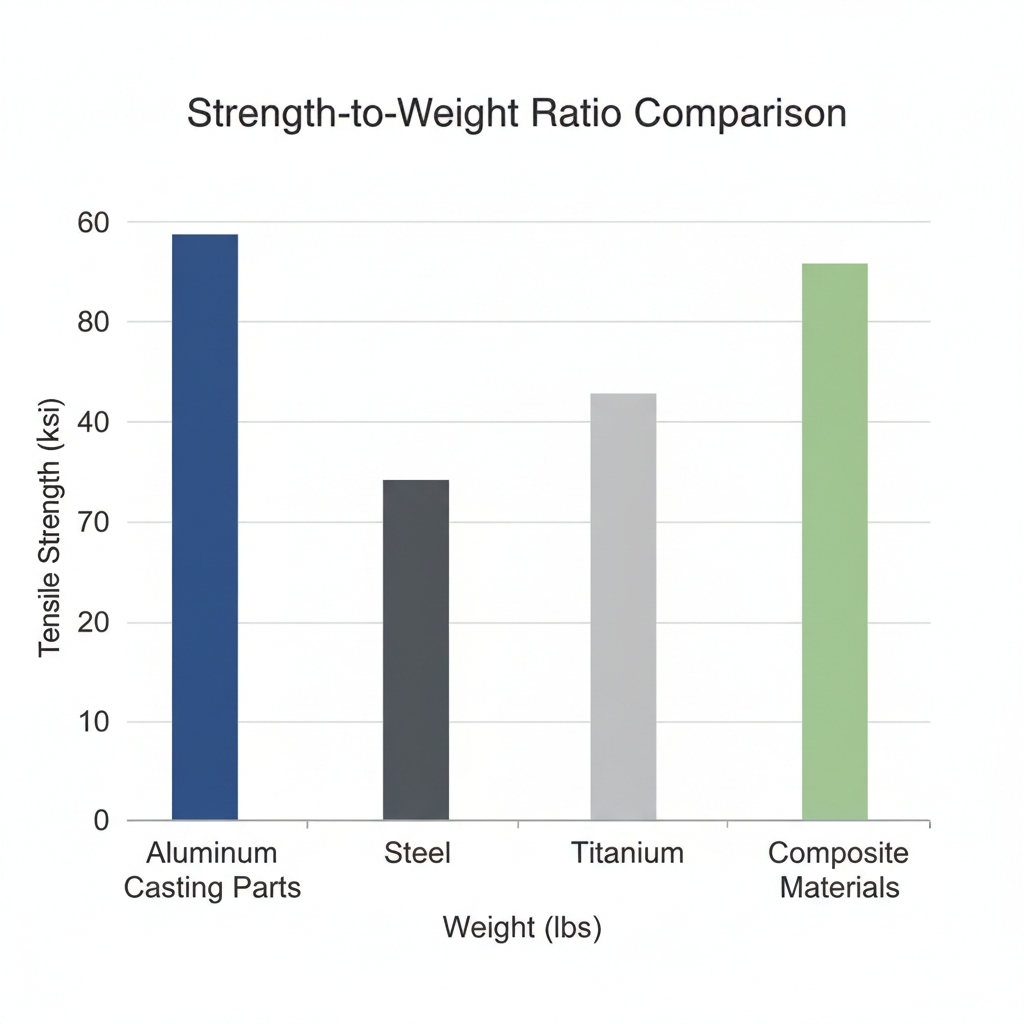

Sourcing components that perfectly balance lightweight properties with extreme structural integrity remains a constant challenge for engineers and procurement managers across the manufacturing sector. Selecting an inadequate manufacturing method frequently leads to heavy, inefficient parts or, worse, component failure under mechanical stress, resulting in expensive recalls and operational downtime. To resolve these structural challenges, precision aluminum casting parts offer the ideal resolution, delivering complex geometries with superior strength-to-weight ratios that other methods cannot match. With decades of metallurgical expertise, we provide the reliability and consistency your supply chain demands for high-performance applications.

