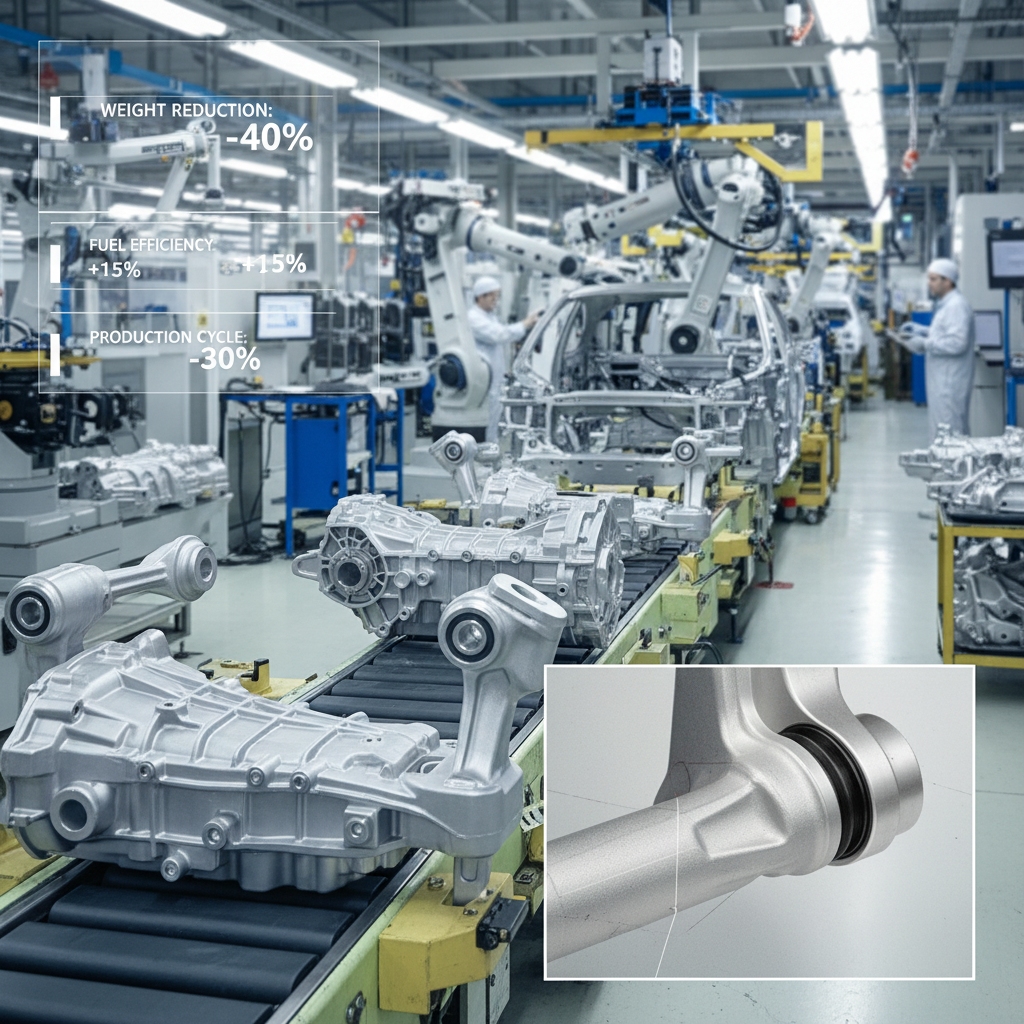

Manufacturers frequently encounter critical failures and soaring logistical costs when relying on heavy, outdated ferrous components that simply cannot meet modern efficiency standards. Component breakdown leads to expensive downtime, ruined product batches, and damaged reputations that take years to rebuild. Here is the deal: Ignoring weight-reduction trends leads to fuel inefficiencies, sluggish machinery performance, and lost contracts in competitive sectors like automotive and aerospace. Implementing the correct manufacturing strategy using advanced aluminum casting material ensures superior strength-to-weight ratios and long-term operational reliability. With decades of metallurgical data analyzing industrial outputs, we provide the technical roadmap for precision fabrication to transform your production capabilities. You can explore our specialized aluminum casting manufacturing process to understand how we mitigate these risks.

