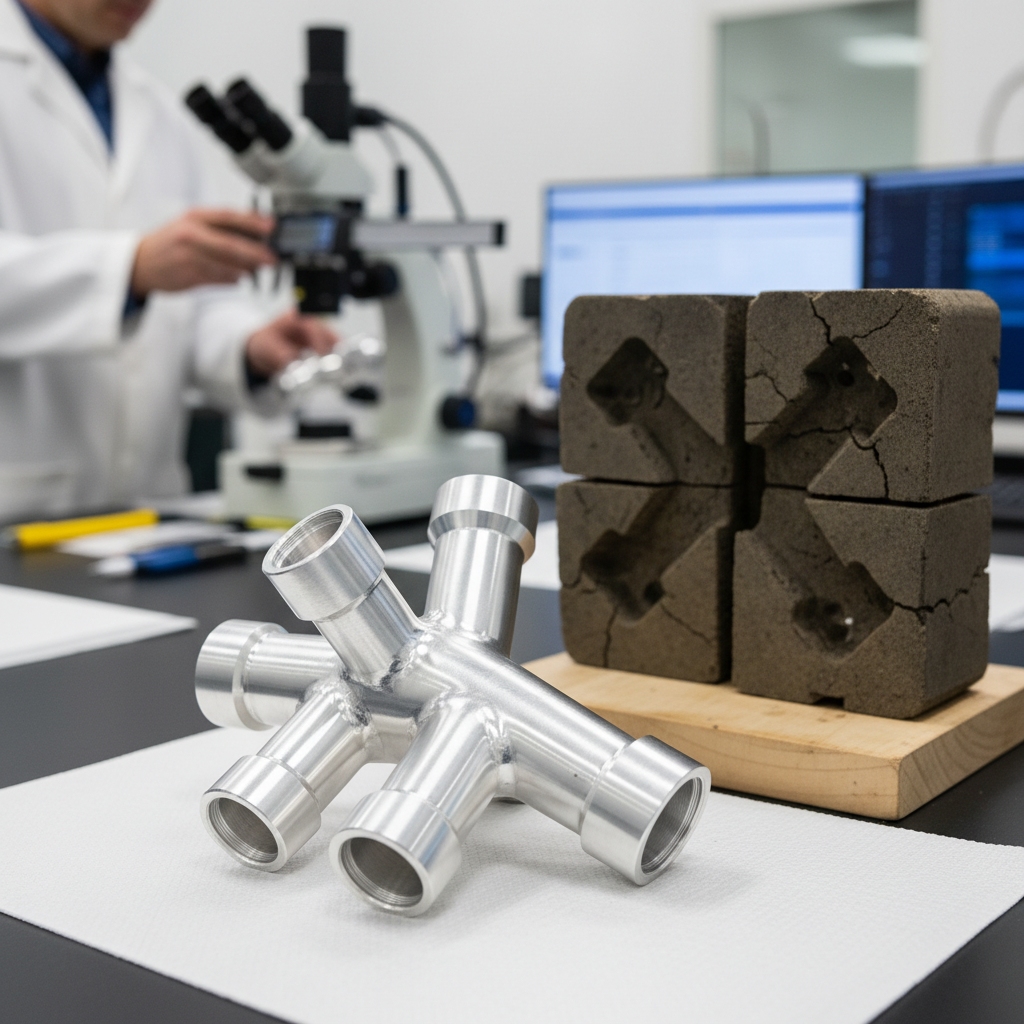

Precision metal parts often demand high-cost tooling or expensive machining hours, creating a significant barrier for prototypes and short production runs. Choosing the wrong method for plaster casting aluminum components leads to poor surface finishes found in sand casting or the exorbitant setup costs of die casting that can kill your budget before you even start. Plaster casting offers the perfect middle ground, delivering aluminum casting parts with die-cast quality surfaces and low tooling costs ideal for complex geometries. Leveraging decades of metallurgical expertise, this guide breaks down exactly how to utilize this “simulated die casting” process for your manufacturing needs.

1. What Is a Plaster Casting and How Is It Defined?

Plaster casting is a specialized manufacturing process where a gypsum-based slurry serves as the molding material to produce near-net-shape metal components. Here’s the deal: unlike sand casting which uses granular aggregates, plaster casting utilizes a fine-grain plaster mixture that replicates the master pattern with incredible fidelity, earning it the nickname “simulated die casting.” It is specifically designed for non-ferrous metals like aluminum, zinc, and copper, as the mold material cannot withstand the high melting points of ferrous materials like steel.

