A356 aluminum investment casting is a process that has gained immense popularity across various industries due to its excellent material properties and versatile applications. This alloy, commonly used in automotive, aerospace, and industrial applications, offers superior strength, corrosion resistance, and dimensional accuracy. In this article, we will explore the intricacies of A356 aluminum investment casting, including its benefits, applications, and how it compares to other casting methods.

1. Introduction to A356 Aluminum Investment Casting

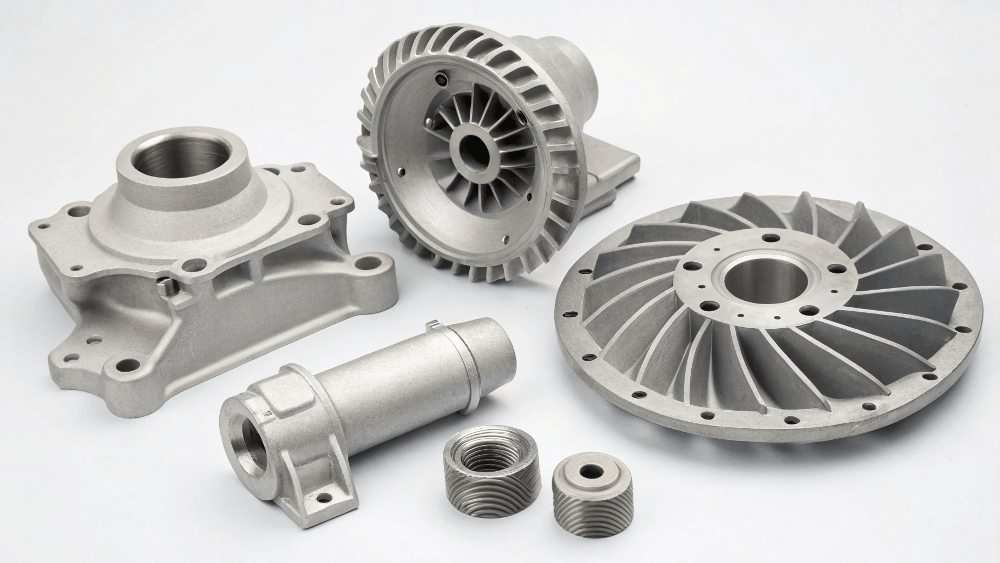

A356 aluminum is a high-strength alloy that is often used in investment casting due to its excellent fluidity, good corrosion resistance, and superior surface finish. This material is particularly useful in applications where strength and weight ratio are important, such as in aerospace and automotive industries. A356 aluminum investment casting is a cost-effective and reliable method for creating complex, intricate parts with high precision.

But here’s the kicker: while A356 aluminum offers numerous benefits, it also requires a deep understanding of its casting process and properties to truly unlock its potential. This article will dive into the different aspects of A356 aluminum investment casting and explain why it is one of the most sought-after materials in precision casting. By the end, you will have a thorough understanding of how A356 is used in various industries and what makes it a preferred choice for high-performance applications.

2. What is A356 Aluminum?

A356 aluminum is an alloy that primarily consists of aluminum, silicon, and magnesium. The material is known for its high strength-to-weight ratio, making it ideal for industries like aerospace, automotive, and military. The silicon content in A356 aluminum enhances its fluidity during the casting process, allowing for the creation of complex shapes and geometries.

What’s the real story? While A356 aluminum is highly versatile, its composition and casting method are crucial to ensuring it meets the required performance standards. For instance, the amount of silicon and magnesium in A356 affects its strength, hardness, and corrosion resistance. This alloy is also known for its excellent weldability and machinability, making it an ideal choice for parts that need to undergo post-casting processes such as machining or assembly.

| Property | Value |

|---|---|

| Silicon content (%) | 6.5–7.5 |

| Magnesium content (%) | 0.3–0.45 |

| Tensile strength (MPa) | 200–300 |

| Yield strength (MPa) | 160–220 |

| Elongation (%) | 2.5–5 |

3. The Investment Casting Process for A356 Aluminum

Investment casting, also known as lost-wax casting, is a process in which a pattern is made from a material such as wax, and then covered with a ceramic shell. The shell is heated to harden, and the wax is melted away. A356 aluminum is then poured into the mold to create the final part. This method allows for precise control over the geometry and surface finish of the cast parts, making it ideal for complex, high-precision components.

