What Is the Investment Mold Casting Process?

Ever wonder how we manufacture incredibly complex metal parts with smooth surfaces and zero draft angles? That’s where the investment mold casting process shines. Also known industrially as the lost-wax casting process, this technique is the gold standard for producing detailed components that other manufacturing methods simply can’t handle. At our facility, we leverage over 20 years of experience to transform this ancient art into a modern, high-tech workflow.

Origins: From Lost-Wax to Modern Precision

While the core concept traces back to ancient artistic traditions, modern precision investment casting is a highly engineered industrial solution. The process involves creating a wax pattern, coating it in a ceramic shell, and then melting the wax away—hence the name “lost-wax.”

Today, we combine this traditional method with advanced technologies like SLA rapid prototyping and CAE simulation. This allows us to move from a digital design to a physical part with exceptional speed and accuracy, bridging the gap between historical craftsmanship and Industry 4.0 efficiency.

Benefits: Why No Draft Angles Matter

One of the biggest headaches in manufacturing is designing for the mold release. In processes like die casting or sand casting, you usually need a “draft angle” (a slight taper) so the pattern can be removed without damaging the mold.

Investment casting eliminates this constraint. Because we melt the wax pattern out of the ceramic shell during the dewaxing phase (using autoclaves or flash fire), there is no need to physically pull a solid pattern out. This offers distinct advantages:

- Zero Draft Angles: We can cast straight walls and 90-degree angles.

- Complex Geometries: Undercuts, internal channels, and intricate details are easily achievable.

- Near-Net-Shape Casting: Parts come out of the mold very close to their final dimensions, drastically reducing machining costs.

Best Use Cases: Intricate Designs and Tight Tolerances

When precision is non-negotiable, high precision metal casting is the answer. We specialize in “problem parts”—components with geometries so complex that machining them from a solid block would be too expensive or physically impossible.

Ideal scenarios for investment casting include:

| Requirement | Why Investment Casting Wins |

|---|---|

| Complex Shapes | Allows for thin walls, blind holes, and intricate internal passages. |

| Tight Tolerances | Achieves high dimensional accuracy (ISO 8062 standards) right out of the mold. |

| Surface Finish | Delivers a superior finish (Ra 3.2-6.3) compared to sand casting. |

| Material Variety | Compatible with Titanium, Stainless Steel, and High-Temperature Alloys. |

By choosing the investment mold casting process, we help industries ranging from medical to automotive achieve parts that meet exacting standards without the waste and limitations of traditional machining.

Step-by-Step Investment Mold Casting Walkthrough

At Dongying Vast, our investment mold casting process follows a rigorous 14-step workflow to transform raw design concepts into high-precision metal components. We control every stage of this “lost wax” cycle in-house, ensuring that even the most complex geometries meet strict dimensional standards.

Pattern Creation: Wax Injection and SLA Prototyping

The process begins with creating a replica of the final part. For high-volume production, we inject molten wax into a metal die to create a precise wax pattern. If you need faster turnaround or are in the development phase, we utilize SLA rapid prototyping casting. This allows us to 3D print the pattern directly, bypassing the time and cost of tooling creation for initial samples.

Tree Assembly and Gating Design

Once the wax patterns are ready, we assemble them onto a central wax runner system, often called a “sprue.” This creates a tree-like cluster. Our engineers carefully design the gating system during this phase to ensure smooth metal flow and minimize turbulence during the pour.

Ceramic Shell Building

To create the mold, we dip the entire wax tree assembly into a ceramic slurry, followed by a coating of fine sand (stucco). We repeat this dipping and drying process multiple times to build a robust ceramic shell casting mold capable of withstanding high temperatures and molten metal pressure.

Dewaxing and Mold Preheating

We place the dry ceramic shells into an autoclave where steam heat melts the wax, allowing it to drain out. This leaves behind a hollow cavity in the exact shape of your part—hence the name lost wax casting process. Before pouring, we fire the ceramic shells to strengthen them and preheat the mold to prevent thermal shock.