1. What Defines Industrial Aluminum Casting Material Processes?

Industrial aluminum casting material processes involve introducing molten aluminum alloys into a pre-designed mold cavity to create net-shape or near-net-shape components. This transformation allows for the creation of intricate parts that would be impossible or prohibitively expensive to machine from solid blocks. The core mechanism begins with melting raw ingots to specific liquid temperatures, ensuring the metal reaches the precise viscosity required for flow. Once molten, the material is injected or poured into permanent steel dies or sacrificial sand molds, depending on the required volume and tolerance. Controlled solidification follows, which is the most critical phase for establishing the grain structure and mechanical properties of the final part.

Historically, this technology has evolved from ancient copper casting to the sophisticated aluminum alloys we see today. The shift from iron to aluminum in the mid-20th century marked a turning point, driven by the need for lighter, more fuel-efficient vehicles and aircraft. Modern techniques now incorporate advanced pressure controls and vacuum systems to eliminate porosity. You might be wondering how this impacts today’s production speeds. The ability to produce net-shape components significantly reduces secondary machining requirements, conserves raw material inputs, and facilitates faster turnaround times for high-volume orders. Understanding the fundamental transformation of aluminum casting material from liquid to solid is the first step in optimizing your production line for efficiency and complexity.

The Casting Lifecycle

| Stage | Description | Key Benefit | |

|---|---|---|---|

| Preparation | Pattern and mold creation | Determines final accuracy and tolerance | |

| Pouring | Introducing molten alloy | Fills complex voids and thin walls | |

| Solidification | Cooling and crystallizing | Sets mechanical properties and grain structure | |

| Finishing | Trimming and treating | Ensures surface quality and final dimensions |

