Die casting aluminum is a widely used method in manufacturing that produces precision metal parts. If you’re unfamiliar with it, this guide will walk you through the essentials. We’ll explore the process, the materials, the benefits, and everything else you need to know about aluminum die casting. By the end, you’ll have a clear understanding of why aluminum is so commonly used and how die casting works. So, let’s get started!

1. Introduction: Understanding Die Casting Aluminum

When considering the production of durable metal parts, aluminum die casting is one of the most reliable methods. This technique involves injecting molten aluminum into a mold under high pressure to create parts that are both light and durable. But here’s the kicker: aluminum is highly versatile and can be shaped into complex forms with remarkable precision, making it a popular choice for industries like automotive, aerospace, and electronics.

Why should you care about aluminum die casting? The answer lies in the unique benefits this method offers. From excellent thermal and electrical conductivity to its lightweight yet strong nature, aluminum is ideal for creating everything from small consumer goods to heavy-duty machinery components. The die casting process itself allows for high-volume production with minimal material waste, making it an efficient and cost-effective choice for manufacturers.

By the end of this guide, you’ll understand the steps involved in aluminum die casting, its advantages and disadvantages, and why it’s essential for many industries. Let’s dive into the specifics.

| Aspect | Details |

|---|---|

| Material | Aluminum |

| Primary Benefit | Lightweight, durable, corrosion-resistant |

| Industry Applications | Automotive, Aerospace, Electronics, Industrial machinery |

| Key Advantage | High-precision and cost-effective for large-scale production |

2. What is Die Casting Aluminum?

Die casting aluminum is the process of injecting molten aluminum into a reusable metal mold, or die, under high pressure. The process results in precise, durable metal parts that can be used in a wide range of industries. Ready for the good part? Aluminum is an excellent choice for die casting due to its combination of light weight, strength, and resistance to corrosion.

Aluminum die casting offers significant advantages, such as excellent thermal conductivity, making it perfect for parts used in engines, heat exchangers, and electronics. It is also highly resistant to corrosion, which means aluminum die castings can last for years even in harsh environments.

So, why is aluminum so widely chosen? The key lies in its properties. Aluminum is lighter than other metals like steel, which makes it perfect for industries where weight reduction is crucial. This is why aluminum die cast parts are commonly found in the automotive and aerospace industries.

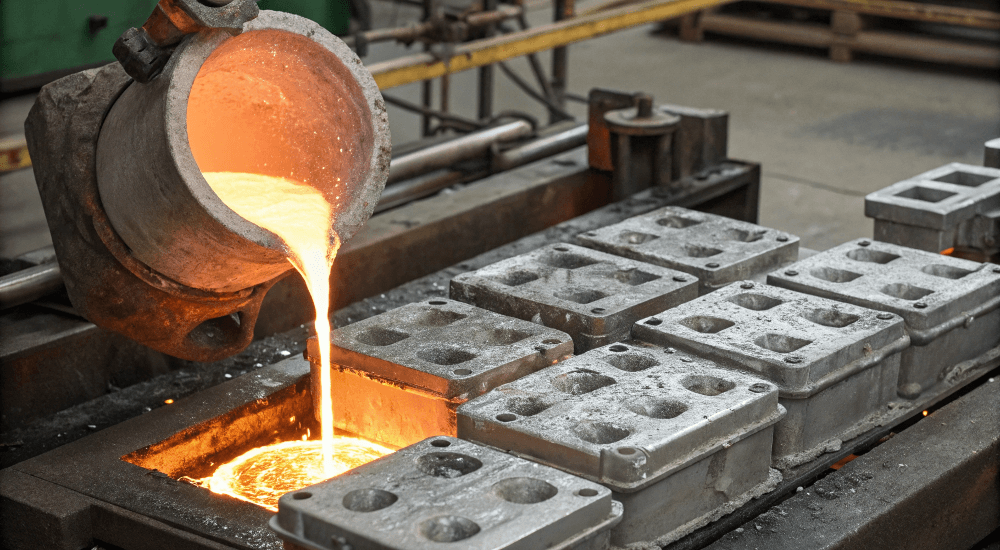

Here’s a quick breakdown of how aluminum die casting works:

- Molten aluminum is poured into the die.

- Pressure is applied to the aluminum.

- The molten metal cools and solidifies in the mold, taking its shape.

- The die is opened, and the cast part is removed.

| Step | Description |

|---|---|

| Step 1 | Molten aluminum poured into the die |

| Step 2 | Pressure applied to ensure the aluminum fills the mold |

| Step 3 | Aluminum cools and solidifies into the desired shape |

| Step 4 | The mold is opened, and the cast part is extracted |

3. How Die Casting Aluminum Works

Die casting aluminum works by forcing molten aluminum into a mold under high pressure. This allows for the creation of parts that are both strong and lightweight. But here’s the twist—there are two main types of die casting methods used for aluminum: cold chamber die casting and hot chamber die casting. These methods are chosen based on the specific requirements of the product.

