Titanium is a metal that has gained significant attention in various industries due to its strength, light weight, and corrosion resistance. However, a common question arises in discussions about titanium: Is titanium an alloy? To answer this question, we first need to explore the nature of titanium itself, the role of alloys, and how titanium is used in its pure and alloyed forms.

1. Introduction: Understanding Titanium’s Composition

Titanium is one of the most important metals used in industries ranging from aerospace to medical devices. It is known for its excellent strength-to-weight ratio, corrosion resistance, and high melting point, making it a versatile material in demanding applications. But before diving into its uses, it’s essential to answer a basic question: Is titanium an alloy? The answer is complex. While titanium itself is not an alloy, it is often alloyed with other metals to enhance its properties for various applications. This article will explore the composition of titanium, its pure form, and the numerous alloys that are created for specific purposes.

Ready to learn more? Titanium’s properties make it an essential material in a range of industries, but understanding the distinction between pure titanium and its alloys is key to grasping its full potential.

2. What Is Titanium? A Brief Overview

Titanium is a chemical element with the symbol Ti and atomic number 22. It was discovered in 1791 by the British clergyman and chemist William Gregor, and its name comes from the Titans of Greek mythology, reflecting its strength and durability. Titanium is a transition metal and is known for its high strength and low density, which makes it ideal for use in industries that require durable and lightweight materials.

But what sets titanium apart from other metals? Here’s the kicker: titanium’s resistance to corrosion is unparalleled, especially in extreme environments. For instance, it doesn’t rust like iron and can withstand the harsh conditions of saltwater, making it an ideal choice for marine and aerospace applications. Additionally, titanium is highly biocompatible, which means it can be safely used in medical implants without triggering adverse reactions.

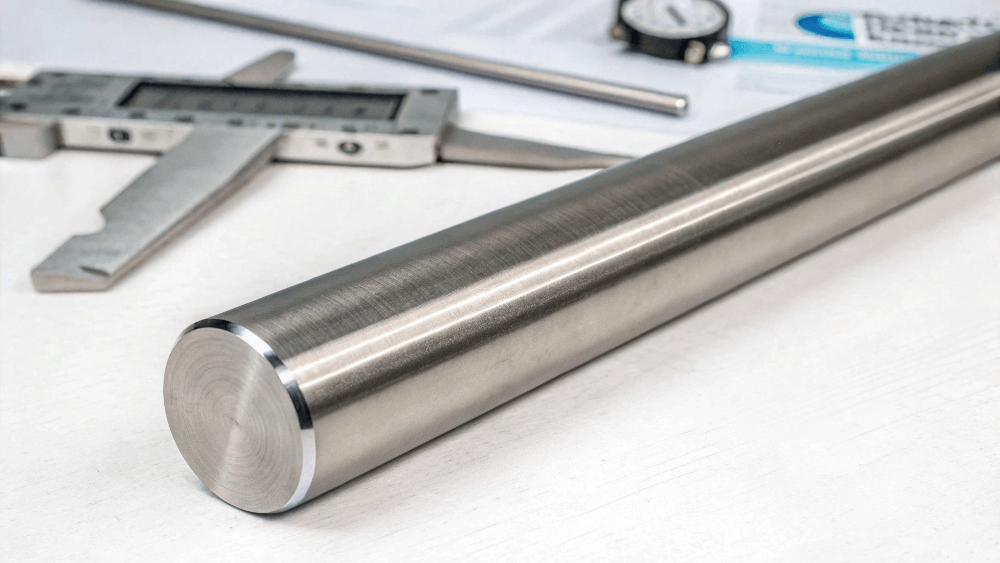

Titanium’s pure form, known as commercial-pure titanium (CP titanium), contains 99% titanium with small amounts of impurities like oxygen and nitrogen. This pure form is used in less demanding applications, such as in certain medical implants or in the production of jewelry. However, for more demanding applications, pure titanium is often alloyed with other metals to enhance its properties. And this is where titanium alloys come into play.

3. The Difference Between Pure Titanium and Alloys

To understand whether titanium is an alloy, we first need to examine the difference between pure titanium and its alloyed forms. Pure titanium has a variety of useful properties on its own, such as excellent corrosion resistance and high strength, but it also has limitations in terms of its mechanical properties and its ability to withstand extreme environments. This is where titanium alloys come in.

