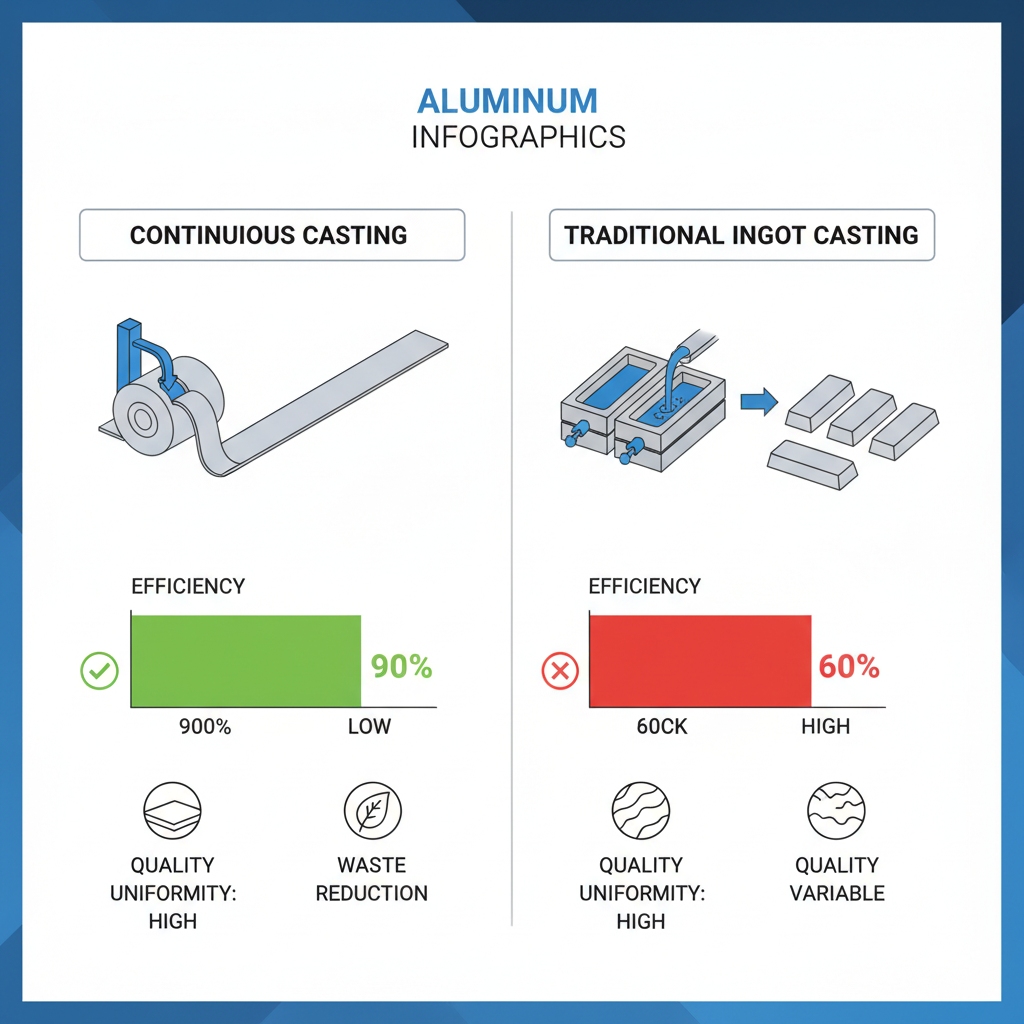

Achieving consistent metallurgical structure and minimizing scrap rates in high-volume production is a persistent struggle for manufacturers. Reliance on batch processing or outdated ingot methods often leads to structural variations, increased energy costs, and significant material waste that eats into profit margins. Implementing advanced aluminum continuous casting protocols transforms molten metal directly into semi-finished shapes, ensuring uniformity and production velocity.

But here is the bottom line: transitioning to continuous flow protocols establishes authority and operational dominance. This shift moves your facility away from the inefficiencies of static molds. It allows for tighter control over grain structure and mechanical properties.

