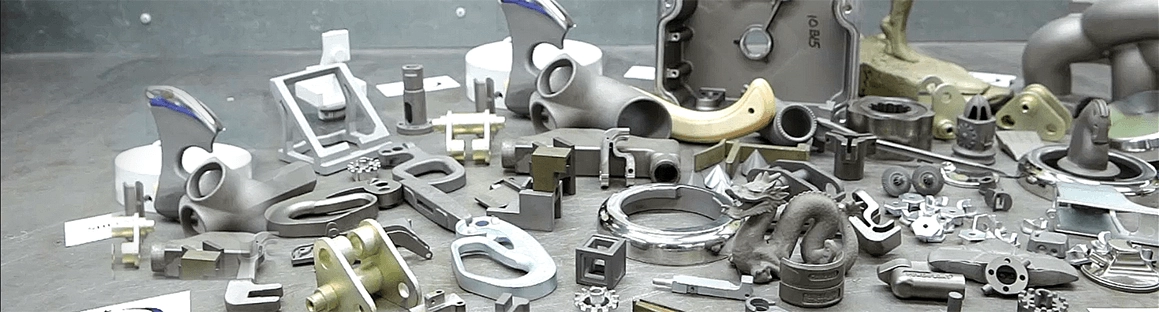

Product Overview: High-Performance Aggregate Industry Castings

At Precision Vast, we stand as a premier foundry-direct supplier of wear-resistant aggregate industry castings designed for the rigorous demands of the mining, earthmoving, and machinery sectors. With over 20 years of global experience, we balance “Cost Per Ton” reduction with “Maximum Uptime,” providing engineered solutions that meet or exceed standard OEM specifications.

We specialize in the investment casting (lost-wax) process and precision CNC machining to deliver high-strength components, including bucket teeth and critical wear parts. By controlling the entire lifecycle—from SLA rapid prototyping and CAE simulation to final heat treatment—we ensure every part withstands the harshest crushing and grinding environments.

Engineered for Durability and Precision

Our manufacturing approach focuses on solving “problem parts” through advanced metallurgy and strict quality control. We utilize high-grade Alloy Steels (including 42CrMo, 35CrMo, and AISI 4140) to maximize wear resistance and impact toughness.

Why choose our aggregate solutions?

- Factory Direct Efficiency: We eliminate dealer markups, offering direct access to our ISO9001 certified facility with an annual capacity of 700 tons.

- Custom Material Science: We accommodate unusual alloy requirements and customize material compositions to match specific operational needs.

- Rapid Response: We guarantee a detailed response to inquiries within 8 hours, ensuring your projects move forward without delay.

- Verified Quality: Every order includes comprehensive material testing reports, including X-ray, hardness testing, and Magnetic Particle Inspection (MPI).

Casting Solutions by Equipment Type

We engineer and manufacture high-performance aggregate industry castings designed to keep your operation running. By leveraging precision investment casting and advanced CNC machining, we deliver wear parts that meet the exacting standards of the mining and earthmoving sectors.

Cone Crusher Castings

Our facility produces heavy-duty components for cone crushers, including cone crusher mantles, bowl liners, torch rings, and feed cones. We utilize advanced CAE casting simulation to optimize chamber profiles, ensuring proper fitment and efficient material flow.

- Precision Fit: CNC machining ensures tight tolerances for seamless installation.

- Material Strength: We use high-grade alloy steels to withstand constant crushing pressure.

Jaw Crusher Castings

For primary crushing stages, we supply rugged jaw crusher plates, cheek plates, and wedge sets. Whether you need standard or corrugated profiles, our casting process allows for complex shapes that maximize rock-breaking efficiency.

- Alloy Expertise: We utilize robust grades like 42CrMo and AISI 4140 to resist cracking under heavy loads.

- Customization: We accommodate specific alloy requirements to tailor hardness for your specific application.