Titanium alloys are made by combining titanium with other metals such as aluminum, vanadium, and iron to improve its properties. For example, one of the most widely used titanium alloys is Ti-6Al-4V, which contains 90% titanium, 6% aluminum, and 4% vanadium. This alloy is much stronger and more heat-resistant than pure titanium, making it ideal for applications in aerospace, where strength and resistance to heat are crucial.

What’s the real story? While pure titanium is valuable, it is the alloys that truly unleash its potential. Titanium alloys are designed to improve specific mechanical properties, such as strength, ductility, and resistance to heat and corrosion. These alloys are used in industries like aerospace, medical devices, and military applications, where the demands are much higher than what pure titanium can provide.

4. Is Titanium an Alloy? The Answer Explained

Now that we’ve established the difference between pure titanium and its alloys, let’s answer the question: Is titanium an alloy? The simple answer is: No, titanium itself is not an alloy. It is a pure metal, but it is often alloyed with other metals to improve its properties for specific applications.

Titanium alloys are created by combining titanium with other metals to form materials with improved strength, corrosion resistance, and other properties that are necessary for high-performance uses. But here’s the kicker: while titanium itself is not an alloy, it is so frequently alloyed that many people associate titanium with alloys. For example, when we refer to titanium used in the aerospace industry or medical devices, we are almost always talking about titanium alloys rather than pure titanium.

So, what’s the real takeaway? Titanium is a metal that, when alloyed with other elements, becomes an alloy. However, pure titanium remains a crucial material in certain applications, where its natural properties are sufficient for the task at hand.

5. Common Titanium Alloys and Their Uses

Titanium alloys are used in a variety of industries, from aerospace to medicine, due to their exceptional properties. Some of the most common titanium alloys include:

● Ti-6Al-4V (Titanium 6-Aluminum-4-Vanadium): This is the most widely used titanium alloy and is known for its strength and corrosion resistance. It is commonly used in aerospace components, such as turbine blades and structural parts, as well as in medical implants. ● Ti-5Al-2.5Sn (Titanium 5-Aluminum-2.5-Sn): This alloy is used in aerospace applications where high strength and resistance to fatigue are required. It is often found in aircraft structures and engines. ● Ti-3Al-2.5V (Titanium 3-Aluminum-2.5-Vanadium): Known for its excellent resistance to corrosion and high-temperature properties, this alloy is commonly used in aircraft parts and chemical processing equipment. ● Ti-6Al-2Sn-4Zr-6Mo (Titanium 6-Aluminum-2-Sn-4-Zirconium-6-Molybdenum): This alloy is used in highly demanding applications such as the manufacture of marine and power plant components due to its resistance to both high temperatures and corrosion.

Ready for the good part? Titanium alloys have revolutionized several industries by providing a unique combination of strength, lightness, and resistance to extreme conditions. Whether in aircrafts, spacecrafts, medical implants, or even consumer products, titanium alloys play a key role in meeting the needs of modern engineering and technology.

| Alloy Type | Primary Use | Key Properties | Typical Applications |

|---|---|---|---|

| Ti-6Al-4V | Aerospace, medical implants | High strength, corrosion-resistant | Aircraft, medical devices |

| Ti-5Al-2.5Sn | Aerospace structures, engines | High strength, fatigue resistance | Aircraft components |

| Ti-3Al-2.5V | Aircraft, chemical processing | Corrosion resistance, high temperature | Aircraft, chemical plants |

| Ti-6Al-2Sn-4Zr-6Mo | Marine, power plant components | High temperature, corrosion resistance | Marine equipment, power plants |

6. The Composition of Titanium Alloys: Key Elements

Titanium alloys are composed of titanium combined with various other elements that enhance their properties. The specific elements used depend on the desired properties and the intended use of the alloy. Here’s where it gets interesting: adding small amounts of different metals to titanium can drastically alter its characteristics. Let’s take a closer look at the common elements added to titanium alloys:

● Aluminum (Al): Aluminum is added to titanium alloys to reduce weight and improve strength. It also enhances the alloy’s resistance to corrosion. For example, in Ti-6Al-4V, aluminum makes up 6% of the alloy, giving it excellent strength-to-weight properties.

