Titanium is a widely recognized and highly valued metal, known for its strength, corrosion resistance, and impressive lightweight properties. As a result, titanium alloys have become indispensable in a variety of industries, from aerospace to medical applications. But here’s the kicker: while titanium itself is a remarkable material, it’s not always the titanium we’re referring to when we talk about its uses. Instead, it’s often titanium alloys, which are created by combining titanium with other metals to improve its properties even further. So, is titanium an alloy? The answer is no—titanium is not an alloy on its own. However, it is frequently alloyed with elements like aluminum, vanadium, and molybdenum, forming titanium alloys that are crucial for numerous high-performance applications. In this article, we’ll explore the composition of titanium alloys, their unique properties, and their widespread use across various industries. Get ready for the full story on what makes titanium alloys one of the most sought-after materials in the world today.

1. What Is Titanium?

Titanium is a transition metal that is commonly known for its incredible strength-to-weight ratio. This unique combination allows it to perform exceptionally well in demanding environments. But wait, let’s dive a bit deeper into what titanium really is.

Titanium, with the chemical symbol Ti, is the ninth-most abundant element in the Earth’s crust, naturally occurring in minerals like rutile and ilmenite. It’s primarily extracted through the Kroll process, which involves reducing titanium tetrachloride with magnesium. As a metal, titanium has several distinguishing features that set it apart from other materials. Its high melting point of 1,668 degrees Celsius makes it ideal for use in high-temperature applications, while its low density—about 60% that of steel—makes it lighter and more versatile.

In its purest form, titanium is highly resistant to corrosion, especially from seawater, chlorine, and acids. This property is critical for applications in environments where metals are typically prone to rust and deterioration. But here’s where it gets interesting—pure titanium is relatively soft and not ideal for heavy-duty applications. However, when combined with other metals in the form of titanium alloys, its strength, flexibility, and resistance are vastly improved.

2. What Makes Titanium Special?

Titanium stands out for a variety of reasons that make it highly valuable across industries. Let’s break down why this metal is such a big deal.

Titanium’s properties are not just a coincidence. They stem from its unique atomic structure. Titanium has a hexagonal close-packed (hcp) crystal structure at lower temperatures and a body-centered cubic (bcc) structure at higher temperatures. This contributes to its excellent resistance to fatigue, creep, and corrosion.

When we talk about titanium’s versatility, we also have to mention its biocompatibility. This quality allows titanium to be used in medical applications like implants without causing any adverse reactions in the human body. Because it can bond well with bone tissue, titanium is particularly useful in dental implants and joint replacements.

On top of these properties, titanium has outstanding resistance to corrosion. It naturally forms a protective oxide layer that prevents rust, even in harsh environments. In fact, it’s one of the most corrosion-resistant metals known, which is why it’s often used in marine, chemical, and aerospace applications where other metals would simply corrode over time.

3. Is Titanium an Alloy?

Now that we’ve covered the basics, let’s circle back to the original question: Is titanium an alloy?

Technically speaking, titanium by itself is not an alloy. It is a pure metal, much like gold or silver. However, what makes titanium truly valuable is its ability to be alloyed with other metals to create various titanium alloys. Titanium alloys combine titanium with elements like aluminum, vanadium, molybdenum, and iron, which drastically enhance the material’s mechanical properties. For example, titanium alloys can be much stronger than pure titanium, yet still lightweight.

A key example is Ti-6Al-4V, one of the most common titanium alloys. It’s made by combining titanium with 6% aluminum and 4% vanadium. This alloy offers a much higher strength-to-weight ratio than pure titanium, making it ideal for aerospace and medical applications. So while titanium itself is not an alloy, its ability to form alloys is what makes it so versatile and useful in so many critical industries.

