What is A356-T6 Aluminum?

At Precision Vast, we specialize in producing high-integrity components using A356-T6 aluminum. This alloy is a premium grade of the aluminum-silicon-magnesium family (often referred to as AlSi7Mg), renowned for its exceptional strength, ductility, and pressure tightness. It is the go-to material for critical structural parts in aerospace, automotive, and industrial machinery where failure is not an option. By utilizing advanced precision investment casting techniques, we deliver A356 parts that meet rigorous global standards.

Understanding the T6 Heat Treatment Condition

The “T6” suffix refers to a specific thermal temper that defines the alloy’s final mechanical state. To achieve A356-T6 properties, we subject the raw castings to a two-step process:

- Solution Heat Treatment: Heating the alloy to dissolve soluble elements (primarily Magnesium and Silicon) into the aluminum matrix.

- Artificial Aging: Holding the parts at a specific temperature to precipitate these elements, significantly hardening the material.

This T6 heat treated aluminum process transforms the casting from a softer state into a durable, high-strength component capable of withstanding heavy loads and stress.

Difference Between A356 and Standard 356 Aluminum

While both alloys share similar chemical baselines, A356 aluminum alloy is the higher-purity version of standard 356. The critical difference lies in the allowable impurities, specifically iron.

A356 vs 356 Aluminum Comparison:

| Feature | A356 Aluminum | Standard 356 Aluminum |

|---|---|---|

| Iron Content | Low (Max ~0.20%) | Higher (Max ~0.60%) |

| Ductility | High | Moderate |

| Strength | Superior | Standard |

| Primary Use | Critical structural components (Aerospace, Auto) | General commercial castings |

The lower iron content in A356-T6 minimizes brittleness, providing superior elongation and fatigue resistance compared to standard 356. This makes it the preferred choice for our clients requiring premium A356 investment casting solutions.

Chemical Composition of A356-T6

We strictly control the A356 aluminum composition to ensure every casting meets the rigorous standards required for high-performance applications. As a hypoeutectic AlSi7Mg aluminum alloy, the precise balance of elements is what separates A356-T6 aluminum from standard commercial grades. Our facility utilizes advanced spectrometry to verify that every melt adheres to these strict chemical parameters before pouring.

Standard Element Ranges

The A356 aluminum alloy is defined by its specific blend of Silicon and Magnesium, with a critical emphasis on maintaining low impurity levels. While exact specifications can vary slightly by standard (ASTM, AMS), the typical composition includes:

- Silicon (Si): 6.5% – 7.5%

- Magnesium (Mg): 0.25% – 0.45%

- Iron (Fe): 0.20% Maximum (Strictly controlled)

- Aluminum (Al): Balance

- Other Impurities (Mn, Zn, Cu): Kept to trace amounts

Importance of Low Impurity Levels

The defining characteristic of a high purity A356 alloy is its low iron content. Unlike standard 356 aluminum, which allows for higher iron levels, A356 limits iron to roughly 0.20%. Excess iron forms brittle intermetallic phases that drastically reduce elongation and fatigue strength. By keeping iron levels low, we ensure the final casting retains the superior ductility and toughness required for safety-critical parts.

Impact of Silicon and Magnesium

The interaction between Silicon and Magnesium is the engine behind the performance of A356-T6 aluminum:

- Silicon (Si): This is the primary alloying element that gives the material its excellent fluidity. High silicon content allows the molten metal to fill complex molds and thin-walled sections during the investment casting process without shrinkage issues.

- Magnesium (Mg): Magnesium is the hardening agent. It combines with silicon to form Magnesium Silicide (Mg2Si). This compound is essential for the T6 heat treatment process, allowing the alloy to achieve high strength and hardness after precipitation hardening.