2. Why Choose Aluminum Casting Material for Modern Manufacturing?

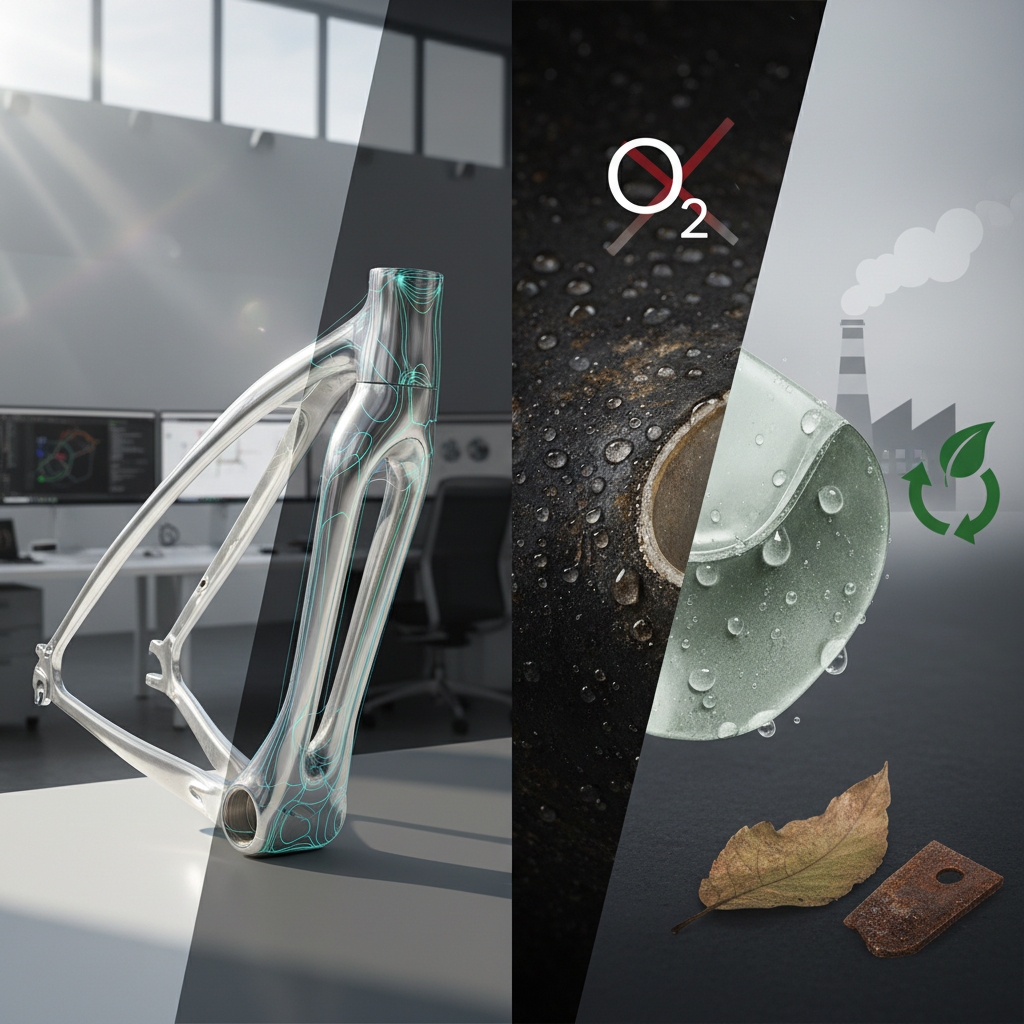

You should choose aluminum casting material because it offers an unparalleled balance of low density, high corrosion resistance, and excellent thermal conductivity. These properties make it the definitive solution for industries striving to reduce weight without sacrificing structural rigidity. When compared to cast iron or steel, aluminum offers a density of approximately 2.7 g/cm³, which is roughly one-third that of ferrous counterparts. This massive reduction in mass translates directly to performance gains. In the automotive sector, lighter components mean significant fuel savings and reduced emissions. For aerospace applications, it increases payload capacity, allowing for more efficient transport of goods and passengers.

Beyond weight, the thermal advantages are substantial. Aluminum casting material dissipates heat rapidly, making it the ideal choice for electronic enclosures, heat sinks, and engine components that operate under high thermal stress. This prevents hotspots in complex assemblies and extends the lifespan of sensitive electronics. But here is the kicker: lighter parts often reduce shipping costs significantly. When you calculate the logistics of moving thousands of units, the weight difference between steel and aluminum can save substantial capital in freight charges. Furthermore, the material contributes to green manufacturing initiatives. Aluminum is highly recyclable, requiring only a fraction of the energy to remelt compared to primary production, thereby reducing the overall carbon footprint of the manufacturing lifecycle.

Material Comparison

| Property | Aluminum Casting Material | Cast Iron | |

|---|---|---|---|

| Density | Low (~2.7 g/cm³) | High (~7.2 g/cm³) | |

| Corrosion Resistance | Excellent (Self-passivating) | Poor (Prone to rust) | |

| Conductivity | High (Thermal/Electrical) | Low | |

| Machinability | Fast and Easy | Slow and abrasive |

3. Which Properties Make Aluminum Casting Material So Versatile?

The versatility of aluminum casting material stems from its adaptability through alloying, where elements like silicon, copper, and magnesium are added to tailor properties like tensile strength and fluidity. This allows engineers to specify exact material behaviors for distinct environments. For instance, silicon is frequently added to improve the fluidity of the molten metal, making it easier to fill intricate molds without voids. Copper is utilized to enhance hardness and high-temperature strength, although it can slightly reduce corrosion resistance. Magnesium is the key additive for improving ductility and corrosion resistance in marine environments. By mixing these elements in precise ratios, manufacturers can create an alloy that perfectly matches the mechanical requirements of the application.

We adhere to certified quality management standards to ensuring these alloy compositions are exact. The stiffness-to-weight ratio is another critical factor. Aluminum matches the rigidity of heavier metals at a fraction of the mass, which is vital for structural frames and brackets that must remain static under load. What is the real story behind choosing the right alloy series? It is about understanding the trade-offs. A 3xx series alloy might be perfect for a complex die-cast housing, while a 5xx series is better suited for a structural bracket exposed to seawater. The natural formation of a protective oxide layer further enhances its utility, reducing the need for expensive surface platings and ensuring long-term durability in outdoor infrastructure.

