How to Choose Quality Lost Wax Casting Supplies: A Buyer’s Guide

Introduction

Welcome to the world of lost wax casting! At PrecisionVast, we take this ancient yet contemporary technique seriously and treat each cast as unique piece that tells a unique tale. At this stage of lost wax casting production, each casting can tell a unique tale; here at PrecisionVast we treat this intricate process with great respect, and like magic it creates stunning metal masterpieces from wax models – such is its magic!

Like any good magic trick, the secret lies in its supplies. Wax, investment material and tools serve as magical wands and capes to an accomplished magician; quality materials ensure that the end product doesn’t simply resemble another metal object but becomes an object worthy of Michelangelo himself.

Why this guide? In the world of lost wax casting, not all supplies are created equal. PrecisionVast’s goal is to guide you through this jungle of options in search of treasure. No matter whether you are an experienced caster or just starting out on this exciting journey – this guide should serve as your compass towards making informed decisions that give consistent results, longevity and bragging rights amongst casting peers.

With this guide, we’ll reveal the secrets to choosing wax, investment material and other essentials that make casting successful and spectacular. Join us as we embark on an incredible adventure that transforms ordinary into extraordinary!

Section 1: Understanding Lost Wax Casting Supplies

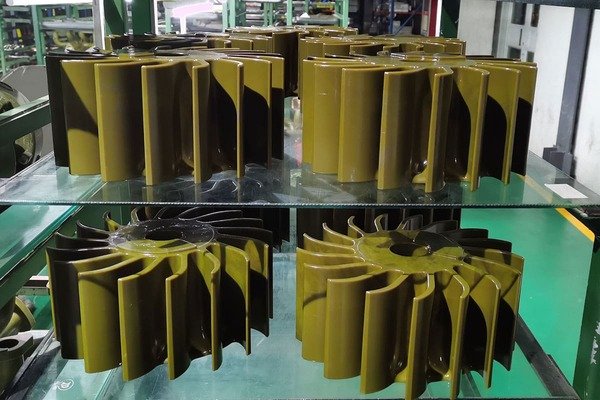

PrecisionVast serves as a meticulous director, overseeing each role played out on stage of lost wax casting, from wax, investment material, crucibles, and melting furnaces – to name but a few! So let us draw back the curtain and reveal some key players: wax, investment material, crucibles, and melting furnaces.

First up is wax – our casting process’s Leonardo DiCaprio. Not just any wax; the quality of it determines how well it captures all of its intricate design features – too brittle might crack under pressure; too soft could warp – making selecting an ideal wax like selecting an A-List star actor for a blockbuster movie!

Investment material is often the star of its own show. This ceramic material encases a wax model, and when the wax has been removed it leaves an exact mold of that wax form. Think of it as the method actor of materials; taking on exactly the shape and thickness required while still offering enough strength and permeability to do its job properly.

Crucibles and melting furnaces – unsung heroes behind the scenes. Crucibles serve as places for metal to take its molten form, like a Phoenix rising from ashes; their task requires handling high temperatures without cracking. Meanwhile, furnaces act as a hub of activity, heating metals at precisely the right temperatures and acting like orchestra conductors to make sure every note hits its perfect pitch.

What factors determine the quality of these supplies? Wax is determined by its composition of materials which determine its flexibility and melting point, while investment material requires finding an enduring mixture that can withstand high temperatures without losing its shape. Crucible quality depends on being resistant to thermal shock while furnace efficiency depends on precise temperature control and even heat distribution.

At PrecisionVast, we understand that understanding these supplies is like unlocking the secret ingredients to creating magical dishes – get them right, and you could soon be on your way to casting masterpieces!

Section 2: Criteria for Selecting Wax

Ah, wax! In the world of lost wax casting, it’s not just about any wax; it’s about finding the perfect star for your metal masterpiece. Here at PrecisionVast, we treat wax selection like a casting audition for a Hollywood blockbuster. Let’s dive into the types of waxes and how to pick your lead actor.

First, let’s meet the cast. There’s carving wax, known for its stiffness and detail retention, perfect for those intricate designs. It’s like the wax world’s meticulous sculptor. Then there’s injection wax, the go-to guy for mass production, known for its fluidity and ease of use. It’s the wax that says, “Let’s get this job done efficiently.” And we can’t forget about repair wax, the handyman that fixes all the casting flaws.

Choosing the right wax is like matchmaking in Hollywood. You’ve got to consider the intricacy of your casting and the melting point. Need fine details? Go for a carving wax that holds its shape like a pro. Working on a large-scale production? Injection wax will be your best buddy, flowing into molds like a dream. And if you’re playing the repair game, repair wax is your savior.

Now, let’s talk about quality checks – the screen tests for waxes. First, do the ‘snap test’: bend a piece of wax, and it should snap cleanly, showing its strength and flexibility. Then there’s the ‘melt test’: heat a small piece and watch how it flows. It should melt evenly and smoothly, like butter on a hot pan. And don’t forget the ‘detail test’: press a detailed object into the wax and check how well it captures the intricacies. It should be like a high-definition photo, capturing every line and curve.

At PrecisionVast, we believe that the right wax can make or break your casting. It’s the unsung hero that deserves as much spotlight as the final metal product. So, take your time, do the tests, and choose the wax that’ll make your casting shine like a star on the Hollywood Walk of Fame.

Section 3: Choosing the Right Investment Material

At PrecisionVast, selecting the right investment material for lost wax casting is like picking the perfect ensemble for a Broadway show. It’s all about harmony and precision. So, let’s take a stroll down the investment material runway and see what suits your casting character best.

