Aluminum die casting is one of the most widely used manufacturing processes, particularly in industries where lightweight, high-precision parts are critical. This article will delve into the aluminum die casting process, how it works, its applications, and its significance across various industries. Whether you’re an OEM, manufacturer, or supplier, understanding this process can give you an edge when selecting casting methods for your projects.

1. What Is Aluminum Die Casting?

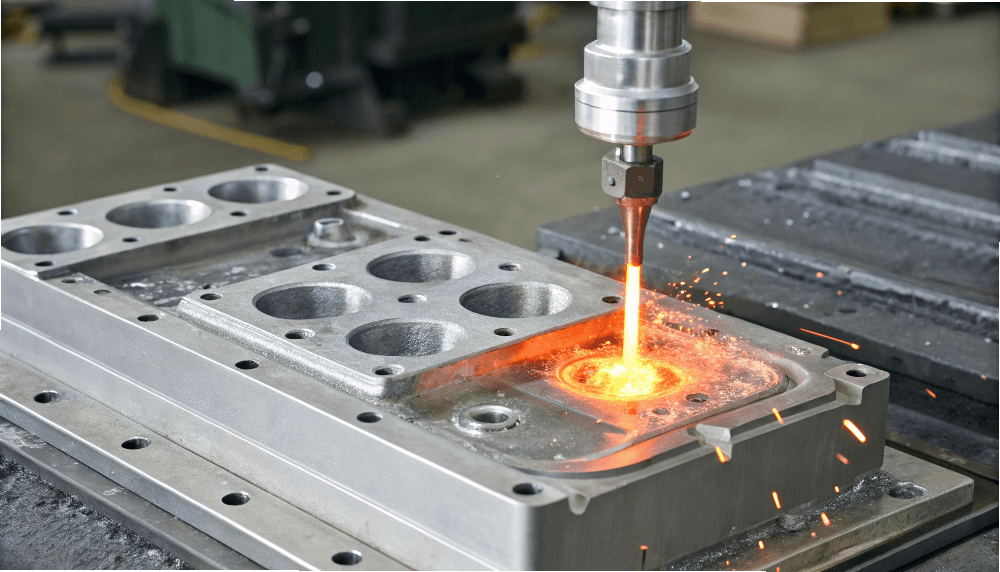

Aluminum die casting is a manufacturing process where molten aluminum is injected into a mold under high pressure to produce intricate parts with high precision. This process is commonly used for making parts in industries like automotive, aerospace, and electronics. What’s the real story? Die casting offers significant advantages, such as the ability to create highly complex shapes, reduce waste, and produce parts quickly.

The process begins with the preparation of the aluminum alloy, which is melted in a furnace. Once molten, the aluminum is injected into a steel mold, or die, using a powerful injection system. The mold is then cooled, and the solidified part is ejected. The pressure applied ensures that the aluminum fills all cavities of the mold, providing excellent detail and uniformity.

What’s the kicker? Aluminum die casting offers unmatched versatility, producing parts that are both strong and lightweight. This makes it ideal for applications where strength-to-weight ratios are critical. From engine blocks to structural components, aluminum die casting is an essential process in today’s manufacturing landscape.

| Step | Process Description |

|---|---|

| 1 | Melting aluminum alloy in a furnace |

| 2 | Injecting molten aluminum into the die under high pressure |

| 3 | Cooling the aluminum inside the die |

| 4 | Ejecting the solidified part from the die |

2. How Does the Aluminum Die Casting Process Work?

Ready for the good part? The aluminum die casting process is divided into several key stages, each crucial for producing high-quality components. The first step involves melting aluminum alloy. The alloy is then injected under high pressure into a die, where it cools and solidifies into the desired shape. Here’s where it gets interesting—aluminum die casting can be done using two primary methods: cold chamber and hot chamber die casting.

In the cold chamber method, the aluminum is melted outside the machine and then transferred into a chamber where it’s injected into the die. This method is used for alloys with higher melting points. On the other hand, in hot chamber die casting, the aluminum is melted in the injection chamber itself, making it ideal for alloys with lower melting points.