Ready for the good part? Investment casting of A356 aluminum offers a wide range of benefits, including reduced material waste, enhanced dimensional accuracy, and the ability to create parts with thin walls and intricate designs. The process also offers flexibility in terms of the sizes and shapes of parts that can be produced. The high precision and surface finish achieved through investment casting make A356 aluminum ideal for critical applications where quality and reliability are paramount.

| Casting Method | Advantages | Disadvantages |

|---|---|---|

| Investment casting | High precision, fine surface finish | Higher cost compared to other methods |

| Sand casting | Lower cost, simple shapes | Lower accuracy, rough surface finish |

4. Key Benefits of A356 Aluminum Investment Casting

A356 aluminum investment casting offers several distinct benefits over other casting methods. One of the primary advantages is its ability to produce complex and detailed parts with high dimensional accuracy. The casting process also allows for the production of parts with thin walls and minimal material waste, which can significantly reduce production costs.

This is where it gets interesting… A356 aluminum also provides exceptional strength-to-weight ratio, which is crucial in applications where reducing weight is important, such as in aerospace components. Additionally, A356 aluminum has excellent corrosion resistance, making it suitable for use in harsh environments, including marine and automotive applications. Its ability to maintain structural integrity even in extreme conditions is another reason why it is highly sought after.

| Benefit | Explanation |

|---|---|

| High strength-to-weight ratio | Ideal for applications requiring lightweight components without sacrificing strength |

| Excellent corrosion resistance | Suitable for harsh environments, including marine and automotive applications |

| Precision and accuracy | Allows for the creation of complex parts with minimal material waste and fine surface finishes |

5. Applications of A356 Aluminum Investment Casting

A356 aluminum investment casting is used in a wide range of industries, thanks to its exceptional material properties. In the aerospace industry, it is often used for making lightweight components such as brackets, housings, and structural parts. In automotive manufacturing, A356 aluminum is used for creating engine components, wheels, and suspension parts that require both strength and durability.

You might be wondering… what makes A356 aluminum investment casting the go-to option for these industries? The answer lies in the material’s ability to combine strength with lightness, reducing overall weight while maintaining performance. Moreover, the precision and surface finish of parts made from A356 aluminum are crucial in these industries, where safety and reliability are of the utmost importance.

| Industry | Common Applications |

|---|---|

| Aerospace | Brackets, housings, engine components |

| Automotive | Wheels, suspension parts, engine blocks |

| Marine | Boat components, propellers |

6. Material Properties of A356 Aluminum for Casting

The material properties of A356 aluminum make it a versatile and high-performing choice for investment casting. A356 aluminum is known for its excellent mechanical properties, including high tensile strength and yield strength. It also exhibits good elongation, allowing it to withstand deformation without cracking. These properties are crucial for ensuring the longevity and durability of cast parts, especially in demanding applications such as aerospace and automotive industries.

But here’s the kicker… the thermal properties of A356 aluminum are also a key factor in its performance. This material has excellent thermal conductivity, which is beneficial in applications that involve heat dissipation, such as engine components. Its low thermal expansion rate ensures that parts maintain their shape and size even under extreme temperature variations.

| Property | A356 Aluminum |

|---|---|

| Tensile strength | 200–300 MPa |

| Yield strength | 160–220 MPa |

| Elongation | 2.5–5% |

| Thermal conductivity | 120 W/mK |

| Thermal expansion rate | 22.2 x 10^-6/K |

7. How A356 Aluminum Compares with Other Casting Alloys

When comparing A356 aluminum with other casting alloys, it is clear that A356 has several advantages. For example, when compared to 356 aluminum, A356 provides better strength and elongation properties, making it a better choice for applications requiring high tensile strength. It also has superior castability due to its higher silicon content, which enhances its fluidity during the casting process.