1. What is the aluminum continuous casting process?

Continuous casting is a manufacturing technique where molten aluminum is solidified into a semi-finished billet, bloom, or slab for subsequent rolling in the same heat. This method contrasts sharply with static ingot casting by maintaining a steady flow of liquid metal. It creates an “endless” production line that maximizes throughput. You might be wondering: how does the orientation affect the output? Vertical casters are typically used for high-quality billets, while horizontal machines handle smaller cross-sections.

- Solidifies metal into continuous lengths.

- Reduces reheating requirements.

- Supports immediate downstream processing.

- Differentiates between vertical and horizontal setups.

How does it differ from batch processing?

Unlike batch processing which requires individual mold preparation for every pour, continuous casting runs non-stop for days or weeks. This fundamental difference eliminates the downtime associated with resetting molds. It ensures that thermal conditions remain constant throughout the entire production run. Consequently, the metal exhibits superior homogeneity compared to batch-produced equivalents.

- Reduces setup time significantly.

- Maintains thermal consistency.

- Improves overall yield.

- Eliminates start-stop inefficiencies.

Why is this critical for B2B manufacturing?

It provides the volume and consistency required for large-scale supply chains in automotive and construction sectors. Large OEMs demand material properties that do not fluctuate between batches. Continuous casting aligns perfectly with JIT (Just-In-Time) manufacturing principles. This method turns a batch-based bottleneck into a streamlined flow, increasing yield by up to 10-15% over static methods.

- Enables economies of scale.

- Aligns with JIT delivery schedules.

- Stabilizes material supply.

- Reduces scrap rates drastically.

Key Takeaway: Continuous casting is not just a method; it is a supply chain strategy that guarantees volume and uniformity essential for modern industrial contracts.

| Feature | Batch Casting | Continuous Casting | |

|---|---|---|---|

| Operation Mode | Intermittent (Start/Stop) | Non-stop flow | |

| Yield Efficiency | Lower (Butt/Crop ends) | High (95%+) | |

| Thermal Cycle | Cyclic heating/cooling | Steady state | |

| Primary Use | Specialized/Low volume | High volume/Standard shapes |

Analysis: Continuous casting removes the cyclical thermal stress found in batch processing, resulting in superior microstructural homogeneity.

2. How has aluminum casting technology evolved?

What were the early limitations?

Early iterations struggled with cooling rate control, often resulting in center cracks and surface tears in aluminum alloys. In the 1950s, operators found it difficult to manage aluminum’s high oxidation rate during the pour. This often led to inclusions that compromised the metal’s integrity. However, that changed quickly: engineers began developing better filtration and shielding methods.

- Poor cooling rate regulation.

- Frequent center cracking issues.

- High oxidation susceptibility.

- Surface tearing prevalance.

How did automation change the landscape?

The integration of PLCs and automated meniscus level control in the 1980s allowed for precise speed and temperature regulation. Computer modeling revolutionized the understanding of flow dynamics within the mold. This removed the reliance on manual operator intervention and intuition. Consistency became a programmed guarantee rather than a variable outcome.

- Precise meniscus level control.

- Digital temperature regulation.

- Reduced manual intervention.

- Enhanced flow dynamic modeling.

What is the current state of the art?

Modern systems utilize electromagnetic stirring and AI-driven cooling adjustments to virtually eliminate porosity. These “Smart Foundries” monitor thousands of data points per second. They adjust water flow and withdrawal speeds in real-time to prevent defects. The evolution from manual pouring to digital process control has transformed aluminum casting from an art into a precise science.

- Electromagnetic stirring implementation.

- AI-driven cooling adjustments.

- Real-time defect prevention.

- Digital process control.

Key Takeaway: The shift from manual oversight to AI-driven process control has turned aluminum casting into a defect-predictive science rather than a reactive one.

| Era | Key Innovation | Impact on Aluminum | |

|---|---|---|---|

| 1950s | Vertical Casting | Feasibility for large billets | |

| 1980s | Automated Controls | Consistent grain structure | |

| 2020s | Digital Twins/AI | Predictive defect prevention |

Analysis: The trajectory of casting technology moves consistently toward removing human variability to ensure identical mechanical properties across thousands of tons of product.

3. How does the continuous casting machine work?

What is the function of the tundish?

