Introduction

Struggling with inconsistent aluminum quality and rising production costs in your manufacturing operations? Traditional casting methods often lead to high scrap rates, delaying deliveries and straining budgets. But here’s how it changes everything: Continuous casting aluminum streamlines molten metal into uniform semi-finished products, slashing waste by up to 30% while boosting efficiency. As experts in precision manufacturing, we deliver reliable solutions that help B2B partners like you achieve superior output. Explore our aluminum casting services to see how this process fits your needs. This guide covers the essentials, from mechanics to applications, empowering you to optimize your supply chain.

What is Continuous Casting Aluminum?

Continuous casting aluminum represents a pivotal advancement in metal fabrication, where molten aluminum solidifies into long, uniform shapes like billets or slabs without interruption. You pour the liquid metal into a cooled mold, and as it hardens, machinery pulls it steadily forward, creating semi-finished products ready for further processing. Unlike batch methods that halt production repeatedly, this approach ensures seamless flow, ideal for high-volume B2B demands in automotive or construction. You might be wondering why it’s essential now: With global aluminum needs surging 5% annually, adopting this technique lets you meet tight deadlines while maintaining consistency. It minimizes human error through automation, directly impacting your bottom line by reducing rework. For instance, a mid-sized fabricator switched to continuous casting and cut lead times by 25%, proving its value in competitive markets. This process suits low-alloy aluminum best, leveraging its low melting point for smooth operation. Overall, it transforms raw material into reliable stock, positioning your operations for scalable growth.

| Aspect | Description | Benefit for Your Business | |

|---|---|---|---|

| Core Mechanism | Molten pour into cooled mold | Uniform shapes reduce machining needs | |

| Output Forms | Billets, slabs, rods | Versatile for downstream extrusion | |

| Adoption Rate | Used in 70% of global aluminum | Ensures supply chain reliability |

History of Continuous Casting Aluminum

The journey of continuous casting aluminum began in the mid-19th century with early experiments in steel, but aluminum adaptations emerged post-World War II amid rising demand for lightweight materials. By the 1950s, pioneers like Alcoa developed direct chill casting, enabling efficient billet production that revolutionized aerospace components. Here’s the deal: You trace its evolution to understand modern efficiencies—initial challenges with alloy compatibility gave way to automated systems in the 1980s, slashing energy use by 20%. Today, innovations like twin-roll casters dominate, supporting B2B sectors with precise outputs. Consider how a European foundry in the 1970s adopted it, boosting productivity 40% during economic booms. This historical shift from ingot methods highlights reliability gains, as uneven cooling in older techniques caused defects now largely eliminated. For your operations, grasping this timeline informs upgrades, ensuring you leverage proven tech for cost-effective scaling. Ongoing refinements, like electromagnetic stirring, continue to refine quality, making it indispensable for sustainable manufacturing.

| Milestone | Year | Key Impact | |

|---|---|---|---|

| Early Experiments | 1850s | Conceptual foundation for metal flow | |

| Aluminum Adaptation | 1950s | Direct chill method for billets | |

| Automation Era | 1980s | 20% energy savings industry-wide |

How Does Continuous Casting Aluminum Work?

