Are you struggling to balance complex geometric designs with the high mechanical integrity required for safety-critical components? It is easy to find yourself trapped between two extremes: standard die casting often results in internal porosity that leads to failure under high loads, while full forging skyrockets production costs and severely limits design freedom. Here is the deal. Squeeze casting offers a powerful hybrid solution, bridging the gap by delivering the structural density of forged parts with the near-net shape precision of traditional casting. As experts in advanced manufacturing, we help you navigate these technical trade-offs to optimize your production lines.

1. What Is the Aluminum Squeeze Casting Process?

Defining Liquid Metal Forging

Squeeze casting, frequently referred to in technical circles as liquid metal forging, creates a distinct category in manufacturing that effectively merges the high productivity of casting with the mechanical superiority of forging. Unlike traditional casting methods that rely primarily on gravity or gas pressure to fill a mold, this process introduces a critical variable: sustained high hydraulic pressure during the solidification phase. By applying typical pressures ranging from 50 to 150 MPa, the process forces molten metal into intimate contact with the die walls, significantly increasing the heat transfer rate. This rapid cooling results in a refined, equiaxed grain structure that is far superior to the dendritic structures found in gravity castings.

The Hybrid Nature of the Technique

To fully appreciate this technology, one must understand where it sits within the broader spectrum of types of casting . It acts as a bridge, filling the capability gap between the high-volume, lower-integrity output of high-pressure die casting (HPDC) and the low-volume, high-integrity output of solid forging. You might be wondering how this hybrid nature translates to real-world performance. Essentially, it allows engineers to design components with thick wall sections and varying geometries—features usually associated with casting—while achieving the density, ductility, and fatigue strength typically reserved for wrought materials. This unique combination makes it indispensable for safety-critical applications in the automotive and aerospace sectors where component failure is simply not an option.