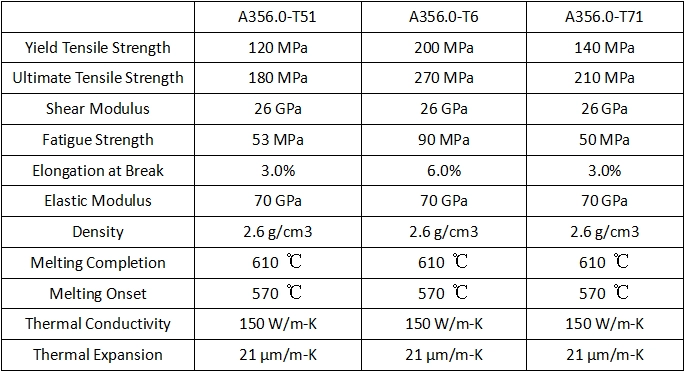

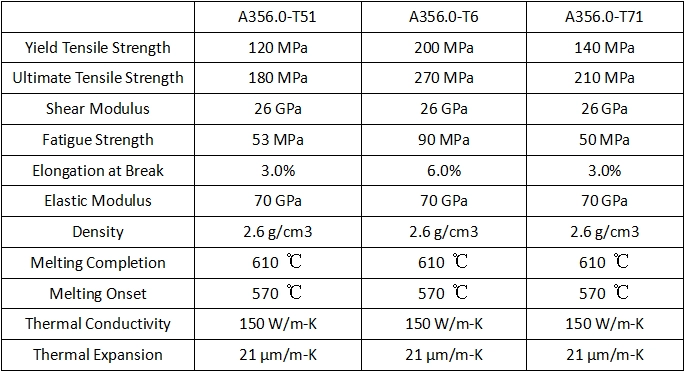

Mechanical Properties of A356-T6

When we handle A356 investment casting projects, achieving precise mechanical properties is non-negotiable. The T6 heat treatment is the game-changer here, transforming the alloy from a standard casting material into a structural powerhouse suitable for critical applications. We strictly monitor these metrics through our ISO9001-certified quality assurance processes to ensure every batch meets the rigorous demands of the US market.

Strength and Ductility Specifications

The Aluminum A356-T6 mechanical properties are defined by a superior balance of strength and ductility. After we apply the T6 solution heat treatment and artificial aging, the material exhibits impressive tensile capabilities that outperform standard as-cast aluminum. To understand how we control these variables during production, check out our aluminum investment casting guide.

- Ultimate Tensile Strength (UTS): Typically ranges between 30 and 40 ksi (205-275 MPa). This ensures the component can withstand significant pulling forces without structural failure.

- Yield Strength: Usually sits around 20-30 ksi (138-205 MPa). This represents the stress limit before permanent deformation occurs, and A356-T6 resists this exceptionally well relative to its weight.

- Elongation: We typically achieve elongation values of 3% to 6%. This ductility is vital because it allows the part to absorb energy and deform slightly under extreme stress rather than snapping brittlely.

Hardness and Fatigue Resistance

Beyond raw tensile strength, T6 heat treated aluminum offers excellent surface hardness and fatigue resistance, which are critical for components subjected to cyclic loading or wear.

- Hardness (Brinell): The T6 temper typically achieves a hardness range of 70-100 HB. This hardness level makes the surface resistant to indentation and wear, improving the longevity of machined parts.

- Fatigue Resistance: For applications like automotive suspension parts or rotating machinery, A356-T6 provides excellent resistance to crack initiation and propagation under repeated stress cycles.

- Density: The alloy maintains the lightweight advantage of aluminum, with a density of approximately 0.097 lb/in³ (2.68 g/cm³), making it ideal for weight-sensitive aerospace and automotive designs.

The T6 Heat Treatment Process Explained

To get the maximum performance out of A356-T6 aluminum, the casting process is just the beginning. The real strength is unlocked during the T6 heat treatment cycle. At our facility, we strictly control this three-step process to ensure every part meets the rigorous A356-T6 properties required for critical applications.

Solution Heat Treatment Steps

The first stage involves heating the A356 investment casting to a specific temperature, typically just below the alloy’s melting point. We hold the parts at this temperature for a set duration. This allows the alloying elements—specifically magnesium and silicon—to dissolve uniformly into the aluminum matrix. This step is crucial for eliminating segregation and preparing the metal for strengthening.

Quenching and Artificial Aging Techniques

Once the solution phase is complete, we rapidly cool the parts, usually by quenching them in water or a polymer solution. This “freezes” the microstructure, trapping the alloying elements in a supersaturated state.

- Quenching: Stops the alloying elements from precipitating out too early.

- Artificial Aging: We then reheat the castings to a lower temperature (around 300°F – 320°F) for several hours. This controlled reheating allows precipitates to form in a way that significantly hardens the material.

How T6 Enhances Mechanical Properties vs As-Cast

The difference between an as-cast part and T6 heat treated aluminum is night and day. Without this treatment, the alloy is relatively soft and lacks the structural integrity needed for high-stress loads.