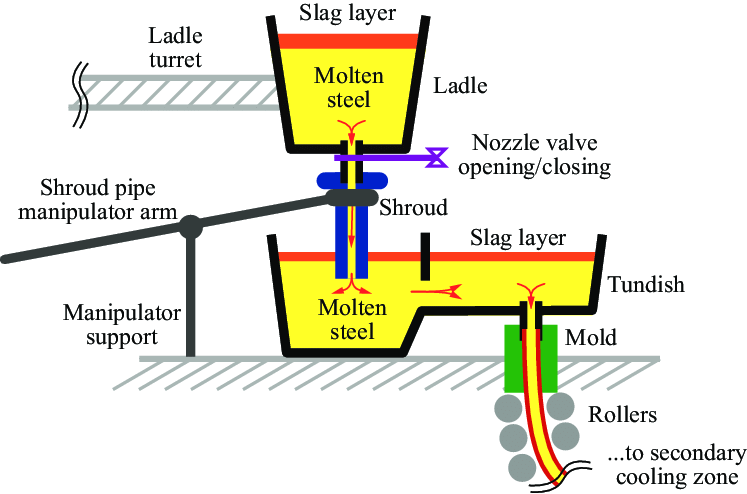

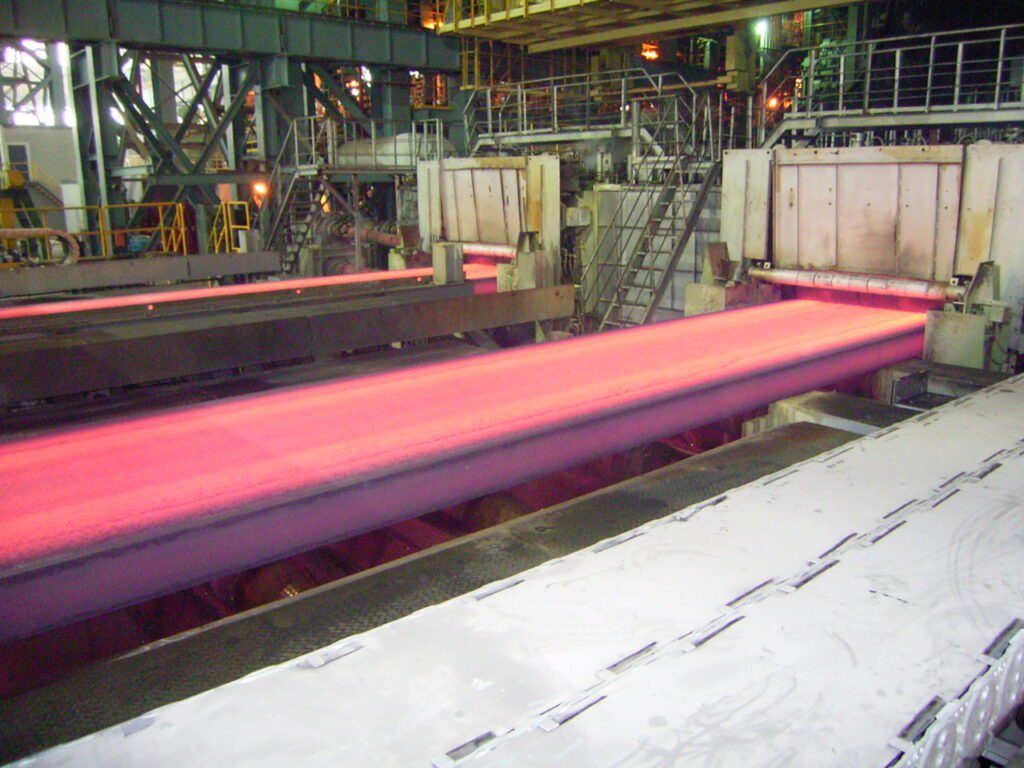

Continuous casting aluminum starts by melting raw stock in furnaces at around 660°C, then refining the molten flow through degassing to remove impurities. You transfer it to a tundish, pouring steadily into a water-cooled mold where outer layers solidify first, forming a shell while the core remains liquid. Rollers guide the strand forward at controlled speeds, with secondary sprays ensuring full hardening. Ready for the good part? This mechanism yields dense microstructures, vital for your structural parts. In practice, a billet exits at 4-6 mm thickness, cut to length via saws—perfect for extrusion feeds. Temperature management hovers at 700-750°C during pour, preventing cracks through precise cooling gradients. For B2B efficiency, automation syncs withdrawal with pour rates, minimizing downtime. One automotive supplier integrated this, achieving 50 tons daily without interruptions. Variations like vertical or horizontal setups adapt to your facility layout, optimizing space. Ultimately, this workflow delivers near-net shapes, cutting secondary operations and enhancing your throughput.

