Structural die casting is a crucial process in manufacturing durable and precise parts. Are you wondering what it entails and how it can benefit your business? Read on for everything you need to know about this key casting method.

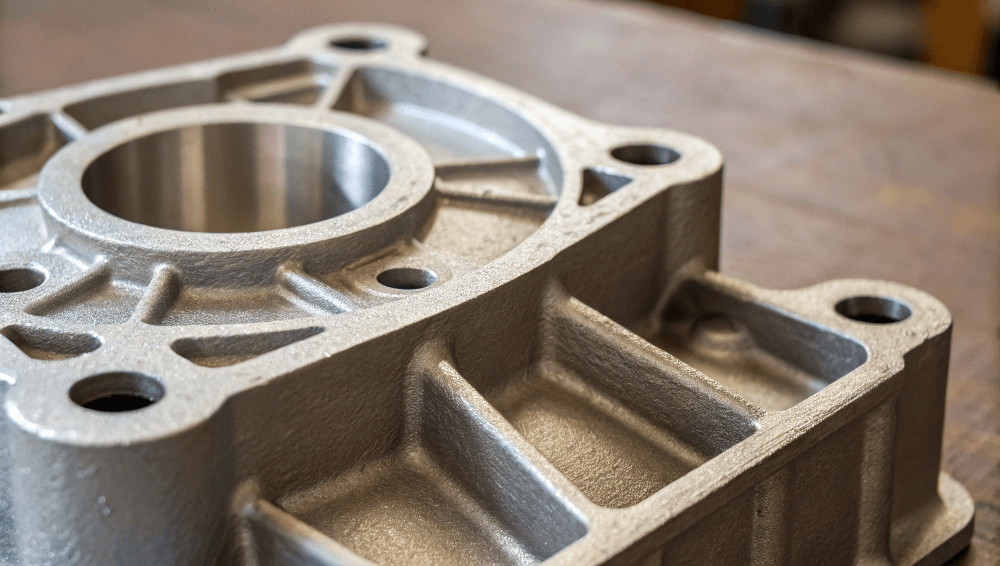

Structural die casting is a process used to create parts by injecting molten material into a mold. It’s highly effective for producing high-quality, durable components in various industries like automotive and aerospace.

Are you looking for the most efficient and effective way to create strong, intricate parts for your business? Structural die casting might be the solution you need, but let’s dive deeper into how it works and the advantages it offers.

1. What is Structural Die Casting?

Structural die casting is a manufacturing process that involves injecting molten metal under high pressure into a mold to form parts. This technique is commonly used to produce complex parts that require high strength and durability.

Structural die casting is one of the most reliable methods for producing intricate parts with high precision. It involves a pressure injection of molten metal into a die.

The material used in structural die casting is usually metals such as aluminum, magnesium, or zinc, chosen for their strength, lightweight nature, and ability to withstand high stress. This process is particularly effective for making parts used in industries like automotive, aerospace, and electronics.

How Does the Structural Die Casting Process Work?

The die casting process involves multiple steps. It starts with the preparation of the mold. Once the mold is ready, molten metal is injected under high pressure into it, where it cools and hardens, taking the exact shape of the mold.

Steps in the structural die casting process:

- Mold preparation: A metal die is created based on the design of the part.

- Injection: Molten metal is injected into the mold under high pressure.

- Cooling: The metal cools and hardens into the shape of the part.

- Ejection: The part is removed from the mold.

Table 1: Steps in the Die Casting Process

| Step | Description |

|---|---|

| Mold Preparation | Design and create the mold |

| Injection | Inject molten metal into the mold |

| Cooling | Let the metal cool and solidify |

| Ejection | Remove the finished part from the mold |

2. How Does Structural Die Casting Compare to Other Casting Methods?

Compared to other casting techniques, structural die casting is unique in terms of its precision and the strength of the parts it produces. How does it stack up against methods like sand casting or investment casting?

While sand casting and investment casting offer benefits, structural die casting stands out for its speed and accuracy.

