Titanium is a unique metal with numerous applications, prized for its strength, low density, and exceptional corrosion resistance. But when people refer to “titanium,” they are often talking about more than just the pure form of the element. Titanium alloys, which are made by combining titanium with other metals, have transformed industries ranging from aerospace to medical devices. But what exactly makes titanium alloys different from pure titanium? And more importantly, is titanium an alloy at all? Let’s explore the distinctions and applications of pure titanium and its alloys.

1. Introduction

Titanium, often hailed as the “space age metal,” has numerous applications due to its unique properties. From aircraft components to medical implants, titanium plays a critical role in modern industries. However, the question arises: Is titanium an alloy? Understanding the difference between pure titanium and titanium alloys is crucial for industries that rely on these materials. This article will answer that question, compare pure titanium and titanium alloys, and discuss the significance of these materials in various fields. Whether you’re a manufacturer, a designer, or an engineer, knowing the distinctions between pure titanium and its alloys is key to making the right material choices for your projects.

What’s the real story? Let’s dive into the world of titanium and its alloys.

2. What is Titanium?

Titanium is a chemical element with the symbol Ti and atomic number 22. It’s a transition metal known for its remarkable strength-to-weight ratio, making it one of the most sought-after materials in industries such as aerospace, automotive, and medicine. Titanium is naturally resistant to corrosion, which means it doesn’t rust, even in harsh environments like seawater or chemical exposure.

Pure titanium, often referred to as “commercially pure titanium,” has a wide range of uses, primarily in aerospace applications, where strength, low weight, and durability are critical. It is commonly used in aircraft, spacecraft, and high-performance automotive parts. In medicine, pure titanium is utilized for its biocompatibility, making it ideal for surgical implants, dental implants, and joint replacements.

So, what’s the real story? Is titanium always used in its pure form? Not exactly. When titanium is alloyed with other metals, it takes on enhanced properties that make it more suited for specific uses.

Titanium’s unique properties have led to extensive research and development. It has been used since the mid-20th century in high-tech applications, with the aerospace industry being one of the earliest adopters. Today, titanium is widely used across various industries for parts that demand high strength and corrosion resistance.

Properties of Titanium

● Strength and Durability: Titanium’s strength is comparable to steel, but it’s significantly lighter.

● Corrosion Resistance: Titanium naturally forms an oxide layer that protects it from corrosion.

● Heat Resistance: Titanium can withstand high temperatures, making it ideal for use in extreme environments.

3. What Are Titanium Alloys?

Titanium alloys are made by combining titanium with other metals to enhance certain properties such as strength, hardness, and heat resistance. By alloying titanium with elements like aluminum, vanadium, molybdenum, and iron, manufacturers create alloys that are tailored for specific applications. These alloys are typically classified into three categories: alpha alloys, beta alloys, and near-alpha alloys.

Ready for the good part? Titanium alloys are used in even more specialized applications compared to pure titanium. The addition of other elements to titanium improves its performance in certain environments. For example, titanium-aluminum alloys are commonly used in aerospace applications, where lightweight and high strength are paramount. On the other hand, titanium alloys with molybdenum are used in the medical field for orthopedic implants.

Types of Titanium Alloys

● Alpha Alloys: Known for their high-temperature stability, used in high-performance applications.

● Beta Alloys: These alloys offer superior strength and are often used in industries requiring both strength and corrosion resistance.

● Near-Alpha Alloys: A combination of both alpha and beta characteristics, offering a balanced performance in various industries.

4. Is Titanium an Alloy?

So, is titanium an alloy? Strictly speaking, no. Titanium is a pure element. However, when combined with other metals to form titanium alloys, it becomes a versatile material with significantly enhanced properties.

But here’s the kicker—while pure titanium is used in certain applications for its unique properties, titanium alloys are often the go-to choice in industries requiring superior performance under stress, high temperature, or heavy load.

Why Titanium Isn’t an Alloy

Titanium, as an individual element, is not considered an alloy. However, it often gets confused with titanium alloys due to its common usage in alloyed forms. Alloys are mixtures of two or more metals, and in the case of titanium alloys, titanium is just one component mixed with other elements.

The important takeaway here is understanding when and why titanium is used in its pure form versus its alloyed versions. Pure titanium is valuable for its resistance to corrosion and biocompatibility, while titanium alloys are favored for their superior mechanical properties.