What’s the difference between the two? In cold chamber die casting, the molten aluminum is poured into the chamber manually before being injected into the mold. This method is typically used for aluminum alloys that are prone to contamination by the hot chamber’s components. On the other hand, hot chamber die casting uses a machine that keeps the aluminum molten inside the chamber, making it quicker and more efficient for certain alloys.

Ready for the good part? Both methods are highly effective, but the choice of method depends on the specific needs of the part being produced. For instance, cold chamber die casting is better suited for complex parts that require high precision, while hot chamber die casting is ideal for parts that need to be produced quickly.

| Die Casting Method | Description |

|---|---|

| Cold Chamber Die Casting | Molten aluminum poured into a separate chamber before injection into the mold |

| Hot Chamber Die Casting | Molten aluminum stays in the chamber, making the process faster and more efficient |

4. Types of Aluminum Used in Die Casting

When it comes to die casting aluminum, not all alloys are created equal. The type of aluminum alloy used can significantly affect the final product’s strength, durability, and performance. Aluminum alloys are typically divided into two categories: casting alloys and wrought alloys. Casting alloys are commonly used in die casting due to their ability to flow easily into the mold and produce high-quality parts.

What’s the real story with alloys? Some common aluminum alloys used in die casting include:

- A380: Known for its good fluidity and corrosion resistance, this is one of the most widely used aluminum alloys in die casting.

- A383: A variation of A380, A383 is ideal for applications requiring high wear resistance.

- A360: This alloy is favored for its excellent machinability and strength, making it ideal for precision parts in industries like aerospace.

Choosing the right alloy depends on the part’s intended use. For example, in automotive applications, alloys with high strength and wear resistance are crucial, while in electronics, alloys with high thermal conductivity may be prioritized.

| Alloy Type | Key Properties | Applications |

|---|---|---|

| A380 | Good fluidity, corrosion resistance | Automotive, electronics |

| A383 | High wear resistance | Automotive, heavy machinery |

| A360 | Excellent machinability, strength | Aerospace, precision engineering |

5. Applications of Die Casting Aluminum

Aluminum die casting is used in a wide variety of industries. What’s the big deal? The versatility of aluminum makes it an ideal choice for applications where both strength and lightweight characteristics are needed.

In the automotive industry, aluminum die castings are used in engine blocks, transmission parts, and body panels, all of which benefit from aluminum’s strength and reduced weight. In aerospace, aluminum die castings are used for components that require high durability while maintaining a light weight, such as aircraft engines and landing gear.

Here’s the kicker: Aluminum die casting is also prevalent in consumer electronics. From laptops to smartphones, aluminum die cast parts are used for their heat dissipation properties, ensuring devices run efficiently without overheating.

Let’s not forget industrial applications like machinery parts and tooling. Aluminum die casting allows for precision in the creation of complex components that must withstand heavy wear and tear.

| Industry | Common Applications | Benefits |

|---|---|---|

| Automotive | Engine blocks, transmission parts, body panels | Lightweight, durable, cost-effective |

| Aerospace | Aircraft engines, landing gear, structural parts | High strength-to-weight ratio, durability |

| Consumer Electronics | Laptops, smartphones, heat sinks | Heat dissipation, compact designs |

| Industrial Machinery | Machinery parts, tooling, gears | Precision, high wear resistance |

6. Advantages of Die Casting Aluminum

Aluminum die casting offers several compelling advantages over other manufacturing methods. But here’s the twist: Aluminum provides a perfect combination of lightweight properties and durability. It’s a metal that’s tough yet easy to work with, making it a prime choice for many applications.

So, why choose aluminum for die casting?

- Lightweight: Aluminum is one of the lightest metals, which makes it perfect for industries that prioritize weight reduction, such as automotive and aerospace.

- Strength: Despite its light weight, aluminum is extremely strong, making it ideal for parts that need to withstand stress without breaking.

- Corrosion Resistance: Aluminum forms a protective oxide layer that makes it highly resistant to corrosion, especially in harsh environments.

- Cost-Effectiveness: Die casting aluminum allows for efficient mass production, which lowers production costs and reduces material waste.

- Precision: Aluminum die casting allows for high precision in creating parts with tight tolerances.