Investment materials are the unsung heroes of casting. They’re not just any old supporting actors; they’re the ones that give your metal star its shape and shine. You’ve got options like gypsum-based materials, known for their affordability and versatility – think of them as the all-rounder in the casting world. Then there’s silica, the high-performance artist, perfect for intricate designs and high-temperature metals.

But how do you choose your star? First, consider thermal expansion. It’s like ensuring your investment material can handle the spotlight without cracking under pressure. Too much expansion, and your casting might resemble a modern art piece rather than the intended design. Next, ponder over the material strength – it’s the backbone of your casting, ensuring that your final product isn’t just a beauty but also a beast in terms of durability.

Now, don’t overlook compatibility with the metal being cast. It’s like ensuring the leading actor and supporting actor have chemistry. Your investment material should complement your metal, accommodating its melting temperature and properties.

And let’s not forget the grand finale – the burnout and setting process. This is where the investment material shows its true colors. A good investment material should leave a clean, detailed cavity after burnout, ready for the molten metal to take the stage. Think of it as the rehearsal before the big opening night, where every little detail counts.

At PrecisionVast, we believe choosing the right investment material is a mix of science, art, and a bit of casting intuition. It’s about understanding the script of your metal and giving it the perfect stage to shine. So, take your time, consider the traits, and let your casting be the talk of the town!

Section 4: Furnaces and Crucibles

Furnaces and crucibles play an integral part in lost wax casting, acting like Batman and Robin to ensure successful production runs. At PrecisionVast, we understand the significance of selecting the appropriate furnace/crucible combination is not less crucial than selecting an ideal superhero outfit.

Consider melting furnaces the kitchen stoves of metal casting; they require heat. But precision in terms of both temperature range and precision is key here – too low and your metal could just sit around wasting its preciousness; too high could mean an untimely meltdown; capacity also matters as does size; you wouldn’t want a furnace too small like one-bedroom apartments for families of four; not to mention energy efficiency: everyone loves saving on bills!

Crucibles are containers used to contain your molten metal, serving as the perfect companion to your furnace. Material choices will depend on both metal type and temperature requirements – you wouldn’t use a paper bag to transport hot soup! Just as different metals need different crucibles tailored specifically to their temperatures (personalities).

Maintain and protect. Treat your furnace and crucible like you would treat a pet dragon: treat them with respect and take great care to ensure proper check-ups, cleanings, and adhering to safety protocols are adhered to regularly – remembering that happy furnace and crucible means an enjoyable casting process!

Overall, choosing and maintaining the appropriate furnace and crucible can make your casting process as seamless as a superhero’s landing. Make an educated choice, maintain regularly, and cast safely!

Section 5: Evaluating Suppliers and Quality Assurance

In the quest for perfect lost wax casting supplies, selecting the right supplier is akin to finding a trusted ally in a high-stakes game. At PrecisionVast, with our 20-plus years of expertise in the precision casting industry, we not only understand the rules of the game, we often write them!

Think of evaluating suppliers as conducting auditions for a crucial role in your production. You’re looking for a supplier who can consistently hit the right notes – quality, reliability, and expertise. It’s not just about who offers the shiniest tools; it’s about who delivers a performance that elevates your entire casting process.

Why consider a supplier like PrecisionVast? Well, experience counts. Our seasoned journey through the twists and turns of the casting world has equipped us with an eye for what truly works. We know the ins and outs of the industry, understanding that quality assurance isn’t just a phrase – it’s our promise.

When scrutinizing certifications and quality processes, it’s like checking the credentials of a seasoned actor. Does your supplier have a track record of excellence? At PrecisionVast, our legacy speaks for itself. It’s a story of continuous improvement, innovation, and commitment to quality that’s evident in every supply we offer.

Remember, building a relationship with your supplier is key. It’s not a one-off transaction but a partnership for future success. With a supplier like PrecisionVast, you’re not just purchasing supplies; you’re gaining a collaborator who is invested in your casting achievements.

As you select your suppliers, consider PrecisionVast – a name synonymous with quality and reliability in the lost wax casting industry. Let our experience be your guide to a world of exceptional casting results.

Conclusion

Let’s come together now for the grand finale of our guide to selecting supplies for lost wax casting! Just think of it as our grand performance ending, taking one last bow before closing our show with some final points that really stood out to us all. Let’s recap all these key points in a quick encore performance?

Keep this in mind as the starting point: wax is the star of this show; choose wisely based on casting intricacy and melting point requirements to secure its success. Next up comes investment material – like an actor in an opera performance it can either elevate or bring down a performance; consider its thermal expansion coefficient, material strength rating and compatibility with metal before choosing it as your investment material of choice.

Furnaces and crucibles are essential backstage players that will ensure your show goes without any hitches. Be sure to get the proper temperature range, capacity and energy efficiency measures in place; and when it comes to matching metal with its respective crucible – think of pairing wine and cheese pairings perfectly!

Supplier selection and quality assurance serve as your show’s producer, making sure everything runs smoothly while meeting all of your high standards every time. Quality, consistency, and strong relationships with suppliers are keys to a successful casting show production.

Never forget, lost wax casting is an ever-evolving art form with endless opportunities. Continuous learning and adapting are part of its appeal; embrace it to discover that lost wax casting may become your path to creating magic rather than metals!

So there you have it – an exhaustive guide for selecting only the highest-quality lost wax casting services for your needs. Focusing on quality will result in castings that not only tell a tale but sing an epic tune! Happy casting!