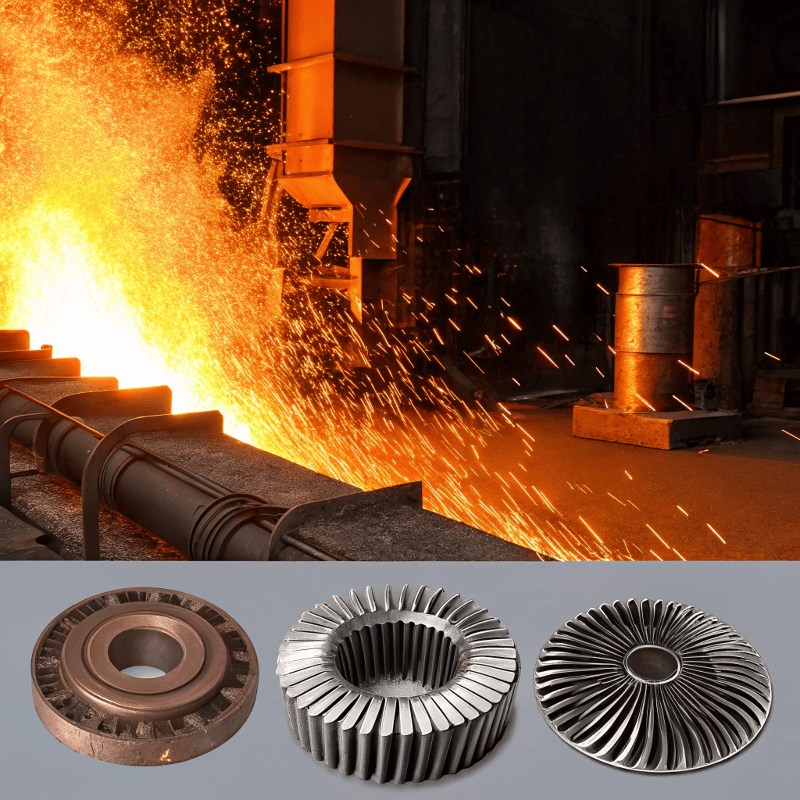

How to Select the Right Casting Alloy for Strength, Weight, and Cost

Standard metals often miss critical targets for corrosion, weight, or strength, forcing compromises that cause premature failures, higher maintenance, and weaker products. A casting alloy solves this by blending metals to engineer properties precisely for your application—delivering the durability, weight, and resistance you need without trade-offs. Defining the Casting Alloy Process Here’s the deal: alloy […]

How to Select the Right Nickel Alloy Casting for High Heat and Corrosive Service

Introduction When components face extreme heat, high pressure, or corrosive media, failures trigger costly downtime and safety risks. The challenge is finding a material that resists creep, corrosion, and structural weakening under relentless stress. Nickel alloy casting solves this—its high-performance chemistries deliver exceptional heat tolerance, corrosion resistance, and long-term strength for your most critical applications. […]