Metal Pouring and Cooling

Gravity pouring is critical here. We pour molten metal—whether it’s stainless steel, titanium, or specific alloys detailed in our guide on the best materials for aluminum casting—into the hot ceramic shell. The preheated mold ensures the metal flows into thin wall sections and intricate details before solidifying.

Shell Removal and Cutoff

After the metal cools and solidifies, we remove the ceramic shell using vibration or water blasting. The individual metal parts are then cut from the central runner tree using high-speed friction saws or abrasive cutoff wheels.

Post-Processing: Heat Treatment and Machining

The raw castings undergo initial finishing, including gate grinding and surface blasting. Depending on the mechanical requirements, we perform heat treatment to adjust hardness and strength. Finally, for parts requiring extremely tight tolerances, we move to our CNC machining department for precision facing, drilling, and tapping.

Key Technical Specifications and Capabilities

When you partner with us, you get access to a precision investment casting workflow designed for high-accuracy components. We strictly adhere to ISO9001 and international tolerance standards to ensure every part fits your exact requirements. Our facility is optimized to handle everything from initial design to final inspection.

Achievable Tolerances and Precision

The investment mold casting process is renowned for its ability to deliver near-net-shape casting results. We consistently achieve tight linear tolerances, significantly reducing the need for expensive secondary machining. By controlling every variable—from the wax pattern to the ceramic shell—we maintain dimensional stability across large production runs.

Surface Finish and Feature Details

One of the biggest advantages of this method is the fine surface finish casting capability. Unlike sand casting, our ceramic molds produce smooth surfaces that require minimal post-processing. We specialize in “problem parts” featuring:

- Complex Geometries: Undercuts and internal passages without draft angles.

- Thin Walls: Lightweight designs that maintain structural integrity.

- Intricate Details: Logos, lettering, and fine textures reproduced accurately.

Production Capacity and Scale

With over 20 years of experience and a 4,000 m² facility, we scale to meet your needs. Whether you need a rapid prototype via SLA printing or a full production run, our 700-ton annual capacity ensures timely delivery. Understanding which casting process is the most important commercially helps in selecting the right volume strategy, and we are equipped to handle diverse demands from 50+ industries globally.

Technical Capability

| Specification | Standard / Capability |

|---|---|

| Tolerance Standard | ISO 8062 / International Precision Standards |

| Surface Finish (As Cast) | Ra 3.2 – 6.3 μm (Improves with Polishing) |

| Wall Thickness | Capable of thin-wall sections for weight reduction |

| Part Complexity | High (Undercuts, blind holes, internal channels) |

| Material Versatility | Steel, Titanium, Aluminum, Superalloys |

| Production Volume | Scalable (Prototyping to High Volume) |

Materials Expertise for Casting

At Dongying Vast, we understand that the investment mold casting process is only as effective as the materials we pour. Our facility is equipped to handle a diverse range of alloys, allowing us to match the specific mechanical properties required by your industry, whether that’s aerospace, automotive, or marine. We adhere strictly to international material standards to ensure every pour meets your exact specifications.

Stainless Steel and Duplex Alloys

We specialize in stainless steel investment casting for components that demand superior corrosion resistance and aesthetic appeal. Our capabilities extend to:

- Austenitic Stainless Steel: Common grades like 304 and 316 for general corrosion resistance.

- Duplex Stainless Steel: Offering higher strength and stress corrosion cracking resistance, ideal for harsh marine or chemical environments.

Carbon and Alloy Steels

For industrial applications requiring high tensile strength and wear resistance, we provide precision casting in various carbon and alloy steel grades. Steel casting is the backbone of modern manufacturing, delivering the structural integrity needed for heavy machinery, automotive parts, and construction hardware. We can heat treat these materials post-casting to achieve specific hardness levels.