Common Alloy Properties

| Alloy Series | Primary Additive | Best Use Case | |

|---|---|---|---|

| 3xx (e.g., A380) | Silicon/Copper | General Die Casting, Engine Parts | |

| 4xx | Silicon | High Fluidity / Thin Walled Parts | |

| 5xx | Magnesium | Corrosion Resistance / Marine | |

| 7xx | Zinc | High Strength Structural Components |

4. How Does Die Casting Utilize Aluminum Casting Material Efficiently?

Die casting utilizes aluminum casting material by forcing it under high pressure into reusable steel molds, creating parts with exceptional surface finishes and dimensional consistency. This method is the industry standard for high-volume production runs where speed and uniformity are non-negotiable. The process typically involves injection pressures of up to 30,000 psi, which ensures that the molten metal fills every microscopic crevice of the die. This capability allows for the production of parts with extremely thin walls and complex details that other methods cannot achieve. Because the steel dies act as a heat sink, the aluminum cools rapidly, resulting in a fine grain structure that improves the mechanical properties of the part.

This method is most cost-effective for production runs exceeding thousands of units because the high initial cost of the steel tooling is amortized over a large volume of parts. Ready for the good part? Die casting minimizes post-processing needs. The parts emerge from the mold with excellent surface finishes (typically 32-63 RMS) and tight tolerances (±0.002 inches), often eliminating the need for extensive machining. However, there are limitations. The high capital investment for tooling can be a barrier for low-volume projects, and the process can trap gas within the metal, leading to porosity if venting is not managed correctly. Despite these challenges, for mass production, die casting remains the most efficient way to convert raw aluminum casting material into finished goods.

Die Casting Metrics

| Metric | Value/Description | |

|---|---|---|

| Production Speed | Very High (60+ parts/hour) | |

| Surface Finish | Excellent (32-63 RMS) | |

| Wall Thickness | Can go as thin as 0.5mm | |

| Tooling Cost | High (requires hardened steel) |

5. When Is Investment Casting the Right Aluminum Casting Material Choice?

Investment casting is the right choice for aluminum casting material when you require complex internal geometries, thin walls, and superior surface finishes that die casting cannot achieve. It creates near-perfect replicas using a sacrificial wax pattern, ideal for aerospace and medical applications. The process, often called lost-wax casting, begins with the creation of a precise wax pattern which is then coated in a ceramic slurry to form a shell. Once the shell hardens, the wax is melted out, leaving a perfect negative cavity. Molten aluminum is then poured into this ceramic shell. This is where it gets interesting: The ceramic shell is broken away to reveal the part, allowing for undercuts and intricate features that would physically lock a permanent metal mold.

This method prioritizes accuracy over speed. It eliminates the need for draft angles, which are required in die casting to eject the part from the mold. This allows for the creation of components with straight walls and complex internal channels. You can achieve exceptional dimensional accuracy with investment casting for parts like turbine blades, surgical instruments, and intricate defense components. While the per-unit cost is higher due to the labor-intensive nature of the process, the reduction in secondary machining often balances the expense. Industries that rely on this method value the geometric freedom and the ability to produce a smoother surface finish straight out of the mold.

Investment vs. Die Casting

| Feature | Investment Casting | Die Casting | |

|---|---|---|---|

| Complexity | Very High (Undercuts allowed) | Medium (Draft required) | |

| Tooling Cost | Low to Medium | High | |

| Part Cost | High | Low | |

| Surface Finish | Superior | Good |

6. Why Use Sand Casting for Large Aluminum Casting Material Parts?

Sand casting is the preferred method for processing aluminum casting material when parts are physically large, production volumes are low, or tooling budgets are restricted. It offers the flexibility to cast massive engine blocks or unique prototypes using economical sand molds. The process utilizes a mold made from compacted sand mixed with a binding agent. Patterns, which create the cavity in the sand, can be made from wood, plastic, or metal. This adaptability makes sand casting the most versatile process regarding size capability; it can accommodate parts weighing from a few ounces to several tons. Here is the bottom line: It is the dominant choice when the sheer scale of the component rules out other methods.

For low-volume runs or prototyping, sand casting is unbeatable. The tooling costs are a fraction of those required for die casting, and patterns can be modified relatively easily if design changes are needed. This allows engineers to test and refine designs without incurring massive sunk costs. However, the trade-off lies in the finish and precision. Sand cast parts generally have a rougher surface texture (250-500 RMS) and lower dimensional accuracy compared to die casting. Consequently, they usually require higher machining allowances to achieve the final mating dimensions. Despite this, for structural parts hidden from view or massive industrial components, sand casting remains the most viable and economic solution.