● Vanadium (V): Vanadium is often used in titanium alloys to improve strength and heat resistance. It is a key component in Ti-6Al-4V, where it contributes to its overall strength and durability.

● Iron (Fe): Iron is added in small amounts to improve the alloy’s machinability. It also helps to increase the alloy’s resistance to oxidation at high temperatures.

● Molybdenum (Mo): Molybdenum is used in titanium alloys to improve corrosion resistance, particularly in acidic environments. It is found in alloys like Ti-6Al-2Sn-4Zr-6Mo, which are used in marine applications.

Titanium alloys can also contain other elements such as zirconium (Zr), niobium (Nb), and tin (Sn), depending on the specific alloy and its intended use. The combination of these elements is what makes titanium alloys so versatile in a variety of applications.

| Element | Function in Titanium Alloys | Example Alloy |

|---|---|---|

| Aluminum | Increases strength, reduces weight | Ti-6Al-4V |

| Vanadium | Improves strength and heat resistance | Ti-6Al-4V |

| Iron | Improves machinability and oxidation resistance | Ti-6Al-4V |

| Molybdenum | Enhances corrosion resistance | Ti-6Al-2Sn-4Zr-6Mo |

| Zirconium | Enhances corrosion resistance | Ti-6Al-2Sn-4Zr-6Mo |

7. Properties of Titanium and Its Alloys

Titanium and its alloys possess a variety of remarkable properties that make them ideal for use in demanding applications. But here’s the kicker: these properties can vary significantly depending on the alloy composition. Below are some of the key properties of titanium and its alloys:

● Strength-to-Weight Ratio: Titanium has a high strength-to-weight ratio, meaning it is lightweight yet strong enough to withstand stress and strain. This makes it ideal for applications in aerospace and automotive industries, where reducing weight while maintaining strength is critical.

● Corrosion Resistance: One of the most notable properties of titanium is its exceptional resistance to corrosion, even in highly corrosive environments such as seawater. This makes titanium alloys particularly useful in marine and chemical processing applications.

● Heat Resistance: Titanium alloys are highly resistant to heat, with some alloys capable of withstanding temperatures up to 1,000°C without significant degradation. This property is essential in aerospace applications, where materials are exposed to extreme temperatures during flight.

● Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and can be used safely in medical implants without causing an adverse reaction in the body. This is why titanium alloys are commonly used in medical devices, such as joint replacements and dental implants.

8. Advantages of Titanium Alloys Over Other Metals

Titanium alloys are often the preferred choice over other metals due to their unique combination of properties. What’s the real story? Let’s compare titanium alloys with other common metals like steel and aluminum to understand why titanium is so highly valued in specific industries.

● Strength: Titanium alloys are significantly stronger than aluminum alloys, making them ideal for high-stress applications. Compared to steel, titanium alloys are lightweight, which reduces the overall mass of the final product without sacrificing strength.

● Corrosion Resistance: Titanium’s corrosion resistance is superior to that of most metals, including aluminum and steel. Unlike steel, which can rust when exposed to moisture, titanium forms a thin oxide layer that protects it from corrosion. This property is particularly valuable in marine environments, where other metals would degrade quickly.

● Weight: Titanium alloys are lighter than steel, which makes them an excellent choice for applications where weight is a concern, such as in aerospace or automotive industries. In comparison, aluminum is lighter than titanium but lacks the strength and durability of titanium alloys.

Ready for the good part? Titanium alloys offer a balance of strength, weight, and resistance to corrosion that most other metals cannot match, making them ideal for demanding applications in aerospace, medical devices, and marine environments.