It’s a preferred choice for high-volume production runs because it allows manufacturers to produce high-strength, detailed parts at a faster pace and lower cost compared to traditional methods. The process is also more consistent and produces parts with excellent surface finishes, reducing the need for post-processing.

Key Differences between Die Casting, Sand Casting, and Investment Casting

| Casting Method | Speed | Surface Finish | Cost | Complexity |

|---|---|---|---|---|

| Die Casting | Fast | Smooth | Low | High |

| Sand Casting | Medium | Rough | Low | Low |

| Investment Casting | Slow | Very smooth | High | High |

3. What Are the Benefits of Structural Die Casting?

What makes structural die casting so beneficial for manufacturers and industries? From durability to cost-effectiveness, there are many reasons why it’s the go-to method for many production lines.

The key benefits of structural die casting are its cost-effectiveness, precision, and ability to produce high-quality parts in large quantities.

The high pressure used in die casting ensures that the metal fills even the smallest and most intricate parts of the mold, resulting in parts with excellent mechanical properties. Additionally, the ability to use a wide range of materials makes it a versatile method for producing parts used in various industries, such as automotive, aerospace, and electronics.

Key Benefits of Structural Die Casting

- High precision and quality: Parts produced are highly accurate and need minimal post-processing.

- Cost-effective: Ideal for high-volume production runs due to the efficiency of the process.

- Durable: Parts created through structural die casting are known for their strength and resistance to wear and tear.

Table 2: Benefits of Structural Die Casting

| Benefit | Description |

|---|---|

| High Precision | Offers accurate and consistent parts |

| Cost-effective | Ideal for large-volume production runs |

| Durability | Parts are highly resistant to wear and tear |

4. What Materials Are Best for Structural Die Casting?

What materials are commonly used in structural die casting? Depending on the desired properties of the final product, manufacturers often choose materials that provide the best performance in terms of strength, weight, and resistance to wear.

Aluminum, zinc, and magnesium are among the most commonly used materials in structural die casting.

Each material offers specific advantages. For example, aluminum is lightweight yet strong, making it perfect for automotive and aerospace applications. Magnesium is often used when a combination of low weight and high strength is required.

Most Common Materials in Structural Die Casting

- Aluminum: Lightweight and corrosion-resistant.

- Zinc: Cost-effective and strong.

- Magnesium: Lightweight with excellent strength-to-weight ratio.

Table 3: Material Comparison for Structural Die Casting

| Material | Strength | Weight | Cost | Common Uses |

|---|---|---|---|---|

| Aluminum | High | Low | Medium | Automotive, Aerospace |

| Zinc | Medium | Medium | Low | Electronics, Hardware |

| Magnesium | High | Very Low | High | Aerospace, Automotive |

5. What Industries Use Structural Die Casting?

Structural die casting is used in a variety of industries due to its ability to produce durable, high-strength parts with complex geometries. Which industries rely most on this process for their manufacturing needs?

Industries such as automotive, aerospace, and electronics frequently rely on structural die casting to produce high-quality, precision parts.

In the automotive industry, for example, structural die casting is used to produce components like engine blocks, transmission cases, and wheels. These parts require strength and durability, which is why the high-pressure injection method of die casting is ideal. Similarly, the aerospace industry uses die casting for producing lightweight yet strong parts for aircraft, while the electronics sector depends on it for heat sinks, housings, and connectors.

Industries That Benefit from Structural Die Casting

- Automotive: Components such as engine parts, wheels, and transmission cases.

- Aerospace: Lightweight structural components, such as brackets and engine casings.

- Electronics: Parts like connectors, heat sinks, and housings.

- Consumer Goods: Durable parts for appliances and gadgets.

Table 4: Key Industries Using Structural Die Casting

| Industry | Common Uses | Example Parts |

|---|---|---|

| Automotive | Engine blocks, wheels, transmission cases | Engine components, wheel rims |

| Aerospace | Aircraft components, structural parts | Brackets, engine casings |

| Electronics | Heat sinks, connectors, enclosures | Heat sinks, computer housings |

| Consumer Goods | Durable consumer products | Appliance parts, gadget housings |

6. How Does Structural Die Casting Compare to Other Casting Methods?

Structural die casting offers several distinct advantages over traditional casting methods like sand casting or investment casting. But how exactly does it compare?