Impact Crusher (HSI/VSI) Castings

Our impact crusher hammers (blow bars) and impact plates are built to handle high-velocity impacts. We focus on balancing hardness and toughness through precise heat treatment and material selection. Understanding what are heat-resistant metals helps us select the right alloys that maintain structural integrity even when processing generates significant friction and heat.

- Wear Resistance: Engineered to reduce change-out frequency in high-abrasion environments.

- Quality Assurance: Every part undergoes rigorous NDT (Non-Destructive Testing) to prevent premature failure in the field.

Advanced Metallurgy and Material Science

In the aggregate sector, the lifespan of your equipment comes down to the science inside the metal. We don’t just pour metal; we engineer aggregate industry castings to withstand specific wear profiles, balancing hardness with toughness to keep your plant running. Our foundry leverages strict process controls to deliver abrasion resistant castings that meet exact chemical and physical property requirements.

Material Selection for Maximum Wear Life

We customize the metallurgy based on the rock hardness and crushing stage to maximize uptime.

- Manganese Steel Series: For high-impact applications like jaw and cone crushers, we utilize Hadfield steel grades. Whether you need Mn14% for standard duty, or Mn18% and Mn22% for extreme impact toughness, our work hardening alloys ensure the surface gets harder the more it gets hit, while the core remains ductile to prevent breakage.

- High Chrome White Iron: When abrasion is the main enemy—like in secondary or tertiary crushing—our high chrome solutions deliver exceptional hardness. These are ideal for high chrome blow bars where impact is managed, but sliding abrasion is severe.

- TIC / Ceramic Inserts (MMC): For the ultimate in wear life, we offer Metal Matrix Composites (MMC). By embedding ceramic columns into the casting, we create TIC insert castings that can last 2x–3x longer than standard mono-alloy parts. This proprietary technology combines the hardness of ceramic with the durability of steel.

Custom Alloy Engineering

One size rarely fits all in mining. We have the capability to adjust chemical compositions—tweaking elements like Molybdenum and Vanadium—to suit your specific geology. Just as we analyze how high-temperature alloys enhance performance in thermal environments, we apply that same metallurgical rigor to optimize wear resistance for your specific site conditions. From manganese steel liners to complex alloy steels like 42CrMo and 4140, we deliver the precise formulation your machinery requires.

OEM Brand Compatibility and Fitment Assurance

We know the biggest headache in sourcing aftermarket parts is the fear that they simply won’t fit when the crew tries to install them. At Precision Vast, we eliminate that risk. Our aggregate industry castings are manufactured to exacting standards, ensuring they drop right into your existing setup without modification. We don’t just guess at dimensions; we utilize advanced Coordinate Measuring Machines (CMM) to verify every tolerance before a single part ships.

Precision Engineering for Major Equipment

Whether you are running standard jaw crushers or complex cone crushers, our components serve as reliable OEM compatible crusher spares. We support operations running equipment from major global manufacturers, providing a cost-effective alternative to OEM pricing without sacrificing performance. Our team manages a vast library of specifications to ensure seamless cross-referencing for mining replacement parts.

Reverse Engineering and Custom Solutions

For older machinery where parts are obsolete, or for unique “problem parts” that wear out too fast, we offer comprehensive reverse engineering services. We don’t just copy a part; we optimize it.

- Design & Simulation: We utilize CAE casting simulation to predict performance and refine the design before production begins.

- Rapid Prototyping: By leveraging investment casting tooling and SLA (Stereolithography) printing, we can produce a physical prototype for fitment verification within days, not weeks.

- Material Customization: If a standard alloy isn’t holding up, we can adjust the metallurgical composition to handle your specific abrasion levels.

This approach ensures that even quarry machinery spares with lost documentation can be reproduced with modern metallurgical improvements, keeping your plant running at maximum efficiency.

Manufacturing Excellence and Quality Assurance

At Precision Vast, we control the entire production lifecycle to deliver reliable aggregate industry castings. Our process begins with advanced CAE casting simulation and ERP management, allowing us to optimize mold designs and eliminate potential defects before production starts. We specialize in precision investment casting (lost-wax) and CNC machining, ensuring that even complex shapes meet exacting standards without the need for extensive secondary work.

