Lost Wax Casting Supplies: What’s the Cost Comparison?

Introduction

Welcome to the intricate and fascinating world of lost wax casting, where every detail matters and every supply counts! Think of it as the art of transforming a wax sculpture into stunning metal – a process that’s as old as time but still amazes us today. Now, let’s talk about something that might not be as enchanting but is crucial – the cost of supplies.

In lost wax casting, the price tag on your supplies can play a lead role in your production’s success story. It’s like planning a gourmet meal; you need to know the cost of ingredients to avoid surprises when the bill arrives. Understanding the expenses involved in wax, investment material, crucibles, and furnaces is more than just number-crunching; it’s about making informed decisions that balance quality with your budget.

So, buckle up as we dive into the financial waters of lost wax casting supplies. We’re setting the stage for an in-depth cost comparison that’s going to be as enlightening as it is essential. It’s time to get savvy about spending without compromising on the magic of your metal masterpieces!

Section 1: Overview of Lost Wax Casting Supplies

In the world of lost wax casting, the supplies are more than just tools; they’re the unsung heroes that make the magic happen. As experts at PrecisionVast, let’s unpack the essential kit for this age-old art.

First, meet the waxes – the chameleons of the casting world. They come in various forms: carving, injection, and repair waxes, each with its unique role. The carving wax for detailed work, injection wax for precision in mass production, and repair wax, the handy sidekick for fixing imperfections.

Next up, investment materials – the backbone of your casting. This unsung hero transforms from a fluid state to a firm mold, cradling your wax model with care and precision. It’s like the reliable best friend who’s always there to support.

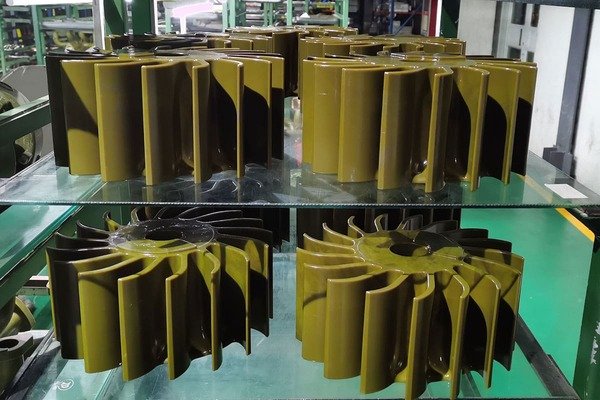

Then, we have crucibles and furnaces – the power couple of the casting process. Crucibles hold your metal as it transforms from solid to liquid, while furnaces bring the heat, literally. They work in tandem to ensure your metal is melted to perfection, ready for its big reveal.

Each of these supplies plays a vital role in the lost wax casting symphony. With the right ensemble, you’re set to create masterpieces that echo through time. And that’s just the beginning of our journey into the world of casting!

Section 2: Cost Analysis of Waxes

In the meticulous world of lost wax casting, selecting the right wax is akin to picking the perfect ingredient for a gourmet recipe. At PrecisionVast, we understand that every wax has its price tag, and the cost is influenced by more than just the price per pound. Let’s delve into the cost comparison of carving, injection, and repair waxes and how to choose the most cost-effective option.

Carving wax, often the choice for detailed and intricate work, usually comes with a higher price. It’s the caviar of waxes – luxurious and specialized. Its cost is justified by its quality and the ability to hold fine details, crucial for high-end art pieces or jewelry.

Injection wax, the workhorse of mass production, is generally more affordable. Think of it as the all-purpose flour in baking – versatile and cost-effective. Its lower melting point and ease of flow make it ideal for detailed and consistent casts, especially in large quantities.

Repair wax, though often overlooked, is an essential tool in the kit. It’s the band-aid of waxes – not always the star, but a lifesaver when needed. Its cost is relatively low, but its value in fixing imperfections is priceless.

When selecting a wax, consider the melting point and intended use. Higher melting point waxes can withstand more heat, which might be necessary for certain metals. For cost-effectiveness, align the wax’s properties with your casting needs. If high detail isn’t crucial, opting for a more affordable wax that still meets your requirements can save costs.

Remember, in lost wax casting, the wax you choose sets the stage for your final product. At PrecisionVast, we recommend investing in the wax that aligns with your project’s needs without breaking the bank. It’s about finding that sweet spot where quality meets affordability.

Section 3: Investment Materials and Their Price Points

In the quest for the perfect cast, the investment material you choose is like the foundation of a building – crucial and impactful. At PrecisionVast, we understand that the cost of investment materials can make a significant dent in your budget, so let’s navigate these waters with precision.

Diving into the costs, let’s start with the composition of investment materials. It’s a bit like picking ingredients for a gourmet dish – the better the ingredients, the higher the cost. High-quality materials that can withstand extreme temperatures without cracking are often pricier, but they’re worth their weight in gold for achieving flawless results.

Thermal properties play a leading role in influencing the cost. Materials that offer superior thermal expansion and high-temperature resistance usually come with a heftier price tag. It’s like paying for an all-weather, versatile jacket – costly, but invaluable in challenging conditions.

The quantity required also affects the cost equation. Bulk purchases can often lead to cost savings, akin to buying wholesale. However, don’t let the lure of lower prices lead you to compromise on quality. It’s a fine balance between quantity, cost, and the quality you need for your specific casting.

Choosing the right investment material based on your budget and casting requirements is key. At PrecisionVast, we advise weighing the pros and cons of each material. It’s about matching your casting needs with the right investment material without breaking the bank. After all, a successful casting is not just about the final product, but also the journey there – cost-effective, efficient, and precise.

Section 4: Crucibles and Furnaces: Evaluating Material, Durability, and Energy Efficiency

In the meticulous world of lost wax casting, crucibles and furnaces are much more than just equipment – they are the steadfast companions that endure the heat and forge the metal. At PrecisionVast, we recognize the importance of evaluating these key components not just for their immediate cost, but for their long-term value.

When it comes to crucibles, the material choices – like ceramic and clay graphite – come with their own price tags and perks. Ceramic crucibles, often more expensive, are the aristocrats of the crucible world, offering superior heat resistance and longevity. Clay graphite crucibles, on the other hand, are the sturdy workhorses, more affordable and efficient for frequent use.

The durability of crucibles is a crucial factor in long-term costs. Investing in a high-quality crucible might feel like splurging at first, but it’s like buying a luxury car that lasts longer and requires less maintenance – saving you money down the road.

Moving on to furnaces, energy efficiency is the name of the game. A furnace that guzzles less power not only reduces your carbon footprint but also cuts down on operational costs. It’s like choosing an electric car over a gas-guzzler – good for the planet and your wallet.

Selecting the right crucibles and furnaces is about finding the perfect balance between upfront cost and long-term savings. At PrecisionVast, we advise considering the material quality, durability, and energy consumption of these crucial tools. It’s about investing in equipment that not only meets your current needs but also ensures cost-efficiency for years to come. After all, in the world of lost wax casting, the best value for money comes from tools that last.

Conclusion

And there we have it, a comprehensive journey through the cost landscape of lost wax casting supplies. From the nuanced selection of waxes to the critical choice of investment materials, and the balancing act between crucibles and furnaces, at PrecisionVast, we’ve covered it all. This cost comparison isn’t just about numbers; it’s about understanding the delicate balance between quality and cost. Successful casting isn’t just about the right materials; it’s about making informed choices that align with your specific needs and budget. Remember, in the art of casting, the best value is found in supplies that meet your unique requirements without compromising on the final masterpiece.