What’s the real story? While A356 aluminum is a top contender, other alloys, such as A380, may be preferred in certain applications due to their higher strength and improved machinability. The choice between these alloys depends largely on the specific requirements of the application, such as strength, machinability, and corrosion resistance.

| Alloy | Strength (MPa) | Silicon Content (%) |

|---|---|---|

| A356 Aluminum | 200–300 | 6.5–7.5 |

| A380 Aluminum | 280–380 | 7–9 |

| A2024 Aluminum | 480–570 | 4.4–6.2 |

8. Heat Treatment of A356 Aluminum in Investment Casting

Heat treatment is a crucial step in the investment casting process for A356 aluminum, as it helps enhance the material’s mechanical properties and performance. The most common heat treatment process for A356 aluminum is solution heat treatment, followed by aging. This process increases the strength and hardness of the alloy while maintaining its good elongation properties.

Ready for the good part? The heat treatment process can also improve the material’s resistance to stress corrosion cracking, making it even more suitable for applications in harsh environments. However, improper heat treatment can lead to residual stresses, which may cause warping or distortion in the final product. Therefore, careful control of the heat treatment process is essential for achieving optimal results.

| Heat Treatment Process | Effect on Material |

|---|---|

| Solution heat treatment | Increases strength and hardness |

| Aging | Improves resistance to stress corrosion cracking |

| Annealing | Reduces internal stresses and improves ductility |

9. Common Defects in A356 Aluminum Castings and How to Avoid Them

Like any casting process, A356 aluminum investment casting can experience defects that affect the quality and performance of the final product. Common defects include porosity, shrinkage, and cold shuts. Porosity, in particular, can lead to weak spots in the casting, reducing its strength and durability.

This is where it gets interesting… minimizing these defects requires attention to detail during every step of the casting process, from pattern design to the cooling phase. Ensuring that the mold is properly heated, and controlling the cooling rate, are critical steps in reducing the likelihood of defects. Additionally, using high-quality raw materials and maintaining a clean and controlled environment during the casting process can significantly improve casting quality.

| Defect | Cause | Solution |

|---|---|---|

| Porosity | Trapped gas in the mold | Proper venting and degassing |

| Shrinkage | Inconsistent cooling rate | Controlled cooling and mold design |

| Cold shut | Incomplete fusion of molten metal | Adjusting pouring temperature and speed |

10. Design Considerations for A356 Aluminum Castings

Designing parts for A356 aluminum investment casting requires careful consideration of factors such as wall thickness, geometry, and material flow. Since A356 aluminum has excellent fluidity, it is possible to create parts with intricate shapes and thin walls. However, excessively thin sections may lead to defects like cold shuts or porosity.

But here’s the kicker… optimizing the design for manufacturability is crucial in reducing production costs and ensuring the part meets performance specifications. The design should also account for post-casting processes like machining, which may require additional considerations in terms of material removal and surface finish.

| Design Factor | Considerations |

|---|---|

| Wall thickness | Should be consistent to avoid defects |

| Geometry | Complex shapes are possible but should be optimized for casting |

| Material flow | Ensure even material distribution to avoid porosity |

11. Cost-Effectiveness of A356 Aluminum Investment Casting

While A356 aluminum investment casting offers many benefits, it is important to consider the cost-effectiveness of this process. The initial setup costs for investment casting can be higher compared to other methods such as sand casting, but the precision and quality of the parts produced can offset these costs in the long run.

What’s the real story? The cost of A356 aluminum investment casting depends on factors such as part complexity, volume, and post-casting operations. For low to medium production volumes, investment casting may be the more cost-effective option compared to machining or other casting methods. For high-volume production, other casting methods may offer better economies of scale.

| Cost Factor | Impact on Production Cost |

|---|---|

| Part complexity | Increased complexity increases cost |

| Production volume | Higher volumes reduce per-part cost |

| Post-casting operations | Machining and finishing can add to cost |

12. Post-Casting Processes for A356 Aluminum

After A356 aluminum parts are cast, they often undergo several post-casting operations, including machining, surface finishing, and assembly. These processes are necessary to achieve the final dimensions, improve surface quality, and ensure that the part meets its performance requirements.