What’s the takeaway here? Understanding the differences between cold and hot chamber die casting allows manufacturers to choose the right method based on the alloy and application. This process ensures that parts are produced with consistent quality, minimizing defects like porosity or surface blemishes.

| Method | Description | Suitable Alloys |

|---|---|---|

| Cold Chamber | Aluminum melted outside and transferred to the chamber for injection | High-melting point alloys |

| Hot Chamber | Aluminum melted in the injection chamber itself | Low-melting point alloys |

3. What Are the Benefits of Using Aluminum Die Casting?

But here’s the kicker—aluminum die casting offers numerous benefits, especially for high-volume production. One of the key advantages is its cost-effectiveness. Since the process is highly automated, manufacturers can produce large quantities of parts quickly and at a lower cost compared to other methods like sand casting or forging.

Another significant benefit is precision. Aluminum die casting can produce parts with tight tolerances, reducing the need for secondary machining. This saves both time and money. The ability to create complex shapes also allows designers more flexibility in their product development, giving them the freedom to innovate without worrying about manufacturing constraints.

What else should you know? Aluminum die casting is also incredibly efficient in terms of material usage. The high pressure ensures that the molten metal fills the entire mold, reducing waste and maximizing material utilization. The strength and durability of the final product make it suitable for industries like automotive, where safety and performance are paramount.

| Benefit | Description |

|---|---|

| Cost-effective | Lower production costs due to automation |

| Precision | Produces tight tolerances, reducing secondary machining |

| Efficiency | High material utilization, reducing waste |

4. What Types of Products Are Made Using Aluminum Die Casting?

Ready for more examples? Aluminum die casting is used to manufacture a wide range of products across various industries. In the automotive sector, die-cast aluminum parts are commonly found in engine blocks, transmission housings, and structural components. These parts need to be lightweight, strong, and durable, which aluminum die casting excels at providing.

In electronics, die-cast aluminum enclosures are used for everything from smartphones to computer components. The lightweight yet sturdy nature of aluminum makes it the perfect material for protecting sensitive electronics while maintaining portability.

What else is worth noting? Aluminum die casting is also essential in aerospace, where components like turbine housings and valve bodies need to withstand high stress and extreme temperatures. The ability to create complex shapes and maintain high strength makes aluminum die casting a go-to method in these critical applications.

| Industry | Example Products |

|---|---|

| Automotive | Engine blocks, transmission housings, structural parts |

| Electronics | Enclosures for smartphones, laptops, computers |

| Aerospace | Turbine housings, valve bodies |

5. What Are the Different Aluminum Alloys Used in Die Casting?

But here’s the twist: the type of aluminum alloy used in die casting can significantly affect the final product’s performance. Different alloys have distinct properties that make them suitable for various applications. For example, alloy 380 is often used in the automotive industry due to its excellent castability and strength. It’s ideal for making parts like engine blocks and transmission cases.

Another commonly used alloy is 413, which offers higher strength and thermal conductivity. This makes it suitable for applications in electronics and aerospace, where heat resistance and performance under high temperatures are essential.

What’s the bottom line here? Selecting the right alloy for die casting is crucial. The alloy must match the application requirements in terms of strength, durability, and thermal conductivity. The correct alloy choice ensures that the final product meets both performance and aesthetic standards.

| Alloy | Properties | Common Applications |

|---|---|---|

| 380 | Excellent castability, strength | Automotive parts like engine blocks |

| 413 | Higher strength, thermal conductivity | Electronics, aerospace |

6. How Does Aluminum Die Casting Compare to Other Methods?

Here’s the comparison you’ve been waiting for! While aluminum die casting is highly efficient, it’s important to understand how it stacks up against other casting methods. For instance, compared to sand casting, die casting offers higher precision and faster production times. Sand casting, while versatile, is slower and results in less detailed parts.

When compared to investment casting, aluminum die casting is more cost-effective for high-volume production. Investment casting, though highly precise, can be expensive due to its slower production speed and complex mold-making process.

What’s the real takeaway? Aluminum die casting stands out when it comes to producing large quantities of parts with complex shapes and tight tolerances. For industries looking to scale production while maintaining quality, aluminum die casting is the method of choice.

| Method | Comparison to Die Casting | Advantages |

|---|---|---|

| Sand Casting | Slower, less precise | Versatile, low cost for low volumes |

| Investment Casting | More precise, slower | Highly detailed, but more expensive |

7. What Are the Key Challenges in the Aluminum Die Casting Process?

Now, let’s dig into the challenges. Despite its advantages, aluminum die casting is not without its difficulties. One of the most common issues is porosity, which can affect the strength and durability of the final product. Porosity occurs when gas bubbles are trapped in the molten metal, causing weak spots in the casting.