Sand Casting Capability

| Attribute | Rating/Value | |

|---|---|---|

| Max Part Weight | Unlimited (Tons) | |

| Tooling Cost | Low | |

| Lead Time | Short | |

| Surface Roughness | High (250-500 RMS) |

7. What Alternative Methods Shape Aluminum Casting Material?

Beyond the primary three, methods like Lost Foam, Permanent Mold, and Centrifugal casting offer niche solutions for shaping aluminum casting material. These specialized techniques address specific needs, such as internal coring, directional strength, or rotational symmetry. Permanent Mold casting, for example, uses gravity to fill reusable steel molds. Unlike high-pressure die casting, the metal flows in gently, which reduces turbulence and trapped gas. This results in a part with better structural integrity and strength than sand casting, thanks to the faster cooling rate provided by the metal mold. It turns out this creates a perfect middle ground between the low cost of sand casting and the high speed of die casting.

Lost Foam casting offers a unique advantage for complex geometries like engine heads. A foam pattern is buried in sand, and the molten aluminum vaporizes the foam as it enters, taking its shape exactly. This eliminates parting lines and allows for the assembly of multiple foam parts into one complex casting, simplifying the final product. Centrifugal casting takes a different approach by spinning the mold at high speeds. The centripetal force pushes the molten aluminum to the outer walls, creating dense, defect-free cylindrical parts like pipes and bearings. Impurities, which are lighter, are forced to the center and can be machined away, resulting in exceptional purity and mechanical strength.

Alternative Process Matrix

| Process | Key Strength | Typical Application | |

|---|---|---|---|

| Permanent Mold | Strength & Finish | Wheels, Pistons | |

| Lost Foam | Complex Geometry | Cylinder Heads | |

| Centrifugal | Density & Purity | Pipes, Rings | |

| Shell Mold | Surface Precision | Gear Housings |

8. Where Will You Find Aluminum Casting Material in Industry?

You will find aluminum casting material permeating every sector of the global economy, from the engine block in your vehicle to the casing of your laptop. Its ubiquity is driven by the universal need for lightweight, durable, and thermally conductive components. In the automotive industry, it is the cornerstone of fuel efficiency and electric vehicle range extension. Engine blocks, transmission cases, suspension components, and wheels rely on alloys like A380 and 319 to reduce vehicle mass without compromising safety. Think about it: Every kilogram saved in the chassis allows for a heavier battery pack or greater range in an electric vehicle.

The medical sector also leans heavily on these materials. Precision housings for MRI and X-ray machines require materials that are lightweight yet rigid enough to maintain calibration. Furthermore, aluminum’s non-magnetic properties are essential in these magnetic environments. In aerospace, the stakes are even higher. Aluminum casting material is used for structural nodes, brackets, and instrumentation housings where high strength-to-weight ratios are non-negotiable. Even in the consumer market, power tools and appliances utilize cast aluminum for its durability and heat dissipation, ensuring that handheld devices remain cool and manageable during operation. If you have a project in any of these sectors, you should reach out to our professional team to discuss manufacturability.

Industry Applications

| Sector | Component Examples | Key Property Utilized | |

|---|---|---|---|

| Automotive | Pistons, Housings | Heat Dissipation/Weight | |

| Aerospace | Brackets, Fixtures | Strength-to-Weight | |

| Energy | Turbine accessories | Corrosion Resistance | |

| Consumer | Power tools | Durability/Handling |

9. How Durable Are Components Made From Aluminum Casting Material?

Components manufactured from aluminum casting material are exceptionally durable, capable of lasting decades under cyclic loads when properly designed and treated. While they do not act as bearing surfaces due to softness compared to steel, their resistance to environmental degradation and fatigue makes them reliable for long-term service. Durability is often enhanced through heat treatment processes, such as T6, which involves solubilizing and aging the alloy. This significantly increases hardness and tensile strength, relieving internal stresses that may have formed during the casting process. Let’s face it: Raw castings rarely meet high-performance specs without this critical post-processing step.

