High-Performance Alloy Casting Solutions for Complex Geometries

At Dongying Vast, we specialize in solving manufacturing challenges for parts with intricate details and strict mechanical requirements. Our alloy casting services provide a direct path from digital design to physical reality, utilizing advanced investment casting services to produce components that other methods simply cannot match. By leveraging SLA rapid prototyping technology alongside traditional foundry techniques, we accelerate development cycles, allowing us to move from a 3D model to a cast sample in record time.

We deliver net shape casting precision, meaning your parts emerge from the mold with tight tolerances that minimize or eliminate the need for expensive secondary machining. Our facility is fully equipped to handle both ferrous and non-ferrous materials, ensuring consistent quality whether you need a single prototype or a high-volume production run.

Core Manufacturing Capabilities

- Precision Engineering: Capable of casting complex “problem parts” with thin walls, undercuts, and internal cavities.

- Material Versatility: Expert handling of Stainless Steel, Carbon Steel, Titanium, and Aluminum alloys.

- Quality Assurance: Full adherence to ISO9001 standards for guaranteed process control and repeatability.

- Scalability: Flexible production lines supporting everything from R&D samples to annual volumes exceeding 700 tons.

Comprehensive Alloy Selection for Critical Applications

We utilize advanced metallurgy to cast over 100+ alloy grades, ensuring your components meet specific mechanical properties like corrosion resistance and tensile strength. Selecting the right material is the foundation of successful alloy casting. We guide you through the complexities of casting metallurgy to match the perfect grade to your application’s environment. Whether your parts face saltwater corrosion or high-stress loads, understanding the heat resistance properties of alloys and other mechanical factors is critical for longevity.

We support a vast library of materials for custom metal parts manufacturing, ensuring we have the right solution for every project requirement:

- High-Performance Alloys: Engineered for extreme durability and thermal stability.

- Corrosion-Resistant Grades: Ideal for marine environments and chemical processing equipment.

- Structural Metals: Formulated to balance weight reduction with high tensile strength.

Our team ensures every melt adheres to strict chemical compositions before it ever reaches the mold, guaranteeing that the final alloy cast performs exactly as designed.

Ferrous Alloy Capabilities

Our foundry services are built on a strong foundation of ferrous metal expertise. When your project demands high tensile strength and superior durability, our alloy casting solutions deliver net-shape results that minimize secondary machining. We strictly adhere to AISI and ASTM standards to ensure every pour meets the rigorous demands of the US market.

We specialize in three primary ferrous categories to support critical industries:

- Stainless Steel Casting: We routinely cast austenitic grades like 304 and 316 for excellent corrosion resistance in food and marine applications, as well as precipitation-hardening grades like 17-4PH for high-strength requirements.

- Carbon & Alloy Steels: Ideal for structural components, our precision metal casting process ensures these materials maintain their mechanical integrity for heavy-duty industrial use.

- Duplex Stainless Steel: For the harshest environments involving high stress and chloride corrosion, our duplex pours offer the perfect balance of microstructure stability.

From simple brackets to complex valve bodies, we handle intricate geometries that other manufacturing methods simply can’t achieve, ensuring you get reliable parts direct from our factory.

