnesium or aluminum casting. The medical field demands hygiene and precision. Smooth cast surfaces are easy to sterilize. In consumer goods, metal feel conveys quality. Laptops and smartphones use precision chassis. Aluminum precision casting provides the rigid backbone for devices we use every day. It protects delicate electronics.

9. What Major Benefits Does the Process Offer?

Cost-Effectiveness at Scale

Here is the bottom line. Making one part is cheap with printing. Making a million is cheap with casting. The unit cost curve flattens dramatically. Once the mold is paid for, the only costs are metal and energy. Machining requires a machine for every single part. It takes minutes or hours. Casting produces a part every few seconds. For large production runs, aluminum precision casting is undeniably the most economic route. It is the engine of mass affordability.

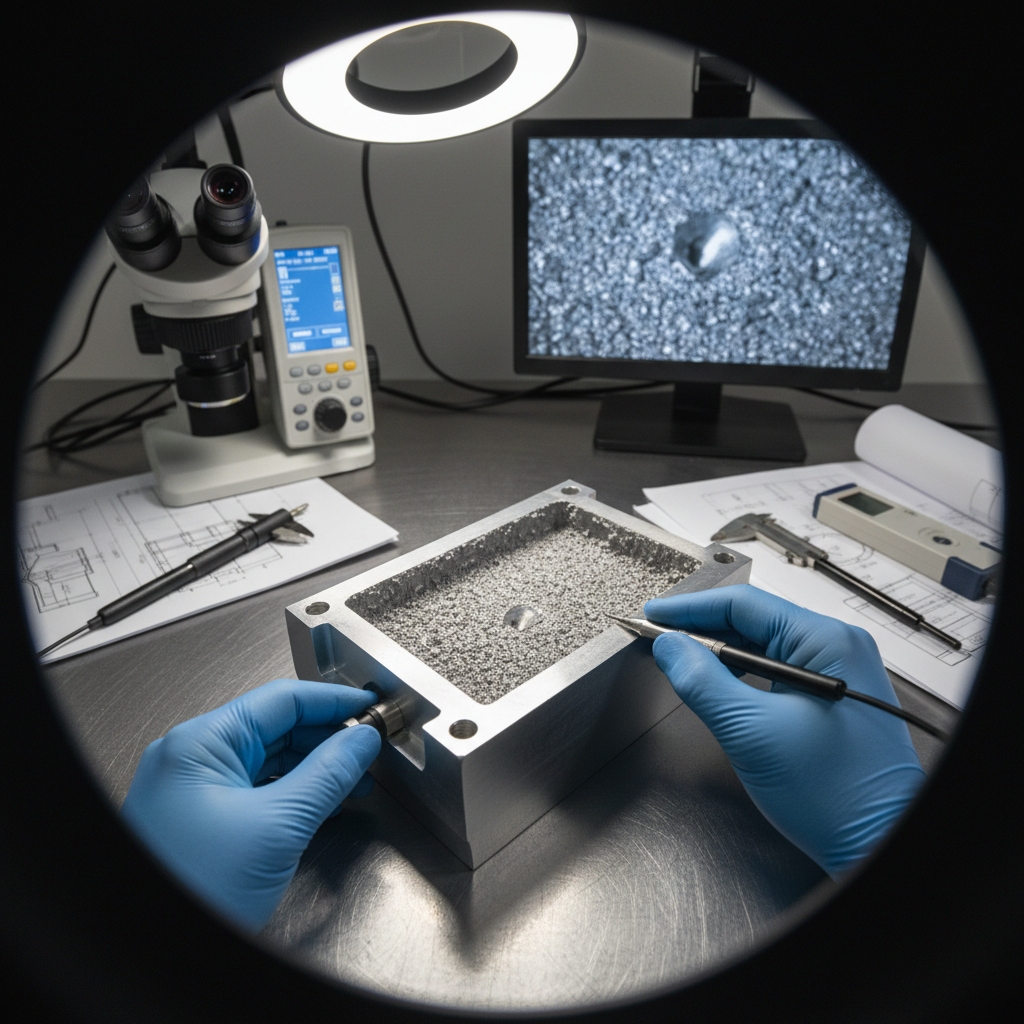

Precision and Tolerance Control

Modern casting facilities are laboratories of precision. They hold tolerances of +/- 0.002 inches in some cases. This reduces the need for downstream processing. If a hole is cast to size, you do not need to drill it. If a surface is flat, you do not need to mill it. This “near-net-shape” capability is the core value proposition. It simplifies the entire manufacturing flow.