To guarantee performance in high-wear mining environments, we apply rigorous heat treatment protocols to optimize the metallurgical properties of our alloy steels. Quality is not an afterthought; it is embedded in every step. We provide comprehensive material testing reports with every order to validate that your parts can withstand the demands of the job site.

Quality Control (QC) Checklist

Our ISO9001-certified facility utilizes a multi-stage inspection process to ensure every component meets your specifications:

- Chemical Analysis: We use spectrometer testing to verify the exact composition of alloys, ensuring materials like carbon steel castings and 42CrMo meet strict industry grades.

- Internal Integrity: We conduct X-ray testing and Magnetic Particle Inspection (MPI) to identify and eliminate internal flaws or surface cracks.

- Dimensional Precision: Our team utilizes CMM (Coordinate Measuring Machines) to verify tolerances on intricate geometries.

- Hardness Verification: We perform hardness testing to ensure optimal wear resistance and impact toughness for heavy-duty applications.

Why Source Directly from Precision Vast?

Sourcing aggregate industry castings directly from the foundry is the most effective way to protect your bottom line without sacrificing quality. We operate as a true one-stop solution, managing the entire lifecycle of your wear parts—from the initial design and simulation to the final delivery.

Factory Direct Pricing

By eliminating the middleman, we provide significant cost advantages. Our factory-direct model removes the layers of dealer markups, often resulting in 20-40% savings for our customers. You pay for the metallurgical quality and precision engineering of your foundry direct wear parts, not for a distributor’s overhead. We focus on cost-efficiency through precise tolerances that reduce the need for extensive secondary machining.

Streamlined Global Logistics

We understand that timely delivery is critical for mining and aggregate operations. We handle the complexities of international shipping so you don’t have to.

- Door-to-Door Service: We offer DDP (Delivered Duty Paid) and DAP shipping terms, managing customs clearance and inland freight to get parts directly to your facility.

- Rapid Response: We guarantee a detailed response to all inquiries within 8 hours, ensuring your supply chain moves fast.

Production and Quality Control

We don’t just pour metal; we deliver finished, ready-to-install components. Our facility handles everything from heat treatment to specialized investment casting surface treatments that enhance corrosion and wear resistance. With an annual capacity of 700 tons and strict ISO9001 quality management, we ensure that your mining replacement parts meet exacting standards every time.

Frequently Asked Questions (FAQ)

Improving Wear Life for Aggregate Parts

Can you improve the wear life of my current blow bars?

Yes. We specialize in engineering solutions for “problem parts” that wear out too quickly in harsh aggregate environments. Our team utilizes CAE casting simulation and deep metallurgical expertise to optimize component longevity. By understanding how to analyze physical properties of heat-resistant alloys, we can adjust chemical compositions—such as modifying 42CrMo or high-chrome alloys—to withstand specific impact and abrasion levels better than standard off-the-shelf parts.

Minimum Order Quantity (MOQ) Policies

Do you have a minimum order quantity (MOQ) for custom castings?

We offer high flexibility compared to traditional foundries. Since we handle the entire lifecycle from design to finishing, we can accommodate varying project sizes. We utilize SLA (Stereolithography) 3D printing for rapid prototyping, allowing us to produce single test units before committing to volume production. This ensures you get the exact aggregate industry castings you need without being locked into massive initial orders.

Identifying Parts Without Numbers

How do I identify the correct part number using nameplates or on-site measurement?

If the OEM nameplate is unreadable or the part number is missing, we can still help. We provide reverse engineering services using advanced CMM (Coordinate Measuring Machine) technology. Simply send us the worn sample or detailed on-site measurements. We will generate precise 3D models and verify tolerances to ensure the replacement part fits your crusher or earthmoving equipment perfectly. We guarantee a detailed response to your inquiry within 8 hours.