Non-Ferrous and Specialty Alloy Solutions

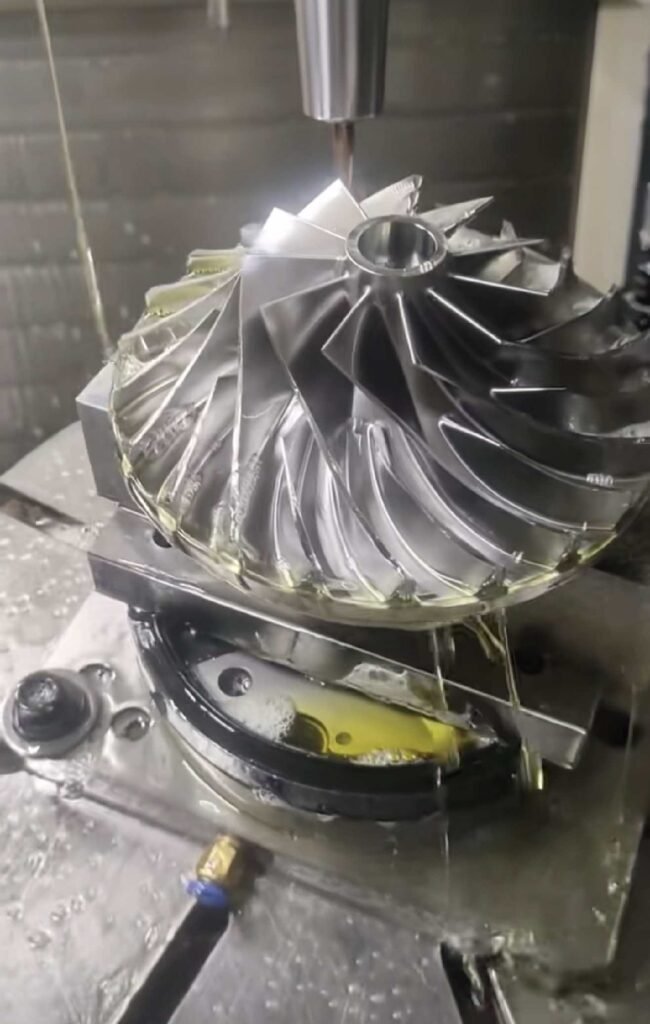

Beyond standard ferrous metals, our foundry specializes in high-performance non-ferrous metal casting for applications demanding superior strength-to-weight ratios and thermal resistance. We handle the difficult “problem parts” that other manufacturers often turn away, utilizing advanced alloy casting techniques to maintain strict metallurgical integrity across complex geometries.

Our capabilities cover a wide spectrum of specialty materials tailored for critical US industries:

- Titanium Alloy Casting: We deliver components with exceptional strength and low density, ideal for aerospace and medical applications where weight reduction is non-negotiable.

- Aluminum Investment Casting: Our process produces lightweight, corrosion-resistant parts with thin walls and intricate details, commonly used in automotive and marine sectors.

- High-Temperature Superalloys: Engineered for extreme environments, these custom metal parts manufacturing solutions maintain mechanical stability in high-heat applications like turbine blades and exhaust systems.

Whether you need a single alloy cast prototype or high-volume production, we ensure every pour meets precise chemical and physical specifications.

Precision Investment Casting Process (Lost-Wax)

We take the guesswork out of alloy casting by integrating time-tested traditional methods with cutting-edge manufacturing technology. Our facility utilizes the lost wax casting process, a technique renowned for producing complex geometries with exceptional surface finishes. By combining this with modern engineering tools, we deliver net shape casting results that significantly reduce the need for secondary machining, saving you both time and material costs.

To ensure every pour meets strict specifications, we employ a rigorous 14-step workflow. This ranges from precise pattern assembly and shell building to dewaxing and final surface treatments. Whether we are handling a specialized superalloy project or a high-volume carbon steel casting export order, our process controls remain absolute.

Modern Technology Meets Craftsmanship

We leverage advanced digital tools to optimize the investment casting services we provide:

- SLA Rapid Prototyping: We use Stereolithography (SLA) 3D printing to create wax patterns directly from your CAD files. This allows for rapid prototyping casting, enabling us to test designs and fit without the lead time or expense of hard tooling.

- CAE Simulation: Before a single drop of metal is poured, we run Computer-Aided Engineering (CAE) simulations. This analyzes metal flow and solidification to predict potential defects like shrinkage or porosity, ensuring sound casting metallurgy.

- Precision Tooling: Our in-house mold design capabilities allow us to handle intricate internal structures and thin-walled parts that other methods cannot achieve.

Rigorous Quality Control and NDT Capabilities

Quality isn’t just a checkbox for us; it is the foundation of our alloy casting process. We operate under strict ISO9001 standards to guarantee that every component leaving our factory meets the exact specifications required for your application. Whether it is a single prototype or a high-volume production run, we apply the same level of scrutiny to ensure structural integrity and dimensional precision.

To maintain this standard, we utilize a comprehensive suite of inspection technologies and Non-Destructive Testing (NDT) methods:

- Spectrometer Material Analysis: We verify the chemical composition of the molten metal before pouring to ensure the alloy grade matches your requirements perfectly.

- CMM Dimensional Inspection: Our Coordinate Measuring Machines (CMM) validate that complex geometries and linear tolerances align with your CAD data.

- Non-Destructive Testing (NDT): We employ X-Ray testing to detect internal porosity and Magnetic Particle Inspection to identify surface cracks without damaging the part.