2. How Does the Squeeze Casting Workflow Operate?

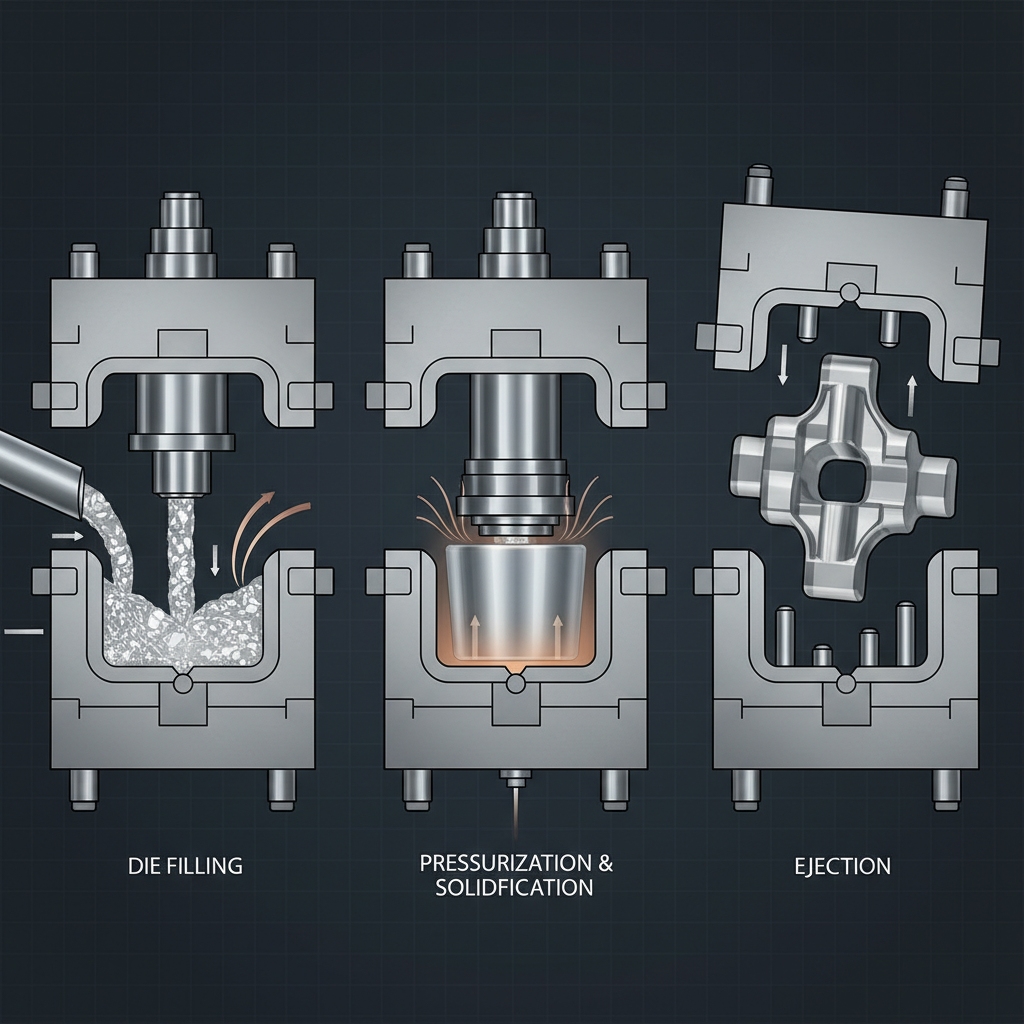

Preparation and Precise Pouring

The workflow begins well before the metal enters the mold, starting with the meticulous preparation of the molten aluminum alloy. The melt must be thoroughly degassed and cleaned to remove impurities, as the high-pressure nature of the process will trap any inclusions inside the part rather than allowing them to float to risers. Simultaneously, the die is preheated to a specific operating temperature (often between 200°C and 300°C) and lubricated with a specialized release agent. Ready for the good part? Unlike the violent, high-velocity injection used in standard die casting, squeeze casting employs a slow, laminar pouring or injection speed. This controlled entry is crucial because it minimizes turbulence, preventing the entrapment of air and oxides that would otherwise compromise the structural integrity of the final component.

Pressurization and Solidification Phase

Once the precise volume of molten metal is introduced into the die cavity, the upper die or a dedicated hydraulic ram is activated to close the mold. This is the defining moment of the process: substantial hydraulic pressure is applied directly to the liquid or semi-solid metal. This pressure is maintained throughout the entire solidification cycle, actively feeding molten material into any shrinkage voids that attempt to form as the aluminum cools and contracts. This “feeding” capability is what eliminates porosity. After the part has completely solidified, the ram retracts, and the component is ejected. The result is a near-net shape part that often requires minimal post-processing, although integrating CNC machining services is common for achieving final mating tolerances on critical surfaces.

3. What Distinguishes Direct Squeeze Casting from Indirect Squeeze Casting?

Direct Squeeze Casting Mechanics

Direct squeeze casting is the closest relative to forging and is often termed “liquid metal forging.” In this variation, the molten metal is poured directly into the lower half of an open die. The upper die, or punch, then descends to close the cavity, applying pressure directly to the entire surface of the molten pool. This method ensures maximum pressure transmission and heat transfer efficiency because there are no intermediate channels. This is where it gets interesting. Because there is no gating system (runners or sprues), the material yield is exceptionally high, often approaching 100%. However, this direct approach generally limits geometric complexity, making it best suited for simpler shapes like wheels, pistons, or simple structural blocks.

Indirect Squeeze Casting Mechanics

Indirect squeeze casting, closely resembling vertical high-pressure die casting, injects the metal into the die cavity through a gating system. The metal is pushed by a piston through a relatively large gate at a slow velocity to maintain laminar flow. Once the cavity is filled, the piston continues to exert pressure through the gate system during solidification. While this method may result in slightly lower pressure transmission efficiency compared to the direct method, it offers significantly greater design flexibility. It allows for the production of more complex geometries, internal coring, and multi-cavity molds. Manufacturers often choose this route when the part design includes intricate features that require the flow characteristics of a gate system.

| Feature | Direct Squeeze Casting | Indirect Squeeze Casting | |

|---|---|---|---|

| Metal Entry | Direct pour into die cavity | Injection via gate/runner system | |

| Pressure Application | Direct contact via upper ram | Transmitted through gate system | |

| Material Yield | Very High (~100%) | Lower (due to runners/biscuits) | |

| Geometric Complexity | Limited to simpler shapes | Suitable for complex designs | |

| Typical Applications | Pistons, Wheels, Brake Discs | Knuckles, Control Arms, Brackets |

