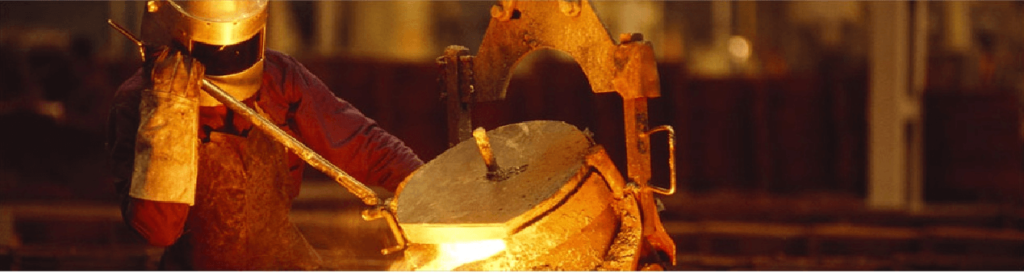

When sourcing carbon steel precision castings from China, ensuring the quality of these components is paramount. Carbon steel castings are integral to various industries, from automotive and aerospace to construction and energy. The integrity of these components can make or break the performance of your final product, so a thorough understanding of how to verify their quality is essential. This blog post will guide you through a detailed process to ensure that the carbon steel castings you source from a China carbon steel precision casting manufacturer meet the highest standards.

Introduction to Carbon Steel Casting Inspection Standards

Carbon steel castings are essential components in industries where strength, durability, and reliability are critical. These industries rely heavily on the quality of the materials used in their production processes, which makes the inspection of carbon steel castings a crucial step. Inspection standards ensure that the castings meet the required specifications, minimizing the risk of failure in their final application.

Importance of Inspection Standards

Inspection standards are the backbone of quality assurance in manufacturing. They serve as a benchmark for evaluating whether a product meets the necessary specifications. For carbon steel castings, these standards cover various aspects, including dimensional accuracy, surface finish, mechanical properties, and the evaluation of defects.

Dimensional accuracy ensures that the castings fit perfectly into the larger assemblies they are part of. Surface finish impacts not only the aesthetic appeal of the casting but also its performance, particularly in applications where friction or wear is a concern. Mechanical properties, such as tensile strength and hardness, determine how the casting will perform under stress. Lastly, defects such as cracks, porosity, or inclusions can compromise the integrity of the casting and lead to failure in critical applications.

When sourcing from a China carbon steel precision casting manufacturer, it is vital to ensure that the supplier adheres to these inspection standards. Not only does this guarantee the quality of the castings, but it also ensures that the products are safe for their intended use.

Overview of Global and Chinese Standards

Inspection standards for carbon steel castings vary by region, with international standards like ISO and ASTM being widely recognized across the globe. In China, the GB/T standards are the national benchmarks for quality. These standards are similar in many ways to their international counterparts but are tailored to the manufacturing practices and materials commonly used in China.

ISO standards, such as ISO 8062-3:2007 for dimensional and geometrical tolerances, and ASTM A216 for carbon steel castings suitable for fusion welding, are among the most widely used in the global industry. These standards define the allowable deviations from the ideal design, ensuring that the castings can function as intended even under demanding conditions.

The GB/T standards, such as GB/T 11352-2020, are specific to China and serve the same purpose as ISO and ASTM standards. However, there can be differences in the testing methods and the limits for certain properties. For instance, a casting that meets GB/T standards may have slightly different tolerances or testing requirements compared to one that meets ISO or ASTM standards.

When dealing with a China carbon steel precision casting manufacturer, it’s important to understand these standards and how they compare to the ones you’re accustomed to in your home market. Ensuring that your supplier adheres to the appropriate standards is a crucial step in verifying the quality of the castings you receive.

By aligning your quality expectations with these standards, you can confidently source carbon steel castings from China, knowing that they will meet the rigorous demands of your industry. This alignment also simplifies the inspection process, as you can rely on standardized procedures and criteria to assess the quality of the castings.

In the next section, we will delve deeper into the specific properties of carbon steel castings and how these properties influence the overall quality and performance of the components you source from a China carbon steel precision casting manufacturer.

Understanding Carbon Steel Castings

Carbon steel castings are known for their exceptional mechanical properties, making them a popular choice in industries that require components with high strength, toughness, and wear resistance. To fully grasp the importance of verifying their quality, it is essential to understand the composition and properties of carbon steel, the common types of castings, and how these factors influence the overall performance of the final product.

Composition and Properties

Carbon steel is an alloy primarily composed of iron and carbon, with carbon content ranging between 0.02% and 2.14% by weight. The carbon content significantly influences the steel’s characteristics. As the carbon content increases, the steel becomes harder and stronger but also less ductile, making it more susceptible to cracking under stress. This trade-off between strength and ductility is a critical consideration when selecting the appropriate type of carbon steel for specific applications.