Structural die casting excels in terms of precision and speed, making it the method of choice for high-volume production of complex parts.

Unlike sand casting, which produces parts that require extensive finishing, die-cast parts are highly accurate and often require minimal post-processing. Investment casting, while offering excellent detail, tends to be slower and more expensive for large runs. Die casting, on the other hand, combines both speed and precision, which makes it a more cost-effective choice for large production runs.

Comparison of Casting Methods

- Die Casting: Best for high-volume production with precise parts and minimal finishing.

- Sand Casting: Slower, requires more finishing, suitable for simple parts.

- Investment Casting: Excellent for fine detail, but costly and slower.

Table 5: Comparison of Casting Methods

| Method | Speed | Precision | Cost | Suitability |

|---|---|---|---|---|

| Die Casting | Fast | High | Low | High-volume production |

| Sand Casting | Medium | Low | Low | Simple parts |

| Investment Casting | Slow | Very High | High | Detailed parts |

7. What Are the Key Challenges in Structural Die Casting?

While structural die casting is an effective process, it does come with its own set of challenges. What obstacles should manufacturers be aware of when implementing this process?

Challenges in structural die casting include material handling, managing complex shapes, and ensuring quality control.

The high pressure and temperatures involved in the process can lead to issues such as air bubbles and incomplete fills, which can affect the part’s quality. Additionally, die casting equipment can be expensive, and the molds themselves can wear out over time, requiring frequent replacements. Managing these challenges effectively requires skilled personnel and high-quality materials.

Common Challenges in Structural Die Casting

- Material handling: Ensuring consistent material quality is essential to prevent defects.

- Complex shapes: Some designs may require more specialized equipment and techniques.

- Quality control: Ensuring parts meet high-quality standards without defects.

Table 6: Challenges in Structural Die Casting

| Challenge | Description | Solution |

|---|---|---|

| Material Handling | Ensuring material consistency | Use high-quality alloys |

| Complex Shapes | Difficulty in casting intricate designs | Advanced mold design techniques |

| Quality Control | Preventing defects like air bubbles | Stringent quality assurance |

8. What Are the Common Defects in Structural Die Casting?

Defects in structural die casting can undermine the strength and quality of the parts. What are the most common defects that manufacturers face, and how can they be avoided?

Common defects include porosity, cold shuts, and surface imperfections, which can be prevented with careful control of the process.

Porosity occurs when air bubbles get trapped in the metal during the casting process, resulting in weak points. Cold shuts happen when the metal cools too quickly, leaving visible seams on the surface. These defects can be minimized by ensuring that the mold is heated properly and the metal is injected at the right temperature and pressure.

Common Defects and How to Avoid Them

- Porosity: Caused by trapped air bubbles.

- Cold shuts: Visible seams from cooling metal.

- Surface imperfections: Result from poor mold quality or poor material handling.

Table 7: Common Defects and Prevention Methods

| Defect | Cause | Prevention Method |

|---|---|---|

| Porosity | Trapped air bubbles | Control pressure and temperature |

| Cold Shuts | Metal cooling too quickly | Proper mold and metal temperature |

| Surface Imperfections | Poor mold quality or handling issues | Use high-quality molds and materials |

9. How Long Does It Take to Complete a Structural Die Casting Project?

The time it takes to complete a structural die casting project depends on several factors, including the complexity of the design and the production volume. How long can you expect a project to take?

Structural die casting typically takes less time than other casting methods, but the timeline varies based on project complexity.

For simple parts, the process may take just a few hours. However, for more complex components requiring specialized molds, it can take several days. The time needed for cooling, mold preparation, and post-processing must all be considered in the overall project timeline.

Timeline for Structural Die Casting Projects

- Simple parts: A few hours to produce.

- Complex parts: Several days for mold preparation and production.

- Large-scale production: Weeks to complete full production runs.