1. What Is Precision Aluminum Casting?

Precision aluminum casting is a sophisticated manufacturing process that forces molten aluminum into high-tolerance molds to create complex, near-net-shape components. We define precision aluminum casting parts as components requiring minimal machining due to the high accuracy of the initial cast. Engineers favor this technique because it allows for the creation of intricate internal channels and thin walls that would be impossible or cost-prohibitive to achieve through machining from a solid block. Here is the deal… the ability to replicate exact specifications thousands of times makes this process indispensable for modern mass production.

How Does the Process Work?

A workflow begins with precise melting and preparation of specific aluminum alloys, ensuring a chemical composition meets strict standards. Once molten, metal is injected or poured into precision-engineered molds. Understanding the step-by-step casting process —from wax injection to shell building—is crucial for engineers looking to maximize design efficiency. After metal fills a cavity, controlled cooling phases solidify the component before ejection. This sequence guarantees that final products maintain intended geometric integrity and mechanical properties.

Distinct Casting Methods

Manufacturers employ several distinct methods depending on volume and complexity. High-Pressure Die Casting (HPDC) forces metal into steel molds at high speed, making it perfect for high-volume runs. Investment Casting, or lost wax, utilizes ceramic shells to capture incredible detail for lower volumes or highly complex shapes. Permanent Mold Casting uses gravity for filling reusable metal molds, offering a middle ground between speed and tooling cost.

Key Characteristics

Primary characteristics setting this method apart include exceptional dimensional stability and smooth surface finishes right out of a mold. Parts often emerge with tolerances so tight that secondary processing is negligible. Furthermore, capability forming thin walls allows for significant weight savings without compromising structural rigidity. Efficiency in material usage translates directly into cost savings plus performance improvements within final assemblies.

| Characteristic | Description | Benefit | |

|---|---|---|---|

| Dimensional Stability | Maintains shape under stress | Reduces assembly errors | |

| Surface Finish | Smooth, typically 32-63 Ra | Less polishing required | |

| Thin Wall Capability | Walls as thin as 0.060″ | Material savings & lighter weight | |

| Near-Net Shape | close to final dimensions | Lowers machining costs |

2. Why Choose Aluminum for Critical Parts?

Aluminum is selected for critical applications because it offers an exceptional strength-to-weight ratio that steel and iron simply cannot compete with in many modern contexts. When you specify precision aluminum casting parts, you are prioritizing efficiency without sacrificing durability or performance. A material supports heavy loads while reducing overall mass of an assembly, which acts as a primary goal in sectors ranging from transportation to robotics. You might be wondering… how much difference does this weight reduction actually make?

Weight Reduction Benefits

In automotive applications, every ounce saved contributes to improved fuel efficiency and lower emissions. For electric vehicles, lighter components directly extend battery range. Beyond vehicles, reduced weight lowers shipping and handling costs for logistics operations and makes installation easier for end-users. A lighter assembly also means less wear and tear on supporting structures, extending life for an entire system.

Thermal Conductivity

Aluminum possesses outstanding heat dissipation properties, acting as a natural heat sink. This makes it ideal for electronic enclosures, LED lighting fixtures, and engine components where temperature management is critical. Preventing overheating ensures that sensitive electronics or mechanical systems operate within their optimal temperature ranges, thereby preventing premature failure. Steel or plastic alternatives often trap heat, leading to performance throttling.

Electrical Advantages

Beyond thermal management, aluminum offers good electrical conductivity, making it a cost-effective alternative to copper in certain applications. It also provides excellent EMI/RFI shielding capabilities, protecting sensitive circuits from electromagnetic interference. Dual capability conducting electricity while shielding against interference makes cast aluminum housings a standard in telecommunications plus computer hardware.

3. How Does Casting Ensure Durability?

Casting processes ensure durability by creating a uniform grain structure that distributes stress loads evenly across an entire component. Durable precision aluminum casting parts resist fatigue better than welded assemblies because they are formed as a single, monolithic unit. Joints, welds, and fasteners introduce stress concentrators where cracks often initiate; casting eliminates these weak points entirely. But here is the kicker… material properties can be further enhanced through heat treatment.

Unified Structure

A cast part eliminates weak points typically found in welded joints or bolted assemblies. By forming components as one piece, engineers achieve consistent material properties throughout a part’s geometry. This unified structure proves far superior at resisting mechanical shock and vibration, which eventually rattle multi-piece assemblies apart. Homogeneity within cast metal ensures that there are no hidden discontinuities causing catastrophic failure under load.

