What is A356 Investment Casting?

At Precision Castings of Tennessee, we utilize A356 investment casting to deliver components that define industry standards for quality and complexity. This manufacturing method combines the high-strength, lightweight properties of the A356 aluminum alloy with the extreme accuracy of the lost wax casting process. By injecting wax into a metal die, coating it with a ceramic slurry, and melting the wax away, we create a hollow shell that forms the perfect mold for molten aluminum.

This process allows us to produce near-net-shape casting components. Unlike other methods that require extensive material removal, our parts emerge from the mold with intricate details, internal passages, and complex undercuts already formed. This capability significantly reduces—and often eliminates—the need for expensive secondary machining, providing a more cost-effective “Total Cost of Ownership” for our partners in the aerospace and defense sectors.

Why A356 is the Top Choice for Precision Parts

We recommend A356 for applications requiring a superior strength-to-weight ratio and pressure tightness. This alloy is specifically formulated for excellent fluidity, which allows us to cast thin wall aluminum casting sections—down to 0.060″ in localized areas—without compromising structural density.

Key benefits of choosing A356 for your components include:

- High Structural Integrity: Ideal for critical safety components in aerospace and medical devices.

- Corrosion Resistance: Excellent durability in harsh environments.

- Heat Treatability: A356 responds exceptionally well to T6 heat treatment, enhancing mechanical properties significantly.

- Weldability: The material allows for easy repair or assembly via welding if necessary.

Investment Casting vs. Sand Casting

When engineers evaluate manufacturing options, the comparison often comes down to precision aluminum parts versus rougher alternatives. While sand casting is suitable for large, low-tolerance parts, it cannot match the surface finish or dimensional accuracy of our investment casting process.

Here is how our process stands apart:

- Surface Finish: We achieve a typical surface finish of 125 RMS, which is significantly smoother than the rough texture characteristic of sand castings.

- Dimensional Accuracy: We hold standard linear aluminum casting tolerances of ±.005” per inch, whereas sand casting typically requires much looser tolerances and substantial machining stock.

- Complexity: Our process handles “impossible” geometries with ease, while sand casting is limited by the need to remove a pattern from packed sand without disturbing the mold.

By leveraging our AS9100D and ISO 9001:2015 certified processes, we ensure that every A356 investment casting project meets the rigorous demands of modern engineering.

A356 Chemical Composition and Material Specs

When we engineer parts for aerospace and defense applications, the specific chemistry of the metal is just as important as the geometry of the mold. A356 investment casting relies on a precise blend of elements to achieve its renowned strength-to-weight ratio and pressure tightness. The A356 alloy composition is primarily aluminum, but the addition of Silicon (Si) and Magnesium (Mg) is what transforms it into a high-performance engineering material.

Breakdown of Aluminum, Silicon, and Magnesium Content

The “secret sauce” in A356 is the balance between Silicon and Magnesium.

- Silicon (6.5% – 7.5%): Silicon provides excellent fluidity. This allows the molten metal to fill intricate, thin-walled sections of our investment casting shells without premature freezing. It also improves castability and reduces shrinkage.

- Magnesium (0.25% – 0.45%): Magnesium is the hardening agent. It precipitates out during the heat treatment process (specifically T6), significantly boosting the yield strength and hardness of the final component.

For a more detailed look at how these elements translate into real-world performance, you can review our breakdown of A356 aluminum alloy properties and uses.

The Role of Impurities: Iron and Copper

Controlling impurities is critical for maintaining the structural integrity of A356 aluminum investment casting projects.

- Iron (Fe): We keep iron levels low (typically under 0.20%). Excess iron can form brittle phases that drastically reduce elongation and ductility, making the part prone to cracking under stress.

- Copper (Cu): While copper adds hardness in some alloys, in A356, we keep it low (usually under 0.20%) to ensure superior corrosion resistance, which is vital for parts exposed to harsh environments.