Aluminum and Titanium Alloys

Handling reactive metals requires specialized expertise and equipment. We are proud to offer titanium investment casting, a process that produces lightweight components with an exceptional strength-to-weight ratio. Similarly, our aluminum casting services are perfect for complex geometries where weight reduction is critical without sacrificing performance.

High-Temperature Superalloys

When components must survive in extreme thermal environments, standard metals fail. We utilize nickel-based and cobalt-based superalloys designed to maintain stability under high heat and stress. Understanding why we choose high-temperature alloy casting is essential for industries like power generation and aerospace, where part failure is not an option.

Advantages of Investment Mold Casting

When we execute the investment mold casting process, we aren’t just pouring metal; we are solving complex engineering problems. As a manufacturer with over 20 years of experience, we see firsthand how this method outperforms others when precision is non-negotiable. The primary edge here is the ability to handle “problem parts”—components with geometries so intricate that other manufacturing methods simply cannot produce them efficiently.

Unmatched Design Freedom

The most significant benefit we offer through complex geometry casting is the elimination of design constraints. Unlike sand casting or machining, the ceramic shell mold allows for undercuts, thin walls, and complex internal passageways without draft angles. This means engineers can design for functionality rather than manufacturing limitations.

Near-Net-Shape Efficiency

We focus on near-net-shape casting, which means the part comes out of the mold very close to its final dimensions. This drastically reduces the need for secondary machining and lowers material waste. For industries requiring robust materials, understanding the advantages of lost wax casting for carbon steel products highlights how we maintain high strength while minimizing post-casting processing.

Key Benefits at a Glance:

- Fine Surface Finish Casting: We achieve superior surface quality (Ra values) directly from the mold, often eliminating the need for extensive polishing.

- Repeatability: Our ISO9001-certified workflow ensures that the 1,000th part is identical to the first, maintaining strict investment casting tolerances.

- Cost-Efficiency: For medium-volume production runs, the reduction in waste and machining time makes this process highly economical compared to full CNC machining.

- Material Versatility: From titanium to high-temperature superalloys, we can cast virtually any material that melts.