Corrosion Resistance

Aluminum naturally forms a thin, protective oxide layer immediately upon exposure to air. This self-healing barrier shields parts from further oxidation, making them highly suitable for outdoor, marine, and industrial environments. Unlike steel, which requires constant painting or galvanizing preventing rust, aluminum maintains structural integrity with minimal maintenance, ensuring a longer lifecycle for products.

Temperature Resilience

Cast aluminum maintains its dimensional integrity even in fluctuating temperatures. It resists warping under thermal stress, a common issue with plastic components or dissimilar metal assemblies. Resilience makes it suitable for high-heat engine environments or freezing high-altitude aerospace applications. Material expands and contracts predictably, allowing engineers designing with confidence regarding thermal fits plus clearances.

4. Which Industries Need Precision Parts?

Industries requiring strict adherence to safety, performance, and weight specifications, such as aerospace and automotive, rely heavily on precision casting technologies. These sectors demand precision aluminum casting parts to meet rigorous regulatory standards and aggressive performance metrics. Failure in these fields can be catastrophic, meaning reliability of a casting process is non-negotiable. It gets better… versatility allows casting to serve diverse needs across medical and energy sectors as well.

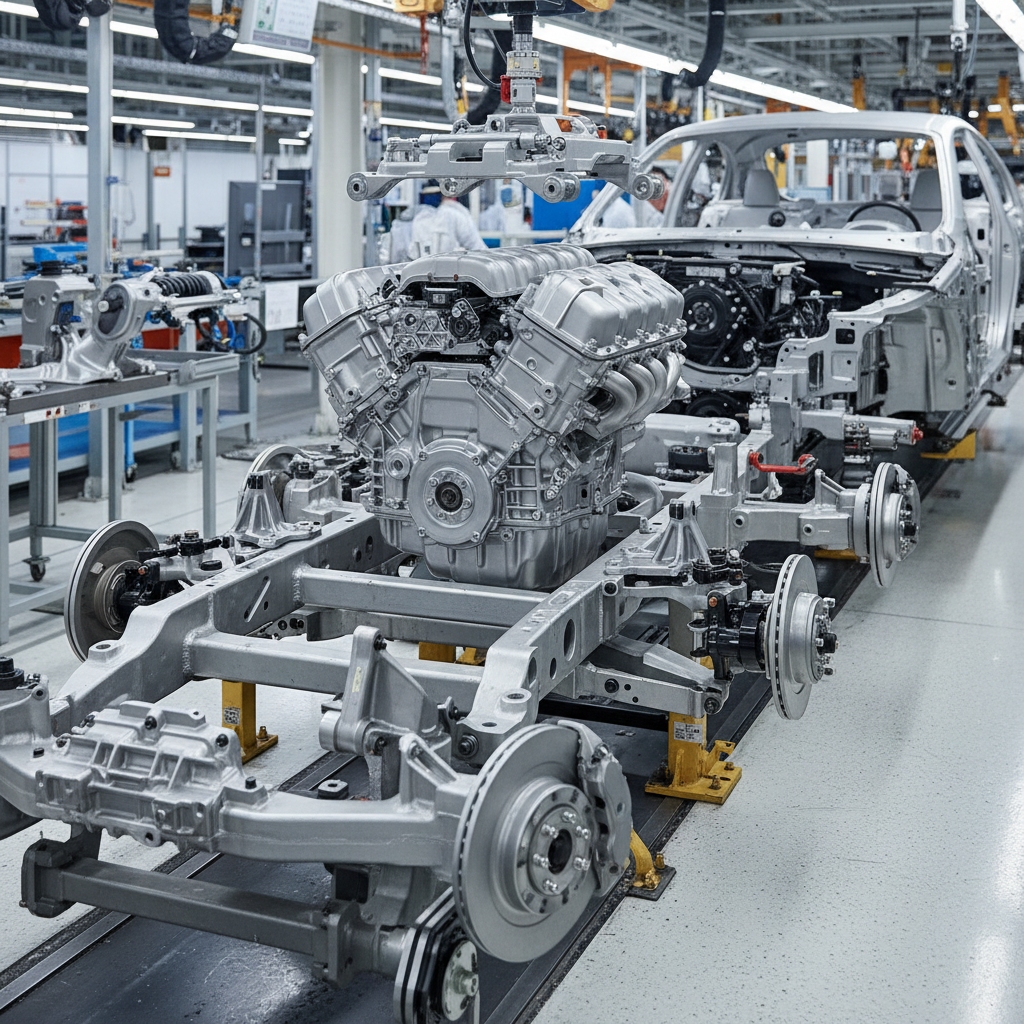

Automotive Sector

Automotive manufacturers utilize casting for everything from engine blocks and transmission cases to structural nodes. Suspension components are frequently cast to reduce unsprung weight, improving vehicle handling and ride comfort. With a rise of electric vehicles, complex battery housings and motor mounts are increasingly cast from aluminum to offset heavy weight from battery packs, maximizing range plus efficiency.

Aerospace Applications

In aerospace, weight represents an enemy of flight. Cabin interior components, seat frames, and instrument casings are cast to shave off grams that add up to significant fuel savings over life of an aircraft. Wing structure brackets and fuel system components also benefit from high strength-to-weight ratio. Ability casting complex aerodynamic shapes reduces drag while improving overall efficiency for an airframe.

Medical Equipment

Medical fields demand precision and hygiene. Handheld diagnostic devices utilize aluminum castings for their lightweight and ergonomic feel. Prosthetic components require strength from metal but must be light enough for daily wear. Furthermore, imaging equipment housings, such as those for MRI or X-ray machines, rely on aluminum’s shielding properties plus structural rigidity protecting sensitive sensors.

| Industry | Typical Component | Primary Benefit | |

|---|---|---|---|

| Automotive | Engine Block | Thermal management & weight reduction | |

| Aerospace | Seat Frame | Fuel efficiency through weight savings | |