| Process Step | Temperature Range | Duration | |

|---|---|---|---|

| Melting | 660°C | 1-2 hours | |

| Pouring & Solidification | 700-750°C | Continuous | |

| Cooling & Withdrawal | Ambient to 100°C | 5-10 minutes per meter |

Materials Used in Continuous Casting Aluminum

Continuous casting aluminum thrives with alloys exhibiting good fluidity and narrow freezing ranges, primarily 1xxx, 3xxx, and 5xxx series for their compatibility. You select based on end-use—pure aluminum for conductivity in wiring, or Al-Mg blends for corrosion resistance in marine parts. What’s the real story? Impurities like hydrogen demand rigorous filtration, as even trace amounts cause porosity in your high-stakes components. Common choices include 3003 (Al-Mn) for general fabrication, offering 1-2% manganese to enhance strength without brittleness. Silicon additions in 4xxx series improve castability, though limited to 1% to avoid cracking. For B2B versatility, these materials support recycling, with up to 95% scrap reuse aligning with sustainability goals. A packaging firm using 5182 alloy saw 15% better formability post-casting. Degassing units and ceramic filters ensure purity, directly safeguarding your product integrity. This selection process not only matches mechanical needs but also optimizes costs, as low-alloy feeds reduce setup complexities in your lines.

| Alloy Series | Key Elements | Typical Applications | |

|---|---|---|---|

| 1xxx | Pure Al | Electrical conductors | |

| 3xxx | Mn (1-2%) | Beverage cans, sheets | |

| 5xxx | Mg (2-3%) | Marine hulls, automotive |

Advantages of Continuous Casting Aluminum

Continuous casting aluminum excels in efficiency, transforming molten input directly into usable forms and eliminating multiple reheating steps you face in ingot processes. This yields 30-50% higher throughput, crucial for your scaling demands. This is where it gets interesting: Cost savings hit 20-30% through waste reduction—near-net shapes mean less scrap, directly padding your margins. Quality shines with uniform grain structures, boosting tensile strength by 15% over traditional casts, ideal for aerospace tolerances. Energy use drops as continuous flow avoids batch inefficiencies, supporting your green initiatives. A construction supplier reported 25% lower operational costs after adoption, thanks to fewer defects like segregation. Versatility spans simple billets to strips, fitting diverse B2B needs without retooling. Enhanced surface finish cuts post-processing, freeing resources for innovation. Overall, these perks position continuous casting as a strategic edge, enabling you to deliver premium products faster and cheaper while meeting industry standards effortlessly.

| Advantage | Quantitative Gain | Business Impact | |

|---|---|---|---|

| Efficiency | 30-50% throughput | Faster market delivery | |

| Cost Reduction | 20-30% savings | Improved profitability | |

| Quality Uniformity | 15% strength boost | Fewer returns, higher trust |

Challenges and Limitations in Continuous Casting Aluminum

High setup costs pose the biggest hurdle in continuous casting aluminum, with equipment like molds and furnaces demanding substantial upfront investment—often $10-20 million for a full line. You navigate this by phasing implementations, but smaller operations struggle against economies of scale. But here’s the kicker: Temperature fluctuations risk defects like porosity, where gas bubbles weaken your billets if cooling isn’t precise. Maintenance intensifies due to wear from 750°C operations, requiring frequent inspections to avoid downtime costing thousands hourly. Alloy limitations restrict high-solute mixes, as wide freezing ranges cause cracks in 6xxx series for automotive. Scalability favors large volumes; low runs amplify per-unit expenses. A fabricator faced 10% yield loss initially from uneven solidification, underscoring training needs. Space demands for cooling zones add facility constraints. Yet, with expert oversight, you mitigate these through simulations and alloys tweaks, turning potential pitfalls into manageable aspects that still outperform batch methods in the long run.