| Metal | Strength | Corrosion Resistance | Weight | Applications |

|---|---|---|---|---|

| Titanium | High | Excellent | Low | Aerospace, Medical |

| Aluminum | Moderate | Fair | Very Low | Aircraft, Automotive |

| Steel | Very High | Poor (rusts easily) | High | Construction, Manufacturing |

9. How Titanium Alloys Are Made

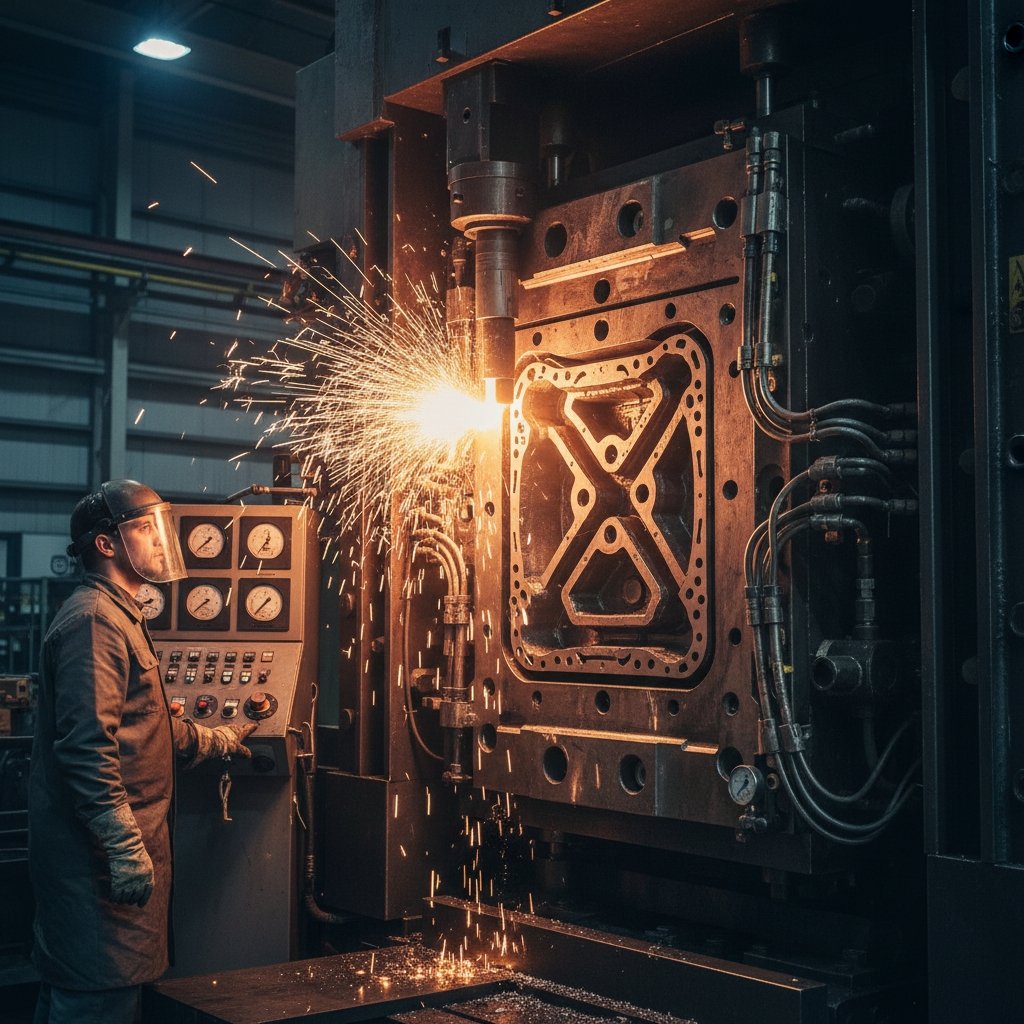

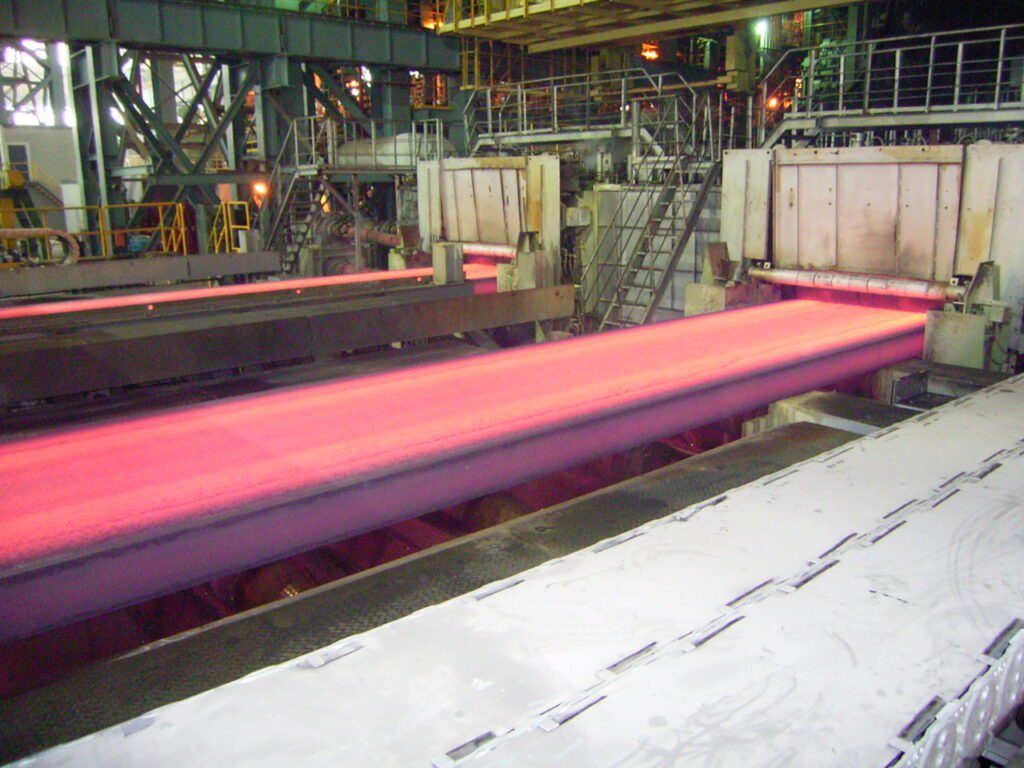

The process of making titanium alloys involves combining pure titanium with other metals to form a new material with enhanced properties. This is where it gets interesting: the alloying process itself is quite complex and requires precise control to ensure the final product meets the required specifications.

Titanium alloys are typically produced using processes such as vacuum arc remelting, casting, and forging. These processes involve melting the titanium and its alloying elements together, often in a vacuum environment, to prevent contamination. Once the alloy has been formed, it is shaped into the desired form, whether it be sheets, plates, bars, or other shapes.

In some cases, titanium alloys are produced through powder metallurgy, where titanium powder is mixed with other alloying elements and then compressed into shape before being sintered at high temperatures. This process allows for the creation of complex shapes with minimal waste, making it ideal for applications where precision is critical.

Titanium alloys are often processed into final forms through forging, casting, or rolling depending on the specific application and desired properties of the finished product.

10. The Role of Titanium in Aerospace and Medical Fields

Titanium alloys play a critical role in several industries, but none more so than aerospace and medical. Titanium’s unique properties make it the perfect material for use in these demanding fields.