| Medical | MRI Housing | EMI Shielding & Structural rigidity | |

| Energy | Turbine Blade | Complex geometry & durability |

5. How Do Alloys Impact Part Performance?

Alloy choice dictates final mechanical properties, including hardness, ductility, and machinability of a cast part. Selecting a right alloy is the first step in engineering successful precision aluminum casting parts that meet specific operational requirements. Different blends of aluminum with silicon, copper, or magnesium yield vastly different results. What is the real story? “Best” alloy is always dependent on application, not just material cost.

A356 Aluminum

A356 remains a favorite in aerospace and automotive industries due to high strength plus excellent ductility. It is particularly excellent for pressure-tight applications, such as pumps and valves, where leak-proof performance is mandatory. Ideally suited for heat treating (T6 temper), A356 gains significant hardness and strength after processing, making it a versatile choice for structural components.

A380 Aluminum

A380 stands as the most common die casting alloy, offering a best combination of material cost and mechanical properties. It possesses excellent fluidity, allowing it to fill complex molds with thin walls easily. Its good thermal properties and pressure tightness make it a workhorse for consumer electronics, gearboxes, and general industrial housings where extreme specialized properties are not required.

Specialty Alloys

Beyond standards, engineers utilize specialty alloys for niche needs. Zinc-aluminum blends are used when specific hardness or wear resistance is required. Low-copper options serve marine applications where maximum corrosion resistance is paramount. Foundries can even create custom formulations for proprietary needs, adjusting chemical balance favoring machinability, anodizing quality, or thermal conductivity.

6. Cost Analysis: Casting vs Machining?

Casting proves significantly more cost-effective than machining for medium to high-volume production runs due to reduced material waste and faster cycle times. While machining removes material to reveal a part, casting builds it, which is inherently more efficient. Producing precision aluminum casting parts via casting lowers per-unit cost drastically as volume increases. Let’s look at the numbers… breakeven points typically happen sooner than many buyers expect.

Tooling vs Unit Price

Primary barrier to entry for casting involves higher initial tooling investment. Designing and machining a steel mold is expensive. However, this cost is amortized over thousands of parts, leading to a drastically lower per-part price compared to machining. For high-volume production runs, utilizing professional aluminum die casting services significantly lowers per-unit cost due to faster cycle times and reduced material waste. A machined part might cost

50,whilecastequivalentdropsto50, while cast equivalent drops to 50,whilecastequivalentdropsto

5 once a tool gets paid for.