Another challenge is temperature control. The aluminum needs to be heated to the right temperature before being injected into the mold, and maintaining this temperature is critical for ensuring quality. Any fluctuation can result in defects.

What’s the kicker here? While these challenges may seem daunting, they are manageable with the right techniques and technology. Monitoring and controlling the die casting process at every step can help minimize defects, ensuring high-quality products.

| Challenge | Solution | Impact |

|---|---|---|

| Porosity | Improved mold design, gas venting | Ensures strong, defect-free parts |

| Temperature Control | Automated systems for monitoring | Prevents defects and ensures quality |

8. How Can the Aluminum Die Casting Process Be Optimized?

Ready for the good part? Optimizing the aluminum die casting process involves a combination of advanced techniques and modern technologies. Automation plays a significant role in improving efficiency and reducing human error. Robots and automated systems can monitor and control various aspects of the process, such as temperature and pressure, ensuring consistency and quality.

Additionally, improvements in mold design and material selection can help reduce defects and enhance the performance of the final product. New alloys and coatings are being developed to improve die life and reduce wear, further enhancing the efficiency of the die casting process.

What else is important? Automation and innovation are key to staying competitive in the die casting industry. By embracing new technologies and refining existing processes, manufacturers can continue to improve quality while reducing production costs.

| Optimization Method | Benefit | Impact |

|---|---|---|

| Automation | Improved efficiency, reduced errors | Faster production and consistent quality |

| Material Improvements | Enhanced die life, reduced wear | Increased process reliability |

9. How Do You Ensure High-Quality Aluminum Die Castings?

What’s the real story when it comes to quality? Ensuring high-quality aluminum die castings involves a comprehensive approach to the process. First and foremost, mold design is critical. A well-designed mold ensures that the molten aluminum fills all cavities without causing defects like porosity or cold shuts.

Another essential factor is temperature control. The molten aluminum must be at the right temperature to ensure that it flows smoothly into the mold. If the temperature is too high or too low, the casting will be compromised.

What’s the kicker here? Quality control isn’t just about monitoring the process—it’s also about testing the final product. Post-casting inspections, including X-ray analysis and pressure testing, can help detect hidden defects and ensure that the product meets industry standards.

| Quality Control Method | Description | Importance |

|---|---|---|

| Mold Design | Proper design ensures smooth casting | Reduces defects like porosity |

| Temperature Control | Monitoring molten aluminum temperature | Ensures proper filling and quality |

| Post-Casting Inspections | X-ray analysis, pressure testing | Detects hidden defects and ensures standards |

10. What Are the Environmental Impact and Sustainability of Aluminum Die Casting?

This is where it gets interesting—aluminum die casting is relatively environmentally friendly compared to other manufacturing processes. Aluminum is 100% recyclable, and die castings can often be made from recycled materials, reducing the overall environmental impact. Additionally, the process is highly efficient, which reduces waste and energy consumption.

Aluminum die casting also offers an eco-friendly advantage in industries like automotive, where lightweight components help reduce fuel consumption. As manufacturers look for more sustainable solutions, aluminum die casting is becoming an increasingly popular choice.

What’s the takeaway here? With a focus on recycling and waste reduction, aluminum die casting presents a sustainable solution for industries looking to reduce their carbon footprint while maintaining high performance.

| Environmental Impact | Benefit | Industry |

|---|---|---|

| Recycling | Reduced material waste, sustainable | Automotive, Aerospace |

| Energy Efficiency | Reduced energy consumption | Electronics, Automotive |

11. How Much Does Aluminum Die Casting Cost?

Let’s talk numbers—understanding the cost of aluminum die casting is crucial for manufacturers considering this process. The cost is influenced by several factors, including mold complexity, material selection, and production volume. Typically, aluminum die casting is more cost-effective for high-volume production runs due to its efficiency and minimal waste.

What’s the real story? For low-volume production, die casting can be more expensive due to the upfront costs of tooling and setup. However, as production volumes increase, the cost per part decreases significantly, making it an ideal option for large-scale manufacturing.