Environmental resilience is another pillar of aluminum’s durability. Upon exposure to oxygen, aluminum naturally forms a thin, microscopic oxide layer that seals the metal and prevents deep rust. This self-healing mechanism makes it suitable for outdoor and marine exposures where ferrous metals would rapidly deteriorate. However, engineers must account for fatigue limitations. Unlike steel, aluminum has no defined fatigue limit, meaning it will eventually fail under cyclic loading if the stress is high enough. Therefore, design strategies such as increasing wall thickness in high-stress areas and ensuring zero porosity are vital to preventing crack initiation and extending the component’s service life.

Durability Factors

| Factor | Effect on Aluminum | Mitigation Strategy | |

|---|---|---|---|

| Oxidation | Surface protection | Anodizing/Coating | |

| High Heat | Softening over time | Heat Treatment (T6) | |

| Cyclic Load | Fatigue cracking | Over-engineering/Design | |

| Abrasion | Surface wear | Inserts or Coatings |

10. How Do You Optimize Costs With Aluminum Casting Material?

You optimize costs with aluminum casting material by balancing tooling investments against production volume and designing for manufacturability (DFM). Smart design choices, such as uniform wall thickness and draft angles, dramatically reduce waste and cycle times. The relationship between volume and process selection is the primary cost driver. For low volumes (under 100 units), sand or plaster casting is economical because the tooling is cheap. For mid-volumes, permanent mold is appropriate. However, once you exceed 5,000 units, the high cost of die casting tooling is justified by the incredibly low per-part price. Why does this matter? Mismatched processes destroy profit margins; using sand casting for 10,000 parts would be prohibitively slow and expensive in finishing costs.

Design changes can also yield massive savings. Coring out thick sections not only saves material weight but also prevents shrinkage defects, reducing the scrap rate. Adding ribs provides necessary stiffness without the cost of solid mass. Standardizing tolerances to be as loose as functionally possible reduces expensive machining time. Furthermore, the economic benefit of recycling cannot be overstated. Aluminum casting material is 100% recyclable with high scrap value. Re-melting runners, gates, and rejected parts reduces raw material purchase costs and lowers the energy bill, as re-melting requires only 5% of the energy needed to produce primary aluminum.

Cost Optimization Levers

| Lever | Action | Result | |

|---|---|---|---|

| Volume | Match process to quantity | Amortized tooling cost | |

| Design | Uniform walls / Ribs | Reduced material usage | |

| Tolerances | As loose as possible | Reduced machining | |

| Alloy | Standard vs. Custom | Lower raw material cost |

Conclusion

To dominate in today’s competitive industrial landscape, manufacturers must prioritize materials that offer agility, strength, and efficiency. Aluminum casting material provides the perfect synergy of lightweight performance and geometric versatility, solving the dual problems of rising fuel costs and complex assembly requirements. Whether you need high-volume automotive parts or intricate aerospace components, selecting the right casting process is the pivot point for success.

At Precisionvast, we envision a future where precision engineering removes the barriers to innovation. We are dedicated to providing top-tier manufacturing services that transform your blueprints into tangible, high-performance realities. If you are ready to optimize your production line with superior alloy solutions, consider us your precision manufacturing partner to discuss your project requirements today.

Frequently Asked Questions

Q1: Can I weld parts made from aluminum casting material?Yes, but it requires careful alloy selection. While many casting alloys like 3xx series are difficult to weld due to gas porosity and silicon content, specialized alloys and post-casting treatments can make welding feasible for assembly or repair.

Q2: What is the best aluminum casting material for high strength?The “best” alloy depends on the specific stress type, but A356 (treated to T6) and certain 7xx series alloys are generally superior. They offer excellent tensile strength and elongation, making them the go-to choices for structural automotive and aerospace applications.

Q3: Is aluminum casting material expensive compared to steel?It is generally more expensive per pound than steel, but cheaper per unit of volume due to low density. Furthermore, the ability to cast net shapes reduces expensive machining time and tooling wear, often making the total finished part cost competitive or lower.

Q4: What is the difference between cast and forged aluminum?Forging produces a stronger part, but casting offers greater design freedom. Forging aligns the grain structure for maximum toughness but is limited to simple shapes, whereas casting allows for complex internal cavities and intricate details that forging cannot replicate.

Q5: Does aluminum casting material rust?No, it does not rust like iron, but it can corrode. Aluminum naturally forms a thin, protective oxide layer that prevents deep oxidation. In harsh marine or chemical environments, anodizing or powder coating is recommended to enhance this natural protection.