Material Waste Reduction

Machining parts from a billet often turns 50% or more of expensive raw material into chips (scrap). Casting acts as a near-net-shape process, meaning material usage is very close to final part weight. Runners, gates, and overflows can be recycled immediately within a foundry, creating a closed-loop system. This eco-friendly manufacturing footprint reduces material purchase costs and aligns with sustainability goals.

Speed of Production

Once a mold is made, production speed becomes blistering. Cycle times are often measured in seconds or minutes, not hours. Die casting machines can produce parts every 30 to 60 seconds. Furthermore, molds can be designed with multiple cavities, producing 2, 4, or even 8 parts simultaneously. This scalability allows manufacturers ramping up production rapidly meeting market surges.

| Production Volume | Casting Cost Impact | Machining Cost Impact | Best Choice | |

|---|---|---|---|---|

| 1-50 Units | Prohibitive (High Tooling) | Low (No Tooling) | Machining | |

| 500-1,000 Units | Moderate (Amortization starts) | High (Time consuming) | Evaluate Both | |

| 10,000+ Units | Very Low (Economies of Scale) | Prohibitive | Casting |

7. What Defects Should You Watch Out For?

Common defects in casting include porosity and shrinkage, both of which can compromise structural integrity if not managed correctly. High-quality precision aluminum casting parts must be rigorously inspected ensuring freedom from internal voids that could lead to failure under pressure. Understanding these potential pitfalls allows engineers designing parts that are more “castable” and robust. Here is the bottom line… most defects are preventable with correct process control.

Gas Porosity

Gas porosity manifests as small, spherical voids within metal, caused by trapped air or gas during pouring or injection phases. This weakens a part and can cause leaks in pressurized applications. It is mitigated by vacuum assist systems that evacuate air from molds before injection and by optimizing venting channels. Detection is typically achieved via X-ray analysis or destructive testing.

Shrinkage Voids

As aluminum cools, it contracts. If metal solidifies in a way that isolates a pocket of molten liquid, shrinkage voids occur when that last pocket freezes. This is controlled by proper gate and riser design, which feeds extra molten metal into casting as it cools. Simulation software predicts risk areas before a mold is even cut, allowing engineers adjusting geometry promoting directional solidification.

Cold Shuts

A cold shut happens when two fronts of molten metal meet but fail to fuse completely, leaving a seam or crack. This usually occurs if metal freezes before filling a mold or if injection speed is too slow. Addressed by optimizing pour temperature and increasing injection velocity, ensuring complete fusion of material represents critical necessity for structural continuity.

8. How Critical Is Mold Design for Accuracy?

Mold design stands as a single most critical factor achieving tight tolerances and ensuring repeatability across production runs. A poorly designed mold will produce inconsistent parts regardless of machine operator skill. We engineer molds specifically to guarantee your components meet strict dimensional accuracy standards and geometric tolerances (GD&T) essential for assembly. Ready for the good part? Advanced simulation ensures mold works on first shot.

Draft Angles

Draft angles are slight tapers applied to vertical walls, essential for ejecting parts without damage. Without draft, parts would bind to mold due to friction plus shrinkage. However, excessive draft changes part dimensions. Art of mold design lies in minimizing draft maintaining near-net shape while balancing ejection ease with dimensional needs.

Thermal Management

A mold represents not just a shape; it acts as a heat exchanger. Cooling lines utilizing water or oil run within mold steel to control rate of solidification. Proper thermal management prevents warping and distortion by ensuring parts cool evenly. It also extends lifespan for tools by reducing thermal shock to mold steel, preventing heat checking (surface cracking).

Flow Simulation

Modern engineering relies on flow simulation software predicting exactly how molten metal will enter and fill cavities. This data allows designers optimizing gate placement—an entry point of metal—to reduce turbulence during injection. Turbulence traps air, leading to porosity. Smooth, laminar flow ensures dense, high-quality casting.