4. How Titanium Alloys Are Made

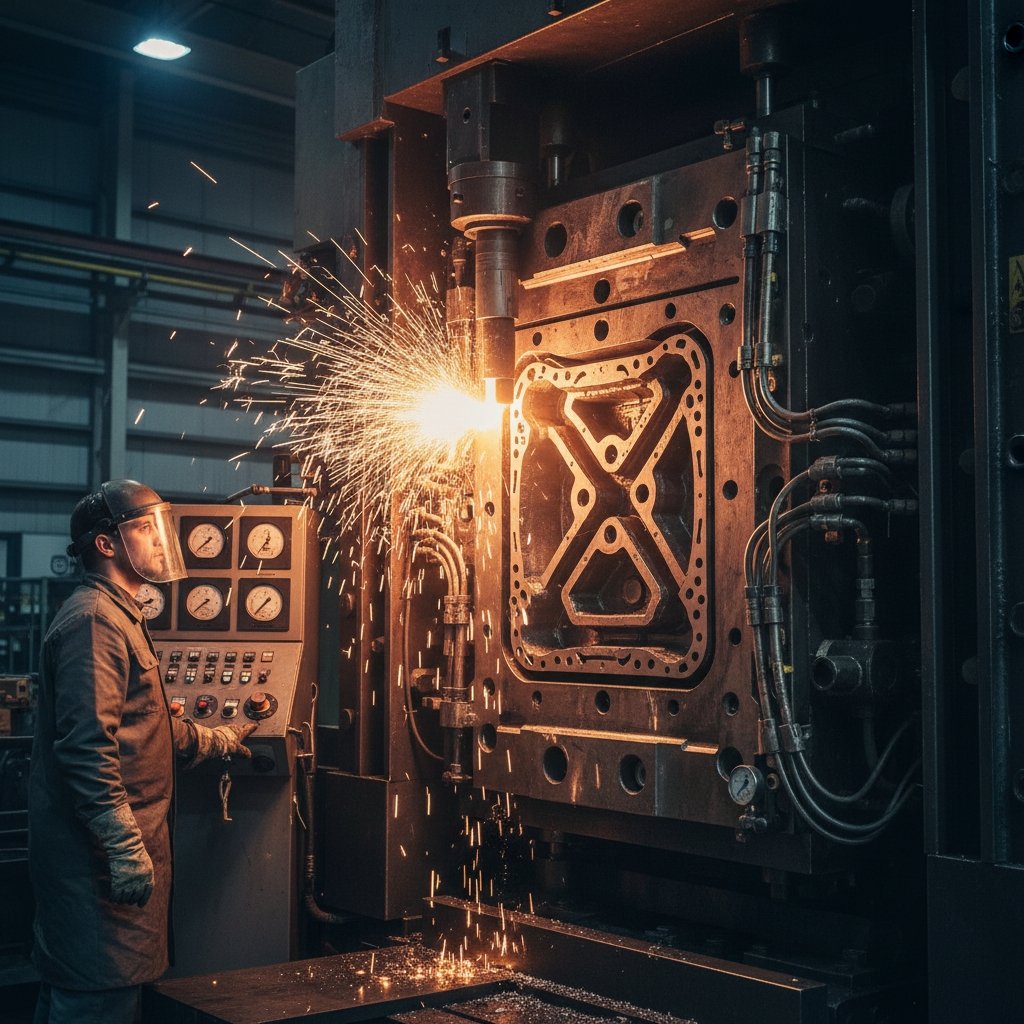

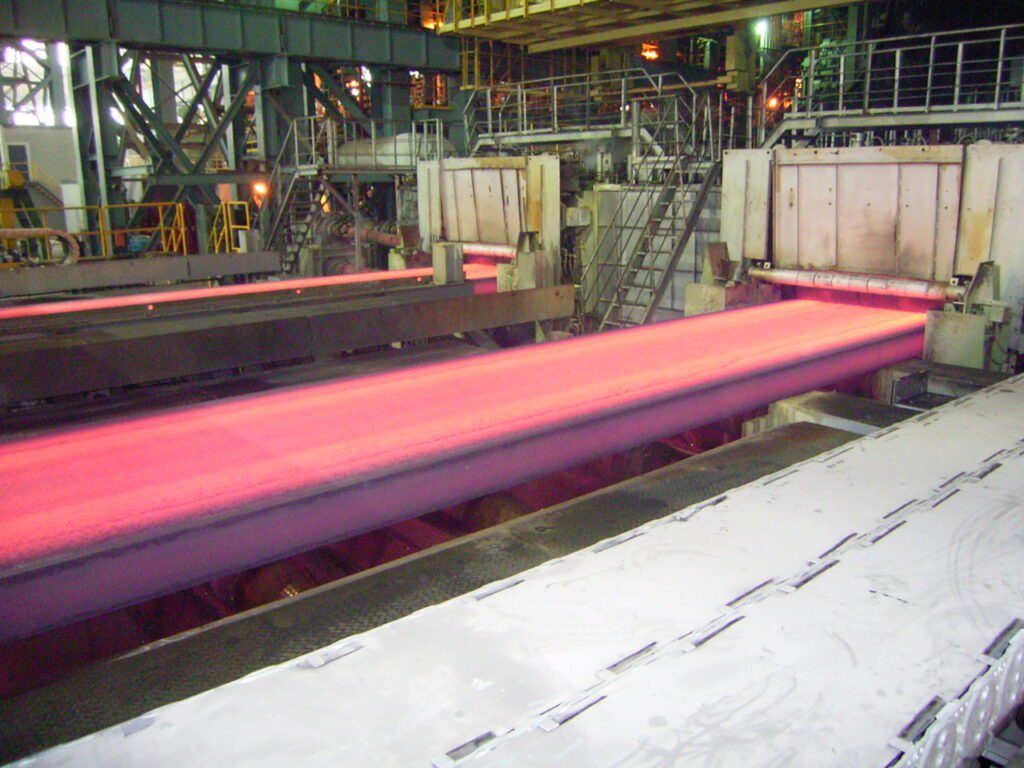

Creating titanium alloys involves combining pure titanium with other metals to enhance specific properties. Titanium alloys are generally made using processes such as ingot casting, powder metallurgy, or wrought processing. In this section, we’ll explore the alloying process and the key elements commonly added to titanium.

The alloying process begins by melting titanium along with other metals. Elements like aluminum, vanadium, and molybdenum are added to the molten titanium in specific proportions to achieve the desired properties. For example, adding aluminum increases the alloy’s strength, while molybdenum improves its resistance to corrosion. Once the alloy has been formed, it undergoes various processes like forging, rolling, and heat treatment to ensure the material’s structure is consistent and uniform.

But here’s the kicker: the combination of titanium with these metals does more than just improve strength—it enhances the material’s resistance to high temperatures, fatigue, and creep. Titanium alloys also offer better workability and weldability, which are critical in manufacturing processes, particularly in the aerospace and automotive industries.

5. Common Types of Titanium Alloys

There are several different types of titanium alloys, each designed for specific applications based on the desired characteristics of the material. Let’s explore the three main categories: alpha, beta, and alpha-beta alloys.