In addition to carbon, other elements such as manganese, silicon, and trace amounts of sulfur and phosphorus are present in carbon steel. Manganese improves toughness and hardness, while silicon acts as a deoxidizer during the manufacturing process. However, excessive amounts of sulfur and phosphorus can lead to brittleness, which is undesirable in most applications.

Common Types of Carbon Steel Castings

Carbon steel castings are typically classified based on their carbon content, which can be low, medium, or high. Each type has distinct properties that make it suitable for different applications:

- Low Carbon Steel Castings (0.02% – 0.3% Carbon): Also known as mild steel, these castings are highly ductile and easy to machine. They are commonly used in applications where toughness and ductility are more important than hardness, such as in automotive parts, construction components, and machinery.

- Medium Carbon Steel Castings (0.3% – 0.6% Carbon): These castings offer a balance between strength and ductility, making them suitable for parts that require higher strength than mild steel can provide. They are often used in gears, axles, and other components that are subjected to moderate wear and stress.

- High Carbon Steel Castings (0.6% – 2.14% Carbon): These castings are extremely hard and strong but less ductile, making them ideal for applications that require high wear resistance, such as cutting tools, dies, and high-stress machine parts. However, their brittleness must be carefully managed to prevent premature failure.

Performance Characteristics

The performance characteristics of carbon steel castings are directly influenced by their composition and the casting process used. Here are some of the key properties that determine their suitability for various applications:

- High Strength and Toughness: Carbon steel castings are known for their excellent strength and toughness, making them suitable for applications that require components to withstand heavy loads and impact. The toughness of carbon steel ensures that it can absorb energy without fracturing, which is crucial in safety-critical parts.

- Good Machinability: One of the advantages of carbon steel castings is their machinability, particularly in the case of low and medium carbon steels. This property allows manufacturers to produce complex shapes and designs with high precision, which is essential in industries such as automotive and aerospace.

- Corrosion Resistance: Although carbon steel is not as corrosion-resistant as stainless steel, it can still be treated to improve its resistance to environmental factors. Surface treatments such as galvanizing, painting, or coating can significantly enhance the corrosion resistance of carbon steel castings, making them suitable for use in harsh environments.

- Cost-Effectiveness: Carbon steel is a relatively affordable material, providing a cost-effective solution for a wide range of applications. The availability of various grades of carbon steel allows manufacturers to select the most appropriate material based on the specific requirements of the application, balancing cost and performance.

- Wide Application Range: Due to their versatility, carbon steel castings are used across numerous industries, including automotive, aerospace, construction, and energy. Their ability to be tailored to specific needs makes them a preferred choice for many manufacturers.

Understanding these properties is crucial when sourcing from a China carbon steel precision casting manufacturer. Ensuring that the castings meet the required specifications for strength, toughness, machinability, and corrosion resistance is essential to achieving the desired performance in the final product.

In the following section, we will explore the relationship between carbon steel casting inspection standards and the manufacturing process. This will help you understand how adherence to these standards can guide manufacturers in producing high-quality castings that meet your exact requirements.

Relationship Between Carbon Steel Casting Inspection Standards and Manufacturing

Inspection standards play a pivotal role in the manufacturing and quality control processes of carbon steel castings. These standards are not just guidelines but essential tools that help manufacturers ensure that their products meet the required specifications and performance criteria. Understanding how these standards influence manufacturing practices is key to verifying the quality of castings sourced from a China carbon steel precision casting manufacturer.

Role of Inspection Standards in Manufacturing

Inspection standards are integral to every stage of the manufacturing process, from the initial design and material selection to the final inspection of the finished product. These standards provide manufacturers with a clear set of criteria that must be met to ensure the castings are fit for their intended use.

During the design phase, inspection standards help engineers define the tolerances, dimensions, and mechanical properties required for the casting. These parameters are critical in ensuring that the casting will perform as expected under operating conditions. For example, in the automotive industry, a slight deviation from the specified dimensions can lead to poor fitment, which can affect the performance and safety of the vehicle.

Material selection is another area where inspection standards are crucial. The standards dictate the chemical composition and mechanical properties that the material must possess. This ensures that the carbon steel used in the casting has the necessary strength, toughness, and corrosion resistance for the application. By adhering to these standards, manufacturers can minimize the risk of defects that could compromise the quality of the casting.

The manufacturing process itself is also governed by inspection standards. These standards outline the procedures for casting, heat treatment, and surface finishing, ensuring that each step is carried out to achieve the desired properties in the final product. For instance, standards may specify the cooling rate during the casting process to prevent the formation of internal stresses or defects such as cracks and porosity.

Impact on Quality Control

Quality control is the final line of defense in the manufacturing process, and inspection standards are essential in guiding this critical phase. Quality control involves a series of tests and inspections that verify whether the castings meet the specifications set out during the design phase. These tests can include dimensional checks, non-destructive testing (NDT), and mechanical property testing.

