The Key to Quality Castings: Mastering Gate and Runner Design in Investment Casting

Introduction to Investment Casting

Investment casting, a time-honored technique, plays a pivotal role in manufacturing high-quality components. Known for its precision and versatility, this process molds metals into intricate shapes, meeting stringent specifications across various industries. Precisionvast, leveraging its deep-rooted expertise in this field, stands at the forefront of revolutionizing investment casting.

Precisionvast’s specialized approach in designing gate and runner systems sets them apart. By intricately planning the pathways through which molten metal flows into molds, Precisionvast ensures flawless casting results. Their expertise in tailoring these systems means fewer defects, optimized material usage, and enhanced structural integrity of the final product. This combination of skill and innovation positions Precisionvast as a leader in delivering top-tier investment casting solutions.

Precisionvast’s Approach to Gate and Runner System Design

Optimizing Gate Size for Enhanced Flow

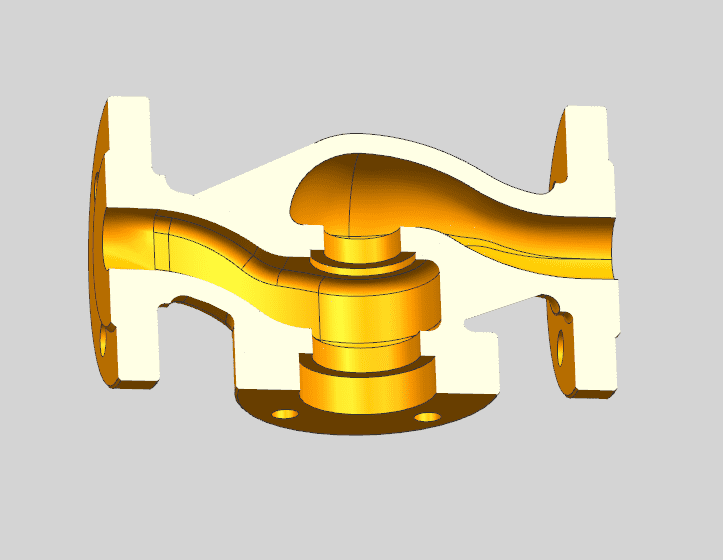

Precisionvast focuses meticulously on the size of gates in the casting process. The gate size is crucial as it determines the flow rate of molten metal into the mold. Precisionvast calculates the optimal gate size to ensure a steady, turbulence-free flow, which is essential for achieving a high-quality casting surface and minimizing defects.

Strategic Placement of Gates and Runners

The placement of gates and runners is another area where Precisionvast excels. Strategic placement is vital to ensure complete mold filling and to reduce the occurrence of cold shuts and misruns. Precisionvast’s experts analyze the mold’s geometry to determine the most effective locations for gates and runners, ensuring uniform metal distribution and cooling.

Proportionality in Design for Uniform Casting

Proportionality in the gate and runner design is key to maintaining the integrity of the final casting. Precisionvast pays close attention to the proportion between the gate, runner, and the casting itself. This balance is crucial to control the metal’s flow rate, cooling rate, and solidification pattern, all of which directly impact the casting’s overall quality.

Precisionvast’s detailed and strategic approach to gate and runner system design in investment casting clearly demonstrates their expertise, leading to superior quality castings with enhanced efficiency.

Optimizing Casting Quality through Advanced Design Techniques

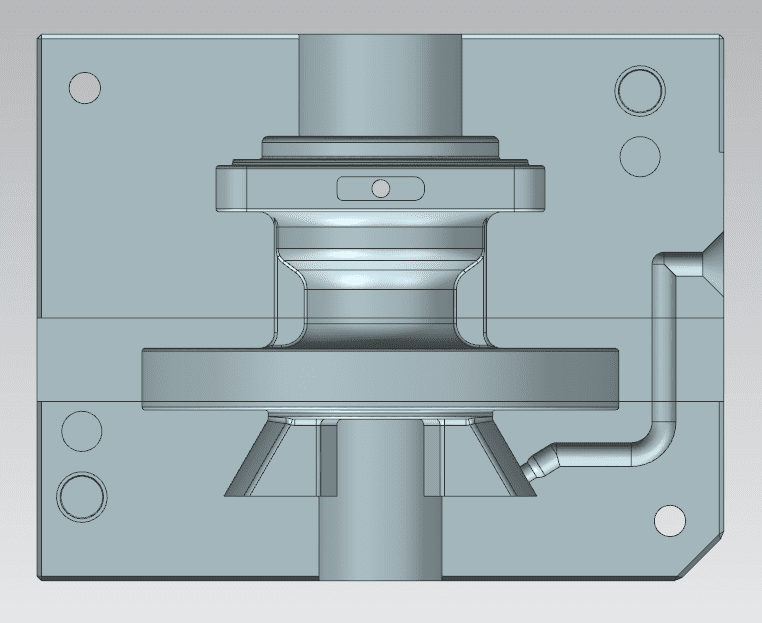

Precisionvast harnesses advanced design techniques to elevate the quality of their investment castings. Central to this is the use of computational fluid dynamics (CFD) simulations. These sophisticated simulations enable precisionvast to meticulously analyze and optimize the flow of molten metal within the molds. By doing so, they can accurately predict and mitigate potential issues like turbulence, which can lead to defects in the final product.

Precisionvast’s innovative strategies in gate and runner design significantly impact casting quality, efficiency, and performance. The use of CFD and other advanced tools allows for the creation of precise, complex geometries while minimizing material waste and production time. This approach not only improves the structural integrity and surface finish of the castings but also enhances the overall efficiency of the production process.

In various applications, from automotive to aerospace, precisionvast’s advanced design techniques have proven to be a game-changer, delivering superior quality castings that meet the highest industry standards.