Alpha alloys contain primarily titanium with small amounts of other elements, like aluminum. These alloys are known for their excellent strength and resistance to corrosion. Beta alloys, on the other hand, contain a higher proportion of beta-stabilizing elements, such as vanadium or molybdenum. These alloys offer high strength, good ductility, and excellent formability.

Alpha-beta alloys combine the best properties of both alpha and beta alloys. The strength of alpha alloys with the ductility and formability of beta alloys make them ideal for applications requiring both high strength and good workability. Ti-6Al-4V, one of the most widely used titanium alloys, is an example of an alpha-beta alloy. It’s commonly found in aerospace, medical implants, and marine applications due to its superior strength, light weight, and resistance to corrosion.

6. Properties of Titanium Alloys

Titanium alloys have a wide range of properties that make them highly desirable in numerous industries. Some of the most notable properties include high strength, corrosion resistance, light weight, and biocompatibility. These attributes make titanium alloys particularly valuable in sectors like aerospace, medical, and automotive manufacturing.

Strength-to-weight ratio is one of titanium’s standout properties. Titanium alloys are much stronger than steel yet significantly lighter. This makes them ideal for aerospace applications where weight reduction is crucial. Titanium alloys also maintain their strength at high temperatures, which is why they are used in jet engines and gas turbines.

Corrosion resistance is another key benefit of titanium alloys. The protective oxide layer formed on the surface of titanium alloys makes them resistant to corrosion, even in harsh environments such as seawater. This property is highly valuable for industries like marine engineering and chemical processing.