What should you know here? While the initial investment may be high, the long-term savings and efficiency of aluminum die casting make it an attractive option for many industries.

| Cost Factor | Impact | Considerations |

|---|---|---|

| Tooling | High initial cost | Long-term savings for high volumes |

| Production Volume | Cost per part decreases | Ideal for large-scale production |

12. What Are the Key Trends Shaping the Future of Aluminum Die Casting?

Ready to dive into the future? The aluminum die casting industry is evolving rapidly, with new technologies and techniques transforming the way parts are produced. One of the biggest trends is the adoption of 3D printing for mold making. This technology allows for faster, more cost-effective production of molds, reducing lead times and improving efficiency.

Additionally, the development of new alloys and coatings is improving the performance of aluminum die castings, allowing them to withstand higher stresses and temperatures. These innovations are opening up new opportunities in industries like aerospace and electronics.

What’s the takeaway here? The future of aluminum die casting looks bright, with advancements in technology and material science driving innovation and expanding the possibilities for manufacturers.

| Trend | Description | Impact |

|---|---|---|

| 3D Printing | Faster mold production | Reduced lead time, lower cost |

| New Alloys & Coatings | Enhanced die casting performance | Improved strength and thermal resistance |

13. How Do You Choose the Right Aluminum Die Casting Supplier?

When it comes to choosing the right supplier, experience and technical capabilities are key. A reliable aluminum die casting supplier should have a proven track record of delivering high-quality parts on time and within budget. It’s important to look for a supplier that offers comprehensive services, from design assistance to post-production support.

What’s the kicker here? The best suppliers will also offer flexibility in terms of order volumes and be able to scale production to meet your needs. Be sure to ask for references and review case studies to ensure they have experience in your specific industry.

What should you remember? Selecting the right partner is crucial for ensuring the success of your aluminum die casting projects. Look for a supplier who can meet your technical, quality, and logistical requirements.

| Supplier Criteria | Importance | What to Look For |

|---|---|---|

| Experience | Proven track record | Case studies, references |

| Flexibility | Ability to scale production | Adaptability to order volume |

14. What Is the Lead Time for Aluminum Die Casting?

What’s the deal with lead times? The lead time for aluminum die casting can vary depending on several factors, including mold complexity and production volume. Typically, die casting takes anywhere from a few days to a few weeks. However, lead times can be shortened with proper planning and efficient production processes.

What’s the real story? High-volume orders typically have shorter lead times, as the production process becomes more efficient with larger quantities. For smaller runs, the lead time may be longer due to the time required for mold creation and setup.

What’s the bottom line? Managing lead time effectively is essential to ensuring timely delivery of your parts. Work closely with your supplier to set realistic timelines and avoid delays.

| Factor | Impact on Lead Time | Consideration |

|---|---|---|

| Mold Complexity | Increases lead time | Simplify mold design for faster production |

| Production Volume | Larger orders reduce lead time | High-volume runs lead to faster completion |

15. How Does Aluminum Die Casting Contribute to Product Innovation?

But here’s the twist—aluminum die casting plays a significant role in driving innovation across many industries. The precision and versatility of the process allow engineers and designers to create new products that were previously impossible to manufacture. This opens up opportunities for innovation in automotive, aerospace, electronics, and beyond.

What’s the takeaway here? By using aluminum die casting, companies can bring new and innovative products to market faster, while maintaining high standards of quality and performance. The ability to create complex parts with high precision has made aluminum die casting a cornerstone of modern product development.

| Industry | Innovation Example | Benefit |

|---|---|---|

| Automotive | Lightweight engine parts | Improved fuel efficiency |

| Aerospace | High-strength turbine housings | Enhanced performance under stress |

FAQ Section

Q1: What is aluminum die casting?

Aluminum die casting is a manufacturing process where molten aluminum is injected into a mold under high pressure, producing intricate and durable parts used in various industries.

Q2: How does the aluminum die casting process work?

The process involves melting aluminum, injecting it under high pressure into a mold, and cooling it to form precise parts with tight tolerances and complex shapes.

Q3: What are the benefits of aluminum die casting?

Benefits include cost-effectiveness for high-volume production, the ability to produce complex shapes, reduced material waste, and precise, high-quality parts.

Q4: What industries use aluminum die casting?

Industries such as automotive, aerospace, electronics, and industrial machinery frequently use aluminum die casting for parts like engine blocks, enclosures, and structural components.

Q5: How much does aluminum die casting cost?

The cost varies depending on factors like mold complexity and production volume. However, it becomes more cost-effective as production volume increases.