Ready for the good part? Post-casting operations can also include heat treatment, painting, and welding, depending on the application. Proper post-casting handling is crucial for maintaining the integrity of the part and ensuring that it performs as expected in its intended application.

| Post-Casting Process | Purpose |

|---|---|

| Machining | Achieve final dimensions and surface finish |

| Heat treatment | Improve material properties |

| Welding | Join components together |

13. Sustainability of A356 Aluminum Investment Casting

Sustainability is an increasingly important consideration in manufacturing, and A356 aluminum investment casting offers several advantages in this regard. The process generates minimal waste, and aluminum is highly recyclable, making it an environmentally friendly material choice.

But here’s the kicker… by choosing A356 aluminum, companies can not only improve their sustainability efforts but also reduce the carbon footprint of their products. Additionally, the energy consumption associated with the casting process can be minimized through the use of advanced technologies and techniques.

| Sustainability Factor | Impact on the Environment |

|---|---|

| Material recyclability | Aluminum can be reused multiple times with minimal degradation |

| Waste generation | Investment casting produces minimal waste compared to other methods |

| Energy consumption | Advanced technologies can reduce energy use in casting |

14. Challenges in A356 Aluminum Investment Casting

While A356 aluminum investment casting offers many advantages, it also presents some challenges. One of the main challenges is controlling the cooling rate to avoid defects such as shrinkage or porosity. Additionally, ensuring consistent material quality is essential to achieving uniform results.

What’s the real story? Overcoming these challenges requires a combination of expert knowledge, advanced technology, and strict quality control measures. As long as these challenges are addressed, A356 aluminum investment casting can provide exceptional results that meet the highest standards of quality and performance.

| Challenge | Solution |

|---|---|

| Cooling rate control | Use advanced cooling techniques and mold design |

| Material consistency | Use high-quality materials and strict quality control |

15. Future Trends in A356 Aluminum Investment Casting

As the demand for high-performance materials continues to grow, A356 aluminum investment casting is expected to play a key role in various industries. With advancements in casting technology and improved material properties, A356 aluminum will continue to be a preferred choice for applications requiring precision, strength, and durability.

Ready for the good part? The future of A356 aluminum investment casting looks bright, with ongoing innovations in materials, processes, and equipment. These developments will drive further improvements in casting quality and efficiency, enabling manufacturers to produce even more complex parts at lower costs.

| Future Trend | Expected Impact |

|---|---|

| Advanced materials | Increased strength and performance |

| Automation in casting | Reduced production time and costs |

| Enhanced casting techniques | Improved quality and reduced defects |

Conclusion

In conclusion, A356 aluminum investment casting is a versatile and highly effective manufacturing method that offers a variety of benefits, including strength, precision, and corrosion resistance. While there are challenges to overcome, the advantages far outweigh the drawbacks, especially for industries that demand high-performance components. By understanding the intricacies of the casting process, material properties, and design considerations, manufacturers can unlock the full potential of A356 aluminum investment casting.

FAQ Section

Q1: What is A356 aluminum investment casting?

A356 aluminum investment casting is a method used to create high-precision parts from A356 aluminum alloy, which is known for its strength, corrosion resistance, and fluidity.

Q2: How does the investment casting process work for A356 aluminum?

The process involves creating a mold using a wax pattern, which is covered with a ceramic shell. Once the mold is hardened, the wax is melted away, and A356 aluminum is poured into the mold to create the final part.

Q3: What are the main benefits of A356 aluminum investment casting?

The main benefits include high dimensional accuracy, excellent strength-to-weight ratio, and corrosion resistance, making it suitable for aerospace, automotive, and industrial applications.

Q4: How does A356 aluminum compare to other alloys in casting?

A356 aluminum offers better strength and elongation properties compared to many other alloys, making it ideal for applications that require high tensile strength and durability.

Q5: What are the key challenges in A356 aluminum investment casting?

The key challenges include controlling the cooling rate to avoid defects such as porosity and ensuring material consistency to achieve uniform results across all castings.