The tundish acts as a reservoir that feeds molten aluminum into the mold at a regulated rate while allowing impurities to float to the surface. It serves as a crucial buffer between the ladle and the mold. Maintaining a constant temperature here is vital for flow stability. Here is the critical part: the metal head pressure must remain stable to ensure even flow into the mold.

- Acts as a flow buffer.

- Facilitates impurity flotation.

- Maintains temperature stability.

- Regulates metal head pressure.

How does primary cooling occur?

Primary cooling happens in the water-cooled copper mold, where a thin solid shell forms around the liquid core of the aluminum. This shell must be strong enough to contain the molten interior. The “meniscus” level is strictly controlled to ensure uniform shell thickness. Oscillation is applied to the mold to prevent the aluminum from sticking to the copper walls.

- Forms the initial solid shell.

- Utilizes water-cooled copper.

- Controls meniscus level.

- Prevents sticking via oscillation.

What happens in the secondary cooling zone?

Water sprays directly target the semi-solid strand to complete solidification as it exits the mold. This zone dictates the final metallurgical structure by controlling the cooling speed. Uneven cooling here can cause internal stresses or warping. The balance between primary shell formation and secondary core solidification determines the billet’s integrity.

- Direct water spray application.

- Completes core solidification.

- Uses support rollers.

- Controls internal stress generation.

Key Takeaway: The mechanical integrity of the billet is entirely dependent on the precise synchronization between the withdrawal speed and the multi-stage cooling zones.

| Component | Function | Critical Parameter | |

|---|---|---|---|

| Tundish | Flow buffer & cleaning | Constant metal head | |

| Copper Mold | Primary shell formation | Heat transfer rate | |

| Spray Zone | Core solidification | Water flow density | |

| Straightener | Mechanical pulling | Withdrawal speed |

Analysis: Successful continuous casting relies on synchronizing the withdrawal speed with the cooling rate to prevent “breakouts” where the molten core ruptures the shell.

4. Which aluminum alloys fit this process best?

Can you cast 6xxx series alloys?

Yes, the 6xxx series (Al-Mg-Si) is the most commonly produced family due to its excellent extrudability and response to continuous casting. These alloys are staples in structural applications worldwide. But there is a challenge: managing the magnesium content requires precise atmosphere control. Oxidation of magnesium can lead to inclusions if not handled correctly.

- Excellent extrudability profile.

- Ideal for structural use.

- Requires magnesium management.

- High response to casting.

What about high-purity alloys?

1xxx series aluminum is frequently cast for electrical conductivity applications, requiring strict filtration during the process. These alloys demand exceptional cleanliness to maintain their conductive properties. Manufacturers use them for rotor manufacturing and electrical busbars. Filtration systems must be robust to remove even microscopic particulates.

- Used for electrical conductors.

- Requires strict filtration.

- Ideal for rotor manufacturing.

- High cleanliness demand.

Are there alloys that are difficult to cast?

Alloys with wide freezing ranges, such as certain 2xxx and 7xxx series, are prone to hot cracking and require specialized casting speeds. The “mushy zones” in these alloys create weak points during solidification. Operators must reduce speed and adjust cooling aggressively. While versatile, continuous casting requires specific parameter adjustments based on the freezing range.

- Prone to hot cracking.

- Wide freezing ranges.

- Requires slower speeds.

- Needs aggressive cooling adjustments.

Key Takeaway: While continuous casting is versatile, success depends on matching the cooling parameters to the specific freezing range and chemical reactivity of the alloy series.

| Alloy Series | Castability | Primary Application | |

|---|---|---|---|

| 1xxx | Excellent | Electrical conductors, Foil | |

| 3xxx | Good | Beverage cans, Roofing | |

| 5xxx | Moderate | Marine, Automotive sheet | |

| 6xxx | Excellent | Extrusions, Structural |

Analysis: Selecting the right alloy involves balancing the mechanical requirements of the final part with the thermal limitations of the continuous casting machine.

5. Why choose continuous casting for manufacturing?

How does it improve material yield?

Continuous casting achieves yields exceeding 95% by eliminating the cropping losses associated with the head and tail of individual ingots. In traditional methods, significant portions of the metal are cut off and remelted. This process minimizes that waste stream effectively. To view our casting capabilities and product offerings , explore our catalog.