5. Types of Titanium Alloys

Titanium alloys come in various compositions, each designed to meet specific performance needs. These alloys can be broadly classified into three categories: alpha alloys, beta alloys, and near-alpha alloys. Let’s explore each category and its applications in more detail.

What’s the real story here? Let’s break down the different types of titanium alloys and see why they’re crucial to so many high-performance applications.

Alpha Alloys

Alpha alloys are primarily composed of titanium and small amounts of other metals such as aluminum or tin. These alloys are known for their excellent weldability and high-temperature stability, making them ideal for aerospace and military applications where parts are exposed to extreme heat. For example, the titanium alloy Ti-6Al-4V, which contains both aluminum and vanadium, is one of the most commonly used alloys in the aerospace industry.

Beta Alloys

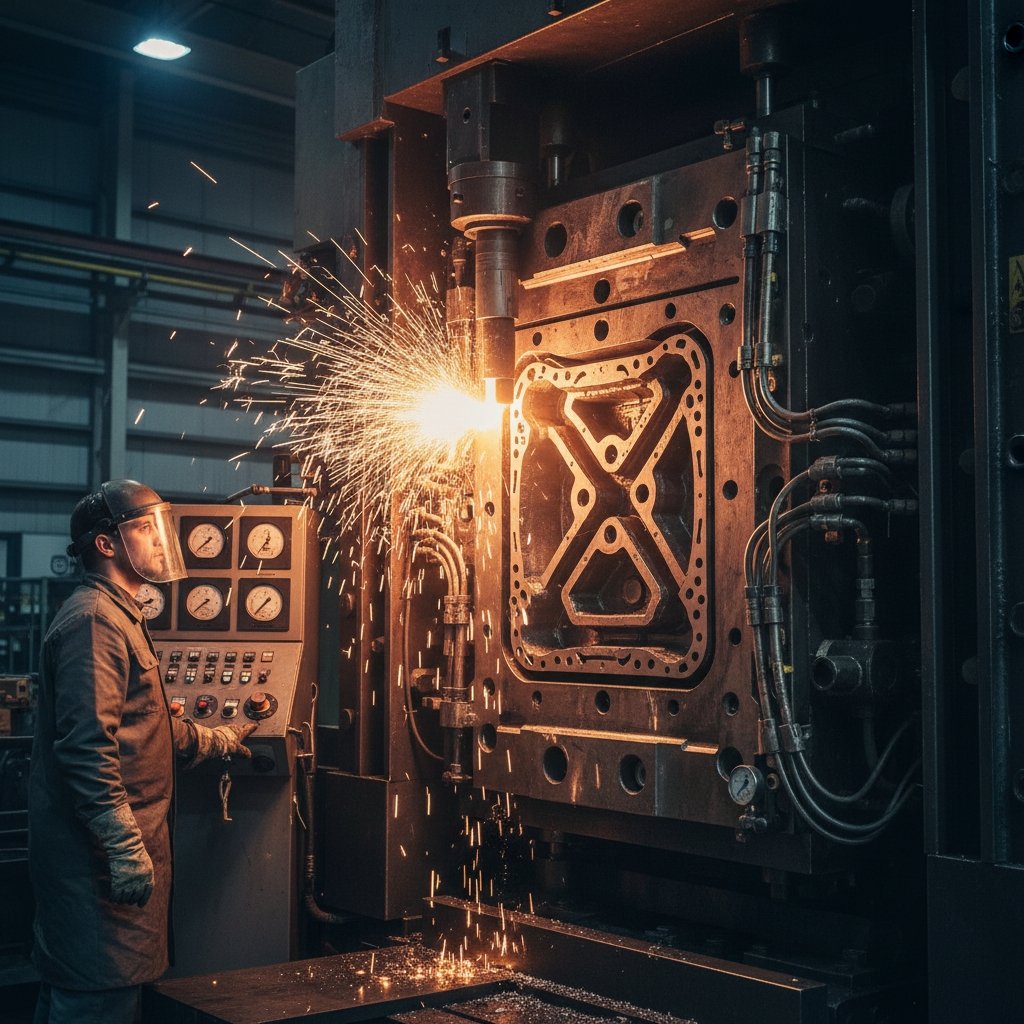

Beta alloys, on the other hand, are known for their strength and hardness. These alloys are made by adding elements such as molybdenum, niobium, or chromium to titanium. They are ideal for applications that require high strength at room temperature, such as automotive components, marine parts, and heavy-duty machinery. Beta alloys can be heat-treated to achieve high tensile strength, making them indispensable in manufacturing.