4. Which Aluminum Alloys Are Best Suited for Squeeze Casting?

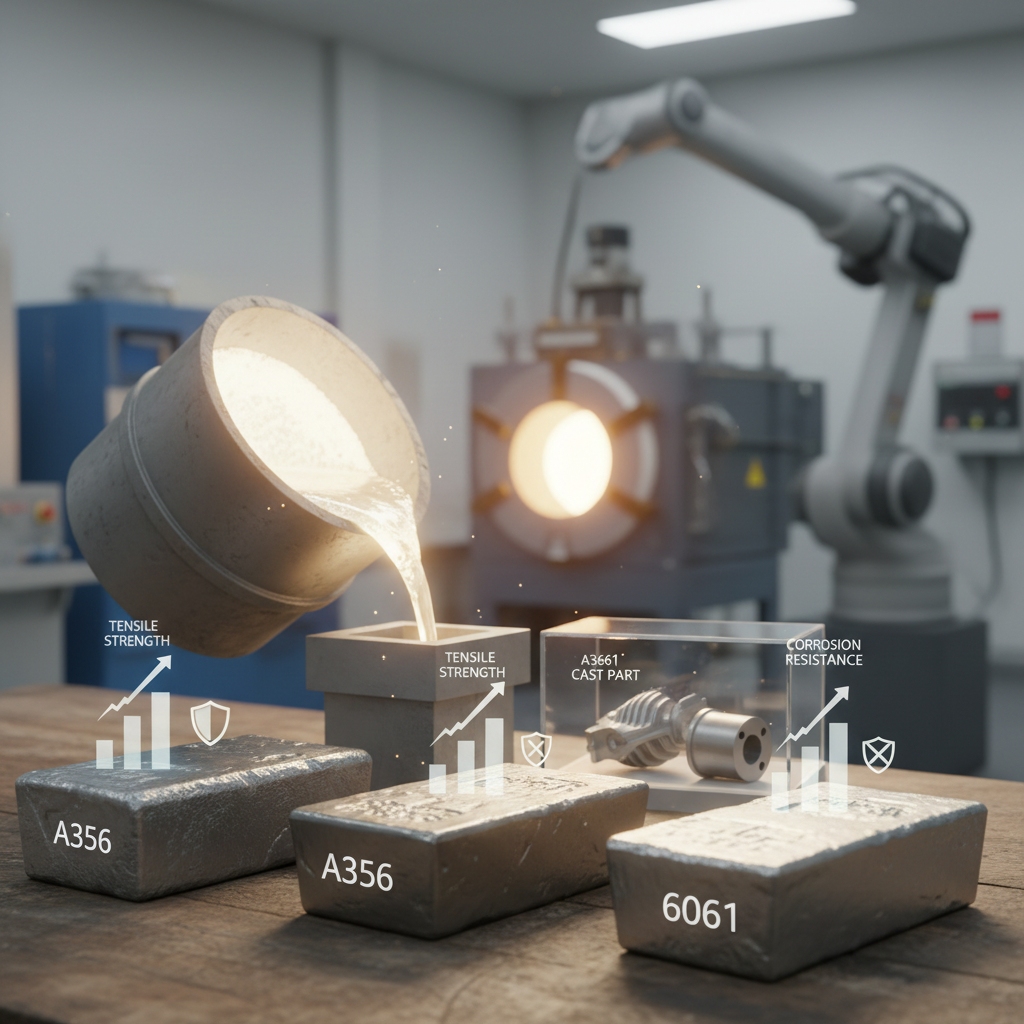

Bridging Wrought and Casting Alloys

One of the most significant advantages of squeeze casting is its versatility regarding material selection. What is the real story? Unlike traditional casting methods that are restricted to high-fluidity alloys (like the Al-Si series), squeeze casting can effectively process high-strength wrought aluminum alloys. The high pressure applied during solidification overcomes the poor fluidity and hot-tearing tendencies associated with wrought alloys, such as the 2000 and 7000 series. This capability is revolutionary for engineers, as it allows for the manufacturing of components with forging-like properties—high tensile strength and ductility—using a casting process.

