Getting aluminum casting right is a tightrope walk. Incorrect temperatures lead to costly defects like porosity and cracks, ruining entire production batches and wasting valuable resources. These failures aren’t just inconvenient; they erode profit margins, delay project timelines, and damage your professional reputation. This guide provides the expert insights needed to master your aluminum casting temperature, ensuring you produce high-quality, defect-free parts consistently.

The Core Aluminum Casting Temperature Range

The ideal aluminum casting temperature for pouring is typically between 680°C and 750°C (1256°F and 1382°F). This window provides optimal fluidity for the molten metal to fill the mold completely without introducing excessive heat that can cause defects. Staying within this range is the first step toward a successful cast.

Why does this range matter so much?

This temperature directly impacts the final mechanical properties of your cast part, including its tensile strength and hardness. Proper temperature control is essential for forming a fine, consistent grain structure. What does this mean for you? A stronger, more reliable final product.

- It determines grain structure formation.

- It affects hydrogen absorption, a primary cause of porosity.

- It influences surface finish and dimensional accuracy.

Key Takeaway: Adhering to the 680-750°C aluminum casting temperature range is the most critical factor for preventing common defects and achieving desired part strength.

| Temperature Anomaly | Resulting Defects & Issues | |

|---|---|---|

| Too Low (<680°C) | Misruns, Cold Shuts, Incomplete Fill | |

| Optimal (680-750°C) | Good Fluidity, Fine Grain Structure | |

| Too High (>750°C) | Shrinkage, Gas Porosity, Hot Tearing |

This analysis shows that deviations from the optimal temperature window directly cause predictable, costly defects.