Table 8: Estimated Time for Structural Die Casting

| Project Complexity | Time Required | Example Projects |

|---|---|---|

| Simple Parts | A few hours | Basic automotive parts |

| Complex Parts | Several days | Aerospace components, engine parts |

| Large-Scale Runs | Weeks | High-volume automotive production |

10. What Are the Costs Involved in Structural Die Casting?

When considering structural die casting for your business, it’s essential to understand the costs associated with the process. How do these costs break down, and how can you manage them effectively?

The cost of structural die casting involves multiple factors, including materials, labor, equipment, and mold maintenance.

Material costs are generally the largest expense, as the type of metal used (e.g., aluminum, zinc) can vary in price. Additionally, mold creation can be expensive, especially for complex parts. However, once molds are created, they can be used for large production runs, lowering the cost per unit over time.

Breakdown of Costs in Structural Die Casting

- Material costs: The price of metals like aluminum or zinc.

- Labor costs: Cost of skilled workers required for the casting process.

- Equipment costs: Machinery needed for melting and injection.

- Mold costs: High upfront cost for mold creation.

Table 9: Breakdown of Structural Die Casting Costs

| Cost Category | Description | Approximate Percentage of Total Cost |

|---|---|---|

| Material Costs | Costs of raw materials like aluminum or zinc | 40% |

| Labor Costs | Wages for workers involved in production | 20% |

| Equipment Costs | Investment in machinery and tools | 25% |

| Mold Costs | Upfront costs for mold design and creation | 15% |

11. What Are the Latest Trends in Structural Die Casting?

Structural die casting continues to evolve as new technologies emerge. What are some of the latest developments in this field that businesses should be aware of?

Innovations in structural die casting are focusing on automation, sustainability, and advanced materials.

Automation is reducing labor costs and increasing efficiency, while advancements in 3D printing and computer modeling are enabling manufacturers to produce even more complex and precise molds. Sustainability is also becoming a major focus, with manufacturers exploring ways to recycle materials and reduce waste in the casting process.

Emerging Trends in Structural Die Casting

- Automation: Increased use of robotic arms and AI to streamline production.

- Sustainability: Focus on reducing waste and reusing materials.

- Advanced Materials: Development of new alloys for better performance.

Table 10: Emerging Trends in Structural Die Casting

| Trend | Description | Example |

|---|---|---|

| Automation | Use of robotics and AI to improve efficiency | Automated die casting machines |

| Sustainability | Focus on reducing waste and recycling materials | Use of recycled aluminum in die casting |

| Advanced Materials | New alloys that enhance the performance of parts | Development of stronger, lighter alloys |

12. How to Maintain and Repair Die Cast Parts?

To extend the lifespan of die-cast parts, regular maintenance and timely repairs are essential. What steps should businesses take to ensure these parts remain in top condition?

Proper maintenance involves regular inspection and cleaning of die-cast parts, while repairs often include welding or re-casting damaged parts.

Die-cast parts, particularly those used in harsh environments, are prone to wear and tear. Regular cleaning and inspection for cracks, corrosion, or deformities can help identify problems early. If parts are damaged, techniques such as welding or re-casting can be employed to restore them.

Maintenance and Repair Tips for Die Cast Parts

- Regular cleaning: Prevent buildup of dirt and debris that can cause wear.

- Inspection: Check for cracks, corrosion, or surface damage regularly.

- Repairs: Use welding or re-casting methods to fix damaged parts.

Table 11: Maintenance Tips for Die Cast Parts

| Maintenance Task | Description | Frequency |

|---|---|---|

| Cleaning | Prevent dirt buildup on the surface | Every 3-6 months |

| Inspection | Check for cracks, corrosion, or surface damage | Every 6 months |

| Repairs | Use welding or re-casting methods for damage | As needed |

13. How Can You Choose the Right Die Casting Supplier?

Choosing the right supplier is crucial for ensuring the quality of your structural die-cast parts. What criteria should you use to select a reliable supplier?

Selecting a die casting supplier involves evaluating their technical capabilities, production capacity, and customer service.