Alloy Specifics and Applications

The most commonly used alloy is A356 (Al-Si-Mg), favored for its excellent balance of castability, corrosion resistance, and pressure tightness. It is widely used for automotive suspension parts and wheels. However, for applications requiring superior mechanical performance, wrought alloys like 6061 and 7075 are utilized. The 7075 alloy, known for its exceptional strength-to-weight ratio, is particularly valuable in aerospace and defense applications. By enabling the casting of these wrought grades, manufacturers can replace expensive machined billets with near-net shape castings, significantly reducing material costs and machining time. For more intricate non-structural parts, standard aluminum casting solutions utilizing high-fluidity alloys remain a viable alternative.

| Alloy Type | Series Example | Primary Benefit | Typical Squeeze Application | |

|---|---|---|---|---|

| Casting | A356 | Fluidity & Pressure Tightness | Engine Blocks, Wheels, Knuckles | |

| Wrought | 6061 | Weldability & Corrosion Resistance | Marine Hardware, Structural Frames | |

| Wrought | 7075 | High Tensile Strength | Aerospace Structural Nodes | |

| Casting | A380 | Cost-Effective General Use | Housings, Brackets |

5. What Are the Key Advantages of Using Squeeze Casting?

Elimination of Porosity and Defects

The primary and most celebrated advantage of the squeeze casting process is the virtual elimination of gas porosity and shrinkage voids. In standard die casting, trapped gas is a pervasive issue that weakens parts and prevents heat treatment. But here is the kicker. In squeeze casting, the combination of laminar (non-turbulent) filling and high solidification pressure ensures that gas is not entrapped and that the metal is continuously fed into solidification zones. This results in components with near 100% density, which is a strict requirement for pressure-tight applications like hydraulic valves and master cylinders.

Heat Treatment and Mechanical Superiority

Because squeeze cast parts are free from internal porosity, they can be subjected to full solution heat treatments (such as T6) without the risk of blistering. Blistering occurs in standard die castings when trapped gas expands during the heating cycle, ruining the part surface and structure. The ability to heat treat squeeze cast aluminum significantly enhances yield strength and ductility, allowing these parts to serve as direct replacements for heavier iron or steel components. Additionally, the fine grain structure achieved through pressurized rapid cooling provides superior fatigue strength, making these parts ideal for cyclic loading conditions found in automotive suspension systems.