- Eliminates cropping losses.

- Reduces remelting requirements.

- Achieves 95%+ yield.

- Minimizes waste streams.

Does it reduce energy consumption?

By casting closer to the final shape and enabling direct rolling, the process significantly cuts the energy needed for reheating. “Heat retention” allows the metal to move to the next stage without cooling down completely. The numbers speak for themselves: energy bills drop when reheat furnaces are bypassed. This has massive implications for reducing a facility’s carbon footprint.

- Enables direct rolling.

- Maximizes heat retention.

- Lowers reheating costs.

- Reduces carbon footprint.

How does it affect production speed?

The linear, uninterrupted nature of the process allows for massive throughput, suitable for fulfilling high-volume orders rapidly. Production is measured in tons per hour rather than pieces per shift. This velocity is essential for meeting global supply demands. For high-volume aluminum production, continuous casting offers an unbeatable combination of efficiency.

- Linear process flow.

- Massive throughput capability.

- High-volume order fulfillment.

- Rapid production velocity.

Key Takeaway: The dual impact of 95%+ material yield and reduced energy inputs makes continuous casting the most economically viable option for high-tonnage production.

| Metric | Traditional Ingot | Continuous Casting | |

|---|---|---|---|

| Material Yield | 75-85% | 95%+ | |

| Energy Use | High (Reheating req.) | Lower (Direct Rolling) | |

| Throughput | Batch constrained | Continuous flow |

Analysis: The economic advantage of continuous casting comes from the simultaneous reduction of scrap metal and energy input per ton of finished aluminum.

6. What limitations exist in continuous casting?

Is the initial investment high?

The capital expenditure for a continuous casting line is substantial, making it viable only for high-volume production facilities. The cost of machinery and infrastructure is a major barrier to entry. Smaller shops cannot typically justify this expense. Let’s be realistic: ROI takes time and requires consistent order volume.

- High machinery costs.

- Substantial infrastructure needs.

- Long ROI period.

- High volume requirement.

Can you switch alloys easily?

No, changing alloy grades requires purging the tundish and resetting parameters, which creates downtime and transitional scrap. This “grade transition” problem results in mixed-alloy material that must be scrapped. It makes the process inefficient for small, custom batches. Factories generally schedule long runs of a single alloy to mitigate this.

- Requires tundish purging.

- Creates transitional scrap.

- Inefficient for small batches.

- Causes production downtime.

What maintenance does the system require?

The water-cooled molds and oscillation mechanisms require rigorous maintenance to prevent catastrophic breakouts and surface defects. Molds wear down over time and lose their dimensional accuracy. Nozzles can clog with oxides, disrupting the flow. Continuous casting is a powerhouse for volume, but lacks agility for high-mix environments.

- Rigorous mold maintenance.

- Oscillation mechanism checks.

- Nozzle clogging prevention.

- Wear monitoring.

Key Takeaway: Continuous casting is a “commitment to volume”—it penalizes low utilization and frequent alloy changes but rewards long, steady production runs.

| Challenge | Impact | Mitigation Strategy | |

|---|---|---|---|

| High CapEx | Barrier to entry | Ensure high volume demand | |

| Inflexibility | Hard to switch grades | Schedule long runs | |

| Maintenance | Downtime risk | Predictive monitoring |

Analysis: Manufacturers must carefully audit their production volume; continuous casting is a liability if the facility cannot sustain high utilization rates.

7. Where are continuous cast aluminum parts used?

What role does it play in automotive?

Continuous cast billets are the primary feedstock for forged suspension components and extruded chassis parts essential for vehicle lightweighting. The automotive industry demands high strength-to-weight ratios. Industries and applications vary, but safety components rely heavily on this consistency. Crash management systems also utilize these high-integrity materials.

- Forged suspension arms.

- Extruded chassis parts.

- Crash management systems.

- Lightweighting components.

How is it used in construction?

The construction industry relies on continuous cast aluminum for window profiles, curtain walls, and structural reinforcement due to its consistency. Architects demand straightness and surface finish quality. Consider this scope: entire skyscrapers utilize these profiles for their facades. Structural integrity is non-negotiable in these applications.