Dimensional checks ensure that the castings conform to the specified tolerances, while NDT methods such as ultrasonic testing or radiography are used to detect internal defects without damaging the casting. Mechanical property testing, such as tensile and hardness tests, verifies that the castings have the required strength and durability.

Inspection standards provide the benchmarks against which these tests are measured. By adhering to these standards, manufacturers can identify and rectify defects before the castings are shipped to the customer. This not only ensures that the castings meet the required quality but also helps build trust between the manufacturer and the customer.

When sourcing from a China carbon steel precision casting manufacturer, it is crucial to verify that the manufacturer adheres to the relevant inspection standards throughout the manufacturing process. This adherence ensures that the castings you receive will meet the high standards required for your application, reducing the risk of costly failures or rejections.

In the next section, we will discuss the key quality standards for carbon steel castings, including the differences between international and Chinese standards. Understanding these standards will help you ensure that the castings you source from China meet the necessary quality criteria.

Key Quality Standards for Carbon Steel Castings

Quality standards are the foundation of the casting industry, providing the necessary guidelines for producing reliable and high-performing components. These standards define the material properties, dimensional tolerances, and testing procedures that must be followed to ensure the integrity of carbon steel castings. When working with a China carbon steel precision casting manufacturer, understanding these standards is crucial for verifying the quality of the castings you receive.

International and Chinese Standards

Several international standards are widely recognized in the casting industry, with ISO and ASTM being two of the most prominent. These standards are designed to ensure that castings meet the required specifications, regardless of where they are manufactured.

- ISO Standards: The International Organization for Standardization (ISO) has developed several standards relevant to carbon steel castings. For instance, ISO 8062-3:2007 specifies the dimensional and geometrical tolerances for castings, ensuring that they meet the necessary accuracy for their intended use. ISO standards are recognized globally, making them an important benchmark for manufacturers who export their products.

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides a comprehensive set of standards for various materials, including carbon steel. ASTM A216, for example, covers carbon steel castings suitable for fusion welding for high-temperature service. This standard defines the chemical composition and mechanical properties required for castings used in critical applications, such as pressure vessels and piping systems.

In China, the GB/T standards serve as the national benchmarks for quality. These standards are similar to ISO and ASTM standards but are tailored to the specific manufacturing practices and materials commonly used in China.

- GB/T Standards: The GB/T 11352-2020 standard is one of the key standards for carbon steel castings in China. It specifies the technical requirements, testing methods, and inspection rules for castings. While GB/T standards are generally aligned with international standards, there can be differences in the testing methods and acceptable limits for certain properties.

When sourcing from a China carbon steel precision casting manufacturer, it is important to understand these differences and ensure that the castings meet the appropriate standards for your market. This may involve specifying that the castings comply with ISO or ASTM standards, even if they are produced in accordance with GB/T standards.

Performance Evaluation

The performance of carbon steel castings is directly linked to their adherence to quality standards. Castings that meet the required standards are more likely to perform reliably in their intended applications, reducing the risk of failures that could have serious consequences.

Performance evaluation involves testing the castings to ensure they meet the specified requirements for strength, toughness, and dimensional accuracy. This testing is typically carried out during the quality control phase, using both destructive and non-destructive methods.

- Destructive Testing: This type of testing involves physically testing a sample of the casting to destruction to measure properties such as tensile strength, hardness, and impact resistance. While destructive testing provides valuable data, it is limited to a small number of samples and cannot be applied to every casting.

- Non-Destructive Testing (NDT): NDT methods, such as ultrasonic testing, radiography, and magnetic particle inspection, are used to detect internal defects without damaging the casting. These methods are crucial for verifying the quality of castings that will be used in safety-critical applications.

Case studies have shown that castings that do not meet the required standards can lead to catastrophic failures in service. For example, a casting used in a high-pressure valve that fails due to a defect could result in a serious safety incident. By ensuring that the castings meet the appropriate standards, manufacturers can minimize the risk of such failures.

When sourcing from a China carbon steel precision casting manufacturer, it is essential to specify the required standards and ensure that the castings are tested in accordance with those standards. This not only ensures the quality of the castings but also provides peace of mind that they will perform reliably in their intended application.

In the following section, we will discuss the essential steps for quality verification when sourcing carbon steel castings from China. These steps will help you ensure that the castings meet the required standards and are free from defects.

Essential Steps for Quality Verification

Quality verification is a critical step in the procurement process, particularly when sourcing from a China carbon steel precision casting manufacturer. Ensuring that the castings meet the required specifications involves a series of checks and tests, both before and after production. By following these steps, you can minimize the risk of receiving defective or substandard castings.