6. What Potential Drawbacks Should You Consider?

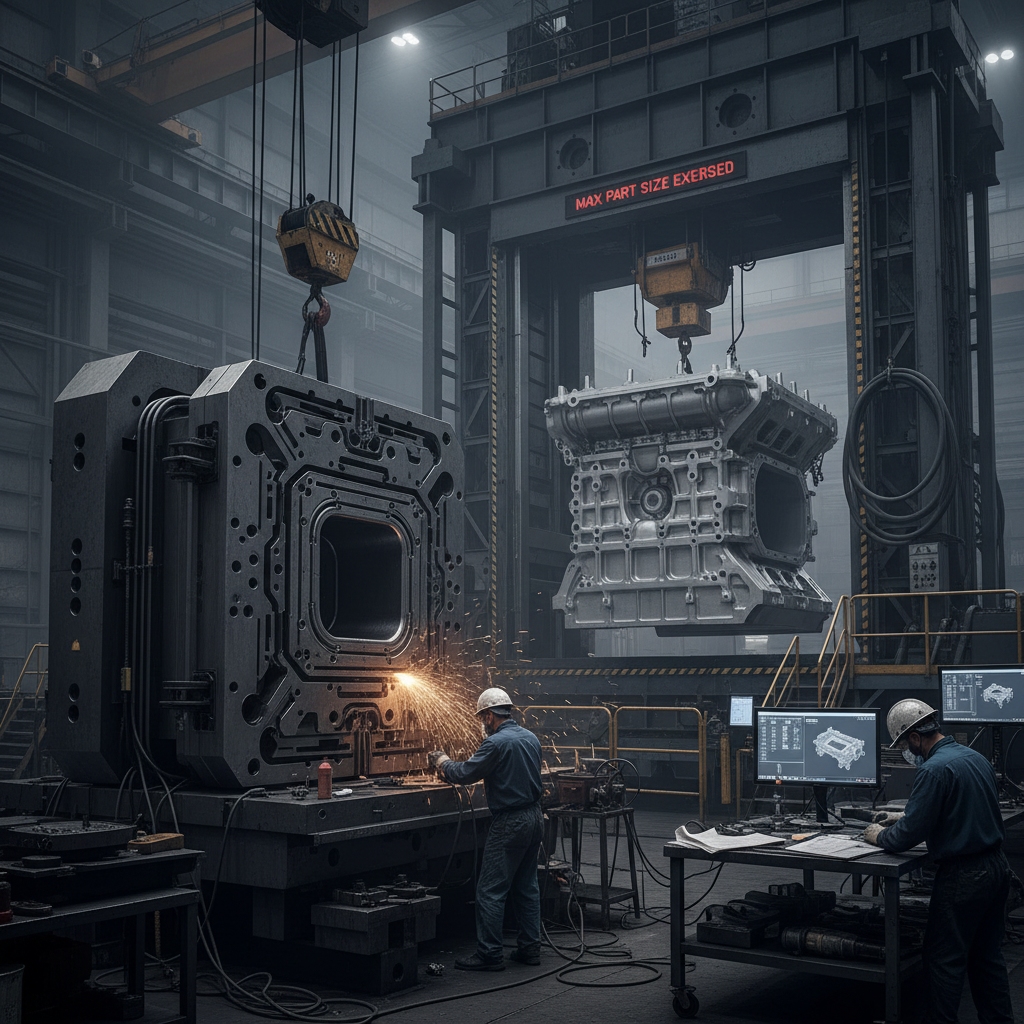

Complexity and Size Limitations

Despite its impressive list of benefits, squeeze casting is not a universal solution for every manufacturing challenge. It is important to consider that the process has distinct geometric limitations, particularly with the direct squeeze method. The need to apply direct pressure via a punch limits the ability to create undercuts or intricate internal passages that would be easily achievable with investment casting. While indirect squeeze casting offers more flexibility, it still lags behind the geometric freedom of lost-wax methods. Furthermore, the immense clamping force required to counteract the cavity pressure restricts the maximum size of the parts; producing very large components would require press tonnages that are often economically unfeasible.

Cost Implications and Cycle Time

The tooling costs for squeeze casting are significantly higher than for gravity casting processes. The molds must be constructed from high-grade hot-work tool steels (like H13) to withstand the extreme thermal and mechanical stresses, leading to higher upfront capital investment. Additionally, the cycle times are generally longer than conventional high-pressure die casting because the component must remain under dwell pressure until it is fully solidified to ensure density. This extended cycle time can impact the total cost of ownership for high-volume parts where speed is the priority. For complex geometries that do not require structural properties, aluminum investment casting services might offer a better balance of cost and design freedom.

7. How Does Squeeze Casting Compare to High-Pressure Die Casting?

Velocity and Flow Dynamics

The fundamental difference between these two competing technologies lies in the velocity at which the molten metal enters the mold. Let’s look closer. In traditional die casting services , molten metal is injected at extremely high speeds (often exceeding 40 m/s). While this allows for thin walls and rapid filling, it inevitably causes turbulent flow that traps gas bubbles within the metal matrix. Squeeze casting, by contrast, utilizes a slow, controlled laminar flow (typically less than 0.5 m/s) to fill the cavity. This deliberate pace allows air to escape through vents rather than being mixed into the melt, creating a sounder casting.

Structural Integrity and Applications

This difference in flow dynamics leads to a divergence in applications. HPDC parts, due to their inherent porosity, are generally limited to non-structural housings, covers, and cosmetic parts where mechanical failure is not a life-safety issue. They cannot be welded or heat-treated reliably. Squeeze cast parts, possessing the integrity of a forged material, are fully compatible with welding and solution heat treatment. This makes them the clear winner for load-bearing components. While HPDC wins on cycle speed and piece price for commoditized parts, squeeze casting dominates where performance and safety are critical.

| Attribute | High-Pressure Die Casting (HPDC) | Squeeze Casting | |

|---|---|---|---|

| Injection Speed | High (Turbulent Flow) | Low (Laminar Flow) | |

| Internal Porosity | Common (Gas entrapment) | Very Low / None | |

| Heat Treatment | Generally Not Possible (Blistering risk) | Full T6 Capability | |