Near-Alpha Alloys

Near-alpha alloys are a combination of both alpha and beta phases. These alloys have an excellent balance of strength and corrosion resistance, making them ideal for both aerospace and industrial applications. For example, Ti-6Al-2Sn-4Zr-6Mo is a near-alpha alloy used in turbine blades and other high-stress components that require both strength and heat resistance.

6. Commercially Pure Titanium vs Titanium Alloys

When comparing commercially pure titanium and titanium alloys, the difference lies in their composition and the properties that result from that composition. Commercially pure titanium is, as the name suggests, pure titanium with minimal additions of other elements. In contrast, titanium alloys are intentionally mixed with other metals to improve specific properties like strength and heat resistance.

Let’s delve deeper into how these two forms of titanium compare.

Commercially Pure Titanium

Commercially pure titanium is characterized by its low density, excellent corrosion resistance, and high strength-to-weight ratio. It’s commonly used in medical implants, where biocompatibility is crucial. Its resistance to corrosion, especially in seawater and acidic environments, makes it a popular choice for marine applications as well.

Titanium Alloys

Titanium alloys, however, offer enhanced strength, flexibility, and heat resistance. These alloys are ideal for industries that require materials to withstand extreme conditions. Aerospace is one of the primary sectors where titanium alloys are used extensively. Titanium alloys are also used in the automotive and medical industries, where mechanical properties like fatigue resistance and wear resistance are essential.

7. Properties of Pure Titanium

Pure titanium is renowned for its remarkable properties, which include a high strength-to-weight ratio, excellent corrosion resistance, and superior durability in harsh environments. These properties make it invaluable in industries like aerospace, medicine, and marine engineering.

Let’s take a closer look at what makes pure titanium so unique.

Strength and Durability

Titanium’s strength is one of its most valuable characteristics. It’s nearly as strong as steel but much lighter, making it ideal for applications where strength and low weight are critical, such as in the aerospace industry. Its high tensile strength means that it can withstand heavy loads without failing.

Corrosion Resistance

Pure titanium is highly resistant to corrosion, making it an ideal choice for use in environments where other metals would quickly degrade. This resistance extends to seawater, chlorine, and many industrial chemicals. In fact, titanium is often used in applications where exposure to these elements would cause other metals to fail.

Heat Resistance

Titanium has excellent heat resistance, allowing it to maintain its properties even at high temperatures. This makes it a favorite material for use in high-performance engines, such as those in aircraft and spacecraft.

Applications of Pure Titanium

From surgical implants to heat exchangers, pure titanium’s properties make it a top choice for industries that require corrosion resistance and strength. In medical applications, its biocompatibility makes it suitable for use in implants, joint replacements, and dental devices.

8. Properties of Titanium Alloys

Titanium alloys are designed to meet specific performance criteria, such as increased strength, heat resistance, and flexibility. These properties are achieved by adding other elements, such as aluminum, vanadium, and molybdenum, to titanium.

Let’s explore the enhanced properties of titanium alloys and how they compare to pure titanium.

Strength and Toughness

Titanium alloys are significantly stronger than pure titanium, making them ideal for high-stress applications. The addition of elements such as molybdenum and vanadium increases the tensile strength of the material, allowing it to perform under much higher stresses. This is crucial in industries like aerospace, where components are subjected to extreme loads and forces.

Corrosion Resistance

Titanium alloys retain the excellent corrosion resistance that pure titanium is known for. However, certain alloys can offer even greater resistance to specific environmental factors. For example, titanium alloys with high amounts of aluminum or vanadium are particularly resistant to corrosion in high-temperature environments.

Heat Resistance

Titanium alloys also have enhanced heat resistance compared to pure titanium. They can withstand higher temperatures without losing their mechanical properties, making them suitable for high-performance engines and turbine blades. Alloys like Ti-6Al-4V are designed to perform in extreme heat, which is essential in industries like aerospace and power generation.