- Window profiles.

- Curtain walls.

- Structural reinforcement.

- Architectural facades.

Is it used in consumer packaging?

Yes, the vast majority of aluminum foil and beverage can stock originates from continuous slab casters. These applications require extremely thin gauges without pinholes. Food safety standards dictate the purity levels required. From the car you drive to the building you work in, continuous cast aluminum is ubiquitous.

- Aluminum foil stock.

- Beverage can sheet.

- Thin gauge requirements.

- Food safety compliance.

Key Takeaway: The structural reliability of continuous cast aluminum makes it the invisible backbone of modern automotive safety and architectural durability.

| Industry | Application | Key Property Req. | |

|---|---|---|---|

| Automotive | Chassis/Suspension | Strength/Weight ratio | |

| Construction | Window profiles | Surface finish/Straightness | |

| Packaging | Foil/Cans | Formability/Purity |

Analysis: The ubiquity of continuous cast aluminum is due to its ability to meet stringent industry standards for chemical composition and mechanical performance at scale.

8. How does it compare to other casting methods?

Continuous casting vs. Sand casting?

Sand casting is ideal for complex, low-volume geometries, whereas continuous casting is strictly for simple, uniform profiles in high volumes. Sand molds allow for intricate internal channels and undercuts. Continuous casting focuses on efficiency rather than geometric complexity. For detailed comparisons on methods like investment casting , review our technical guides.

- Sand fits complex shapes.

- Continuous fits uniform profiles.

- Sand is lower volume.

- Continuous is high efficiency.

Continuous casting vs. Die casting?

Die casting forces metal into a mold for net-shape parts; continuous casting produces the raw material (billets/slabs) used to make those parts. Here is the distinction: one creates the feedstock, the other creates the final component. Die casting provides excellent surface finish on complex parts. Continuous casting ensures the internal quality of the metal itself.

- Die casting makes parts.

- Continuous makes feedstock.

- Die casting uses pressure.

- Continuous uses gravity/extraction.

When should you choose continuous casting?

You should choose continuous casting when you need to produce thousands of tons of uniform feedstock rather than finished complex components. Use a decision matrix based on volume and shape complexity. If you need bars, rods, or slabs, this is the correct path. It is rarely a competitor to shape casting; it is the upstream provider.

- High volume requirements.

- Uniform feedstock needs.

- Simple profile shapes.

- Upstream supply chain role.

Key Takeaway: Continuous casting is not a method for making parts; it is a method for making the material from which parts are made.

| Feature | Continuous Casting | Sand Casting | Die Casting | |

|---|---|---|---|---|

| Product Shape | Constant profile (Bar/Slab) | Complex 3D shapes | Complex 3D shapes | |

| Volume | Very High | Low to Medium | High | |

| Surface Finish | Good (Feedstock) | Rough | Excellent |

Analysis: Understanding the supply chain is vital; continuous casting creates the canvas (billet), while sand and die casting paint the picture (finished part).

9. How can you prevent common casting defects?

What causes centerline segregation?

Centerline segregation occurs when alloying elements migrate to the liquid core during solidification, caused by excessive casting speed or inadequate cooling. The physics of solute rejection drive impurities to the last place to freeze. Operators must adjust spray cooling intensity to manage this. Correcting the thermal gradient helps lock elements in place.

- Excessive casting speed.

- Inadequate cooling rates.

- Solute rejection physics.

- Spray intensity adjustments.

How do you stop gas porosity?

Hydrogen gas trapped in the molten aluminum creates voids; this is prevented by rigorous degassing and protective atmosphere shielding in the tundish. Hydrogen solubility drops drastically as aluminum freezes. The solution is precise: implement rotary degassing units before the pour. Argon shrouding techniques further protect the stream from humid air.

- Rigorous degassing.

- Atmosphere shielding.

- Rotary degassing units.

- Argon shrouding.

Can surface cracks be eliminated?

Surface cracking is mitigated by optimizing mold oscillation frequencies and ensuring uniform lubrication between the mold and the shell. Friction is the enemy of a smooth surface. Controlling oscillation marks reduces stress concentration points. Defect prevention is a game of thermal management across the billet cross-section.