| Weldability | Poor | Excellent | |

| Mechanical Strength | Moderate | High | |

| Cost Per Part | Low (High Volume) | Moderate to High |

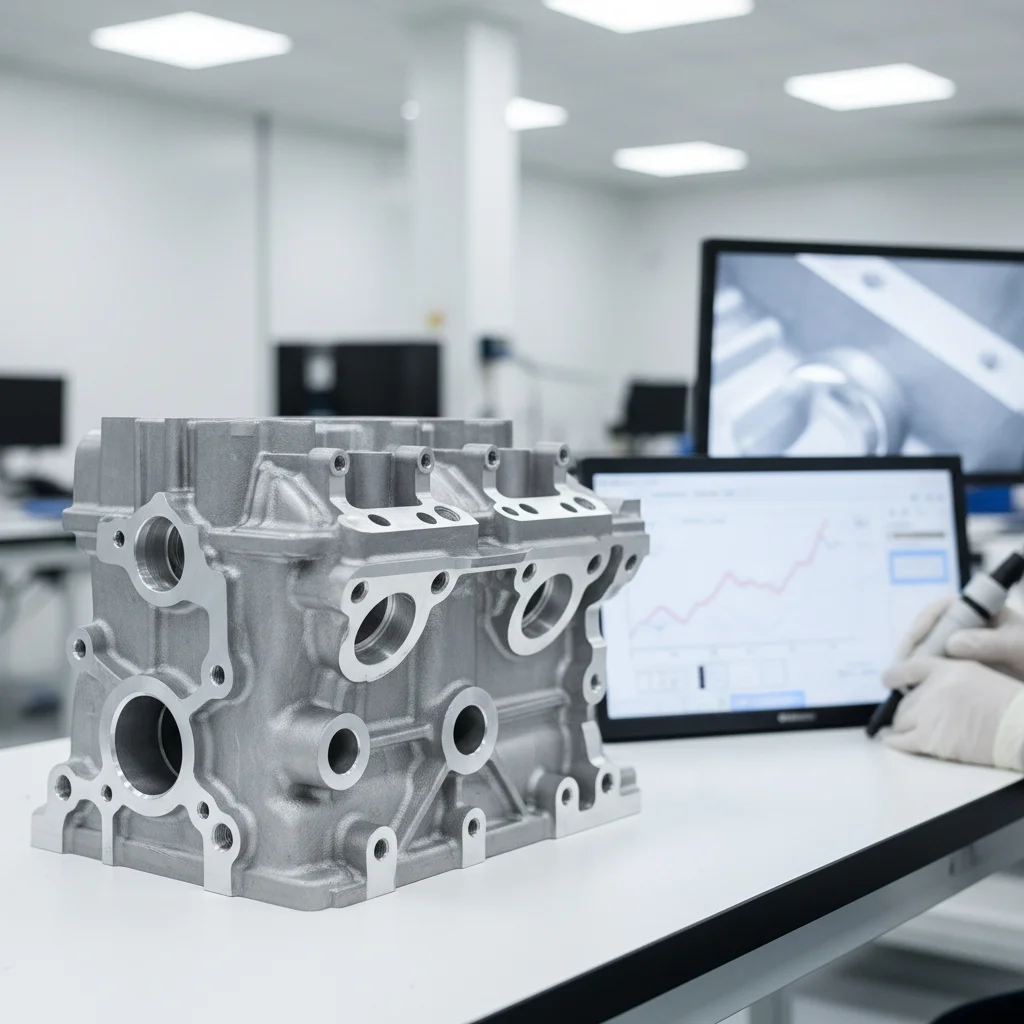

8. What Are the Major Industrial Applications of Squeeze Cast Parts?

Dominance in the Automotive Sector

The automobile industry is the primary driver of squeeze casting technology, largely due to the push for vehicle lightweighting to improve fuel economy and range for electric vehicles. The elimination of microporosity makes squeeze cast aluminum ideal for safety-critical chassis and suspension components. Parts such as steering knuckles, control arms, engine mounting brackets, and scroll compressor housings are prime examples. Why does this matter? By using squeeze casting, automakers can replace heavy cast iron or expensive forged steel components with lightweight aluminum parts that still possess the necessary fatigue strength and ductility to withstand road shocks and cyclic loading.

Critical Roles in Aerospace and Defense

Beyond the automotive world, the technology is widely adopted in the aerospace and military sectors. These industries demand components that must pass rigorous non-destructive testing, including X-ray inspection (ASTM E155 standards). Squeeze casting is used to manufacture structural nodes, missile casings, and hydraulic valve bodies. The ability to cast high-strength wrought alloys like 7075 allows aerospace engineers to design complex structural elements that are lighter than steel but stronger than conventional castings. In defense applications, track components for armored vehicles benefit from the process’s wear resistance and toughness.