| Challenge | Cause | Mitigation Strategy | |

|---|---|---|---|

| High Costs | Equipment investment | Phased rollout, financing | |

| Defects | Temperature variance | Advanced sensors, controls | |

| Maintenance | Thermal wear | Scheduled overhauls |

Applications of Continuous Casting Aluminum

Continuous casting aluminum powers automotive engine blocks and chassis, where lightweight billets reduce vehicle weight by 10-15% for better fuel economy. You integrate these in assembly lines for seamless extrusion into profiles. Imagine your sector transformed: In aerospace, slabs form turbine housings enduring extreme stresses, with uniform density ensuring safety compliance. Construction relies on rods for beams and frames, offering corrosion resistance in harsh environments. Electronics benefit from conductive strips in heat sinks and wiring, dissipating heat efficiently in devices. A marine builder used 5xxx alloys for hull components, cutting maintenance 20%. Packaging draws on thin sheets for cans, leveraging recyclability. Energy sectors employ pipes from cast stock for transmission lines. This versatility spans B2B needs, from high-volume automotive to custom aerospace, driving innovation. With our services , you access tailored applications that enhance durability and performance across industries.

| Industry | Key Products | Performance Gain | |

|---|---|---|---|

| Automotive | Engine blocks, wheels | 10-15% weight reduction | |

| Aerospace | Turbine blades | Enhanced stress tolerance | |

| Construction | Beams, frames | Superior corrosion resistance |

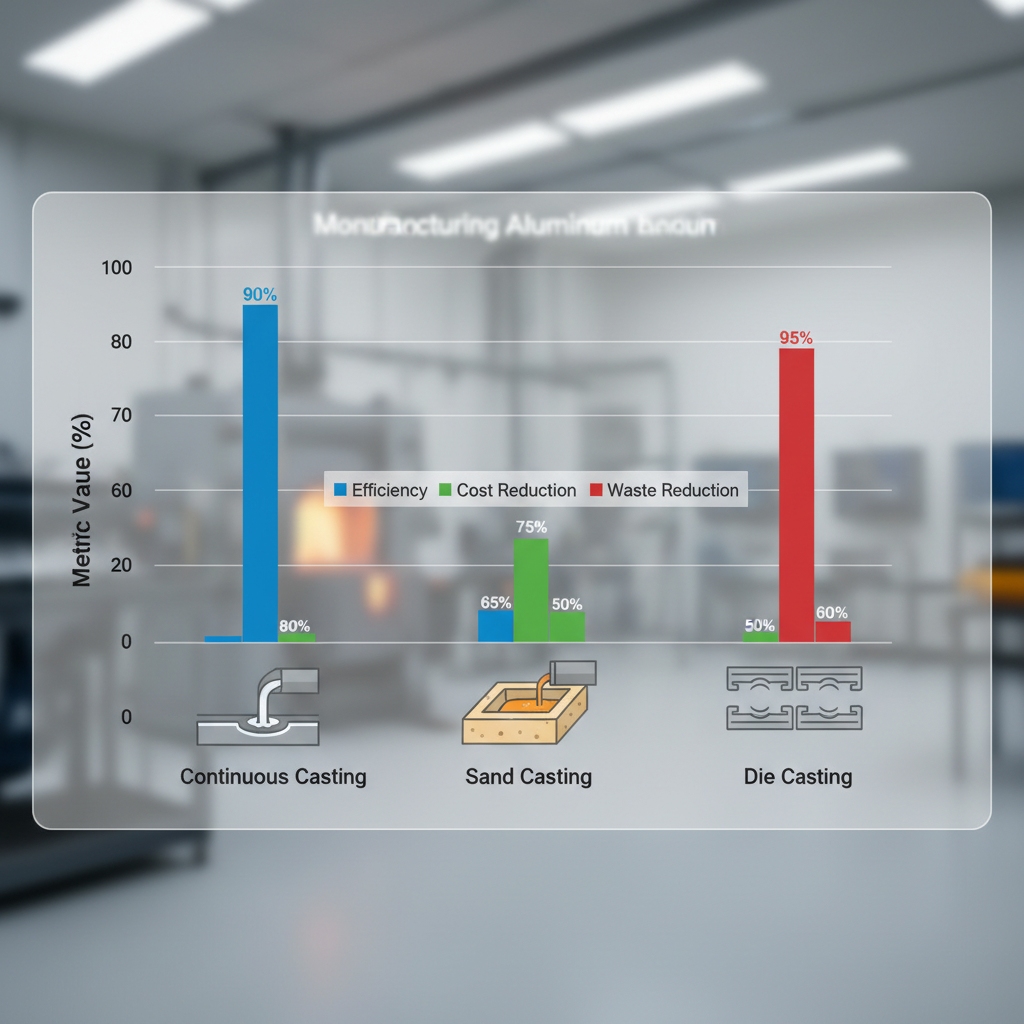

Continuous Casting Aluminum vs. Other Casting Techniques

Continuous casting aluminum outperforms sand casting in uniformity, producing defect-free billets versus sand’s rough surfaces needing heavy machining—saving you 25% in post-processing. Die casting shines for intricate parts under pressure, but continuous edges it for high-volume simples with lower tooling costs long-term. Let’s break it down: Lost foam offers design freedom without seams, yet continuous casting minimizes waste better for scalable runs, ideal for your structural needs. Sand suits prototypes cheaply but lags in speed; die excels in precision for small batches, though porosity limits welding. A comparison shows continuous at 40% faster throughput than sand, with 15% better yield over die for alloys. Environmental edges favor continuous via recycling integration. For B2B decisions, choose based on volume—continuous for efficiency in billets, others for complexity. Explore casting comparisons for deeper insights.