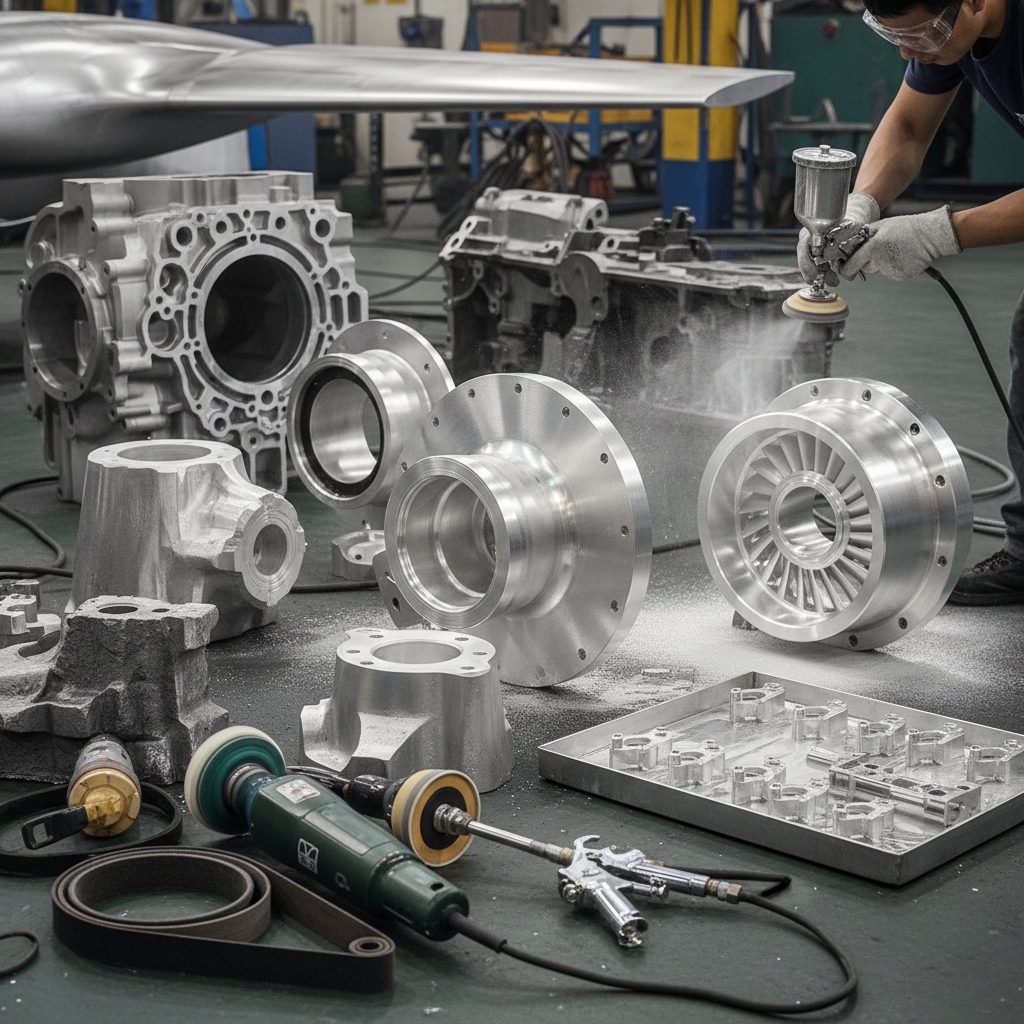

9. What Surface Finishes Are Available?

Aluminum castings can accept a wide variety of finishes, from functional chemical conversions to aesthetic powder coatings. While raw cast finish is often sufficient for internal components, consumer-facing parts require enhancement. Beyond raw cast, we employ various surface treatment methods —such as anodizing and powder coating—to enhance both appearance and environmental resistance of final parts. Think about this… finish often defines customer perception regarding quality.

Bead Blasting

Bead blasting involves shooting glass or ceramic beads at part surfaces. This process removes flash (excess material) and minor surface imperfections, creating uniform matte texture. It acts as excellent preparation step for painting or anodizing, ensuring better adhesion. It also hides flow marks or minor discoloration inherent to casting processes.

Anodizing

Anodizing involves electrochemical processes thickening natural oxide layers on aluminum surfaces. It significantly increases corrosion and wear resistance. Anodizing also allows for color customization, as porous oxide layers can absorb dyes. Hardcoat anodizing creates ceramic-hard surfaces that are non-conductive, offering extreme protection for industrial components.