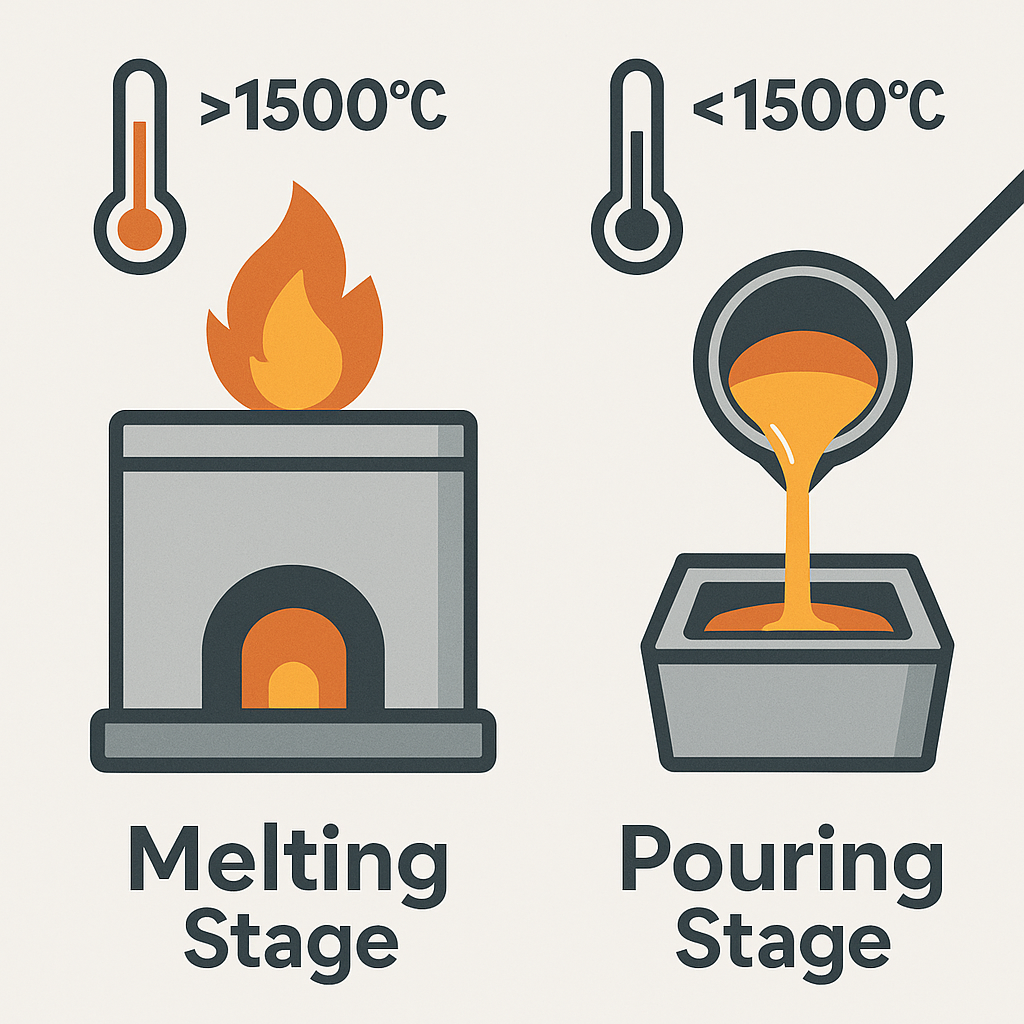

Melting Aluminum Casting Temperature Explained

The melting phase focuses on transforming solid ingots into a homogenous liquid, which occurs between 463°C and 671°C (865°F and 1240°F), depending on the specific alloy. This initial stage is foundational, as improper melting can compromise the integrity of your material before you even pour. It’s a critical part of the overall investment casting process .

How does melting temp affect alloy integrity?

Improper melting can cause the loss of essential alloying elements through oxidation, altering the metal’s final properties. A controlled melting rate is key to preserving the intended composition. Here’s the deal: you must protect the molten surface from excessive air exposure.

- “Burning off” elements like magnesium degrades the alloy.

- A protective layer of flux should be used on the molten surface.

- The melting rate should be controlled and steady.

Key Takeaway: To prevent alloy degradation, always melt aluminum within the specific range listed on its technical data sheet and use flux to protect the molten bath.

| Alloy (AA) | Typical Melting Range (°C) | Key Characteristics | |

|---|---|---|---|

| A356 | 557 – 613 | Excellent castability, high strength | |

| A380 | 521 – 593 | Common die-casting alloy | |

| 319 | 516 – 604 | Good casting & machining properties |

This table shows how different alloys have unique melting points, reinforcing the need for alloy-specific procedures.

Pouring Aluminum Casting Temperature Control

The pouring aluminum casting temperature is the temperature of the molten metal as it enters the mold. This must be high enough for a complete fill but low enough to minimize defects. This balance is achieved by adding “superheat” to the molten metal.

Why is pouring temp different from melting?

Pouring temperature includes a “superheat”—typically 50-100°C above the alloy’s liquidus point—to compensate for heat loss during transfer. This ensures the metal remains fluid long enough to completely fill the mold cavity before solidifying. You might be wondering, is this always necessary?

- Superheat ensures fluidity despite heat loss in the ladle.

- It helps prevent defects like cold shuts and misruns.

- The amount of superheat depends on the casting’s size and complexity.

Key Takeaway: Don’t rely on the furnace temperature; always measure the molten metal in the ladle just before pouring to confirm the correct superheat and pouring temperature.

| Measurement Tool | Principle | Pros | Cons | |

|---|---|---|---|---|

| Type K Thermocouple | Direct Contact | High accuracy, industry standard | Consumable tips | |

| Infrared Pyrometer | Non-Contact | Fast, safe for operator | Less accurate, affected by smoke |

This comparison highlights why a direct-contact thermocouple is the preferred tool for critical temperature verification.

Alloy’s Role in Aluminum Casting Temperature

The specific aluminum casting temperature you need is heavily dependent on the alloy’s composition. Elements like silicon, copper, and magnesium directly influence the melting point, fluidity, and solidification characteristics of the metal. You cannot use a one-size-fits-all approach.

Do all aluminum alloys melt the same?

Different aluminum alloys have unique melting ranges and casting characteristics. For instance, eutectic alloys have a narrow freezing range, while others have a wider one, impacting how they solidify. The simple answer is no.

- Casting alloys (e.g., A380) behave differently from wrought alloys (e.g., 6061).

- The alloy series (1xx.x to 8xx.x) indicates different primary alloying elements.

- Always check the technical data sheet for your specific alloy.

Key Takeaway: Alloy composition is a primary driver of the required temperature; always adjust your process parameters based on the specific alloy being cast.

| Alloying Element | Impact on Melting Point | Impact on Fluidity | |

|---|---|---|---|

| Silicon (Si) | Significantly lowers | Significantly improves | |

| Copper (Cu) | Can create a wide freezing range | Moderate improvement | |

| Magnesium (Mg) | Slight effect; primarily for strength | Can reduce fluidity if uncontrolled |

This table illustrates how key elements dictate the thermal behavior of the aluminum during casting.