These advantages make aluminum die casting a top choice for industries that demand quality, precision, and durability at a competitive price.

| Advantage | Description | Benefits |

|---|---|---|

| Lightweight | Aluminum is much lighter than other metals like steel | Reduces weight in automotive and aerospace industries |

| Strength | Aluminum maintains strength under stress despite being lightweight | Suitable for durable, high-stress applications |

| Corrosion Resistance | Aluminum naturally resists corrosion | Suitable for harsh environments |

| Cost-Effectiveness | Low per-unit cost in mass production | Economical for large-scale manufacturing |

| Precision | High tolerance and accuracy in the molding process | Ideal for precision parts in technical industries |

7. Disadvantages and Challenges of Die Casting Aluminum

While aluminum die casting offers several benefits, it also comes with its own set of challenges. What’s the real downside? One major issue is the potential for defects. These defects can range from minor cosmetic issues like surface blemishes to more serious structural flaws such as porosity or cracking. Managing these defects requires careful control over the die casting process.

Another challenge is the high initial cost of setting up die casting machines and molds. Although the per-unit cost of aluminum die castings is low, the upfront investment in equipment can be significant. Is there a way around this? Many manufacturers offset this cost by focusing on high-volume production, which can reduce costs over time.

Finally, not all parts are suitable for aluminum die casting. Some complex geometries or designs may be better suited to other methods, like injection molding or forging.

| Challenge | Description | Solutions |

|---|---|---|

| Defects | Common defects include porosity, cracking, and surface blemishes | Control temperature, alloy quality, and pressure |

| High Initial Investment | Significant investment in die casting equipment and molds | Focus on high-volume production to reduce cost |

| Part Complexity | Complex parts may not be suited for die casting | Consider other methods like injection molding |

8. Factors Affecting the Quality of Aluminum Die Castings

To produce high-quality aluminum die castings, several factors must be considered. What’s the real story here? First and foremost, die design plays a critical role in the quality of the cast part. A well-designed die ensures that the molten aluminum flows evenly and fills the mold without leaving gaps or defects.

But here’s where it gets interesting: The metal quality also plays a big part. Aluminum alloys with high purity levels result in stronger, more durable parts. Additionally, temperature control is crucial in the die casting process. Too high or too low a temperature can result in defects like porosity or cracks in the final product.

Finally, post-processing techniques like heat treatment and surface finishing can enhance the final quality of the die-cast part, ensuring it meets the required specifications.

| Quality Factor | Impact on Die Casting | Best Practices |

|---|---|---|

| Die Design | Ensures even metal flow and high precision | Invest in quality die design and maintenance |

| Metal Quality | High-purity aluminum alloys lead to stronger, more durable parts | Use verified, high-purity alloys |

| Temperature Control | Affects the final structure and surface finish | Maintain consistent temperature throughout the process |

| Post-Processing | Heat treatment and finishing improve mechanical properties | Apply heat treatments and surface finishing |

9. Common Defects in Die Casting Aluminum and How to Prevent Them

Defects in aluminum die casting are common, but many can be avoided with careful control of the process. Here’s the kicker: Porosity is one of the most common defects in aluminum die casting, and it happens when air pockets get trapped inside the casting. This can weaken the part and make it unsuitable for some applications.

What’s the real story with defects?

- Porosity: Can be caused by improper venting, insufficient pressure, or contamination in the aluminum.

- Cold Shut: This happens when the molten metal cools too quickly before fully filling the mold, leaving a seam.

- Misruns: Occur when the molten metal doesn’t fill the entire mold cavity.

To prevent these defects, manufacturers must carefully control die temperature, mold design, and metal quality throughout the casting process.

| Defect | Cause | Prevention |

|---|---|---|

| Porosity | Air pockets trapped during the casting process | Improve venting, use cleaner alloys, increase pressure |

| Cold Shut | Molten metal cooling too fast and not filling the mold | Adjust temperature and flow rates |

| Misruns | Molten metal not filling the mold completely | Optimize die design, ensure proper metal flow |

10. How to Choose the Right Aluminum Die Casting Manufacturer

Choosing the right aluminum die casting manufacturer is crucial for ensuring that your parts meet quality standards. But here’s the real deal: Price isn’t the only factor to consider. Look for a manufacturer with a proven track record of high-quality die castings and the ability to meet your production needs.

What should you focus on when choosing a supplier?

- Experience: An experienced manufacturer is more likely to deliver quality products on time.

- Quality Control: Check for certifications like ISO 9001 to ensure the manufacturer follows industry-standard quality practices.

- Capabilities: Ensure the manufacturer can handle the size and complexity of the parts you need.

- Communication: Clear communication throughout the process is essential to ensure everything goes smoothly.

| Factor | Why It Matters | What to Look For |

|---|---|---|

| Experience | Experienced manufacturers are more reliable | Check their portfolio, client testimonials |

| Quality Control | Ensures the parts meet industry standards | ISO 9001 certification, quality assurance processes |

| Capabilities | Ability to handle the size and complexity of your parts | Ask about their equipment and production capacity |

| Communication | Prevents misunderstandings and delays | Ensure clear, frequent communication channels |

11. Die Casting vs Other Manufacturing Methods

Die casting is one of many methods available for producing metal parts, but how does it compare to other processes? What’s the bottom line? Die casting is most often compared to sand casting, forging, and injection molding.