| Method | Strength | Weakness vs. Continuous | |

|---|---|---|---|

| Sand Casting | Low cost for prototypes | Rough finish, high waste | |

| Die Casting | High precision | Expensive molds, porosity | |

| Lost Foam | Complex shapes | Slower for volumes |

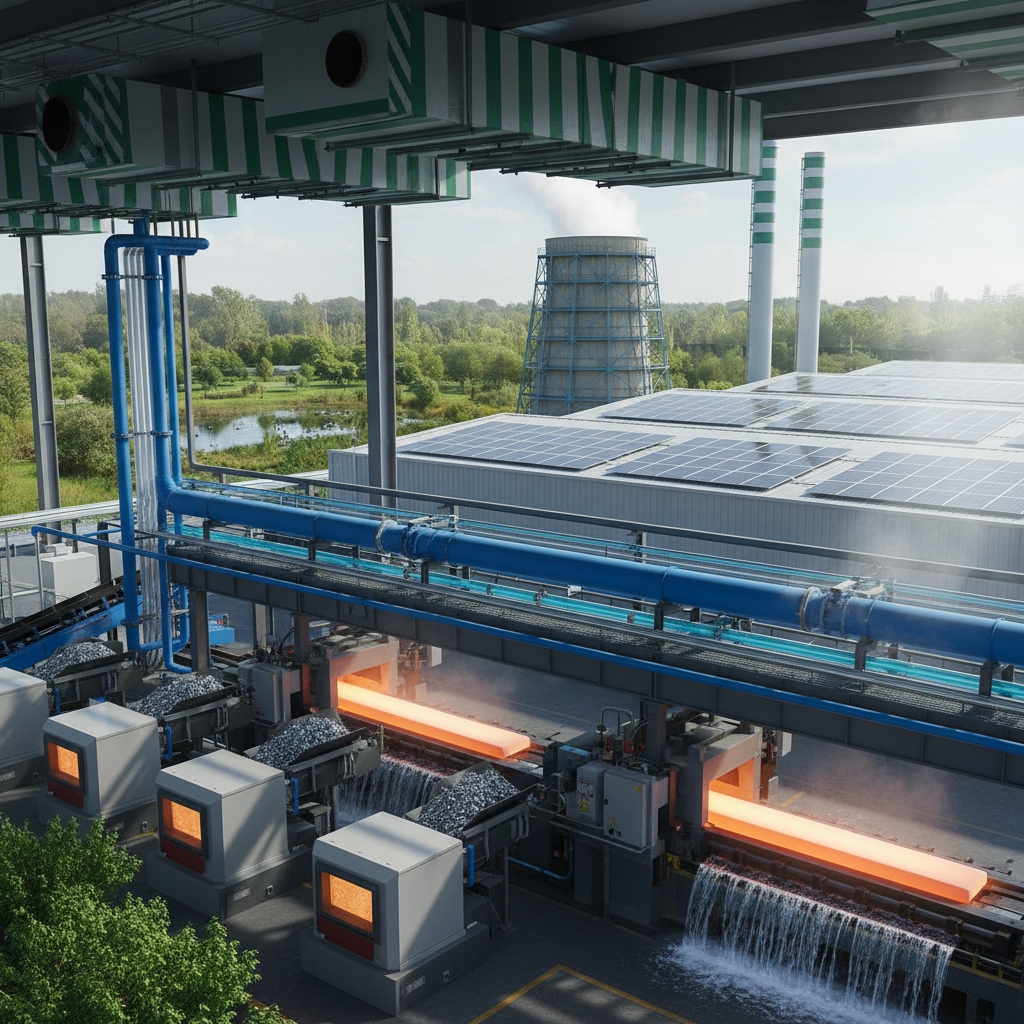

Environmental Impact and Sustainability of Continuous Casting Aluminum

Continuous casting aluminum cuts energy by 20-30% over batch methods, as uninterrupted flow avoids reheating, aligning with your ESG targets. Recycling integrates seamlessly, using 95% less power for scrap—reducing emissions dramatically. Sustainability isn’t automatic: Water cooling demands management, but closed loops recycle 90%, minimizing discharge. Emissions from melting drop with filters capturing particulates, though NOx requires scrubbers. A facility adopting this saw carbon footprint halve, proving viability. Waste like slag finds reuse in construction, closing loops. For B2B, it supports green certifications, with alloys like recycled 5xxx enhancing circularity. Challenges include initial fossil fuel reliance, mitigated by renewables. Overall, this process fosters sustainable supply chains, helping you meet regulations while innovating responsibly. Check our homepage for eco-focused solutions.