Material Recycling and Efficiency

Sustainability is a growing mandate. Aluminum is infinitely recyclable. You can melt down an old engine block. You can cast a new one with no loss of properties. The aluminum precision casting industry is a massive recycler. They consume scrap metal. They turn it into value. Runners and gates—waste metal from the casting process—are thrown right back into the furnace. It is a closed-loop system. It minimizes environmental impact.

| Metric | CNC Machining | Precision Casting | Benefit of Casting | |

|---|---|---|---|---|

| Material Waste | High (Chips) | Low (Recyclable runners) | Eco-friendly | |

| Cycle Time | Minutes/Hours | Seconds/Minutes | High Throughput | |

| Unit Cost (High Vol) | Constant | Decreases rapidly | Scalability | |

| Geometry Limits | Line of Sight | Complex Internal | Design Freedom |

10. What Limitations Should Engineers Consider?

Addressing Porosity Issues

What is the catch? Bubbles. Gas porosity and shrinkage porosity are the nemesis of the foundryman. If air gets trapped, it creates weak spots. If metal shrinks unevenly, it tears. Engineers must design mold flow carefully. This prevents defects. Simulation software predicts where these defects might occur. While aluminum precision casting is advanced, fighting physics is a constant battle. X-ray inspection is often required for critical parts. It ensures no hidden voids exist.

Tooling Cost Considerations

Molds are expensive. A high-pressure die cast mold is made of premium tool steel. It must withstand thermal shock and immense pressure. This tool can cost tens of thousands of dollars. If you only need 500 parts, amortization cost is too high. Casting is a commitment. You must be sure of your design. Changing a steel mold is difficult. It is costly. This high barrier to entry makes it less suitable for rapid prototyping phases.

Size and Weight Constraints

There is a limit to how big you can go. While gigacasting is pushing boundaries, casting a massive ship part in one go is difficult. Managing cooling of a giant mass of aluminum is tricky. Uneven cooling leads to warping. Equipment size is also a factor. Die casting machines for large parts are the size of a house. Aluminum precision casting is generally best suited for small to medium-sized components. Thermal dynamics must be tightly controlled.

| Defect Type | Cause | Solution | |

|---|---|---|---|

| Gas Porosity | Trapped air/vapor | Improve venting, vacuum assist | |

| Shrinkage | Uneven cooling rates | Add risers, adjust cooling lines | |

| Cold Shut | Metal cooling early | Increase melt temp or speed | |

| Flash | Mold separation | Increase clamping force | |

| Warping | Ejection while hot | Longer cooling cycle |

Final Thoughts

Aluminum precision casting remains a cornerstone of modern manufacturing. It uniquely combines ability to create complex shapes with economic efficiency. Material strength is maintained throughout. From the phone in your pocket to the plane in the sky, these components are everywhere. While challenges like tooling costs and porosity management exist, benefits for high-volume production are undeniable. Ultimately, for engineers seeking to scale production while maintaining high performance, this process is not just an option. It is a necessity.

FAQ

Q1: What is aluminum precision casting?Aluminum precision casting is a manufacturing process. It involves pouring molten aluminum into a mold to create parts. These parts feature high dimensional accuracy and complex geometries. They require minimal machining.

Q2: How does the investment casting process work?Investment casting uses a wax pattern coated in a ceramic shell. The wax is melted out (lost wax). Molten aluminum is poured into the hollow ceramic cavity. This forms detailed parts.

Q3: What are the main benefits of using aluminum for casting?Aluminum offers an excellent strength-to-weight ratio. It features natural corrosion resistance. It has high thermal conductivity. It is fully recyclable. This makes it ideal for diverse industrial applications.

Q4: When should I choose die casting over sand casting?Choose die casting for high-volume production runs. It is best when tight tolerances and smooth surface finishes are required. Use it despite higher initial tooling costs.

Q5: What are common defects in aluminum castings?Common defects include porosity (air bubbles) and shrinkage (voids from cooling). Cold shuts (incomplete filling) also occur. These can be managed through proper mold design and process control.