Lighter, Stronger, Faster: Titanium in the Aerospace Industry

“Explore how titanium’s strength-to-weight ratio revolutionizes aerospace, making aircraft lighter, faster, and stronger. A deep dive into the metal’s impact.”

How to Choose the Right Stainless Steel Cookware for Your Kitchen

Unlock the secrets to choosing the perfect stainless steel cookware for your kitchen with our expert tips on quality, compatibility, and maintenance.”

Stainless Steel in Modern Architecture: Glorious, Robust and Occasionally “Cool”

In this blog post, PrecisionVast experts explore in detail the wide range of applications for stainless steel in modern architecture and its benefits and challenges. From façade cladding to structural components to interior design elements, stainless steel has become a favourite in the construction industry for its corrosion resistance, strength and aesthetic value. The article also discusses the problems that can be encountered during the use of stainless steel, such as cost, processing techniques and construction challenges, and provides specialist solutions. Through innovative design and technology, PrecisionVast is committed to optimising the use of stainless steel to ensure its continued progress and excellence in modern architecture.

Carbon Steel vs Stainless Steel: The “Song of Ice and Fire” in the Materials World

Discover Carbon Steel vs. Stainless Steel: an in-depth comparison of strength, corrosion resistance, cost, and future trends to provide a scientific basis for your material choices.

Innovative applications for precision castings in the automotive industry

Innovative applications for precision castings in the automotive industry

The Art and Science of Metal Casting

“Explore the art and science of metal casting: from ancient techniques to modern innovations, discover how creativity meets technology in this craft.”

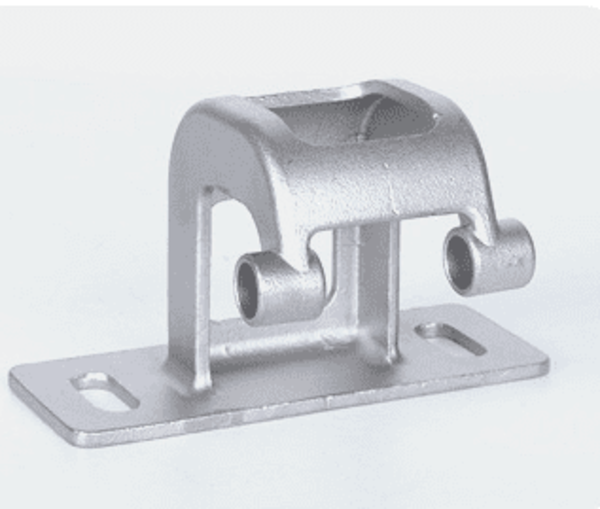

precision investment casting manufacturers

Precision investment casting technology is favoured by many industries due to its unique advantages. In the aerospace field, the technology is used to produce complex engine parts, structural components and so on. The medical device industry also widely adopts precision investment casting technology for the production of various implantable medical devices. In addition, the demand for precision casting parts in the automotive, energy and high-end manufacturing industries is also growing.

With the theme of technological research and application outlook of full metal jacket casting, this paper aims to provide an in-depth discussion of the latest progress, challenges and future trends in this cutting-edge field.

One of the keys to all-metal sheath casting technology is appropriate material selection. The matching of sheath material and core casting material has a decisive influence on the overall performance of the casting. Commonly used sheath materials include high-strength alloy steel, corrosion-resistant alloys, high-temperature alloys and so on.

what is titanium alloy–The material of the future

The article provides an in-depth exploration of the unique properties of titanium alloys, advances in manufacturing technology, and applications in a number of industries, with a particular focus on aerospace, medical, automotive manufacturing, and new energy sectors. Through the lens of PrecisionVast, it demonstrates how titanium alloys are the material of the future and how the company is driving the development and application of titanium alloy technology through technological innovation and close collaboration. The article also foresees the application of titanium alloys in emerging fields, demonstrating the key role of materials science in driving social progress and sustainable development.

How Does Investment Casting Work?

Investment casting, often hailed as precision casting due to its remarkable ability to produce detailed and accurate components, stands as a cornerstone in the manufacturing world. This method, known historically as lost-wax casting, is celebrated for its versatility and precision, offering solutions across various industries, including aerospace, automotive, medical, and defense. This comprehensive exploration delves into the intricate process of investment casting, providing insights into why it surpasses other casting methods in creating complex, precision parts.