Standard Composition Table Analysis

We adhere to strict industry standards to ensure every pour meets aerospace-grade specifications. Below is the typical chemical composition range for A356.0:

| Element | Percentage (%) | Function |

|---|---|---|

| Silicon (Si) | 6.5 – 7.5 | Fluidity & Castability |

| Magnesium (Mg) | 0.25 – 0.45 | Strength & Hardness (Heat Treat Response) |

| Iron (Fe) | 0.20 Max | Controlled to maintain Ductility |

| Copper (Cu) | 0.20 Max | Controlled for Corrosion Resistance |

| Manganese (Mn) | 0.10 Max | Grain Structure Control |

| Zinc (Zn) | 0.10 Max | Impurity Control |

| Titanium (Ti) | 0.20 Max | Grain Refinement |

| Aluminum (Al) | Balance | Base Material |

By strictly maintaining these limits, we ensure that the A356 alloy composition delivers the reliable mechanical properties required for critical structural components.

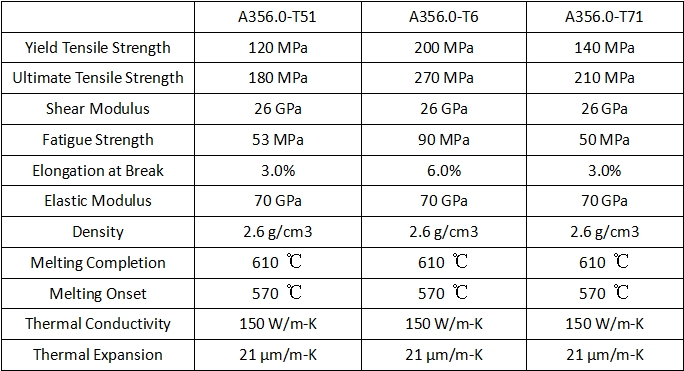

Mechanical Properties: The Power of T6 Heat Treatment

While the A356 investment casting process creates the shape, the heat treatment defines the performance. In its “as-cast” state (F temper), A356 aluminum is relatively soft and lacks the mechanical muscle required for critical aerospace or defense applications. To unlock the alloy’s full potential, we almost exclusively process these components to the T6 temper. This involves a two-step process: solution heat treatment followed by artificial aging, which precipitates magnesium silicide to significantly harden the matrix.

The difference between as-cast and A356 T6 mechanical properties is night and day. Unlike some high-speed structural die casting methods that trap porosity and prevent successful heat treatment, our investment castings are dense enough to undergo this rigorous thermal cycle without blistering. This ensures we achieve the high strength-to-weight ratios that engineers specify for flight-critical hardware.

Key Mechanical Improvements with T6

We rely on T6 heat treatment to stabilize the microstructure and enhance structural integrity. Typical property shifts include:

- Tensile Strength: The ultimate strength increases drastically, allowing the component to withstand higher loads before failure.

- Yield Strength: This is the most critical metric for structural parts. The T6 temper can more than double the yield strength compared to the as-cast state, ensuring the part does not permanently deform under operational stress.

- Elongation: While hardening usually reduces ductility, A356-T6 retains sufficient elongation, providing the toughness necessary to resist brittle fracture under shock loading.

By controlling the solidification rate and subsequent heat treatment, we deliver heat treated aluminum castings that meet strict military and industrial specifications for reliability.

Design Guidelines for A356 Cast Parts

When we engineer A356 investment casting projects, our primary goal is to minimize secondary operations while maximizing structural integrity. The lost wax process offers incredible design freedom, but adhering to specific guidelines ensures we produce consistent, high-quality components that meet aerospace and defense standards.

Standard Linear Tolerances and Accuracy

Precision is the hallmark of our process. We typically hold standard linear tolerances of ±.005 inch per inch. This level of accuracy allows us to deliver near-net-shape casting results, often eliminating the need for expensive machining on mating surfaces. Tighter tolerances are achievable depending on the part geometry and size. For engineers looking to align their blueprints with production capabilities, understanding casting tolerances is essential to avoid over-specifying dimensions that drive up costs unnecessarily.