Defects from Bad Aluminum Casting Temperature

An incorrect aluminum casting temperature is a primary cause of many common casting defects. Understanding the direct link between temperature and specific flaws is essential for effective quality control. This knowledge empowers you to troubleshoot and prevent costly failures.

Can wrong temps cause porosity and cracks?

Yes, high temperatures increase the molten metal’s ability to absorb gas like hydrogen, which then forms bubbles (porosity) during cooling. High temperatures also create greater stress during solidification, leading to hot tears or cracks. Without a doubt, temperature is a leading cause of these defects.

- Gas porosity appears as small, spherical voids.

- Hot tears are ragged cracks that form when the metal is semi-solid.

- Shrinkage porosity results from insufficient feeding of molten metal.

Key Takeaway: Porosity and hot tears are often direct consequences of a poorly managed aluminum casting temperature.

| Defect | Likely Temperature Cause | Visual Appearance | |

|---|---|---|---|

| Gas Porosity | Too high (melting or pouring) | Small, shiny-walled bubbles | |

| Shrinkage Porosity | Too high (pouring) | Jagged, internal voids | |

| Hot Tear | Too high (pouring) | A ragged, open crack | |

| Cold Shut | Too low (pouring) | A line where metal fronts failed to fuse |

This defect analysis directly ties common casting flaws back to specific temperature-related errors.

Measuring Aluminum Casting Temperature

Accurate measurement is non-negotiable for controlling the aluminum casting temperature. Relying on guesswork or visual cues is a recipe for inconsistency and defects. Using the right tools and techniques is fundamental to a repeatable, high-quality process.

What are common measurement mistakes?

Common errors include using uncalibrated equipment or measuring the cooler surface dross instead of the clean metal beneath it. A pyrometer reading can also be skewed by smoke or an incorrect distance from the target. Think about it this way: bad data leads to bad decisions.

- Never assume a new tool is accurate without calibration.

- Always clear dross before immersing a thermocouple.

- Use a thermocouple for final verification, not just a pyrometer.

Key Takeaway: For the most accurate aluminum casting temperature, use a calibrated immersion thermocouple inserted below the surface dross right before you pour.

| Best Practice | Rationale | Common Mistake | |

|---|---|---|---|

| Calibrate tools regularly | Ensures readings are accurate and trustworthy. | Assuming a tool is accurate out of the box. | |

| Immerse thermocouple | Measures the true metal temp, not the cooler surface. | Taking a shallow or surface reading. | |

| Measure just before pouring | Accounts for heat loss during transfer from the furnace. | Relying on the furnace display alone. |

This table of best practices provides a clear roadmap for achieving accurate temperature measurements every time.

Mold’s Impact on Aluminum Casting Temperature

The mold itself acts as a massive heat sink, and its material, temperature, and design directly influence the required pouring aluminum casting temperature. A cold steel mold will extract heat far more rapidly than an insulated sand mold. This interaction must be managed to prevent defects.

Does wall thickness change the temp needs?

Thin-walled sections require higher pouring temperatures to ensure the metal flows into the intricate details before it freezes. Conversely, thick sections can be poured at lower temperatures because their large volume retains heat longer. Absolutely, and here’s why: fluidity must be maintained until the mold is full.

- Thin sections have a high surface-area-to-volume ratio, causing rapid cooling.

- Thick sections act as a heat reservoir.

- A balanced approach is needed for parts with both thick and thin sections.

Key Takeaway: The mold’s design dictates the required fluidity and thus the pouring temperature; thin sections need higher temperatures than thick ones.

| Mold Factor | Impact on Required Pouring Temp | Rationale | |

|---|---|---|---|

| Sand Mold | Lower | Good insulator, slow heat extraction. | |

| Steel Permanent Mold | Higher | High conductivity, rapid heat extraction. | |

| Thin Casting Section | Higher | Metal freezes quickly, needs high fluidity. | |

| Thick Casting Section | Lower | Section retains heat, slower solidification. |

This analysis shows how the mold itself is an active variable in your temperature control strategy.