- Mechanical Property Testing: We conduct rigorous hardness and tensile testing to confirm the mechanical strength of the final alloy cast.

By combining these advanced testing methods, we eliminate the risk of “problem parts” and deliver reliable, high-performance components ready for immediate assembly.

Industry-Specific Casting Applications

We tailor our foundry services to meet the unique demands of over 50 different industries worldwide. Whether you need high-volume automotive components or intricate medical devices, our custom metal parts manufacturing process ensures every piece meets strict regulatory and performance standards. We specialize in producing “problem parts” that other manufacturers find too complex.

Our alloy casting solutions serve these key sectors:

- Automotive: We produce high-strength engine components, brackets, and turbocharger parts. For structural applications requiring durability, knowing what carbon steel is used for casting is essential for optimizing performance and cost.

- Medical: Utilizing Titanium and Stainless Steel, we cast precision instruments and implants that require biocompatibility and tight tolerances.

- Marine: We manufacture corrosion-resistant hardware using Duplex Stainless Steel, designed to withstand harsh saltwater environments.

- Food Machinery: Our investment casting services deliver smooth, defect-free stainless steel parts that meet rigorous hygiene and sanitation standards.

- Aerospace: We handle high-temperature alloys for components that must endure extreme thermal stress and mechanical loads.

The Precisionvast Manufacturing Advantage

When you are sourcing custom metal parts manufacturing, time is usually the biggest bottleneck. We understand that US-based engineers and procurement managers need answers fast, which is why we have optimized our workflow to provide 8-hour quote turnarounds. We don’t believe in making you wait days just to get a price on your alloy casting project. Our team reviews your CAD files and specifications immediately to get you the data you need to move forward.

Beyond speed, we offer the reliability of a robust supply chain. With an annual capacity of 700 tons, we are equipped to handle everything from low-volume prototype runs to mass production without compromising on quality. We operate as a true one-stop solution for foundry services. You don’t need to coordinate between a casting house, a machine shop, and a finishing plant. We handle the entire investment casting services lifecycle under one roof, including design optimization, casting, CNC machining castings, and final surface treatments.

Why partner with us?

- Rapid Response: Get your quotes within 8 hours to keep your development cycle on track.

- Scalable Production: Whether you need ten parts or ten thousand, our 700-ton capacity ensures we meet your demand.

- Comprehensive Processing: We manage the transition from raw cast to finished product, ensuring tight metal casting tolerances.

- Material Versatility: We help you maximize performance, whether you are looking to leverage the benefits of carbon steel casting for structural strength or require high-performance superalloys for extreme environments.

We take the headache out of the supply chain so you can focus on your product. By integrating casting metallurgy expertise with modern manufacturing logistics, Precisionvast delivers net shape casting solutions that fit your schedule and your budget.

Frequently Asked Questions Regarding Alloy Casting

We understand that sourcing custom metal parts involves technical decisions. Below are answers to the most common questions we receive about our investment casting services and capabilities.

What linear tolerances can you achieve?

Precision is the main advantage of the lost wax casting process. We adhere to strict international linear tolerance standards (typically VDG P690 or ISO 8062). Our goal is net shape casting, meaning the part comes out of the mold as close to the final dimensions as possible to minimize the need for secondary CNC machining castings.

Do you handle low-volume prototypes?

Yes. We don’t just do mass production. We utilize rapid prototyping casting techniques, such as SLA (Stereolithography) 3D printing, to create wax patterns without expensive metal tooling. This allows for quick design verification and cost-effective low-volume runs before committing to full-scale production.

What file formats do you accept for quoting?

To provide an accurate quote within our 8-hour guarantee, please send:

- 3D Files: STEP (.stp) or IGES (.igs) formats are best for volume calculations.

- 2D Drawings: PDF files specifying critical dimensions, tolerances, and surface finish requirements.

Can you cast complex alloys?

Absolutely. Our foundry is equipped for a wide range of materials, from lightweight aluminum investment casting to high-strength titanium alloy casting. We also have extensive experience with specialized grades; for instance, you can review our capabilities in stainless steel investment casting to see how we handle corrosion-resistant applications.

How do you ensure material quality?

We don’t guess; we test. Every batch undergoes spectrometer analysis to verify chemical composition. For critical components, we perform Non-Destructive Testing (NDT) like X-ray and magnetic particle inspection to ensure the internal integrity of the alloy cast.