And let’s not forget about biocompatibility. Titanium alloys are commonly used in medical implants because they are non-toxic and bond well with bone tissue. This unique characteristic has led to titanium alloys being used in applications ranging from dental implants to artificial joints.

| Alloy Type | Common Elements | Key Properties | Typical Applications |

|---|---|---|---|

| Alpha | Aluminum, Oxygen | High strength, excellent corrosion resistance | Aircraft components, pressure vessels |

| Beta | Vanadium, Molybdenum | High strength, excellent ductility and formability | Aerospace, military applications |

| Alpha-Beta | Aluminum, Vanadium | Combination of strength and formability | Aerospace, medical implants |

7. Key Applications of Titanium Alloys

Titanium alloys are used in a wide array of applications across various industries. Let’s explore some of the most common uses of these versatile materials.

In the aerospace industry, titanium alloys are used extensively in aircraft engines, airframes, and various structural components. The strength-to-weight ratio makes them ideal for aircraft construction, where reducing weight without compromising on strength is essential. For example, titanium alloys are found in parts of the Airbus A380, one of the world’s largest passenger aircraft.

In the medical field, titanium alloys are used in a variety of implants, including hip replacements, dental implants, and bone screws. The material’s biocompatibility makes it suitable for long-term use inside the human body without causing adverse reactions.

Titanium alloys are also widely used in marine applications, including ship hulls, propellers, and submarine components. Their corrosion resistance makes them ideal for use in harsh saltwater environments, where other metals would quickly corrode.

| Industry | Titanium Alloys Used | Key Features | Example Applications |

|---|---|---|---|

| Aerospace | Ti-6Al-4V | Lightweight, strong | Aircraft engines, airframes |

| Medical | Ti-6Al-4V, Ti-5Al-2.5Fe | Biocompatible, strong | Hip implants, dental implants |

| Marine | Ti-3Al-2.5V | Corrosion-resistant | Ship hulls, propellers |

8. Titanium Alloys in the Medical Field

One of the most important and growing applications of titanium alloys is in the medical field. Titanium’s biocompatibility makes it an ideal material for medical implants and devices.

Take dental implants, for example. Titanium is used because it naturally fuses with bone tissue, a process called osseointegration. This process ensures that the implant becomes a permanent part of the jawbone, allowing for better functionality and a more natural fit.

Titanium alloys are also used in joint replacements, such as knee and hip replacements. The strength and durability of titanium alloys mean that they can withstand the pressure and wear placed on joints, while their lightweight nature helps reduce the overall weight of the implants. Additionally, the corrosion resistance of titanium ensures that these implants will not degrade over time, which is a crucial factor for patients who need long-lasting replacements.

9. Titanium Alloys in Aerospace

Titanium alloys have a long history in aerospace applications, where they are highly valued for their combination of strength and light weight. Ready for the good part? This unique combination makes titanium alloys indispensable in the construction of aircraft, rockets, and spacecraft.

Titanium is used in the aircraft engines of commercial airliners, military jets, and space shuttles. The material’s ability to withstand extreme temperatures while maintaining structural integrity is what makes it ideal for such high-stress environments. **Titanium alloys are also used in the aircraft’s skin and structure, helping to reduce overall weight and improve fuel efficiency.

In rocket propulsion systems, titanium alloys are essential due to their strength at high temperatures and resistance to fatigue. These properties ensure that the alloys maintain their performance during the intense conditions experienced during launch and re-entry.

10. Advantages of Titanium Alloys

There are several key advantages to using titanium alloys, which is why they have become the material of choice for many high-performance industries.

One of the most obvious advantages is the high strength-to-weight ratio. Titanium alloys are much stronger than steel while being significantly lighter. This makes them ideal for applications where reducing weight is crucial, such as in aerospace or military applications.

Another major advantage is corrosion resistance. Titanium alloys are incredibly resistant to corrosion, even in harsh environments like seawater or strong acids. This property makes titanium alloys a favorite choice for industries like marine engineering, where other materials would quickly degrade.

Titanium alloys also have excellent high-temperature performance, making them perfect for use in environments with extreme temperatures, such as gas turbines, jet engines, and chemical processing plants. They can perform well under these harsh conditions without losing their strength or structural integrity.

| Advantage | Key Features | Applications |

|---|---|---|

| Strength-to-weight ratio | Stronger than steel, lightweight | Aerospace, military |

| Corrosion resistance | Resistant to rust, durable | Marine, chemical processing |

| High-temperature performance | Retains strength under heat | Jet engines, turbines |

11. Challenges in Using Titanium Alloys

Despite all of their advantages, titanium alloys are not without their challenges. For one, the cost of titanium alloys can be relatively high compared to other metals. The extraction and processing of titanium are energy-intensive, which can contribute to these higher costs.