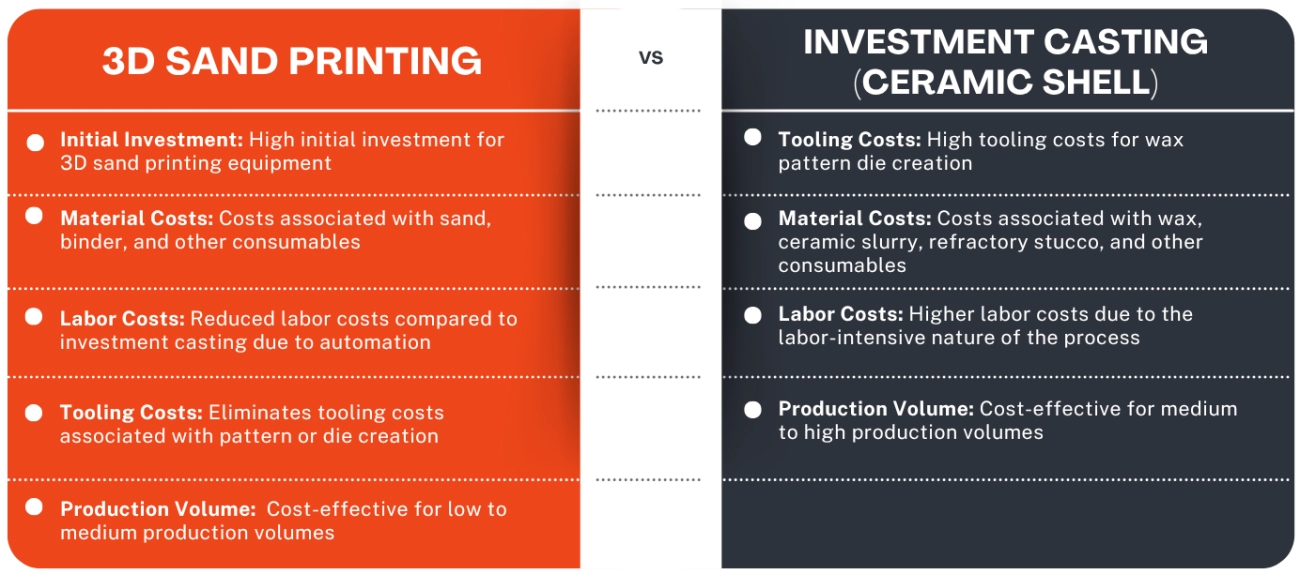

Limitations and Alternative Comparisons

While the investment mold casting process is our bread and butter for creating complex, high-precision parts, we believe in being upfront about where it fits best. It is not the cheapest solution for every single application, and understanding the trade-offs helps us find the right manufacturing path for your specific needs.

Cycle Times and Setup Costs

Precision takes time. Because the lost-wax method involves a 14-step workflow—from wax injection and shell building to dewaxing and pouring—the production cycle is longer than simple stamping or die casting.

- Tooling: Requires an initial investment in aluminum dies to create the wax patterns.

- Lead Time: The ceramic shell building process alone takes days to cure properly to ensure it withstands molten metal pressure.

- Volume: Best suited for medium-to-high volume runs where the initial tooling cost is amortized over thousands of parts.

Comparison: Investment vs. Sand Casting

Sand casting is the heavy lifter of the casting world, but it lacks the finesse of investment casting.

- Sand Casting: Great for massive parts and lower tooling costs, but leaves a rough surface finish and requires significant machining to hit tight tolerances.

- Investment Casting: We use this when you need a “near-net-shape” part. It offers superior surface finishes (Ra 3.2-6.3) and tighter tolerances, reducing the need for secondary machining.

Comparison: Investment vs. Die Casting

Die casting is incredibly fast for non-ferrous metals like aluminum and zinc, but it hits a wall with high-melting-point materials. This is a critical distinction for our clients needing steel components. You can read more about why steel generally cannot be die casted due to the extreme thermal shock that destroys reusable metal molds.

- Die Casting: High speed, lower unit cost for massive volumes (10,000+), limited mostly to soft alloys.

- Investment Casting: Compatible with stainless steel, titanium, and superalloys. It handles undercuts and complex internal geometries that rigid metal dies cannot eject.

Comparison: Investment vs. CNC Machining

CNC machining cuts away material, while investment casting builds it up.

- CNC Machining: Ideal for low volumes (1-50 parts) or simple geometries where tooling costs aren’t justified. However, it generates significant material waste.

- Investment Casting: More cost-effective for complex shapes in harder metals (like Titanium or Stainless Steel) because we reduce material waste significantly.

Quick Comparison Guide

| Feature | Investment Casting | Sand Casting | Die Casting | CNC Machining |

|---|---|---|---|---|

| Precision | High | Low | High | Very High |

| Surface Finish | Excellent | Rough | Good | Excellent |

| Material Choice | Extensive (Steel, Ti, Al) | Extensive | Limited (Al, Zn, Mg) | Extensive |

| Tooling Cost | Medium | Low | High | None/Low |

| Unit Cost | Medium | Medium | Low (High Vol) | High |

Industry Applications and Real-World Examples

The versatility of the investment mold casting process allows us to manufacture components for over 50 different industries globally. Because we can handle a wide range of materials—from titanium and aluminum to high-grade steels—we adapt our production to meet the specific demands of each sector. Whether it is a single prototype or a high-volume run, our facility delivers parts that fit right the first time.

Food Machinery and Medical Equipment

Hygiene and precision are critical in these fields. We utilize stainless steel investment casting to produce sanitary components like meat grinder parts, coffee machine valves, and surgical instruments. The fine surface finish achieved through ceramic shell casting prevents bacteria buildup and ensures easy cleaning. Our stainless steel casting capabilities allow us to meet strict FDA and medical industry standards for corrosion resistance and material purity.