Pre-purchase Due Diligence

Before placing an order with a China carbon steel precision casting manufacturer, it is essential to conduct thorough due diligence on the supplier. This involves researching the manufacturer’s history, capabilities, and reputation in the industry.

Start by evaluating the manufacturer’s experience in producing the specific type of castings you need. Look for evidence of past projects that demonstrate their ability to meet the required standards. Ask for references from other customers who have purchased similar products, and inquire about their satisfaction with the quality and performance of the castings.

It’s also important to assess the manufacturer’s facilities and equipment. A visit to the manufacturing site can provide valuable insights into the quality of the production process. Look for evidence of modern, well-maintained equipment, and ask about the manufacturer’s quality control procedures.

Requesting Material Certifications

Material certifications are essential documents that verify the chemical composition and mechanical properties of the castings. When sourcing from a China carbon steel precision casting manufacturer, always request material test reports (MTRs) for the castings.

An MTR provides detailed information about the material used in the casting, including its chemical composition, mechanical properties, and the results of any testing that has been performed. This document is crucial for ensuring that the material meets the required standards and is suitable for the intended application.

When reviewing the MTR, check that the chemical composition of the material falls within the specified limits for the type of carbon steel you have selected. Also, verify that the mechanical properties, such as tensile strength and hardness, meet the required standards.

Visual Inspection

Visual inspection is one of the first steps in verifying the quality of carbon steel castings. While it may seem straightforward, a thorough visual inspection can reveal a range of potential defects that could compromise the performance of the casting.

During the visual inspection, look for surface defects such as cracks, porosity, and inclusions. Cracks are a serious defect that can lead to failure under load, while porosity and inclusions can weaken the casting and reduce its overall strength. Also, check the surface finish of the casting. A rough or uneven surface can indicate poor-quality workmanship and may affect the performance of the casting in its final application.

Dimensional Verification

Dimensional accuracy is critical for ensuring that the castings will fit properly into the larger assembly. Any deviations from the specified dimensions can lead to problems during installation or operation.

Dimensional verification involves measuring the casting to ensure that it conforms to the specified tolerances. This can be done using a variety of tools, such as calipers, micrometers, and coordinate measuring machines (CMMs). It’s important to measure all critical dimensions, including those that may be difficult to access once the casting is installed.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is a key part of the quality verification process, particularly for castings that will be used in safety-critical applications. NDT methods allow you to detect internal defects without damaging the casting.

Ultrasonic testing is commonly used to detect internal defects such as cracks and voids. This method involves sending high-frequency sound waves through the casting and measuring the reflections to identify any discontinuities. Radiography, or X-ray testing, is another NDT method that provides a detailed image of the internal structure of the casting. Magnetic particle inspection is often used to detect surface and near-surface defects.

Mechanical Testing

Mechanical testing is used to verify that the castings have the required strength and durability for their intended application. Common mechanical tests include tensile testing, hardness testing, and impact testing.

Tensile testing measures the strength of the material by applying a pulling force until the material breaks. The results provide information about the tensile strength, yield strength, and elongation of the material. Hardness testing measures the resistance of the material to indentation, which is related to its wear resistance. Impact testing measures the toughness of the material by determining how much energy it can absorb before fracturing.

By conducting these tests, you can ensure that the castings meet the required mechanical properties and are suitable for their intended application.

In the next section, we will discuss the value and importance of carbon steel castings in different applications. Understanding how these castings are used in various industries can help you make informed decisions when sourcing from a China carbon steel precision casting manufacturer.

Value and Importance of Carbon Steel Castings in Different Applications

Carbon steel castings are indispensable in various industries, owing to their unique combination of strength, toughness, and versatility. These properties make them suitable for a wide range of applications, each with specific performance requirements. Understanding the value and importance of carbon steel castings in different sectors can help you appreciate the need for rigorous quality verification when sourcing from a China carbon steel precision casting manufacturer.

Automotive Industry

In the automotive industry, carbon steel castings are used extensively due to their high strength and durability. Key components such as engine parts, transmission components, and chassis are often made from carbon steel castings. These parts must withstand significant stress and wear over their service life, making it crucial that they are produced to the highest standards.

For example, engine blocks and cylinder heads are typically cast from carbon steel due to the material’s ability to withstand high temperatures and pressures. Similarly, transmission gears require castings that can endure constant friction and impact without failing. Any defects in these castings could lead to catastrophic engine or transmission failure, highlighting the importance of thorough quality verification.

Aerospace Industry

The aerospace industry demands materials with exceptional strength-to-weight ratios, and carbon steel castings meet this requirement in many critical applications. Aircraft engine parts, landing gears, and structural components are often made from carbon steel due to its toughness and resistance to fatigue.

In aerospace applications, even the smallest defect in a casting can have serious consequences. Components such as turbine blades and engine casings must be flawless to ensure the safety and reliability of the aircraft. This makes adherence to stringent quality standards and thorough inspection processes vital when sourcing these components from a China carbon steel precision casting manufacturer.