Another challenge is the difficulty of machining titanium alloys. Due to their hardness and strength, titanium alloys can be difficult to cut, weld, or form into the desired shapes. This makes manufacturing processes more complex and requires specialized equipment.

Finally, the availability of titanium can be another challenge. While titanium is abundant in the Earth’s crust, the process of extracting and refining it into a usable form can be expensive and time-consuming. This limits the availability of high-quality titanium alloys, especially in markets where demand exceeds supply.

12. Future of Titanium Alloys

The future of titanium alloys looks bright, with continued advancements in technology and manufacturing processes. What’s the real story? Researchers are constantly exploring new ways to improve the properties of titanium alloys to make them even stronger, lighter, and more cost-effective.

One area of innovation is in 3D printing. Titanium alloys are increasingly being used in additive manufacturing processes, which allows for complex, lightweight structures that were previously impossible to create with traditional methods. This opens up new possibilities in industries like aerospace, where precision and weight reduction are critical.

Another exciting development is in the field of sustainability. Researchers are exploring ways to recycle titanium alloys more efficiently, reducing the need for virgin materials. This can help lower costs and reduce the environmental impact of titanium alloy production.

13. The Role of Titanium Alloys in Sustainable Manufacturing

Sustainability has become a critical focus for many industries, and titanium alloys are at the forefront of these efforts. As industries seek to reduce their environmental impact, titanium alloys offer several benefits that make them a sustainable choice for the future.

One of the key aspects of sustainability in titanium alloy production is recycling. Titanium alloys can be recycled without compromising their properties, making them a great option for manufacturers seeking to reduce waste. Additionally, the longevity and durability of titanium alloys mean that products made from these materials have a longer lifespan, reducing the need for frequent replacements.

Sustainability in manufacturing also means reducing the environmental impact of production processes. By improving the efficiency of titanium extraction and alloying processes, manufacturers can reduce the energy consumption and emissions associated with producing titanium alloys.

14. The Importance of Titanium Alloys in Modern Industries

Titanium alloys play an essential role in modern industries, thanks to their high performance and reliability. From aerospace to medical implants, titanium alloys provide the strength, durability, and corrosion resistance needed for critical applications.

In aerospace, the need for lightweight materials without compromising strength has driven the demand for titanium alloys. In the medical field, titanium alloys have revolutionized implants and surgical tools, allowing for longer-lasting and more effective treatments.

The bottom line is this: titanium alloys are indispensable in industries that require high-performance materials. Their unique combination of properties ensures that they will continue to be a go-to material for advanced engineering, medical, and industrial applications.

15. Conclusion

In conclusion, titanium alloys are a critical material in today’s high-performance industries. Their strength, durability, and corrosion resistance make them indispensable in aerospace, medical, and other sectors where reliability is crucial. As technology advances, titanium alloys are only going to become more important, with innovations improving their properties and applications.

For businesses, understanding the role of titanium alloys is key to staying competitive in industries that rely on cutting-edge materials. From improving existing products to developing entirely new solutions, titanium alloys offer a wide range of possibilities. If you’re looking for a material that combines strength, lightness, and resistance to extreme conditions, titanium alloys are your answer.

FAQ Section

Q1: What is titanium?

Titanium is a strong, lightweight metal that is highly resistant to corrosion and is commonly used in aerospace, medical, and industrial applications.

Q2: Is titanium an alloy?

No, titanium is a pure metal. However, it is often alloyed with other metals like aluminum, vanadium, and molybdenum to enhance its properties, forming titanium alloys.

Q3: How are titanium alloys made?

Titanium alloys are created by combining titanium with other metals like aluminum, vanadium, and molybdenum to improve their strength, corrosion resistance, and other properties.

Q4: What are the main applications of titanium alloys?

Titanium alloys are used in aerospace, medical implants, automotive components, and marine environments due to their strength, light weight, and resistance to corrosion.

Q5: What are the advantages of using titanium alloys?

Titanium alloys offer a high strength-to-weight ratio, excellent corrosion resistance, and durability in extreme conditions, making them ideal for demanding applications.