- Strength: Yield strength can double compared to the as-cast condition.

- Hardness: We see a major increase in surface hardness, making the part more resistant to wear.

- Ductility: While strength goes up, we maintain enough ductility to prevent brittle failure.

By managing this entire lifecycle in-house—from the initial pour to the final heat treat—we guarantee that our A356-T6 aluminum components deliver consistent, reliable performance every time.

Key Advantages of A356-T6 Castings

When we recommend materials for high-performance projects, A356-T6 aluminum frequently tops the list. This alloy isn’t just about raw specs; it delivers a practical balance of durability and efficiency that manufacturers in the US rely on. We specifically leverage the A356 aluminum alloy properties to produce components that meet rigorous standards across various industries.

Here is why A356-T6 castings are a staple in our production line:

- High Strength-to-Weight Ratio: Through our precise T6 heat treatment process, we elevate the alloy’s strength without adding bulk. This makes it perfect for automotive and aerospace applications where reducing weight is critical but failure is not an option.

- Superior Corrosion Resistance: We often cast parts for marine hardware and outdoor equipment using this alloy. Its chemical composition naturally fights off rust and degradation, ensuring long-term reliability even in harsh environments.

- Excellent Castability for Complex Geometries: One of the biggest reasons we use A356 in our investment casting foundry is its exceptional fluidity. It allows us to fill complex molds completely, creating intricate, thin-walled designs that other materials simply cannot achieve.

- Machinability and Weldability: Post-casting operations are seamless. We can easily CNC machine these parts to tight tolerances, and they offer excellent weldability for assemblies requiring strong structural joints.

Common Applications and Industries for A356-T6

The versatility of A356-T6 aluminum makes it a staple material across industries that demand a balance of lightweight performance and structural integrity. At our facility, we leverage over 20 years of manufacturing experience to deliver precision components that meet strict ISO9001 quality standards. Whether for high-stakes aerospace projects or durable industrial machinery, our A356-T6 investment cast parts provide the reliability required for critical applications.

Key Industry Use Cases

We supply A356-T6 castings to over 800 customers globally, tailoring our production to the specific needs of these sectors:

- Aerospace Components: We manufacture intricate aerospace castings such as mounting brackets, control housings, and structural fittings. The high strength-to-weight ratio of A356-T6 is essential here, allowing for weight reduction without compromising safety or load-bearing capacity.

- Automotive Systems: Our foundry handles both prototype and production runs for transmission cases, suspension control arms, and engine mounts. The T6 heat treatment ensures these automotive transmission and suspension parts can withstand constant road vibration and mechanical stress.

- Medical Devices: Precision is non-negotiable in healthcare. We provide smooth, defect-free castings for medical equipment frames and surgical instrument components that require excellent surface finishes and dimensional accuracy.

- Marine Hardware: Due to its superior corrosion resistance, A356-T6 is widely used for marine fittings, cleats, and housings exposed to harsh saltwater environments.

- Pump and Valve Bodies: We produce pressure-tight castings for fluid handling systems. The material’s density and lack of porosity ensure leak-proof performance in pump and valve bodies.

To better understand how we achieve complex geometries for these industries compared to other methods, you can review our comparative guide on investment casting techniques. Our integrated approach, from mold design to final CNC machining, ensures every A356-T6 part fits your exact specifications.

A356-T6 vs. Other Aluminum Alloys

Selecting the right material is critical for part performance and manufacturing efficiency. At our facility, we frequently guide clients through the differences between A356-T6 aluminum, standard casting alloys, and wrought alternatives to ensure the final product meets engineering standards.

A356-T6 vs. 356: Purity and Ductility Comparison

While both alloys share a similar base, A356 aluminum alloy is essentially the high-purity version of standard 356. The critical difference lies in the iron content. A356 has strictly controlled low iron levels, whereas standard 356 allows for higher impurities.

- Standard 356: Often used for general commercial applications where higher ductility is not the primary concern. The higher iron content can make the material slightly more brittle.

- A356-T6: The lower impurity level significantly boosts elongation and ductility. When combined with the T6 heat treatment, A356-T6 properties offer superior strength and fatigue resistance, making it the preferred choice for critical structural components.