9. How Does Squeeze Casting Stack Up Against Forging?

Balancing Design Flexibility and Strength

Forging has long been considered the gold standard for mechanical strength due to its grain flow alignment. However, forging is severely limited in terms of geometric complexity; it cannot easily produce internal cavities, undercuts, or complex 3D features without extensive and expensive machining. Here is the truth. Squeeze casting offers a strategic “middle ground.” It provides mechanical properties that approach or equal those of forgings (isotropic strength) but with the ability to create complex features like bosses, ribs, and variable wall thicknesses directly in the mold. This significantly reduces the need for subsequent machining operations and assembly steps.

Cost Efficiency and Material Utilization

From a cost perspective, squeeze casting often presents a more economical alternative to forging, especially for complex shapes. Forging typically involves multiple steps—heating, pre-forming, blocking, finishing, and trimming—generating significant flash waste. Squeeze casting is a single-step consolidation process that operates near-net shape, utilizing less raw material and energy. For high-performance parts where cost reduction is a priority alongside strength, squeeze casting is often the superior choice. It allows for the consolidation of multiple parts into a single robust casting, reducing assembly costs and failure points.

| Metric | Conventional Forging | Squeeze Casting | |

|---|---|---|---|

| Geometric Complexity | Low (Simple shapes preferred) | High (Complex 3D features allowed) | |

| Material Utilization | Moderate (Flash waste is common) | High (Near-net shape, minimal runner) | |

| Production Steps | Multiple (Heating, Forming, Trimming) | Single (Melting, Solidifying) | |

| Mechanical Properties | Excellent (Directional grain flow) | Very Good (Isotropic strength) | |

| Machining Required | High | Low (Near-net shape) |

10. What Common Defects Can Occur During the Process?

Oxide Inclusions and Process Control

Even with a robust process like squeeze casting, defects can occur if process parameters are not strictly managed. Don’t forget that oxide inclusions are a primary concern. These occur if the melt is turbulent during the pouring or injection phase, folding surface oxide films into the bulk of the casting. Because the metal solidifies under pressure, these oxides become trapped defects that act as stress concentrators, leading to premature failure under load. Maintaining strict laminar flow and using high-quality, clean melt practices are essential preventative measures.

Thermal and Pressure-Related Defects

Cold laps or “shut runs” can form if the molten metal loses too much heat before the final pressure is applied, preventing the material streams from fusing properly. This is often caused by low die temperatures or excessively slow filling speeds. Additionally, if the pressure is released too early during the cycle—before the center of the casting is fully frozen—blistering or shrinkage porosity can re-emerge during subsequent heat treatment. Rigorous process monitoring using X-ray testing services is essential to detect these internal flaws and ensure that every part meets the required quality standards.

11. What Critical Parameters Influence Casting Quality?

Pressure Magnitude and Timing

The success of a squeeze cast part hinges on the precise application of hydraulic pressure. Let’s dive deeper. The magnitude of the squeeze pressure (typically 50-100 MPa) directly influences the density and grain size of the alloy; higher pressure improves the heat transfer coefficient between the metal and the die. Equally critical is the time delay between pouring and pressurization. If the delay is too long, the metal solidifies prematurely, creating a thick frozen crust that prevents the pressure from effectively consolidating the core of the part. The pressure must be applied while the metal is in a liquid or semi-solid state to be effective.

Thermal Management

Melt temperature and die temperature must be maintained within tight processing windows. If the die is too cold, it induces premature freezing and surface defects; if too hot, it shortens tool life (via soldering) and increases cycle time. The melt temperature must be high enough to ensure fluidity for filling complex details but low enough to minimize hydrogen absorption and shrinkage. Advanced thermal management systems, often using oil or water channels, are employed to regulate the die temperature dynamically throughout the production run to maintain consistency.

| Parameter | Typical Range | Impact on Quality | |

|---|---|---|---|

| Applied Pressure | 50 – 150 MPa | Determines density, porosity elimination, and microstructure refinement | |

| Melt Temperature | 650°C – 750°C | Affects fluidity, filling capability, and risk of gas absorption | |

| Die Temperature | 200°C – 300°C | Controls cooling rate, surface finish, and cycle time | |

| Pressurization Delay | 0 – 10 seconds | Critical to ensure pressure acts on the liquid phase | |

| Pressurization Time | 10 – 40 seconds | Ensures complete feeding of shrinkage voids during freezing |