Construction Industry

The construction industry relies heavily on carbon steel castings for structural components such as beams, columns, and reinforcing bars. These components must provide the necessary support and stability for buildings, bridges, and other infrastructure projects.

Carbon steel’s combination of strength and affordability makes it an ideal material for construction. However, the integrity of these components is crucial, as any failure could result in structural collapse. Ensuring that the castings meet the required standards for strength and dimensional accuracy is essential to maintaining the safety and longevity of construction projects.

Energy Sector

In the energy sector, carbon steel castings are used in various applications, including turbine components, valves, and pipelines. These components must operate reliably under extreme conditions, such as high temperatures, pressures, and corrosive environments.

For example, in power generation, turbine blades made from carbon steel castings must withstand high rotational speeds and temperatures without deforming or cracking. Similarly, valves and pipelines used in the oil and gas industry must resist corrosion and maintain their structural integrity under high pressures. Ensuring that these castings meet the appropriate standards is critical to the safe and efficient operation of energy systems.

Understanding the value and importance of carbon steel castings in these industries underscores the need for rigorous quality verification when sourcing from a China carbon steel precision casting manufacturer. In the following section, we will explore the future trends and opportunities for carbon steel castings, and how advancements in technology are shaping the industry.

Future Trends and Opportunities for Carbon Steel Castings

The carbon steel casting industry is continually evolving, driven by advancements in technology, changing market demands, and the pursuit of higher performance materials. Understanding these future trends and opportunities can help you stay ahead of the curve and make informed decisions when sourcing from a China carbon steel precision casting manufacturer.

Advancements in Casting Technology

One of the most significant trends in the casting industry is the advancement of casting technology. Innovations such as 3D printing, automated casting processes, and improved simulation software are enhancing the precision and efficiency of casting production.

- 3D Printing: Also known as additive manufacturing, 3D printing is revolutionizing the casting industry by allowing for the creation of complex molds and prototypes with unprecedented accuracy. This technology enables manufacturers to produce intricate designs that would be difficult or impossible to achieve with traditional casting methods. It also reduces the time and cost associated with producing prototypes, allowing for faster product development.

- Automated Casting Processes: Automation is becoming increasingly prevalent in the casting industry, improving both the speed and consistency of production. Automated systems can precisely control the casting process, reducing the likelihood of defects and ensuring that each casting meets the required specifications. This is particularly important for high-volume production, where consistency is key to maintaining quality.

- Improved Simulation Software: Casting simulation software has advanced significantly, allowing manufacturers to predict and prevent potential issues before they occur. These simulations can model the entire casting process, from mold filling to solidification, helping to optimize the design and reduce the risk of defects such as porosity and shrinkage.

Increased Demand for Lightweight Materials

As industries such as automotive and aerospace continue to prioritize fuel efficiency and environmental sustainability, there is a growing demand for lightweight materials that offer high strength-to-weight ratios. While carbon steel is traditionally known for its strength, new developments are making it more competitive in lightweight applications.

For example, the introduction of high-strength, low-alloy (HSLA) steels combines the benefits of carbon steel with enhanced strength and reduced weight. These materials are becoming increasingly popular in automotive applications, where reducing the weight of components can lead to significant improvements in fuel efficiency and emissions.

The energy sector is also seeing increased demand for lightweight, corrosion-resistant materials, particularly in renewable energy applications such as wind and solar power. Carbon steel castings, with the appropriate surface treatments, can meet these demands, providing a cost-effective alternative to more expensive materials such as titanium or stainless steel.

Expansion into New Industry Sectors

As casting technology continues to advance, new opportunities are emerging for carbon steel castings in industries that have traditionally relied on other materials. For example, the medical equipment industry is exploring the use of carbon steel castings in applications such as surgical instruments and implants, where strength and biocompatibility are critical.

Additive manufacturing is also opening up new possibilities for carbon steel castings in sectors such as electronics and consumer goods, where intricate designs and customization are increasingly important. The ability to produce complex, high-precision components with carbon steel is making it a viable option for applications that require both strength and aesthetic appeal.

These trends and opportunities highlight the dynamic nature of the carbon steel casting industry and the importance of staying informed about the latest developments. When sourcing from a China carbon steel precision casting manufacturer, it is essential to consider how these advancements can enhance the performance and competitiveness of your products.

In the next section, we will discuss the best practices for collaborating with Chinese manufacturers to ensure that you receive high-quality carbon steel castings that meet your exact specifications.

Collaborating with Chinese Manufacturers

Effective collaboration with a China carbon steel precision casting manufacturer is essential to ensuring that you receive high-quality products that meet your specifications. This collaboration involves clear communication, setting precise quality expectations, and conducting thorough inspections and audits. By following these best practices, you can build a strong working relationship with your manufacturer and ensure the success of your project.