This technique bridges the critical gap between investment casting and sand casting, offering a cost-effective solution for low-to-medium volume production. You gain the ability to cast thin walls and intricate details that would be impossible with coarser molding media.

Key Takeaway

The primary value of plaster casting lies in its ability to produce die-cast quality parts without the five-figure investment in steel tooling.

| Feature | Plaster Casting | Sand Casting | Die Casting | |

|---|---|---|---|---|

| Surface Finish | Excellent (0.8-1.25 µm) | Rough (6-12 µm) | Excellent (0.4-0.8 µm) | |

| Tooling Cost | Low | Low | Very High | |

| Detail Capability | High | Low/Medium | High | |

| Production Volume | Low-Medium | Low-High | High |

Analysis: Plaster casting is the optimal manufacturing choice when surface finish and detail are paramount, but production volumes do not justify the amortization of permanent tooling.

2. How Does the Plaster Casting Process Work Step-by-Step?

The process begins with the creation of a master pattern, typically machined from brass, aluminum, or created via CNC machining plastics, which is then coated with a parting compound. You might be wondering how the mold forms; a slurry of gypsum, strengthening agents, and water is poured over the pattern and vibrated to release air bubbles. Once the plaster sets, the pattern is removed, and the mold undergoes a critical “burnout” phase to remove all moisture before the molten metal is poured.

Vacuum assistance is often employed during the pouring phase to draw the aluminum into the thinnest sections of the mold. After the metal solidifies, the plaster is mechanically broken away to reveal the part, which then moves to finishing.

Key Takeaway

Moisture control during the mold curing phase is the single most critical variable in preventing porosity and steam defects in the final casting.

| Step | Action | Critical Factor | |

|---|---|---|---|

| 1. Pattern | Create master | Surface finish determines final quality. | |

| 2. Molding | Pour plaster slurry | Vibration is essential to remove air. | |

| 3. Burnout | Bake mold | Must be 100% moisture-free. | |

| 4. Casting | Pour Aluminum | Vacuum assist helps fill thin walls (1mm). |

Analysis: The success of the process relies heavily on the permeability of the plaster mix to allow gases to escape while maintaining enough density to replicate fine details.

3. What Are the Primary Uses of Plaster Casting?

Industries that require lightweight, complex geometries with high strength-to-weight ratios, such as aerospace and defense, rely heavily on this method. But here’s the kicker: it is also the standard for manufacturing complex waveguides, electronic chassis, and impellers where air-flow efficiency depends on surface smoothness. Robotics manufacturers utilize it for prototyping arms and joints that must function exactly like production parts.

In the medical field, it is used for non-implantable device housings that require an aesthetic, cleanable surface without extensive post-processing. The process allows for the consolidation of multiple parts into a single cast unit, reducing assembly time.

Key Takeaway

Plaster casting is indispensable for applications where part complexity is high but production volumes are too low for die casting.

| Industry | Application Examples | Why Plaster Casting? | |

|---|---|---|---|

| Aerospace | Impellers, Gearboxes | Thin walls, weight reduction. | |

| Robotics | Arms, Joints | Complex geometry, prototyping. | |

| Medical | Device Housings | Aesthetic finish, precision fit. | |

| Electronics | Heat Sinks | Thermal conductivity, fin detail. |

Analysis: This method dominates in sectors where the cost of secondary machining outweighs the higher per-unit cost of the casting process itself.

4. How Do You Create a Reliable Plaster Mold?

The mold mixture is not standard wall plaster; it is a specific blend of gypsum (plaster of Paris), talc, silica flour, and controlled water ratios. So, what’s the catch? The mold must be permeable enough to let gases escape during the pour, often achieved by using the “Antioch process” or adding foaming agents to the mix. The slurry is poured over the pattern in a flask, allowed to set, and then baked at high temperatures to drive off chemically combined water.

Using investment casting techniques, one can also use lost-wax patterns in plaster, but the reusable split-pattern method is more common for this specific variation. The mold surface must be flawless, as the plaster captures every scratch or imperfection on the master pattern.

Key Takeaway

The permeability of the mold is the deciding factor in preventing back-pressure that causes incomplete fills or “blowholes” in the aluminum.

| Mold Property | Purpose | Impact on Aluminum | |

|---|---|---|---|

| Permeability | Gas escape | Prevents porosity defects. | |

| Thermal Cond. | Slow cooling | Allows filling of very thin sections. | |

| Collapsibility | Easy removal | Prevents hot tearing of the metal. | |

| Strength | Hold shape | Maintains dimensional accuracy. |

Analysis: The low thermal conductivity of the plaster mold keeps the aluminum molten longer than sand molds, enabling the casting of incredibly thin features.