In aerospace, titanium alloys are used extensively for aircraft and spacecraft components. The Ti-6Al-4V alloy, for instance, is used in turbine blades, airframes, and structural components because of its strength, lightweight properties, and ability to withstand high temperatures.

In medical fields, titanium alloys are widely used for implants, especially dental implants, joint replacements, and other medical devices. Titanium is preferred because it is biocompatible, meaning it won’t be rejected by the body. Additionally, titanium’s strength and lightweight properties allow for the creation of durable and effective implants.

What’s the real story here? The aerospace and medical fields have benefited immensely from the introduction of titanium alloys, with improved performance, efficiency, and reliability in critical applications.

| Industry | Applications | Alloy Type | Key Benefit |

|---|---|---|---|

| Aerospace | Aircraft frames, turbine blades | Ti-6Al-4V | Strength, heat resistance |

| Medical | Implants, dental devices | CP Titanium | Biocompatibility, strength |

11. Titanium vs. Other Common Alloys: Which Is Better?

Titanium alloys have advantages that make them an attractive choice over other materials, such as aluminum, steel, and other alloys. But here’s the kicker: each material has its pros and cons, and the right choice depends on the specific requirements of the application.

In the aerospace industry, for instance, titanium alloys are often preferred over steel because they provide a better strength-to-weight ratio and resistance to corrosion, which are crucial for flight safety. Aluminum, on the other hand, is lighter than titanium, but lacks the strength and heat resistance of titanium alloys, making it unsuitable for high-performance applications like aerospace.