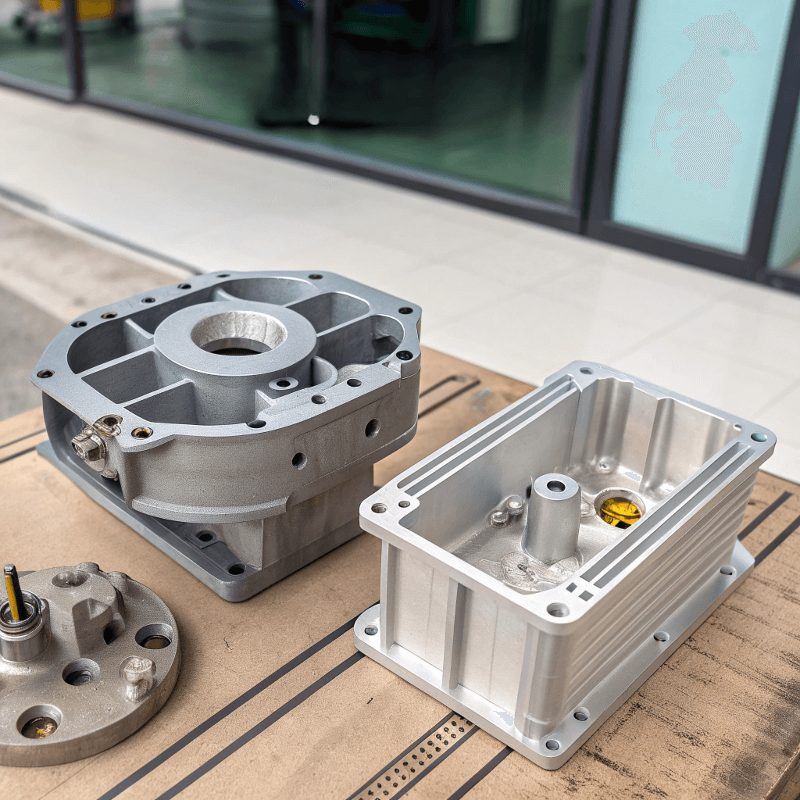

How to Optimize Alloy Die Casting for Lightweight Strength

Sourcing lightweight, high-strength metal parts often creates bottlenecks and budget creep. Inferior methods yield heavier components, weaker structures, and higher unit costs. Alloy die casting solves this with a rapid, precise, and economical approach to produce dimensionally accurate parts—so your project hits strict performance targets while staying on budget. The Fundamentals of Alloy Die Casting […]

How to Use Alloy Casting for Stronger, Lighter Components

Manufacturers face constant challenges in sourcing materials that achieve the ideal balance of strength, weight, and corrosion resistance. Falling short in these areas can drive up long-term costs, cause premature part failures under heavy stress, and damage brand reputation. Alloy casting provides a practical solution by enabling the creation of tailored components that are stronger, […]

What Makes Zinc Alloy Die Casting Superior to Aluminum Casting

Manufacturers constantly face the challenge of sourcing metal parts that combine strength, dimensional accuracy, and cost efficiency. Relying on weaker options like aluminum often undermines design integrity, while alternative processes can drive up tooling expenses and extend production cycles, ultimately delaying market readiness. Zinc alloy die casting provides a reliable answer, offering superior strength, faster […]

How to Choose Alloys for Aluminium Alloy Die Casting

You’ve committed to aluminium alloy die casting, but the next hurdle is selecting the right alloy—a single choice that drives process stability, cycle time, and in-service performance. Pick poorly and you invite production-stopping defects or premature field failures from corrosion, eroding budgets and credibility. This guide cuts through the noise, mapping the key alloy characteristics […]

How to Choose the Right Process for Aluminium Alloy Casting

Introduction: The aluminium alloy casting solution Your program requires complex, lightweight, corrosion-resistant metal parts, yet traditional machining is too slow and costly to sustain volume. Without an efficient route, budgets slip, schedules drift, and components miss weight and performance targets—eroding your advantage. This guide shows how aluminium alloy casting delivers a versatile, near-net-shape solution, enabling […]

How to Improve Durability with Nickel Alloy Casting in Harsh Environments

Struggling with components that fail under high heat or corrosive conditions drains productivity and drives up costs through constant replacements. These failures put both operations and profitability at risk. Nickel alloy casting offers the solution—delivering exceptional durability, resistance to oxidation, and superior performance where conventional metals cannot compete. By leveraging nickel alloy casting, you can […]

What are the Benefits and Drawbacks of High-Pressure Aluminum Die Casting?

High-pressure aluminum die casting is a widely used manufacturing process that allows manufacturers to create high-precision, durable metal parts. This process involves injecting molten aluminum into a die under high pressure, which results in highly detailed and dimensionally accurate parts. But why is it so popular in industries like automotive, aerospace, and electronics? The benefits […]

Top Heat Resistant Metals for High-Temperature Durability

Heat resistant metals are essential in industries that deal with high-temperature environments, ranging from aerospace to automotive applications. These metals are specially designed to maintain their strength, durability, and functionality even when subjected to extreme heat. In this article, we will explore the various types of heat resistant metals, their properties, applications, and how to […]