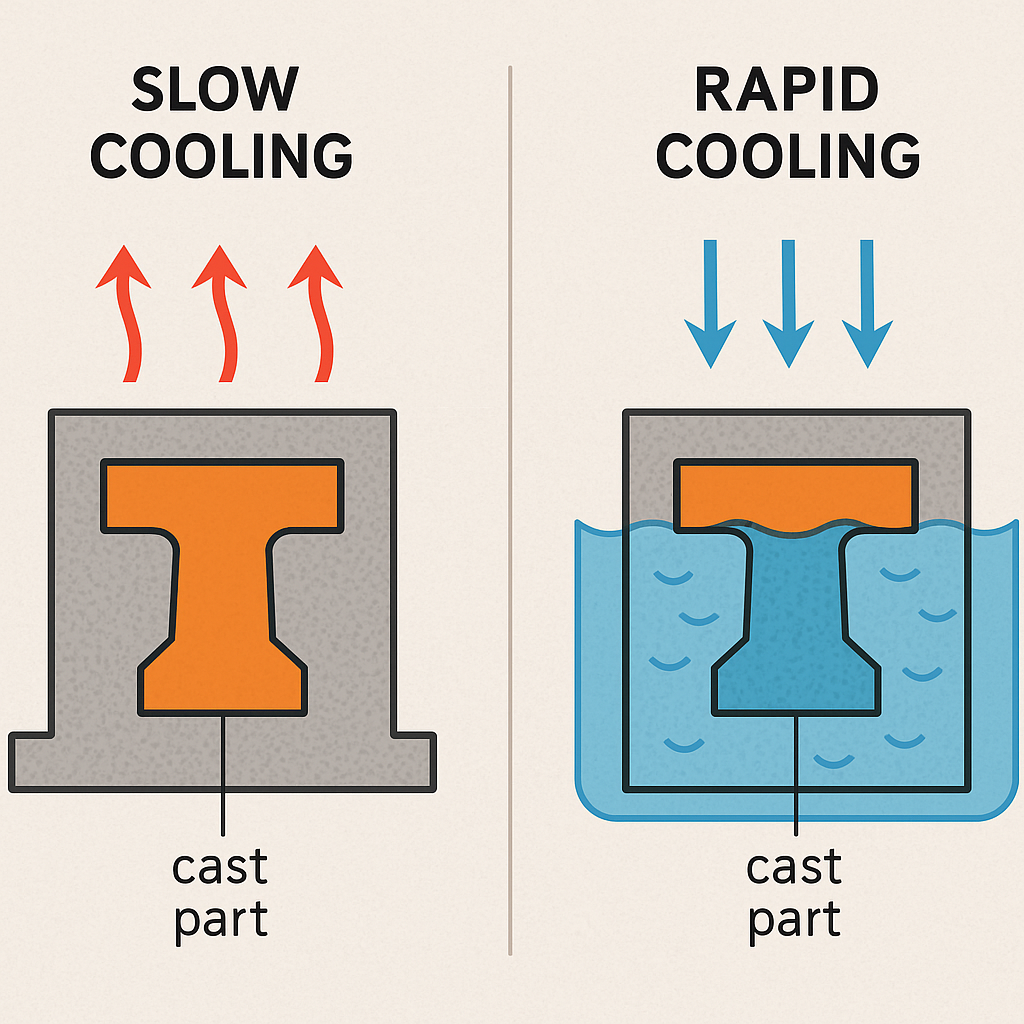

Cooling and Aluminum Casting Temperature

The casting process doesn’t end after the pour; the cooling rate is critical for determining the final microstructure and mechanical properties. A faster cooling rate generally produces a finer, stronger grain structure. Controlling this phase is just as important as managing melting and pouring temperatures.

How does cooling rate impact grain structure?

Faster cooling creates many small nucleation points, resulting in a fine-grained structure that is stronger and harder. Slow cooling allows fewer, larger grains to form, which typically results in a softer but more ductile material. This is a crucial point for achieving desired mechanical specifications.

- Rapid cooling occurs in water-cooled dies or with chills.

- Slow cooling is typical in large, insulated sand molds.

- The desired grain structure depends on the application’s requirements.