Steel is stronger than both titanium and aluminum, but it is heavier and prone to rusting, which makes it less suitable for use in marine or aerospace applications. Titanium alloys, however, are strong, lightweight, and resistant to corrosion, making them the material of choice in these industries.

Titanium alloys can be more expensive than aluminum and steel, but their unique combination of properties often justifies the higher cost, especially in applications where performance and reliability are critical.

12. Environmental Impact of Titanium Mining and Alloy Production

Titanium mining and alloy production have a significant environmental impact. Ready for the good part? The extraction and processing of titanium ore require large amounts of energy and water, and can result in the release of harmful emissions. However, there are efforts underway to minimize the environmental impact of titanium production.

The environmental challenges associated with titanium mining include habitat destruction, water pollution, and air emissions from the extraction and processing stages. One of the key issues is the production of Titanium dioxide as a byproduct, which can lead to environmental contamination if not handled properly.

To address these issues, companies are exploring more sustainable methods of titanium production, such as recycling titanium scrap material. Recycling titanium helps reduce the need for mining new ore and decreases the overall environmental impact of titanium production.

| Environmental Impact | Effect | Mitigation Strategies |

|---|---|---|

| Mining | Habitat destruction, water pollution | Sustainable mining practices |

| Titanium production | Air emissions, energy consumption | Use of cleaner energy, recycling |

13. The Future of Titanium Alloys

The future of titanium alloys is exciting, with ongoing research and development into new and improved materials. This is where it gets interesting: researchers are working on developing alloys that offer even better performance, sustainability, and cost-effectiveness.

One promising development is the creation of titanium alloys with improved fatigue resistance for use in the automotive and aerospace industries. These new alloys could make vehicles and aircraft even more durable and efficient, leading to longer lifespans and better fuel efficiency.

Additionally, advancements in titanium alloy recycling are helping to make titanium more sustainable and affordable. The development of better recycling technologies will allow titanium alloys to be reused more efficiently, reducing the need for raw material extraction and decreasing environmental impact.

| Future Trend | Potential Impact | Application |

|---|---|---|

| Improved fatigue resistance | Increased durability and performance | Aerospace, automotive |

| Enhanced recycling methods | More sustainable production, lower costs | All industries using titanium |

14. Common Misconceptions About Titanium and Its Alloys

There are several misconceptions surrounding titanium and its alloys, and it’s time to set the record straight. What’s the real story? While titanium is often thought of as an indestructible material, it does have its limitations. For example, titanium alloys can be susceptible to wear under certain conditions, particularly in environments with high friction.

Another common misconception is that titanium is always more expensive than steel or aluminum. While titanium alloys can be more costly, the price difference often reflects the superior properties of the material, making it worth the investment in high-performance applications.

Additionally, many people believe that pure titanium is stronger than any titanium alloy, but this is not always the case. In fact, most titanium alloys are stronger than pure titanium because they are designed to meet the demands of specific applications.

15. Conclusion: Why Understanding Titanium and Its Alloys Matters

In conclusion, titanium is a remarkable material that offers exceptional properties, both in its pure form and when alloyed with other metals. By understanding the distinction between pure titanium and its alloys, professionals in industries such as aerospace, medical, and automotive can make better decisions about when and how to use titanium in their designs.

Ready to make a choice? Titanium alloys continue to play a crucial role in advancing technology and improving the performance of products across industries. By staying informed about the properties and benefits of titanium and its alloys, you can harness their potential to achieve the best outcomes for your projects.

FAQ Section

Q1: What is titanium?

Titanium is a chemical element known for its high strength, light weight, and corrosion resistance. It is commonly used in industries such as aerospace, medical devices, and automotive.

Q2: How is titanium alloy made?

Titanium alloys are created by combining pure titanium with other metals like aluminum, vanadium, and iron to improve its properties, such as strength, heat resistance, and corrosion resistance.

Q3: Is titanium an alloy or a pure metal?

Titanium is a pure metal, but it is frequently alloyed with other metals to enhance its properties for specific applications.

Q4: Why is titanium preferred over other metals?

Titanium is preferred over metals like aluminum and steel because of its combination of high strength, light weight, and superior resistance to corrosion and high temperatures.

Q5: Can titanium alloys be recycled?

Yes, titanium alloys can be recycled. Recycling helps reduce the need for mining new titanium and makes the material more sustainable.