Quality Control Techniques in Die Cast Aluminum Fabrication

Welcome to PrecisionVast and die cast aluminum fabrication! Precision isn’t simply our goal; it’s a necessity! As quality guardians at our facility, our job is to make sure each piece leaves looking like perfection – but let’s face it, getting there may take more effort than expected! Creating this level of excellence doesn’t happen overnight but requires expert hands walking across molten aluminum pools!

Quality control in die casting is of utmost importance – it makes all the difference between producing flawless components with sparkling shine, or unintentionally creating metal blobs with uneven finishes and rough textures. Of course, quality control comes with its share of challenges: from maintaining uniformity over thousands of parts to competing against nature with melting metal, hurdles can arise that seem as formidable as Everest itself!

Fear not! At PrecisionVast, we have perfected the art of quality control. Our methods combine science, art and magic in their approach – but you don’t need to believe us when we tell you we know. In this introduction we will reveal all our quality control prowess; all designed to guarantee die cast aluminum fabrication standards which satisfy even the strictest critics.

Section 1: Inspection and Testing Methods

In the realm of die-cast aluminum fabrication at PrecisionVast, quality control is our mantra. Let’s break down the critical inspection and testing methods we use, each a crucial step in ensuring that every product is up to our exacting standards.

Visual Inspection

First up is visual inspection – our initial line of defense. It’s akin to an eagle-eyed expert scanning for any surface irregularities or defects. Our team meticulously examines each piece, ensuring that what meets the eye is as perfect as it gets.

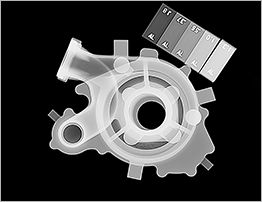

Next, we have the X-ray testing. This isn’t just about looking at bones; it’s our way of seeing through the aluminum to unearth any hidden internal inconsistencies. Think of it as a superpower, revealing secrets hidden within the metal.

Then comes hardness testing. Here, we’re checking whether our aluminum has been hitting the metaphorical gym. This test assesses the strength and resilience of the alloy, ensuring it can handle the rigors of its intended use.

Magnetic Particle Inspection is our method for uncovering what lies beneath. It detects surface and subsurface defects, ensuring that even the parts you can’t see are defect-free.

Tensile Testing

Tensile testing is where we play a game of tug-of-war with the metal. This test checks the alloy’s ability to withstand forces without breaking, ensuring its durability and longevity.

Pressure Testing

Pressure testing is like the deep-sea diving of testing methods. Here, we determine if the product can withstand high-pressure environments, ensuring its reliability under stress.

Dimensional Accuracy Checks

Finally, dimensional accuracy checks are where we play the role of a meticulous tailor. We ensure that every dimension is precise, fitting the specifications to a tee.

Together, these methods form the backbone of our quality control process at PrecisionVast, ensuring that each product isn’t just good, but is the epitome of excellence in die-cast aluminum fabrication.

Section 2: Process Control and Optimization

PrecisionVast takes process control and optimization seriously – like an accomplished chef treats their masterpiece – from temperature and pressure controls through optimization and the die casting process itself to measuring results with great care and expertise. When controlling die casting temperatures and pressure levels during die casting processes, precision matters. Too hot may mean disaster; too low may have no visible outcome at all!

Temperature and pressure control in die casting is our special sauce! Just as an experienced chef knows exactly the temperature needed for perfect steak cooking, we know precisely the intensity and duration of pressure needed for flawless aluminum castings – both art and science combined!

But wait – this metaphor goes further. Mold design and alloy selection serve as our “ingredients”, just as with culinary ingredients. A great recipe (mold design) combined with carefully chosen alloys (alloy selection) produces stunning results; not only improving quality but also decreasing time and materials wasted by this approach.

Here’s an appealing example: by optimizing our mold designs, we have reduced cooling times significantly while speeding up production without compromising quality – leading to less waste, but better aluminum products! A win-win recipe for die casting!

Section 3: Continuous Improvement and Training

PrecisionVast recognizes that perfection is an ongoing journey and therefore adhere to continuous improvement of quality control as our motto. Like fine-tuning an antique car, there’s always something new or tweaked that needs attention; that’s why regular process evaluations and updates are an integral part of keeping production fresh and innovative.

Now, let’s talk about our team. Quality doesn’t only come from processes; it comes from people. At Cast-Technic, staff training is rigorous – like boot camp for die casting experts. Skilled operators play the essential role of orchestrators in our die casting orchestra by making sure every part hits its perfect pitch.

Long term, our commitment to continuous improvement and training is like planting a tree; while it takes time to bear fruit in terms of shade (i.e. high quality standards), its shade (read: top quality standards) will ultimately prove worth every effort made – helping ensure our die-cast aluminum fabrication remains top notch both now and into the future.