| Impact Area | Reduction Achieved | Sustainability Practice | |

|---|---|---|---|

| Energy Use | 20-30% | Continuous flow efficiency | |

| Emissions | 50% via recycling | Advanced filtration systems | |

| Water Consumption | 90% recycled | Closed-loop cooling |

Future Trends in Continuous Casting Aluminum

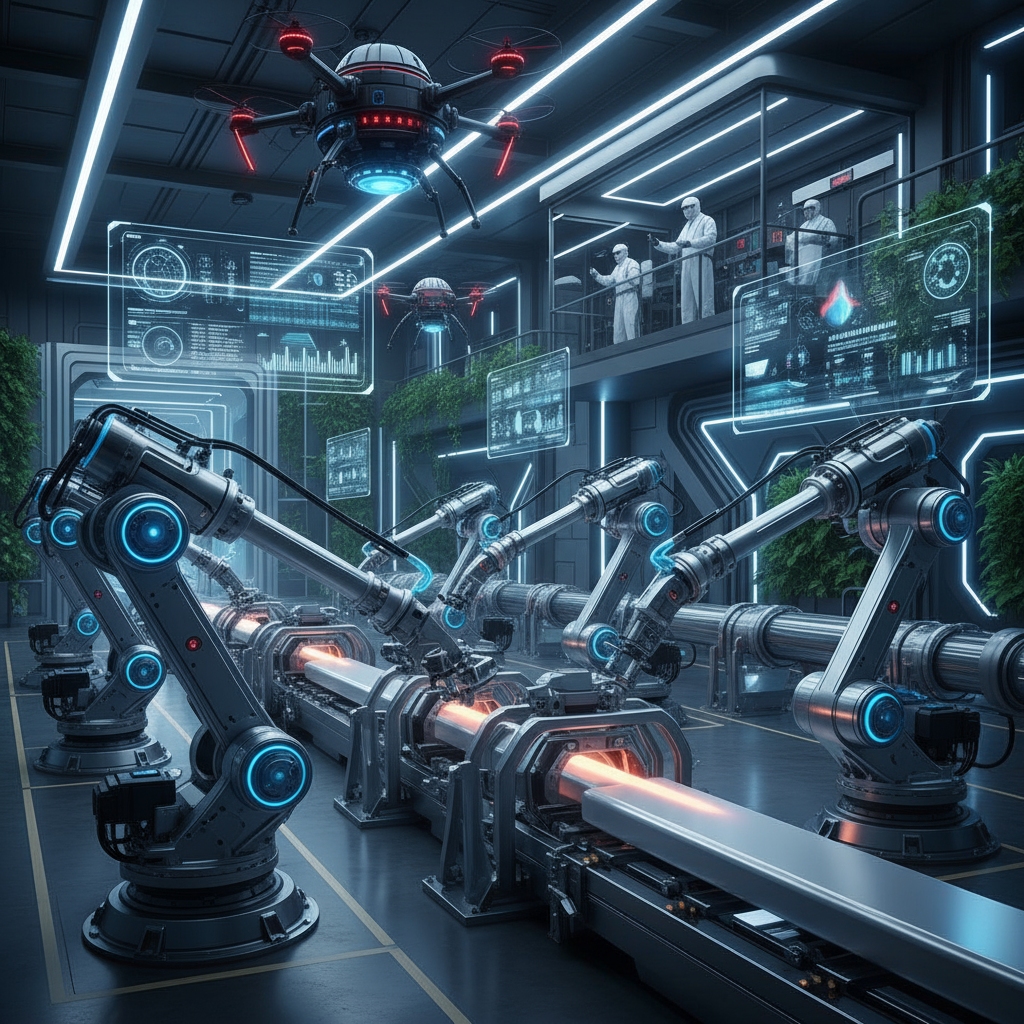

Automation surges in continuous casting aluminum, with AI predicting defects via sensors, cutting downtime 15% for your operations. The future accelerates: Hybrid alloys like high-entropy blends promise 20% stronger outputs, suiting aerospace demands. IoT enables real-time tweaks, optimizing speeds for greener runs. 3D-printed molds speed prototyping, reducing lead times. Sustainability drives bio-lubricants and full electrification, slashing footprints further. A forward-thinking supplier integrated robotics, boosting yields 25%. Simulation software forecasts microstructures, minimizing trials. For B2B, these trends mean adaptable lines handling diverse alloys. With our expertise in emerging trends , you stay ahead. Expect precision near-net shapes dominating, revolutionizing your prototyping.

| Trend | Timeline | Expected Benefit | |

|---|---|---|---|

| AI Automation | 2025-2030 | 15% less downtime | |

| Hybrid Alloys | Ongoing | 20% strength gains | |

| IoT Integration | Immediate | Real-time optimization |

Conclusion