Marine Hardware and Corrosion Resistance

Saltwater environments demand materials that refuse to rust. We cast heavy-duty marine hardware, including cleats, hinges, and pump impellers, often using Duplex stainless steel. This material offers superior resistance to pitting and stress corrosion cracking compared to standard alloys. By using precision investment casting, we create complex hydrodynamic shapes for marine propulsion systems that would be too costly or difficult to machine from solid blocks.

Automotive and Door Lock Hardware

For the automotive and construction sectors, strength and repeatability are paramount. We manufacture intricate door lock housings, gearbox components, and structural brackets that require tight tolerances. The near-net-shape casting ability of our process significantly reduces the need for secondary machining on these parts. Utilizing carbon steel in investment casting provides the necessary tensile strength and durability required for high-stress automotive applications and security hardware.

Quality Assurance and Testing Standards

In the investment mold casting process, consistency and verification are just as critical as the casting itself. We operate under strict ISO9001 certification, ensuring that every component leaving our 4,000 m² facility meets exacting international standards. Our quality control isn’t an afterthought; it is integrated into every stage of our 14-step workflow to guarantee reliability for industries ranging from automotive to marine.

To ensure internal integrity and dimensional accuracy, we utilize a comprehensive suite of testing methods:

- Defect Prevention via CAE Simulation: Before we pour a single drop of metal, we use Computer-Aided Engineering (CAE) to simulate the casting process. This allows us to predict potential defects like shrinkage or porosity and optimize the mold design upfront.

- Non-Destructive Testing (NDT): We employ X-Ray testing to inspect the internal structure of parts without damaging them, ensuring there are no hidden voids. For surface integrity, Magnetic Particle Inspection (MPI) is used to detect even the finest micro-cracks.

- Dimensional Inspection: We verify part geometry using advanced CMM (Coordinate Measuring Machine) technology. This ensures that complex shapes and tight tolerances match your technical drawings perfectly.

- Material Verification: Whether we are validating a batch of carbon steel casting or high-temperature alloys, we perform rigorous hardness and chemical analysis to confirm material properties.

Frequently Asked Questions About Investment Mold Casting

How accurate is investment casting?

The investment mold casting process is renowned for delivering “near-net-shape” components, meaning the parts come out of the mold very close to their final dimensions. At our facility, we adhere to strict international tolerance standards to ensure high precision. This accuracy often eliminates the need for extensive secondary machining, allowing for tight investment casting tolerances right off the production line. We verify this precision using advanced CMM (Coordinate Measuring Machine) inspection to guarantee every dimension meets your specifications.

What is the difference between sand casting and investment casting?

The main difference lies in the surface finish and level of detail. Sand casting uses a sand mold, which typically results in a rougher surface texture and is better suited for large, heavy components where fine detail isn’t critical. In contrast, the lost wax casting process utilizes a ceramic shell created around a precise wax pattern. This allows us to produce parts with intricate geometries, thin walls, and a much smoother surface finish that sand casting simply cannot match.

Is investment casting expensive?

While the initial tooling costs for the aluminum dies used to create wax patterns can be higher than sand casting patterns, the overall value is significant. Precision investment casting reduces material waste and drastically cuts down on expensive machining time because the parts are cast so accurately. For complex shapes that would be difficult or impossible to machine from a solid block, this process is often the most cost-efficient solution for medium to high-volume production.

What materials can be used in investment casting?

One of the biggest advantages of our workflow is material versatility. We can cast a wide range of ferrous and non-ferrous alloys to meet specific mechanical properties. Our capabilities include:

- Stainless Steel Investment Casting: Including Duplex steels for high corrosion resistance.

- Carbon and Alloy Steels: For general industrial strength and durability.

- Non-Ferrous Alloys: We specialize in Titanium alloys and utilize innovative aluminum casting techniques for lightweight applications.

- High-Temperature Alloys: Ideal for parts exposed to extreme heat and stress.