Communication Best Practices

Clear and consistent communication is the foundation of any successful collaboration. When working with a China carbon steel precision casting manufacturer, it’s important to overcome potential language barriers and cultural differences to ensure that your requirements are fully understood.

- Overcoming Language Barriers: While many Chinese manufacturers have English-speaking representatives, it is still important to communicate clearly and concisely. Avoid using jargon or idiomatic expressions that may be difficult to translate. Instead, use simple, straightforward language and provide written documentation of your requirements.

- Cultural Considerations: Understanding cultural differences can also help facilitate smoother communication. For example, in Chinese business culture, it is common to avoid direct confrontation or criticism. Be mindful of this when providing feedback, and focus on constructive suggestions rather than pointing out faults.

- Regular Updates: Maintain regular communication with your manufacturer throughout the production process. This can include weekly or bi-weekly updates on the progress of your order, as well as any potential issues that may arise. Regular updates help ensure that any problems are identified and addressed early, reducing the risk of delays or defects.

Setting Clear Quality Expectations

Setting clear and precise quality expectations is critical to ensuring that the castings you receive meet your requirements. This involves drafting detailed specifications and quality agreements that outline the standards and criteria that the castings must meet.

- Detailed Specifications: Provide your manufacturer with detailed specifications for the castings, including dimensions, tolerances, material composition, and mechanical properties. The more specific you can be, the less room there is for misunderstandings or errors.

- Quality Agreements: In addition to specifications, consider drafting a quality agreement that outlines the testing and inspection procedures that will be used to verify the quality of the castings. This agreement should specify the standards that will be used, the frequency of testing, and the criteria for acceptance or rejection of the castings.

- Documentation: Ensure that all specifications and quality agreements are documented in writing and shared with the manufacturer. This documentation serves as a reference throughout the production process and provides a basis for resolving any disputes that may arise.

On-site Inspections and Audits

Conducting on-site inspections and audits is an important step in verifying the quality of the castings and ensuring that the manufacturing process meets your standards. These visits provide an opportunity to observe the production process firsthand and identify any potential issues before they become problems.

- Planning Your Visit: Before your visit, plan the specific aspects of the production process that you want to inspect. This could include the casting process itself, the heat treatment, or the final inspection. Coordinate with the manufacturer to ensure that you can observe these processes during your visit.

- What to Observe: During your inspection, pay close attention to the cleanliness and organization of the facility, the condition of the equipment, and the expertise of the workers. Look for evidence that the manufacturer is following the agreed-upon procedures and maintaining the necessary quality standards.

- Documenting Your Findings: Take detailed notes and photos during your visit to document your observations. This documentation can be used to follow up with the manufacturer on any concerns or issues that you identify.

Leveraging Third-party Inspection Services

In addition to your own inspections, consider hiring a third-party inspection service to provide an independent assessment of the quality of the castings. Third-party inspectors have the expertise and experience to conduct thorough inspections and testing, and their impartiality can provide additional assurance of the quality of the castings.

- Benefits of Third-party Inspections: Third-party inspections can provide a more objective assessment of the quality of the castings, as the inspectors are not affiliated with either the manufacturer or the buyer. This can help identify any potential issues that may have been overlooked and provide an unbiased evaluation of the castings.

- Choosing a Reputable Service: When selecting a third-party inspection service, choose a reputable company with experience in inspecting carbon steel castings. Look for a service that is accredited and has a proven track record of providing reliable and accurate inspections.

- Integrating with Your Quality Process: Work with the third-party inspection service to integrate their findings into your overall quality verification process. This may involve sharing your specifications and quality agreements with the inspectors and coordinating their inspections with your own.

By following these best practices, you can ensure that the castings you receive from a China carbon steel precision casting manufacturer meet your exact specifications and are free from defects. In the next section, we will discuss how to handle quality issues and disputes that may arise during the procurement process, providing strategies for resolving problems and maintaining a successful working relationship with your manufacturer.

Handling Quality Issues and Disputes

Even with the best planning and quality control processes, issues can still arise when sourcing carbon steel castings from a China carbon steel precision casting manufacturer. When quality issues or disputes occur, it’s important to address them promptly and effectively to minimize their impact on your project. This section will provide strategies for identifying common quality issues, resolving disputes, and understanding the legal considerations involved.

Common Quality Issues

Quality issues with carbon steel castings can manifest in various forms, ranging from minor surface imperfections to significant structural defects. Some of the most common issues include:

- Surface Defects: Surface defects such as cracks, porosity, and inclusions are among the most common issues found in carbon steel castings. Cracks can compromise the structural integrity of the casting, while porosity (small holes within the material) can weaken the casting and reduce its load-bearing capacity. Inclusions, which are non-metallic particles trapped within the metal, can also negatively impact the casting’s mechanical properties.