5. What Are the Best Metals and Alloys for Plaster Casting?

Aluminum alloys are the most common choice for plaster casting due to their relatively low melting points and excellent fluidity. Basically, the “Goldilocks” zone for plaster involves metals that melt below 1,200°C, making aluminum, zinc, and copper alloys the primary candidates. Specifically, aluminum alloys A356 and 319 are industry workhorses because they respond well to heat treatment and offer high pressure-tightness.

Magnesium is also cast using this method, though it requires special inhibitors in the plaster mix to prevent reaction. The process is not suitable for ferrous metals like steel because the high heat would destroy the gypsum mold structure instantly.

Key Takeaway

Aluminum A356 is the preferred alloy for this process, offering the best balance of fluidity for filling molds and mechanical strength after casting.

| Alloy | Characteristics | Typical Use | |

|---|---|---|---|

| A356 | Pressure tight, corrosion resistant | Pump bodies, aerospace. | |

| C355 | Higher strength | Structural brackets. | |

| 319 | Excellent machinability | Engine components. | |

| Yellow Brass | High detail, decorative | Hardware, fittings. |

Analysis: Material selection is strictly limited by the thermal degradation point of the gypsum binder, effectively ruling out high-temperature superalloys.

6. What Are the Major Advantages of Plaster Casting?

The most significant advantage is the ability to achieve near-net-shape components with surface finishes ranging from 63 to 125 RMS. Here is the bottom line: you can cast walls as thin as 0.025 inches (0.6 mm), which is virtually impossible with standard sand casting. This precision significantly reduces the need for surface treatments and machining, saving time and money in the finishing phase.

Additionally, the process imparts minimal residual stress on the parts because the plaster yields slightly as the metal shrinks. This results in dimensionally stable parts that maintain their tolerances (typically ± 0.005 inches per inch) over time.

Key Takeaway

The primary Return on Investment (ROI) for plaster casting comes from the elimination of expensive secondary machining and finishing operations.

| Advantage | Specification | Benefit | |

|---|---|---|---|

| Tolerance | ± 0.005″ per inch | Reduces CNC machining time. | |

| Wall Thickness | Down to 0.060″ (1.5mm) | Lightweighting designs. | |

| Surface Finish | 63 RMS typical | Aesthetic appeal, less polishing. | |

| Draft Angles | Minimal (1-2°) | Closer to final geometry. |

Analysis: While the casting cycle is slower, the reduction in post-processing labor makes it highly competitive for complex parts.

7. What Are the Disadvantages or Limitations of the Process?

The insulating properties of plaster cause the metal to cool very slowly, which can lead to a coarser grain structure and slightly lower mechanical properties compared to permanent mold casting. It turns out that this slow cooling cycle also extends production times, making the process ill-suited for high-volume manufacturing. Furthermore, the gypsum molds are non-reusable and must be destroyed to remove the part, adding to the per-unit cost.

Size is another limitation; plaster molds are relatively fragile and cannot support the weight of massive castings. Generally, parts are limited to under 30-40kg to ensure the mold integrity is maintained during the pour.

Key Takeaway

Engineers must accept a trade-off between the superior surface finish of plaster casting and the slightly reduced tensile strength caused by slow solidification.

| Limitation | Cause | Consequence | |

|---|---|---|---|

| Cycle Time | Slow cooling | Lower production throughput. | |

| Durability | Plaster is brittle | Limited casting size/weight. | |

| Cost | Non-reusable mold | High piece price for large volumes. | |

| Material | Thermal limit | Ferrous metals are excluded. |

Analysis: Use chills (metal inserts) within the plaster mold to increase cooling rates in critical areas and mitigate grain structure issues.

8. How Does Plaster Casting Compare to Sand Casting?

While both are expendable mold processes, they serve different ends of the precision spectrum. Here’s the interesting part: sand casting is faster and cheaper for simple, heavy parts, but plaster casting is the clear winner when tolerances are tight and surface cosmetics matter. If your part requires stainless steel casting , you must use sand or investment casting, as plaster cannot handle the heat.

Plaster casting allows for thinner cross-sections and sharper details, such as lettering or logos, which would wash out in a sand mold. However, sand casting has virtually no size limit and allows for rapid cooling, which is better for certain metallurgical properties.

Key Takeaway

Choose plaster casting when the cost of machining a sand casting to spec exceeds the higher initial cost of the plaster process.

| Feature | Aluminum Plaster Cast | Aluminum Sand Cast | |

|---|---|---|---|

| Min Wall Thickness | 0.060″ | 0.150″ | |

| Linear Tolerance | ± 0.005″ | ± 0.030″ | |

| Lead Time | 2-4 Weeks | 1-2 Weeks | |

| Surface Texture | Smooth / Matte | Rough / Granular |

Analysis: Plaster casting effectively renders the concept of “machining from solid” obsolete for complex aluminum prototypes.

