cast iron vs stainless steel?

Discover the world of cast iron and stainless steel cookware: the precisionvast team analyses in depth the properties, manufacturing processes and culinary suitability of these two popular materials. From precision casting techniques to materials science, learn how to make the right choice for your cooking needs.

Which medium uses the lost-wax casting method?

Lost-wax casting

Metal sculptures

Historical origins

Artistic expression

Technological innovation

Cultural variations

Ancient civilizations

Detailed procedural steps

Enduring significance

Modern manufacturing

Precisionvast-what is investment casting?

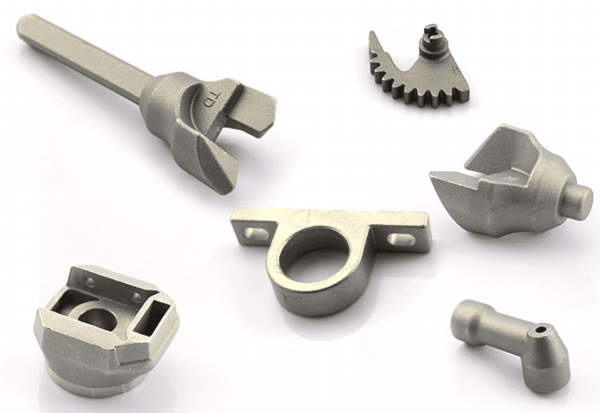

Investment casting (Investment Casting), also known as precision casting or lost wax casting, is a time-honored metal-forming technology that has occupied an indispensable position in the global manufacturing industry with its high-precision and high-complexity casting characteristics. With the continuous progress of technology and growing industrial demand, investment casting is rapidly expanding into new product areas, showing its unique advantages and potential.

Investment casting: the art of industrial craftsmanship

Precision casting is a high-precision manufacturing process to produce metal parts of precise dimensions and high surface finish by using specific molding methods such as investment casting, ceramic casting, metal casting, pressure casting, and vanishing mold casting. This process is widely used in aerospace, automotive, medical equipment, and other fields requiring high precision parts. Precision casting can produce a wide range of products from tiny parts to large components, and some processes such as stainless steel precision casting almost no subsequent cutting process.

Investment casting, also known as lost-wax casting, is a precision casting process used to create metal parts from almost any alloy.

Key advantages of investment casting are outlined, including its precision, ability to produce complex geometries, superior surface finish, and material versatility. These benefits make investment casting a preferred method across various industries such as aerospace, medical, automotive, and military, for manufacturing complex components like engine parts, medical instruments, and military hardware.

The Artistic and Technical Precision in Lost Wax Casting

Lost wax casting

Jewellery making

Contemporary art

Casting Techniques

Metalwork

Sculpture technology

Precision Casting

Artistic Innovation

Jewellery Design

Artist Workshops

Copper Casting

Silver Casting

Creative Crafts

Handmade Art

Bespoke Jewellery

Moulding Techniques

Materialology

Arts & Crafts

Creative Techniques

Metal Sculpture

Large and complex titanium alloy castings melt mold precision casting technology

The casting structure is becoming more and more complex, the outer contour size is getting bigger and bigger, the minimum wall thickness is getting thinner and thinner; the dimensional accuracy is getting higher and higher, and the metallurgical quality requirements are almost harsh; the requirements for the casting’s reliability, safety, and long-time stability are getting more and more clear. All these put forward more and more high requirements for large titanium alloy structural parts.

Titanium Alloys in the Bicycle, Motorcycle and Automotive Industries

Engine components: such as connecting rods and pistons, the use of titanium alloys can reduce weight and improve engine efficiency.

Transmission system: Titanium alloys are also commonly used for transmission system components such as gearboxes and clutches.

Body parts: Especially in high-performance cars and racing cars, titanium alloys are used to make key parts such as suspension systems and wheel hubs.

Specialty parts for luxury models: Some luxury brands use titanium alloys for decorative or special functional applications to increase the uniqueness and attractiveness of their vehicles.

When casting titanium alloy, due to improper process specification, poor quality control of raw materials and other reasons, the castings may have various defects.

When casting titanium alloy, due to improper process specification, poor quality control of raw materials and other reasons, the castings may have various defects. The common defects are as follows:

1, β embrittlement,

2、Localized coarse crystal,

3、Cracks,

4 residual casting organization

5、Bright strip

6, α embrittlement layer

7、Hydrogen embrittlement

Application of new quality productivity in silicone sol investment casting

New quality productivity refers to the productivity with information technology as the core, which emphasizes intelligence, automation and networking. In silicone sol investment casting,