- Dimensional Inaccuracies: Dimensional inaccuracies occur when the casting does not conform to the specified dimensions or tolerances. This can result in parts that do not fit properly in their assemblies, leading to issues during installation or operation.

- Mechanical Property Variations: Variations in mechanical properties, such as tensile strength, hardness, and impact resistance, can result from inconsistencies in the manufacturing process or deviations from the specified material composition. These variations can affect the casting’s performance and reliability in its intended application.

- Heat Treatment Issues: Improper heat treatment can lead to issues such as insufficient hardness, excessive brittleness, or residual stresses within the casting. These problems can reduce the durability of the casting and increase the risk of failure under load.

Resolution Strategies

When quality issues are identified, it’s important to address them quickly and effectively to prevent delays and additional costs. Here are some strategies for resolving quality issues:

- Root Cause Analysis: The first step in resolving a quality issue is to conduct a root cause analysis to determine the underlying cause of the problem. This may involve reviewing the manufacturing process, inspecting the affected castings, and consulting with the manufacturer to identify any deviations from the agreed-upon procedures.

- Corrective Actions: Once the root cause has been identified, work with the manufacturer to implement corrective actions to prevent the issue from recurring. This may involve adjusting the manufacturing process, reworking the affected castings, or conducting additional testing and inspections.

- Negotiation: In cases where the quality issue cannot be resolved through corrective actions alone, it may be necessary to negotiate with the manufacturer to reach a satisfactory resolution. This could involve requesting a refund, replacement of the affected castings, or a discount on future orders.

Legal Considerations

When sourcing from a China carbon steel precision casting manufacturer, it’s important to understand the legal considerations involved in the procurement process. This includes understanding the terms of your contract, warranties, and the options available for seeking legal recourse in the event of a dispute.

- Contracts and Warranties: Ensure that your contract with the manufacturer clearly outlines the quality standards, testing procedures, and inspection criteria that the castings must meet. The contract should also specify the remedies available in the event of a quality issue, such as refunds, replacements, or rework. Additionally, confirm that the manufacturer provides a warranty on the castings, which can provide additional protection against defects.

- Dispute Resolution: In the event of a dispute, it’s important to understand the options available for resolving the issue. This may involve mediation or arbitration, which can provide a more cost-effective and time-efficient alternative to litigation. If legal action is necessary, consult with an attorney who is experienced in international trade law to ensure that your rights are protected.

By following these strategies, you can effectively manage quality issues and disputes, ensuring that your project stays on track and that you receive the high-quality castings you need.

In the next section, we will discuss why Precisionvast is a trusted partner for sourcing carbon steel castings from China, highlighting our commitment to quality, industry experience, and technical expertise.

Why Choose Precisionvast

When sourcing carbon steel castings from China, it’s essential to work with a manufacturer you can trust to deliver high-quality products that meet your specifications. Precisionvast is a leading China carbon steel precision casting manufacturer with a proven track record of providing exceptional product quality, extensive industry experience, and reliable service. Here’s why you should choose Precisionvast for your casting needs:

Exceptional Product Quality

At Precisionvast, we understand that quality is the foundation of any successful project. That’s why we have implemented rigorous inspection and testing procedures at every stage of the production process. From the selection of raw materials to the final inspection of finished castings, we adhere to the highest standards of quality to ensure that our products meet or exceed your expectations.

Our commitment to quality is reflected in our certifications, which include ISO 9001 and ISO/TS 16949. These certifications demonstrate our dedication to maintaining the highest levels of quality management and continuous improvement. When you choose Precisionvast, you can be confident that you are receiving castings that are built to last.

Extensive Industry Experience

With years of experience serving a diverse range of industries, Precisionvast has developed a deep understanding of the unique needs and challenges of our customers. Whether you are in the automotive, aerospace, construction, or energy sector, we have the expertise to deliver castings that meet the specific requirements of your application.

Our team of engineers and technicians brings a wealth of knowledge to every project, ensuring that we can provide customized solutions that address your unique needs. We pride ourselves on our ability to deliver complex, high-precision castings that meet the most demanding specifications.

State-of-the-Art Manufacturing Facilities

Precisionvast’s state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing us to produce castings with exceptional accuracy and efficiency. Our facilities include advanced casting processes, such as sand casting, investment casting, and precision machining, which enable us to produce a wide range of castings with tight tolerances and complex geometries.

In addition to our casting capabilities, we offer a range of value-added services, including heat treatment, surface finishing, and assembly. This allows us to provide a complete solution that meets all of your casting needs, from initial design to final delivery.

Technical Expertise

At Precisionvast, we are committed to providing our customers with the highest level of technical expertise and support. Our team of skilled engineers and technicians is available to assist you with every aspect of your project, from material selection and design optimization to testing and inspection.