Applications of Titanium Alloys

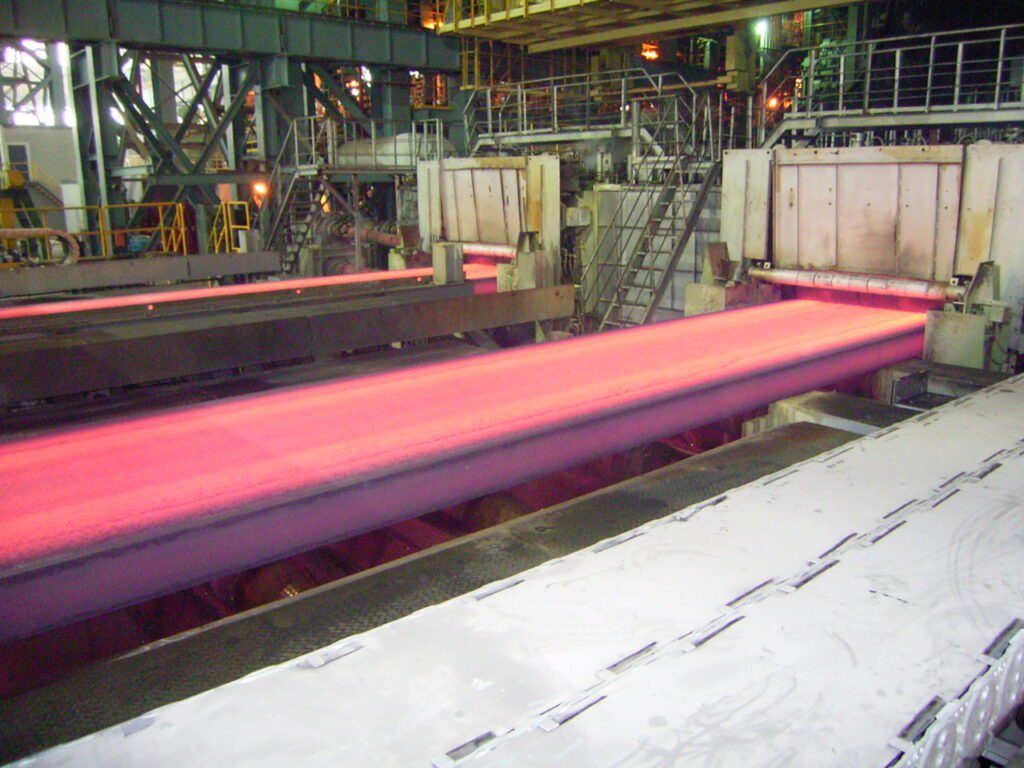

Titanium alloys are used in applications that demand high strength and heat resistance. Aerospace companies use titanium alloys for turbine blades and aircraft frames. In the automotive industry, these alloys are used in parts that must withstand high temperatures and stresses, such as exhaust systems and engine components.

9. The Benefits of Using Titanium Alloys

Titanium alloys offer a wide range of benefits over pure titanium, making them the material of choice in many high-performance applications. Their enhanced strength, heat resistance, and flexibility give them a distinct advantage in industries where these properties are essential.

Ready for the good part? Let’s take a closer look at the benefits of using titanium alloys in various industries.

Strength and Durability

One of the biggest advantages of titanium alloys is their strength. These materials are much stronger than pure titanium, which makes them ideal for use in applications where strength is a primary concern. For example, titanium alloys are used in aircraft components that must withstand high-speed forces and pressure.

Corrosion Resistance

While pure titanium is known for its resistance to corrosion, titanium alloys can offer even better performance in certain environments. Alloys with elements like vanadium or aluminum are designed to withstand highly corrosive environments, such as seawater or acidic chemicals. This makes titanium alloys ideal for marine and chemical processing applications.

Cost-Effectiveness

Despite their high performance, titanium alloys can be more cost-effective than pure titanium in certain applications. The alloying process allows manufacturers to create materials that meet specific performance criteria without the high cost of pure titanium.

Applications in High-Performance Industries

Titanium alloys are used in industries that require materials to perform at the highest levels. In aerospace, titanium alloys are used for turbine blades, aircraft structures, and engine components. The automotive industry uses titanium alloys for high-performance parts like exhaust systems and suspension components.

