Precision casting is an indispensable technology in the manufacture of aero-engine, which provides an important guarantee for the performance and reliability of aero-engine

Precision casting technology in the manufacture of aircraft engines in a wide range of applications and in-depth, in order to improve the performance, reliability and efficiency of the engine has made an important contribution.

Research on nickel-based casting high-temperature alloy and heat treatment process

Nickel-based casting high-temperature alloy refers to nickel as the main component, casting method to directly prepare parts of high-temperature alloy materials. It has excellent high-temperature strength, fatigue stability and fracture toughness and good creep stability and other comprehensive mechanical properties, can be in a high-temperature environment for long-term safe operation, widely used in aerospace, automotive industry, gas turbine field engine turbine blades, the whole leaf disk, the magazine and other high-temperature components. With the development of aero-engine technology, the requirements for the performance of alloy materials have also increased dramatically

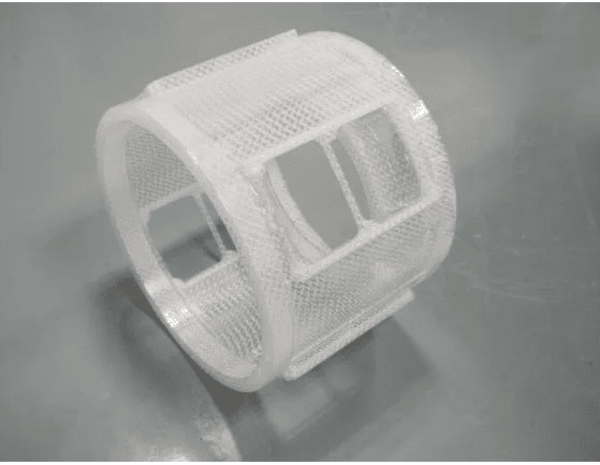

The secret weapon of investment casting -Applications and considerations for ceramic cores

1. Casting cavity than the outer contour of the surface finish requirements are higher

2. The inner cavity of the casting has a complex structure, or the inner cavity of the casting is larger than the mouth of the inner cavity, so it is not possible to make wax molds with wax mold molds.

3. Small and deep holes inside the casting, or thin and long grooves, which can not be completed by 6-7 layers of shell making.

Development of hot isostatic pressing technology and its application in precision casting

Characteristics of hot isostatic pressure equipment Hot isostatic pressure equipment consists of high-pressure vessel, heating furnace, compressor, vacuum pump, gas storage tank, cooling system and computer control system, of which the high-pressure vessel is the key device for the whole equipment.

Application of salt spray test in precision casting

Salt spray test is an important means of evaluating the salt spray corrosion resistance of products or materials, the test results of the scientific and reasonable is crucial. Salt spray test results affect the stability and consistency of many factors, to improve the effectiveness of the results of the salt spray test, test technology is the key. Test personnel not only need to have solid professional knowledge and professional skills, but also need a wealth of practical experience and a comprehensive understanding of the product, from the chemical and environmental engineering, materials, structures and processes and other multidisciplinary fields to understand the salt spray test, scientific and reasonable expression of the test results for the product to better material selection, structural design, process selection, product transportation, storage and use of the product to provide effective information to improve product or material’s salt spray corrosion resistance.

Aluminum alloy surface treatment process

Aluminum alloy surface treatment process Product surface treatment: it is through mechanical and chemical methods of treatment, can form a layer of protection on the surface of the product to protect the body of the protective layer. In the natural world can reach a stable state, increase the corrosion resistance of the body and increase […]

The main application of aluminum alloy in the field of aviation

The main application of aluminum alloy in the field of aviation In aviation equipment, different parts of the aluminum alloy material selection has precise selection requirements. Aluminum alloys used in different parts of the aircraft are mainly 2X24, 7X75, 7X5X, etc. With the continuous improvement of the aluminum alloy material process, the application of grades […]

Aerospace Inconel 718 nickel-based high-temperature alloy research status

Aerospace Inconel 718 nickel-based high-temperature alloy research status With the continuous development of China’s aerospace industry, the requirements for parts with complex, high-precision structure are also higher and higher. Inconel718 (domestic brand GH4169) alloy is a nickel-based precipitation-strengthened high-temperature alloys, due to its good toughness, strength, corrosion resistance, and creep resistance properties within the temperature […]

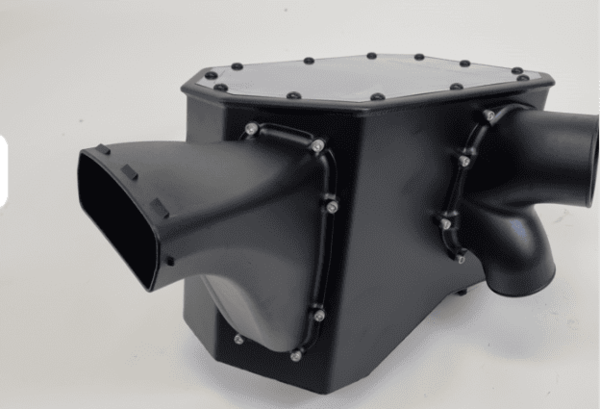

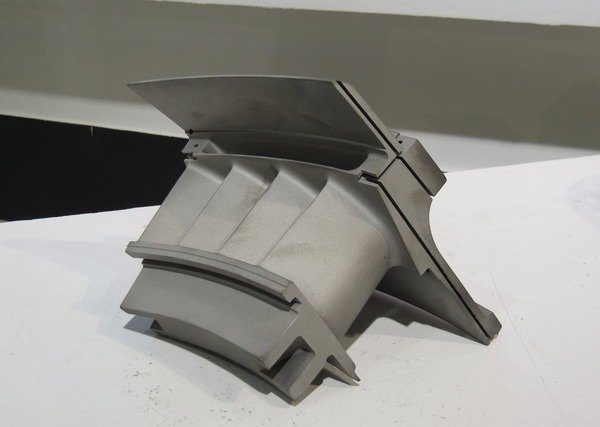

3D printing technology in the field of precision casting applications

3D printing technology in the field of precision casting applications 3D printing technology as an advanced intelligent application can be said to be popular in many fields! One of the application in the field of investment casting is to let the audience applaud! The use of three-dimensional graphics in the computer for sampling molding, so […]

What Are Common Defects in Grey Iron Casting and How to Prevent Them?

The article provides insights into common defects in grey iron casting, like porosity and cold shuts, and highlights strategies like controlled cooling and proper mold design to prevent them.