We understand that every project is unique, and we work closely with our customers to develop customized solutions that meet their specific requirements. Whether you need assistance with a complex design challenge or guidance on selecting the right material for your application, our team is here to help.

Timely Delivery and Competitive Pricing

We understand the importance of timely delivery in keeping your project on schedule. At Precisionvast, we are committed to delivering your castings on time and within budget. Our efficient production processes and strong supply chain management allow us to offer competitive pricing without compromising on quality.

We work closely with our customers to develop realistic timelines and production schedules, ensuring that your castings are delivered when you need them. Our commitment to on-time delivery and competitive pricing makes us a trusted partner for your casting needs.

In the final section, we will address some common questions about carbon steel castings, providing additional insights into the quality verification process and the benefits of working with a reliable China carbon steel precision casting manufacturer.

Q\&A Section

To provide further clarity on the quality verification process and the benefits of working with a China carbon steel precision casting manufacturer, we’ve compiled answers to some common questions.

Common Defects in Carbon Steel Castings

Q: What are some common defects in carbon steel castings?

A: Common defects in carbon steel castings include surface cracks, porosity, inclusions, and dimensional inaccuracies. Surface cracks can occur due to rapid cooling or stress during the casting process. Porosity is caused by trapped gas bubbles within the casting, which can weaken the material. Inclusions are non-metallic particles that become embedded in the metal, and dimensional inaccuracies result from deviations in the casting process.

Ensuring Dimensional Accuracy

Q: How can I ensure the dimensional accuracy of the castings?

A: Dimensional accuracy can be ensured through precise mold design, careful control of the casting process, and thorough dimensional verification using tools such as calipers, micrometers, and coordinate measuring machines (CMMs). Specifying tight tolerances and conducting regular inspections during production are also key to achieving dimensional accuracy.

Available Surface Finishes

Q: What surface finishes are available for carbon steel castings?

A: Carbon steel castings can be finished using various methods, including machining, grinding, polishing, and coating. Common surface finishes include smooth, polished, and rough finishes, depending on the application. Surface treatments such as painting, galvanizing, and powder coating can also be applied to enhance corrosion resistance and improve the appearance of the casting.

Role of Heat Treatment

Q: What role does heat treatment play in the quality of carbon steel castings?

A: Heat treatment is a critical process that enhances the mechanical properties of carbon steel castings. It can improve hardness, strength, and toughness, as well as relieve internal stresses. Common heat treatment processes include annealing, quenching, and tempering, each of which is tailored to achieve specific properties in the casting.

Comparison with Other Casting Materials

Q: How do carbon steel castings compare with other casting materials?

A: Carbon steel castings are known for their strength, toughness, and cost-effectiveness, making them suitable for a wide range of applications. Compared to other materials such as stainless steel or aluminum, carbon steel offers higher strength and durability at a lower cost. However, it is less corrosion-resistant than stainless steel and heavier than aluminum, which may be considerations depending on the application.

By understanding these key aspects of carbon steel castings, you can make informed decisions when sourcing from a China carbon steel precision casting manufacturer. In the final section, we will recap the key points of this blog post and provide additional resources for further reading.

Conclusion

Recap of Key Points

In this blog post, we have explored the essential steps for verifying the quality of carbon steel castings sourced from a China carbon steel precision casting manufacturer. We began by discussing the importance of inspection standards and how they guide the manufacturing process to ensure that castings meet the required specifications. We also covered the key quality standards, including international and Chinese standards, and the critical role they play in performance evaluation.

We then delved into the essential steps for quality verification, including pre-purchase due diligence, requesting material certifications, visual inspection, dimensional verification, non-destructive testing (NDT), and mechanical testing. These steps are crucial for ensuring that the castings you receive are free from defects and meet the necessary quality criteria.

Furthermore, we discussed the value and importance of carbon steel castings in various applications, highlighting their use in the automotive, aerospace, construction, and energy sectors. We also explored future trends and opportunities in the casting industry, including advancements in casting technology and the growing demand for lightweight materials.

Finally, we provided best practices for collaborating with Chinese manufacturers, strategies for handling quality issues and disputes, and an overview of why Precisionvast is a trusted partner for sourcing carbon steel castings from China.

Final Thoughts on Sourcing from China

Sourcing carbon steel castings from a China carbon steel precision casting manufacturer can offer significant advantages in terms of cost, quality, and production capacity. However, it is essential to conduct thorough quality verification and work closely with your manufacturer to ensure that the castings meet your exact specifications. By following the steps and best practices outlined in this blog post, you can minimize the risks associated with sourcing from China and achieve successful outcomes for your projects.

If you are looking for a reliable partner to source high-quality carbon steel castings from China, consider working with Precisionvast. Our commitment to quality, extensive industry experience, and state-of-the-art manufacturing facilities make us the ideal choice for your casting needs. Contact us today to learn more about our services and how we can help you achieve your goals.