So, which method should you choose?

- Sand casting is better for larger, low-volume parts but doesn’t offer the precision that die casting does.

- Forging is better suited for parts that need to withstand extreme stress, but it’s often more expensive and less flexible than die casting.

- Injection molding is typically used for plastics, but can also be used for metals. While it provides good precision, it’s not as effective for high-volume production as die casting aluminum.

| Method | Best Suited For | Advantages |

|---|---|---|

| Die Casting | High-precision, high-volume metal parts | Quick, cost-effective, high precision |

| Sand Casting | Large, low-volume parts | Good for simpler shapes, low-cost setup |

| Forging | Parts under extreme stress | High strength, ideal for tough, high-stress components |

| Injection Molding | Plastic and some metal parts | Good for precise, complex parts, quick production |

12. Trends in the Die Casting Aluminum Industry

The die casting industry is constantly evolving. What’s the latest trend? Innovations in aluminum alloys and die casting technology are making it easier to produce even more precise and durable parts. Additionally, there’s a growing focus on sustainability, with many manufacturers adopting more eco-friendly practices to reduce waste and energy consumption.

What’s the real story?

Advancements in robotics and automation are also changing the way die casting is done, leading to faster production times and reduced labor costs. In the coming years, we can expect further improvements in die casting techniques, making aluminum die casting even more cost-effective and environmentally friendly.

| Trend | Impact | Future Expectations |

|---|---|---|

| Robotics & Automation | Faster production, reduced labor costs | More efficient, precise manufacturing processes |

| Eco-friendly Practices | Reduced waste and energy consumption | More sustainable production methods |

| Alloy Innovations | New alloys lead to stronger, lighter parts | Even more durable and efficient die casting materials |

13. Future of Die Casting Aluminum: What to Expect

What does the future hold for aluminum die casting? The real kicker: Automation and AI are set to revolutionize the industry, making die casting even more efficient and precise. Expect new technologies to enhance quality control, improve production speeds, and lower costs.

Here’s the exciting part: As industries continue to demand more durable, lightweight parts, aluminum die casting will remain a key player in manufacturing, especially for high-demand sectors like automotive and aerospace.

| Future Trend | Potential Impact | Implications for Industry |

|---|---|---|

| Automation & AI | Streamline production, improve quality control | Increased efficiency, reduced human error |

| High-Demand Parts | Increased demand for lightweight, durable parts | Higher demand for aluminum die castings in various industries |

14. Cost Considerations in Die Casting Aluminum

Cost is always a factor in manufacturing, and aluminum die casting is no exception. What should you know? The initial investment in die casting equipment can be high, but the cost per unit decreases significantly with larger production runs. To ensure cost-efficiency, it’s important to balance material costs, tooling costs, and production volume.

What’s the deal? Factors like die design complexity, alloy selection, and the size of the production run will impact your overall cost. Understanding these elements upfront can help avoid unexpected expenses and ensure a successful die casting project.

| Cost Factor | Impact on Total Cost | How to Manage Costs |

|---|---|---|

| Material Costs | Price of aluminum alloys and other materials | Choose alloys based on project needs and budget |

| Tooling Costs | Initial die casting equipment setup | Invest in high-quality, durable dies for long-term savings |

| Production Volume | Larger volumes lead to lower per-unit cost | Focus on high-volume production for cost efficiency |

15. Conclusion: Key Takeaways on Die Casting Aluminum

Aluminum die casting is an efficient, cost-effective method for producing precise, durable parts. Here’s the bottom line: The benefits of using aluminum, such as its light weight, strength, and corrosion resistance, make it ideal for many industries. By understanding the die casting process, selecting the right aluminum alloy, and working with the right manufacturer, you can ensure high-quality results for your projects.

FAQ Section

Q1: What is die casting aluminum?

Die casting aluminum refers to the process of injecting molten aluminum into a mold to create durable, precise parts for various applications.

Q2: How does aluminum die casting work?

Aluminum die casting works by injecting molten aluminum into a metal mold under high pressure, where it cools and solidifies into the desired shape.

Q3: What are the benefits of aluminum die casting?

Aluminum die casting offers several benefits, including lightweight, high strength, corrosion resistance, and cost-effective production for large quantities.

Q4: What types of aluminum are used in die casting?

Common aluminum alloys used in die casting include A380, A383, and A360, each chosen based on their properties like strength and machinability.

Q5: How do you prevent defects in die casting aluminum?

To prevent defects like porosity or cold shuts, manufacturers must carefully control die temperature, alloy composition, and metal quality during the casting process.