Look for a supplier with experience in your industry and the ability to meet your specific needs. Make sure they can provide high-quality parts on time and offer post-production support, including maintenance and repairs. Certifications and compliance with industry standards are also key factors in making your decision.

Criteria for Choosing the Right Die Casting Supplier

- Experience: Ensure they have experience in your specific industry.

- Production capacity: Check if they can handle your required production volume.

- Customer service: Look for reliable support before, during, and after production.

Table 12: Criteria for Choosing a Die Casting Supplier

| Criterion | Description | Importance |

|---|---|---|

| Experience | Supplier should have industry-specific experience | High |

| Production Capacity | Ability to handle your production volume | High |

| Customer Service | Reliable support before, during, and after production | Medium |

14. How Do You Ensure Quality in Structural Die Casting?

Ensuring quality in structural die casting is essential for producing parts that meet industry standards. How can you maintain high-quality standards throughout the casting process?

Quality control in structural die casting involves using proper inspection methods and maintaining strict process standards.

Inspections like x-ray testing and visual checks help detect internal and external defects. Adhering to established process standards, including proper temperature control and mold maintenance, ensures that every cast part meets the desired quality and durability.

Quality Control Measures for Die Casting

- X-ray testing: To detect internal defects like porosity.

- Visual inspections: Check the exterior for cracks and imperfections.

- Process standards: Ensure that the die casting process is executed within the required parameters.

Table 13: Quality Control Measures for Die Casting

| Measure | Description | Application |

|---|---|---|

| X-ray Testing | Detect internal defects like porosity | Post-production inspection |

| Visual Inspection | Check for surface cracks and imperfections | Regular part inspection |

| Process Standards | Ensure temperature and pressure are controlled | During production |

15. What Are the Future Developments in Structural Die Casting?

What’s next for structural die casting? As technologies continue to advance, how will the die casting industry evolve in the coming years?

Future developments in structural die casting include more automation, greater use of sustainable materials, and innovations in mold design.

The focus will likely shift toward even greater precision and efficiency, with the implementation of AI and machine learning to monitor the casting process in real time. Sustainable practices will become more prominent, as manufacturers seek to reduce waste and energy consumption. New developments in mold materials and designs will also enable more intricate and durable parts to be produced.

Future Trends in Structural Die Casting

- Automation: Use of AI and robotics for real-time monitoring and process control.

- Sustainability: Increased focus on recycling and reducing energy usage.

- Innovative mold design: New materials and designs for better performance.

Table 14: Future Developments in Die Casting

| Development | Description | Potential Benefits |

|---|---|---|

| Automation | Use of AI and robotics to improve monitoring | Increased precision and efficiency |

| Sustainability | Focus on recycling and energy-efficient practices | Reduced environmental impact |

| Innovative Mold Design | Use of new materials and techniques for molds | Ability to produce more complex, durable parts |

Conclusion

Structural die casting is an efficient and precise process that provides manufacturers with the ability to produce high-quality, durable parts in high volumes. Its advantages, including cost-effectiveness, high precision, and material versatility, make it a preferred choice for many industries. Understanding the details of this process and how it compares to other casting methods can help businesses make informed decisions for their production needs.

FAQ

- Q1: What is structural die casting?

Structural die casting is a manufacturing process where molten metal is injected into a mold under high pressure to create precise and durable parts, commonly used in automotive and aerospace industries. - Q2: How does the structural die casting process work?

The process involves preparing the mold, injecting molten metal into the mold under pressure, allowing it to cool and harden, and then ejecting the finished part from the mold. - Q3: What are the advantages of structural die casting?

The main advantages include high precision, cost-effectiveness, and the ability to produce complex, durable parts at a faster pace than traditional casting methods. - Q4: What materials are best for structural die casting?

Common materials used include aluminum, zinc, and magnesium, depending on the desired properties such as strength, weight, and cost. - Q5: What industries benefit from structural die casting?

Structural die casting is widely used in industries such as automotive, aerospace, electronics, and consumer goods for producing strong, lightweight parts.