A356-T6 vs. 6061-T6: Casting vs. Wrought Applications

Comparing A356-T6 vs 6061-T6 is often a comparison of manufacturing processes rather than just material specs. 6061-T6 is a wrought alloy, typically supplied as extruded bars, plates, or sheets intended for machining or welding. A356-T6 is formulated specifically for the casting process.

If your design features complex geometries, internal cavities, or organic curves, machining from a solid block of 6061 is inefficient and costly due to material waste. A356 investment casting allows us to produce near-net shapes directly. Understanding standard investment casting tolerance is key here; casting A356 allows for intricate designs that maintain tight precision without the excessive machining time required for 6061.

When to Choose A356-T6 for Your Project

We recommend specifying A356-T6 aluminum when your project requires a balance of castability and high mechanical performance. It is the ideal solution for:

- Complex Shapes: Parts that are too difficult or expensive to machine from stock.

- Pressure Tightness: Components like valve bodies and pump housings that must hold fluid or gas pressure.

- High Stress Loads: Applications in aerospace and automotive sectors where failure is not an option.

Manufacturing A356-T6 Investment Castings

At Dongying Vast, we manage the entire lifecycle of A356 investment casting, ensuring every component meets rigorous industrial standards. Our facility combines traditional lost-wax techniques with modern technology to deliver high-quality A356-T6 investment cast parts for global markets.

Mold Design and Rapid Prototyping

Speed and accuracy are critical in modern manufacturing. We utilize advanced CAE casting simulation to optimize mold designs before production begins, effectively predicting flow and reducing the risk of defects. For projects requiring fast turnaround, we integrate SLA (Stereolithography) 3D printing. This allows for rapid prototyping of precision aluminum casting A356 parts, helping you validate designs quickly without the immediate cost of hard tooling.

Casting Process and Quality Control

Our production flow covers everything from wax injection and shell building to dewaxing and pouring. To guarantee the integrity of a356-t6 aluminum, we adhere to strict ISO9001 standards throughout the process. Our quality control protocols are rigorous and include:

- X-ray Testing: To detect internal porosity or cracks invisible to the naked eye.

- CMM (Coordinate Measuring Machine): For verifying dimensional accuracy against your specifications.

- Hardness Testing: To confirm the effectiveness of the T6 heat treatment.

- Material Analysis: Ensuring the chemical composition matches standard requirements.

Surface Finishes and CNC Machining Options

Once the casting and T6 heat treatment are complete, we provide a true one-stop solution. Our in-house capabilities include CNC machining to achieve tight tolerances that raw castings cannot meet. We also offer various surface treatments such as shot blasting, grinding, pickling, and polishing to ensure your a356 t6 components are clean, smooth, and ready for assembly immediately upon delivery.

Frequently Asked Questions (FAQs)

Is A356-T6 suitable for aerospace applications?

Absolutely. A356-T6 is a top choice for the aerospace industry due to its exceptional strength-to-weight ratio and pressure tightness. We frequently manufacture complex aerospace components like brackets, housings, and fittings using this alloy because it meets rigorous safety and performance standards. Through our specialized aluminum casting services, we ensure these parts maintain the high purity and structural integrity required for flight-critical hardware.

How does T6 temper affect A356 hardness?

The T6 heat treatment process significantly boosts the mechanical hardness of the casting compared to its “as-cast” (F) condition. By undergoing solution heat treatment followed by artificial aging, the A356-T6 properties change to offer superior resistance to wear and deformation. In our facility, we verify these results using precise hardness testing equipment to ensure every batch meets the specific Brinell hardness requirements demanded by your engineering prints.

What is the difference between A356-T6 and A356-T61?

The main difference lies in the aging process.

- A356-T6: Solution heat treated and artificially aged to achieve maximum precipitation hardening. This is the standard for parts needing peak strength and stability.

- A356-T61: Solution heat treated and aged in a way that typically results in slightly lower strength but potentially different internal stress characteristics.

For most high-stress applications, the standard A356.0-T6 aluminum specification is the preferred route we recommend to customers.

Can A356-T6 aluminum be welded?

Yes, A356 aluminum alloy is known for having excellent weldability. Unlike some other high-strength aluminum series that can crack during welding, A356 maintains its structural integrity. This makes it ideal for complex assemblies where cast parts need to be joined with other components. If welding is performed after the T6 cycle, we often advise on post-weld heat treatment protocols to restore the mechanical properties in the heat-affected zone.