Key Takeaway: The cooling rate directly controls the casting’s final strength. Faster cooling generally yields a stronger part and can be managed with chills and proper mold design.

| Cooling Rate | Grain Structure | Resulting Mechanical Properties | |

|---|---|---|---|

| Fast | Fine | High strength, high hardness | |

| Slow | Coarse | Lower strength, higher ductility |

This data clearly connects the post-pour cooling process to the final, tangible properties of the casting.

Tech for Aluminum Casting Temperature

Modern foundries leverage advanced technology to precisely model, monitor, and control the aluminum casting temperature. These tools help move operations from reactive troubleshooting to proactive, data-driven precision. Embracing technology reduces human error and improves part-to-part consistency.

How can software simulate temperature flow?

Solidification modeling software can predict how molten metal will flow, cool, and solidify within a mold design before any metal is melted. This allows engineers to identify and correct potential hot spots or shrinkage areas digitally. Imagine being able to see the future of your casting.

- Simulation helps optimize gating and riser design.

- It prevents costly trial-and-error with physical molds.

- Software like MAGMASOFT or Flow-3D are industry standards.

Key Takeaway: Advanced technology like solidification simulation allows foundries to engineer for quality proactively by mastering the thermal dynamics of a cast before production begins.

| Technology | Function | Key Benefit | |

|---|---|---|---|

| Solidification Simulation | Predicts metal flow and cooling. | Prevents defects before production. | |

| Automated Pouring | Doses molten metal automatically. | Ensures consistent pouring temperature and rate. | |

| Data Logging | Records process parameters. | Enables traceability and quality improvements. |

This summary shows how modern tech provides control over the casting process at every stage.

Best Practices for Aluminum Casting Temperature

Achieving consistent results in aluminum casting requires a disciplined approach rooted in best practices. It’s about combining calibrated tools with documented processes and well-trained personnel. These habits are the foundation of any high-quality casting operation.

How to create a temperature process sheet?

A process sheet, or “recipe card,” should be created for each part you cast. This document specifies every critical temperature parameter, ensuring anyone on your team can reproduce a successful result. It’s all about repeatability.

- List the alloy and its specific melting range.

- Specify the target furnace, ladle, and pouring temperatures.

- Include any mold preheating requirements.

Key Takeaway: Consistency is achieved through documented processes (process sheets) and well-trained staff who understand the critical importance of every aspect of aluminum casting temperature control, a core value we uphold in our company culture .

| Best Practice | Description | Goal | |

|---|---|---|---|

| Daily Calibration | Check all temperature sensors against a known standard. | Accuracy | |

| Process Sheets | Document the specific temperature “recipe” for each part. | Consistency | |

| Operator Training | Educate staff on the ‘why’ behind temperature control. | Competency |

This table outlines the three pillars of a repeatable and reliable temperature control strategy.

Conclusion

Mastering aluminum casting temperature is the cornerstone of producing high-quality, defect-free components. By controlling every stage—from melting to cooling—you eliminate guesswork and ensure reliable, repeatable results. This guide has armed you with the knowledge to combat common casting issues like porosity and shrinkage by mastering thermal control. At Precisionvast, we don’t just cast metal; we forge partnerships based on a commitment to quality and decades of experience.

If you’re ready to partner with an expert who lives and breathes precision, contact Precisionvast today to discuss your next aluminum casting project.

Frequently Asked Questions (FAQ)

Q1: Can I use the same temperature for all aluminum alloys?No. Each aluminum alloy has a unique composition that dictates its specific melting range and fluidity. Always consult the alloy’s technical data sheet and create a unique process recipe for each one.

Q2: What’s the best way to measure molten aluminum temperature?The most reliable method is using a calibrated Type K immersion thermocouple. The probe should be submerged at least 2-3 inches below the dross-free surface until the reading stabilizes.

Q3: How much higher should pouring temp be than melting point?This “superheat” is typically 50°C to 100°C above the alloy’s liquidus temperature (when it’s fully molten). The exact amount depends on the casting’s complexity and the distance from the furnace to the mold.

Q4: Will preheating my mold affect the pouring temperature?Yes. Preheating a mold, especially a steel one, reduces thermal shock and allows you to use a slightly lower pouring temperature. This, in turn, helps reduce the risk of gas porosity and shrinkage.

Q5: Can I judge the temperature by the color of the molten aluminum?No. Judging temperature by color is extremely unreliable, inaccurate, and unsafe. Always rely on calibrated, professional-grade instruments like thermocouples for process control.