Continuous casting aluminum streamlines production with efficient processes, superior materials handling, and clear benefits in quality and cost, while addressing challenges through innovation. It powers diverse applications from automotive to electronics, outshining alternatives in scalability and sustainability. Future trends like AI and green tech promise even greater efficiencies. Embrace this method to future-proof your operations—contact us today for a customized consultation. You can transform challenges into opportunities, driving sustainable growth and client satisfaction now.

FAQ

Q1: Is continuous casting aluminum suitable for small-scale production? No, it’s best for high volumes due to setup costs and optimization for uniform outputs; reasons include economies of scale that favor large runs, reducing per-unit expenses significantly.

Q2: How does continuous casting aluminum handle complex alloys? Moderately well for low-alloy but challenges high-solute ones; reasons involve wider freezing ranges risking cracks, though advancements like slower speeds mitigate this for better control.

Q3: What maintenance is required for continuous casting equipment? Regular and rigorous, focusing on molds and cooling; reasons stem from high-temperature wear, ensuring uptime and defect prevention through scheduled inspections.

Q4: Can continuous casting aluminum replace die casting entirely? Not entirely, as it excels in semi-finished shapes but lacks die casting’s precision for intricate parts; reasons include process differences in pressure vs. flow, suiting varied needs.

Q5: How environmentally friendly is continuous casting aluminum? Highly, with 95% energy savings via recycling; reasons encompass reduced waste and emissions, though water management is key for full sustainability.