- Optimize oscillation frequency.

- Uniform mold lubrication.

- Reduce friction stress.

- Control oscillation marks.

Key Takeaway: Defect prevention requires a holistic approach, controlling everything from hydrogen levels in the liquid metal to the micro-friction of the oscillating mold.

| Defect | Root Cause | Prevention Method | |

|---|---|---|---|

| Segregation | Fast speed/Uneven cooling | Optimize secondary cooling | |

| Porosity | Dissolved Hydrogen | Degassing/Argon shield | |

| Surface Cracks | Friction/Thermal stress | Mold lubrication/Oscillation |

Analysis: Most continuous casting defects are invisible to the naked eye but compromise the structural integrity of the final product, necessitating rigorous process control.

10. What post-processing ensures final quality?

Why is homogenization necessary?

As-cast aluminum billets often have uneven chemical distribution; homogenization heating redistributes these elements to ensure uniform mechanical properties. This process dissolves brittle precipitates that form at grain boundaries. It is essential preparation for extrusion processes. Learn more about casting heat treatment to understand the metallurgical shifts.

- Redistributes chemical elements.

- Dissolves brittle precipitates.

- Ensures uniform properties.

- Prepares for extrusion.

How is the surface prepared?

“Scalping” or peeling is often performed to remove the outer layer of the cast log, which may contain segregation or oscillation marks. This mechanical machining step reveals the clean metal underneath. Don’t skip this step: surface defects can ruin extrusion dies. It guarantees a premium finish on the final product.

- Removes outer segregation.

- Clears oscillation marks.

- Protects extrusion dies.

- Guarantees surface finish.

What inspection methods are used?

Ultrasonic testing is standard for detecting internal cracks or inclusions that could cause failure during downstream processing. NDT (Non-Destructive Testing) protocols verify the billet’s core integrity. Quality assurance teams reject any log with significant echoes. The process doesn’t end at solidification; it ends at verification.

- Ultrasonic testing (UT).

- Detects internal cracks.

- Verifies core integrity.

- Standard QA protocol.

Key Takeaway: Post-processing is the quality firewall; homogenization and scalping ensure that only metallurgically perfect aluminum enters the extrusion or rolling phase.

| Process | Purpose | Outcome | |

|---|---|---|---|

| Homogenization | Heat treatment | Uniform microstructure | |

| Scalping | Machining | Clean surface finish | |

| Ultrasonic Test | Inspection | Internal defect detection |

Analysis: Post-processing transforms a raw cast log into a premium industrial input, ensuring it performs predictably during subsequent manufacturing steps.

Conclusion

Aluminum continuous casting represents the backbone of modern high-volume metallurgy, bridging the gap between raw molten metal and usable industrial feedstock. It solves the problem of inconsistency and waste inherent in older methods. By embracing this technology, manufacturers secure a reliable flow of high-quality material. Whether you need high-volume feedstock or precision components, contact our engineering team at Dongying Vast to optimize your production supply chain today.

FAQ

Q1: Can I use continuous casting for small, custom aluminum batches?No, continuous casting is designed for high-volume production. The setup costs and transition waste make it economically unviable for small, custom runs; for those, sand or investment casting is preferred.

Q2: What is the difference between VDC and HDC in aluminum casting?VDC (Vertical Direct Chill) casts vertically and is best for large billets with uniform structure, while HDC (Horizontal Direct Chill) casts horizontally and is often used for smaller continuous runs like wire rods or T-bars.

Q3: How does continuous casting affect the grain structure of aluminum?It generally produces a finer, more uniform grain structure compared to static ingot casting because of the rapid, controlled cooling rates, which improves the mechanical strength of the alloy.

Q4: What is the typical production capacity of a continuous casting line?Capacity varies by machine size, but a standard industrial continuous casting line can produce anywhere from 10 to over 100 tons of aluminum billet per hour, operating 24/7.

Q5: Can all aluminum alloys be processed via continuous casting?Most wrought alloys (1xxx, 3xxx, 5xxx, 6xxx) are excellent candidates. However, some high-strength 2xxx and 7xxx alloys require highly specialized controls due to their tendency to crack during rapid solidification.