10. Common Applications of Pure Titanium

Pure titanium’s unique properties make it an invaluable material in many industries. From the aerospace sector to medical devices, pure titanium plays a critical role in applications where strength, corrosion resistance, and biocompatibility are essential.

Let’s explore some of the most common applications of pure titanium.

Aerospace

In aerospace, pure titanium is used in aircraft and spacecraft components due to its low weight and high strength. Components like engine parts, turbine blades, and airframes rely on titanium’s ability to withstand extreme temperatures and stresses.

Medical Devices

Pure titanium is widely used in the medical field for implants, prosthetics, and surgical tools. Its biocompatibility makes it an ideal choice for devices that are implanted in the human body, such as dental implants and joint replacements.

Marine Applications

Titanium’s resistance to corrosion makes it ideal for marine applications. Components such as ship hulls, propellers, and offshore oil rig equipment benefit from titanium’s ability to resist the harsh marine environment.

11. Common Applications of Titanium Alloys

Titanium alloys have expanded the possibilities of this remarkable metal, providing enhanced strength, heat resistance, and flexibility for a wider range of applications.

Let’s take a closer look at where titanium alloys are commonly used and why they are so valuable.

Aerospace

Titanium alloys are a staple in the aerospace industry, where strength, heat resistance, and low weight are paramount. Alloys like Ti-6Al-4V are used in turbine engines, airframes, and various aircraft components. Their ability to withstand high temperatures makes them perfect for engine parts exposed to extreme conditions.

Automotive

In the automotive industry, titanium alloys are used in parts that need to withstand high temperatures and stresses. Exhaust systems, suspension components, and engine parts are often made from titanium alloys to improve performance and durability.

Medical Applications

Titanium alloys are used in medical devices that require both strength and flexibility. Orthopedic implants, including hip and knee replacements, are commonly made from titanium alloys. These alloys offer the necessary mechanical properties while maintaining the biocompatibility of pure titanium.

12. How to Choose Between Pure Titanium and Titanium Alloys

Choosing between pure titanium and titanium alloys depends on the specific needs of your project. Each material has distinct advantages, and understanding when to use each is essential for ensuring the best performance in your applications.

Here’s the deal—if you need pure corrosion resistance and biocompatibility, pure titanium is your best bet. If you need enhanced strength and heat resistance, titanium alloys should be your material of choice.

13. Titanium in the Future: Innovations and Developments

Titanium continues to be a material of great interest in various industries. Ongoing research into new alloys, processing techniques, and applications means that the future of titanium is incredibly promising.

Ready for the good part? New developments in titanium technology are opening up possibilities for even more advanced applications. From high-tech aerospace components to medical innovations, the future of titanium looks bright.

14. Pros and Cons of Titanium Alloys vs Pure Titanium

Titanium alloys offer many advantages over pure titanium, but they are not without their challenges. Understanding the pros and cons of each can help manufacturers and engineers make the right choices for their specific needs.

What’s the real story? Let’s break down the key advantages and disadvantages of both pure titanium and titanium alloys.

15. Conclusion

In conclusion, titanium is a versatile material with unique properties that make it essential in many industries. Whether you choose pure titanium or its alloys depends on your specific application, performance requirements, and budget. By understanding the differences between pure titanium and titanium alloys, you can make informed decisions that will benefit your projects in the long run.

FAQ Section

Q1: What is titanium?

Titanium is a strong, lightweight metal known for its excellent resistance to corrosion. It is commonly used in aerospace, medical devices, and marine applications.

Q2: How do titanium alloys differ from pure titanium?

Titanium alloys are made by combining titanium with other metals to enhance specific properties, such as strength, heat resistance, and flexibility. Pure titanium, on the other hand, is a single element with exceptional corrosion resistance but lower strength.

Q3: What are the benefits of using titanium alloys?

Titanium alloys provide increased strength, heat resistance, and versatility compared to pure titanium. These benefits make them ideal for high-performance applications in aerospace, automotive, and medical industries.

Q4: Can titanium alloys be used in medical applications?

Yes, titanium alloys are commonly used in medical implants and devices due to their strength, biocompatibility, and resistance to corrosion.

Q5: Which is better: pure titanium or titanium alloys?

It depends on the application. Pure titanium is better for applications requiring corrosion resistance and biocompatibility, while titanium alloys are better suited for high-performance applications that demand greater strength and heat resistance.