12. How Do Tooling and Mold Design Affect the Outcome?

Material Selection for Durability

Squeeze casting molds operate under punishing conditions, subjected to high thermal shock and immense mechanical stress from the hydraulic ram. As a result, high-quality hot-work tool steels, such as H13, are standard requirements for die construction. The tooling must be robust enough to resist deformation and thermal fatigue (heat checking) over thousands of cycles. Proper heat treatment and surface nitriding of the die are often performed to extend tool life and prevent the aluminum from soldering to the steel surface.

Design for Performance and Venting

Effective mold design is not just about the cavity shape; it includes critical considerations for venting and clearance. Since the process relies on air escaping ahead of the metal front, proper venting is essential to prevent entrapped air pockets. In direct squeeze casting, the clearance between the punch and the die must be carefully calculated (typically 0.05–0.1 mm). It must be tight enough to prevent molten metal from extruding out (flashing) under high pressure, but loose enough to allow the punch to move freely without galling. Advanced investment casting tooling principles are often adapted for indirect squeeze dies to optimize gate placement and thermal balance.

13. Is Squeeze Casting the Right Choice for Your Manufacturing Needs?

Assessing Volume and Performance Requirements

Deciding to implement squeeze casting requires a strategic evaluation of your project’s specific constraints. The bottom line is that if your component requires the mechanical properties of a forging (high strength, ductility, reliability) but has a geometry too complex for that process, squeeze casting is likely your optimal solution. It is the perfect fit for medium-to-high volume production runs of structural parts. However, for high-volume, non-structural parts where cost is the only driver, standard die casting remains the more economic choice.

ROI and Strategic Value

You must calculate the Return on Investment (ROI) by weighing the higher initial tooling and processing costs against the savings from reduced machining, material waste, and assembly steps. For safety-critical applications in automotive or aerospace where failure is not an option, the premium paid for squeeze casting is often justified by the guarantee of quality and performance. Furthermore, the ability to use lighter aluminum alloys instead of steel can provide significant value in terms of end-product efficiency and performance. If you are unsure about the suitability of your design, engaging in rapid prototyping or simulation prior to tooling can validate the feasibility.

Conclusion

Aluminum squeeze casting stands as a pivotal manufacturing technology that effectively bridges the gap between the high efficiency of die casting and the superior strength of forging. By applying sustained pressure during solidification, manufacturers can produce near-net shape components that are free from porosity, fully heat-treatable, and capable of meeting the rigorous safety demands of the automotive and aerospace sectors. As industries continue to push for lighter, stronger, and more complex parts, understanding and leveraging this process will be key to staying competitive in the global market. If you are ready to elevate your component quality and performance, we invite you to evaluate how squeeze casting can solve your toughest engineering challenges.

FAQ

Q1: What is the main difference between die casting and squeeze casting?The primary difference is the metal flow velocity and pressure application. Die casting injects metal at high speeds creating turbulence and porosity, whereas squeeze casting uses slow, laminar flow and applies high pressure during solidification to create a dense, defect-free part.

Q2: Can squeeze cast parts be welded?Yes, due to the virtual elimination of internal gas porosity, squeeze cast parts can be welded reliably without the risk of blistering or weak joints, which is a significant advantage over standard high-pressure die cast components.

Q3: What types of metals can be processed using squeeze casting?While aluminum alloys (both casting grades like A356 and wrought grades like 7075) are the most common, the process is also applicable to magnesium, copper, and zinc alloys, provided the melting points and reactivity are managed correctly.

Q4: Is squeeze casting more expensive than sand casting?Generally, yes. Squeeze casting involves significantly higher initial tooling and equipment costs compared to sand casting. However, for medium to high production volumes, the reduced machining requirements, superior material properties, and faster cycle times can make it more cost-effective per unit.

Q5: What represents the typical pressure range used in this process?Squeeze casting typically employs hydraulic pressures ranging from 50 MPa to over 150 MPa. This high pressure is essential for eliminating shrinkage voids, refining the grain structure, and ensuring the alloy’s mechanical properties are fully realized.