Minimum Wall Thickness and Draft Requirements

A356 alloy is known for its excellent fluidity, which allows us to push the boundaries of thin wall aluminum casting. We can successfully cast wall thicknesses down to 0.060 inches in localized areas, maintaining structural density without sacrificing strength. This is a massive advantage for weight-critical applications. Additionally, because the wax pattern is melted out of the ceramic shell rather than pulled from a rigid mold, draft angle requirements are minimal compared to die casting or sand casting.

Designing for Complex Geometries and Undercuts

We specialize in producing “impossible” geometries that other manufacturing methods cannot touch. Our process supports:

- Complex Undercuts: Features that are inaccessible to CNC tools.

- Internal Passages: Intricate coring for fluid or airflow without external machining.

- Part Consolidation: Combining multi-piece assemblies into a single, stronger casting.

By leveraging these capabilities, we provide aluminum casting tolerances and geometries that reduce total assembly time and improve the overall reliability of the final product.

Manufacturing Process: Silica Sol Shell Building

At our foundry, the journey to a flawless component begins long before the metal is poured. We rely on the silica sol investment casting process to deliver the tight tolerances and superior surface finishes that aerospace and defense clients demand. Unlike sand casting, this method allows us to replicate intricate details with exceptional fidelity.

Creating High-Precision Wax Patterns

Everything starts with the pattern. We inject specialized wax into precision-machined aluminum dies to create a near-perfect replica of the final part. For rapid prototyping or low-volume runs where tooling costs need to be minimized, we can also utilize 3D-printed patterns. This step defines the dimensional accuracy of the entire project, ensuring we meet linear tolerances as tight as ±.005” per inch.

Shell Building and Dewaxing Techniques

Once the wax patterns are assembled onto a “tree,” the shell building begins. We dip the assembly into a high-grade ceramic slurry and coat it with fine sand. This process is repeated multiple times to build a durable ceramic shell around the wax.

- Dipping & Stuccoing: We use specific silica sol binders that provide high strength and stability.

- Drying: Controlled humidity and temperature ensure the shell dries without cracking.

- Dewaxing: We place the dry shells in an autoclave to melt the wax out, leaving behind a hollow, perfect cavity ready for molten metal.

Pouring and Solidification Control for A356

Pouring aluminum requires strict process controls to prevent porosity. While we apply rigorous standards to our carbon and low alloy steel castings, processing A356 aluminum demands specific attention to hydrogen degassing and temperature control. We preheat the ceramic shells to prevent thermal shock and ensure the molten alloy flows into thin-walled sections (down to 0.060″). By utilizing solidification modeling and precise gating designs, we manage the cooling rate to achieve the desired equiaxed grain structure and mechanical integrity.

Comparing A356 to Other Alloys and Methods

When selecting materials for precision aluminum parts, understanding how A356 investment casting stacks up against other alloys and manufacturing processes is critical for project success. We often guide engineers through the trade-offs between casting grades and wrought materials to ensure the final component meets both performance and budget requirements.

A356 vs. 6061: Casting vs. Machining

The comparison between A356 and 6061 usually comes down to the manufacturing method. 6061 is a wrought alloy typically machined from billet or plate, while A356 is formulated specifically for casting.

- Design Freedom: A356 investment casting allows for complex, near-net-shape geometries with internal passages and undercuts that are often impossible or prohibitively expensive to machine from a solid 6061 block.

- Material Efficiency: Machining 6061 results in significant material waste. Casting A356 adds material only where needed, reducing scrap and overall costs for production runs.

- Strength: While 6061-T6 is strong, A356-T6 offers a high strength-to-weight ratio that rivals wrought alloys, making it suitable for structural applications.

A356 vs. A380: Investment Casting vs. Die Casting

A380 is the standard alloy for high-volume die casting, but it falls short in applications requiring high structural integrity.

- Porosity and Integrity: Die casting often traps gas, leading to porosity. Our lost wax casting process using A356 produces dense, pressure-tight components essential for aerospace and defense applications.

- Heat Treatment: A356 responds exceptionally well to T6 heat treatment, significantly boosting mechanical properties. A380 generally cannot be heat treated effectively due to blistering from trapped gases.