Powder Coating

For maximum durability plus aesthetic variety, powder coating represents a standard. Dry powder is electrostatically applied then cured under heat to form a skin. This results in durable, thick protective layers with high resistance to chipping, scratching, and UV fading. It is available in thousands of colors and textures, from glossy to matte or wrinkled.

| Finish | Primary Function | Aesthetic Appeal | Cost | |

|---|---|---|---|---|

| As-Cast | Basic Functionality | Low (Industrial) | Lowest | |

| Bead Blast | Uniformity/Prep | Medium (Matte) | Low | |

| Anodizing | Corrosion Resistance | High (Metallic) | Moderate | |

| Powder Coat | Durability/Color | High (Custom) | Moderate |

10. How Do We Guarantee Part Quality?

We guarantee quality through multi-layered inspection processes involving CMM validation, X-ray testing, and material spectroscopy. In a market flooded with cheap manufacturing options, verifying integrity of precision aluminum casting parts is what separates professional foundries from the rest. Every batch undergoes strict verification before shipment to ensure zero defects reach your assembly line. Why does this matter? Because cost of quality failure far exceeds cost of inspection.

Inspection Technologies

Advanced Coordinate Measuring Machines (CMM) probe parts to verify dimensional accuracy down to micron levels. Spectrometers zap metal to analyze chemical composition, ensuring alloy is exactly what was specified. Real-time X-ray fluoroscopy allows inspectors seeing inside metal, identifying internal porosity or shrinkage without destroying parts.

Certifications

Credible manufacturers operate under strict quality management systems. ISO 9001 compliance represents a baseline, ensuring standardized processes. For automotive clients, IATF 16949 certification is mandatory, requiring even more rigorous process controls plus risk management. Full material test reports and Certificates of Conformance (CoC) are provided with shipments validating compliance.

Summary and Analysis

Key Takeaway: Precision aluminum casting offers optimal balance of cost, performance, and scalability for modern manufacturing. It bridges gaps between high strength of machined parts and low cost of mass production.

| Feature | Precision Casting | CNC Machining | Welding/Fabrication | |

|---|---|---|---|---|

| Volume Suitability | High Volume | Low/Proto | Low/Medium | |

| Unit Cost | Low | High | Medium | |

| Design Complexity | High | Medium | Low | |

| Material Waste | Low | High | Medium | |

| Strength | Isotropic (Uniform) | Isotropic | Weak at joints |

Analysis: As shown in a table above, while CNC machining has its place for prototyping, casting represents superior economic and technical choices for production-scale parts. Our rigorous quality assurance protocols ensure that shifting from machining to casting does not mean sacrificing precision.

Conclusion

We have explored how precision aluminum casting delivers durability, reduces weight, and offers significant cost advantages for high-volume production. From intricate mold design to final surface finish, every step is engineered providing superior component integrity. Choosing a right manufacturing partner ensures your components meet strict industry standards without compromise, protecting your brand’s reputation. Ready to optimize your production with high-performance alloys? Contact PrecisionVast today to discuss your project requirements and receive a detailed quote.

FAQ

Q1: What is the typical tolerance for precision aluminum casting parts?Standard tolerances generally range from ±0.002 to ±0.005 inches per inch, depending on the specific casting method (such as investment or die casting) and the geometry of the part. Tighter tolerances can often be achieved with precision tooling and secondary machining operations.

Q2: How does aluminum casting compare to steel casting in terms of cost?Aluminum casting is generally more cost-effective than steel casting due to lower melting points, which reduces energy consumption and extends mold life. Additionally, the faster cycle times of aluminum processing lead to lower per-unit costs in high-volume production runs.

Q3: Can precision aluminum casting parts be welded?Yes, specific aluminum alloys used in casting, such as 356 and A356, are weldable using TIG or MIG methods. However, care must be taken to maintain the heat treatment temper, and some die-casting alloys are less suitable for welding due to trapped gases.

Q4: What is the minimum wall thickness for aluminum castings?For high-pressure die casting, wall thicknesses can be as thin as 0.060 inches (1.5 mm). Investment casting allows for even thinner walls in certain applications, while sand casting typically requires a minimum wall thickness of roughly 0.125 inches (3 mm).

Q5: How long does the tooling last for aluminum casting?Tooling life varies by process; permanent molds and die casting tools can last for 100,000 to over 500,000 cycles depending on maintenance and mold steel quality. In contrast, sand casting patterns have a shorter life but are significantly cheaper to produce initially.