9. What Factors Influence Plaster Casting Costs?

The cost structure is driven primarily by the complexity of the pattern and the labor intensity of the molding process. Think about it: creating the mold, vacuuming the slurry, baking it for days, and careful demolding requires skilled manual labor that cannot be easily automated. Complex cores required for hollow parts also increase the price, as they must be precisely located and secured.

However, because the process uses a rubber or epoxy split pattern (or even 3D printed masters), the initial tooling cost is significantly lower than cutting a steel die. This makes it economically viable for runs of 10 to 1,000 parts.

Key Takeaway

Plaster casting is a high-labor, low-capital process, positioning it as the most cost-effective solution for bridge production before hard tooling.

| Cost Driver | Impact Level | Optimization Tip | |

|---|---|---|---|

| Labor | High | Automate mixing/pouring if possible. | |

| Pattern | Medium | Use 3D printed masters for prototypes. | |

| Scrap Rate | Low/Medium | Ensure proper mold venting. | |

| Finishing | Low | Near-net shape reduces this cost. |

Analysis: While the piece-price is higher than die casting, the total program cost is lower for low volumes due to the elimination of expensive NRE (Non-Recurring Engineering) charges.

10. How Can You Optimize Design for Plaster Casting?

Design For Manufacturability (DFM) in plaster casting focuses on uniform wall thickness to promote even cooling. What’s the secret? Because plaster insulates, thick sections stay liquid longer; if they are isolated from feed paths, shrinkage porosity will occur. Designers should incorporate generous radii and fillets to reduce stress concentrations, although plaster allows for sharper corners than sand casting.

Draft angles can be kept minimal, often around 1 degree, which helps in maintaining parallel surfaces for casting heat treatment fixtures later in the process. It is also best to utilize raised lettering rather than sunken lettering, as it is easier to machine into the master pattern.

Key Takeaway

Designing for thermal management is more critical in plaster casting than any other method due to the insulating nature of the mold material.

| Design Feature | Guideline | Reason | |

|---|---|---|---|

| Draft Angle | 0.5° – 2° | Easy pattern release. | |

| Fillets | R 0.060″ min | Reduce stress concentrations. | |

| Lettering | Raised | Cheaper to machine into the pattern. | |

| Wall Uniformity | Essential | Prevents isolated shrinkage. |

Analysis: A well-designed plaster cast part should require machining only on mating surfaces and threaded holes.

Conclusion

Plaster casting aluminum acts as the unsung hero of the prototype and short-run manufacturing world, effectively bridging the vast divide between the roughness of sand casting and the high capital cost of die casting. By utilizing this process, manufacturers gain access to aerospace-grade precision, thin walls, and superior surface finishes without breaking the bank on hard tooling.

As 3D printing technologies advance, the synergy between printed wax or PMMA patterns and plaster molding will only tighten, allowing for even more complex aluminum geometries delivered in days, not weeks. Don’t let high tooling costs stall your innovation; if you need precision aluminum parts but aren’t ready for die casting volume, Contact Us Today to see how precision casting can streamline your production.

Frequently Asked Questions (FAQ)

1. Can I use 3D printed parts as patterns for plaster casting?Yes, this is a standard practice known as “Quick Cast.” It eliminates the need for a metal master pattern, significantly speeding up the prototyping phase for complex aluminum geometries by burning out the printed polymer pattern during the mold heating cycle.

2. What is the best aluminum alloy for plaster casting?A356 (or 356) is the most widely used alloy. It offers the best balance of fluidity to fill the mold’s intricate details, excellent corrosion resistance, and high mechanical strength after T6 heat treatment.

3. Can I cast large structural parts using this method?Generally, no. Plaster molds are brittle, and the slow cooling rate of large masses leads to coarse grain structures, which reduces structural integrity; it is best to limit parts to under 30kg.

4. Is plaster casting cheaper than CNC machining?It depends on volume and complexity; for a single simple part, CNC is cheaper. However, for 10-500 complex parts, plaster casting is significantly cheaper because it removes the need to machine away massive amounts of material and reduces programming time.

5. Why is the cooling time so long in plaster casting?Plaster is a thermal insulator, meaning it retains heat rather than conducting it away like sand or steel. While this helps the metal fill thin walls without freezing prematurely, it extends the solidification time, requiring patience during the production cycle.