Corrosion Resistance and Surface Finish

One of the standout features of A356 aluminum investment casting is its excellent corrosion resistance, making it a preferred choice for outdoor enclosures and marine hardware. Additionally, the surface finish we achieve is superior to other casting methods:

- Surface Quality: We typically achieve a surface finish of 125 RMS or better. This is significantly smoother than sand casting, reducing the need for secondary polishing.

- Aesthetics: The fine grain structure and smooth surface provide a professional appearance right out of the mold, ideal for visible components like avionics housings.

Industrial Applications for A356 Components

At Precision Castings of Tennessee, we see A356 investment casting as the backbone of industries where failure is not an option. Because this alloy combines excellent mechanical properties with the ability to form complex, thin-walled geometries, it is the go-to material for critical applications requiring high strength-to-weight ratios. Our facility operates under AS9100D and ISO 9001:2015 certifications, ensuring that every component we pour meets the rigorous demands of the aerospace, defense, and industrial sectors.

Aerospace and Avionics

In the aerospace sector, weight reduction is critical, but structural integrity cannot be compromised. We specialize in producing aerospace aluminum castings that replace heavier multi-part assemblies with single-piece, near-net-shape components.

- Avionics Housings: We cast intricate electronic enclosures with thin walls (down to 0.060″) that provide EMI shielding and heat dissipation.

- Structural Brackets: Our process delivers custom A356 components capable of withstanding high vibration and stress loads, fully heat-treated to T6 specifications for maximum durability.

Automotive and Industrial Performance

For automotive and general industrial applications, pressure tightness and corrosion resistance are paramount. We routinely manufacture parts that require complex internal passages which would be impossible to machine from a solid block.

- Transmission Cases & Pump Bodies: The excellent fluidity of A356 allows us to cast dense, leak-proof pump housings and valve bodies used in hydraulic systems.

- Impellers: We produce precision impellers with complex blade geometries that require minimal balancing and finishing.

Defense and Medical Equipment

Our commitment to quality extends to defense and medical fields, where precision is a matter of safety. We utilize the same rigorous process controls for these components as we do when ensuring consistency in our premium high-temperature alloy work.

- Medical Devices: We cast lightweight, ergonomic structural parts for portable medical equipment and diagnostic scanners.

- Defense Hardware: From optical mounts to weapon system components, we deliver thin wall aluminum casting solutions that meet strict military specifications for surface finish and dimensional accuracy.

FAQ: Common Questions About A356 Casting

We frequently encounter specific technical inquiries regarding our A356 investment casting services. Below are the answers to the most common questions we receive from engineers and procurement teams in the United States.

Is A356 aluminum weldable?

Yes, A356 aluminum is highly renowned for its excellent weldability. This characteristic makes it a top choice for complex structural components that may require joining or repair during final assembly. Unlike some other high-strength alloys that can crack during welding, A356 maintains its structural integrity. This is particularly vital for the aerospace and defense sectors, where we often produce parts that must be integrated into larger assemblies without compromising safety or performance.

What is the difference between A356 and A356.0?

While these terms are often used interchangeably in casual conversation, the distinction lies in the strictness of the chemical composition limits. A356.0 generally refers to the chemical specification for the final casting itself, ensuring the material meets the required mechanical properties after solidification. At our facility, we strictly control the A356 alloy composition, specifically monitoring Silicon and Magnesium levels, to ensure every poured part meets the rigorous aerospace-grade quality standards required by AS9100D certifications.

How does surface finish compare to machined parts?

One of the biggest advantages of the lost wax process is the superior surface finish compared to other casting methods.

- Standard Finish: We typically achieve a surface finish of 125 RMS right out of the mold.

- Comparison: This is significantly smoother than sand casting, which often leaves a rough, granular texture.

- Machining Reduction: While a fully machined billet part might be smoother, our near-net-shape casting capabilities allow us to replicate intricate details so precisely that we often eliminate the need for expensive secondary machining on non-critical surfaces.

For manufacturers deciding between different production methods, understanding these finish capabilities is crucial when comparing die casting vs gravity casting options for their specific aluminum projects. We focus on delivering parts that balance high cosmetic standards with functional precision.