In today’s manufacturing world, finding the right materials for specific applications is crucial for achieving optimal results. 4130 alloy steel is a preferred choice for many industries, particularly in sand casting, due to its durability, strength, and versatility.

4130 alloy steel is highly sought after for sand casting because it combines excellent mechanical properties with cost-effectiveness, making it an ideal choice for a wide range of applications.

Many businesses continue to seek reliable, high-quality solutions for their casting needs. If you’re considering using 4130 alloy steel for sand casting, understanding its properties and advantages can help you make an informed decision and achieve better results.

1. What is 4130 Alloy Steel Sand Casting?

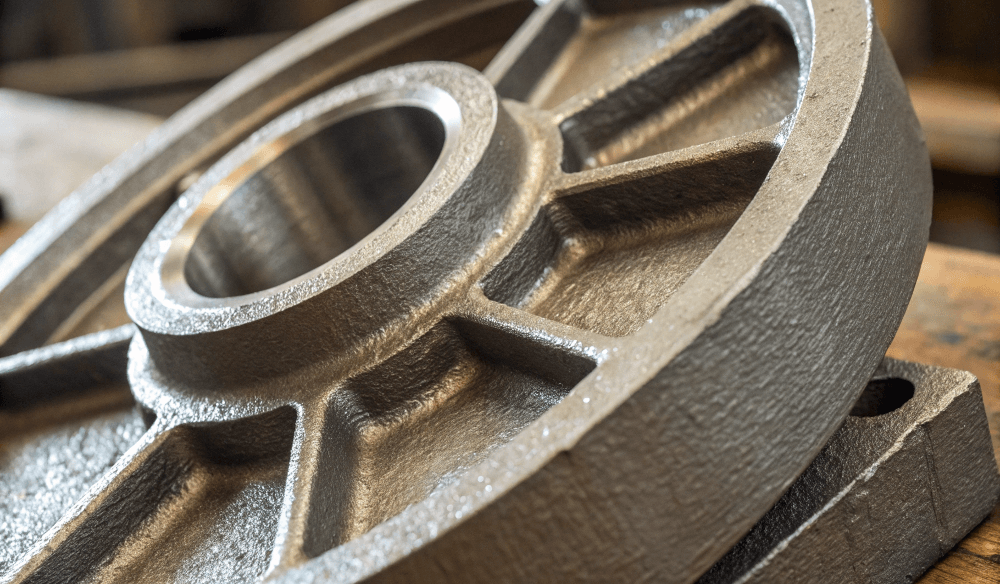

What exactly is 4130 alloy steel sand casting? In simple terms, 4130 alloy steel is a chromium-molybdenum steel with excellent properties for casting, welding, and machining. Sand casting, on the other hand, is a metal casting process where sand is used as the mold material. This process is highly popular due to its flexibility and cost-effectiveness, especially for manufacturing larger and more intricate components.

4130 alloy steel offers high strength, toughness, and resistance to wear, making it an excellent material for sand casting in industries like automotive, aerospace, and more.

The combination of the two processes—4130 alloy steel and sand casting—offers businesses a cost-effective, high-strength solution that can be tailored to meet the needs of various industries. If you’re looking for a reliable material for your sand casting needs, 4130 alloy steel might just be what you’re searching for.

2. Why is 4130 Alloy Steel Popular for Sand Casting?

Why is 4130 alloy steel so commonly used in sand casting? It all comes down to its properties. This steel alloy has excellent tensile strength, high fatigue resistance, and good weldability. These features make it highly desirable for various applications, especially in industries that demand durability and precision.

4130 alloy steel’s unique composition provides an ideal balance of strength and malleability, which is essential for successful sand casting.

Why is 4130 Alloy Steel Preferred Over Other Materials?

| Property | 4130 Alloy Steel | Other Steel Alloys |

|---|---|---|

| Tensile Strength | High | Moderate |

| Fatigue Resistance | High | Low |

| Weldability | Excellent | Moderate |

| Cost | Affordable | Expensive |

By understanding these factors, manufacturers can make informed decisions on when and why to choose 4130 alloy steel over other materials. Its favorable properties ensure that the castings produced are reliable and durable.

3. What Are the Applications of 4130 Alloy Steel Sand Casting?

What industries rely on 4130 alloy steel sand casting? The versatility of 4130 alloy steel makes it an ideal material for many different sectors. From automotive to aerospace, this steel is used in the production of parts that need to withstand high stress and harsh environments.

Common applications for 4130 alloy steel sand casting include automotive parts, structural components, and aerospace applications.

| Industry | Application |

|---|---|

| Automotive | Engine parts, suspension systems |

| Aerospace | Aircraft components |

| Oil & Gas | Valve bodies, pump components |

| Military | Aircraft landing gear, tank parts |

Understanding the range of applications for 4130 alloy steel sand casting will allow you to assess whether it fits the requirements for your next project.

4. How Does the Sand Casting Process Work?

How does the sand casting process work, and how does it apply to 4130 alloy steel? Sand casting involves several key steps: creating a mold, pouring molten metal into the mold, and then cooling it to solidify the casting. The mold is usually made from a mixture of sand, clay, and other binders, ensuring that the casting material can take the shape of the mold effectively.

The process is ideal for 4130 alloy steel because the sand mold can be easily shaped to meet the design requirements of the casting.

The advantages of sand casting for 4130 alloy steel include cost-efficiency, versatility, and the ability to create complex shapes with minimal material waste.

5. How is 4130 Alloy Steel Prepared for Sand Casting?

How is 4130 alloy steel prepared for sand casting? The preparation process for alloy steel involves multiple steps, including melting the material, ensuring it has the right chemical composition, and controlling the casting environment to minimize defects.

Proper preparation is key to producing high-quality sand castings with 4130 alloy steel.

Pre-Casting Procedures for 4130 Alloy Steel

| Step | Process |

|---|---|

| Material selection | Choosing the right alloy |

| Heating | Bringing the steel to the right temperature |

| Mold preparation | Ensuring the mold is ready and clean for pouring |

| Pouring | Pouring the molten steel into the mold |

This thorough preparation process ensures that the alloy steel will have the strength and durability required for demanding applications.

6. What Are the Challenges in Sand Casting 4130 Alloy Steel?

What challenges are associated with sand casting 4130 alloy steel? Despite its numerous advantages, using 4130 alloy steel in sand casting does present some difficulties. Sand casting, though versatile and cost-effective, can result in defects like porosity, shrinkage, and surface imperfections. These challenges can reduce the overall quality of the cast and lead to additional costs and delays in production.

Addressing these challenges requires a clear understanding of the process, continuous monitoring, and preventive measures.

Common Defects and How to Overcome Them

| Defect | Cause | Solution |

|---|---|---|

| Porosity | Trapped gas during solidification | Improve venting and mold design |

| Shrinkage | Cooling rate differences | Use controlled cooling processes |

| Surface Imperfections | Rough mold or improper pouring | Use smoother molds and proper pouring techniques |

By understanding and addressing these common challenges, businesses can ensure that the final 4130 alloy steel casting meets the required standards.

7. How Does 4130 Alloy Steel Compare with Other Casting Materials?

How does 4130 alloy steel stack up against other materials used in sand casting? In comparison to other alloys and metals, 4130 alloy steel is often chosen for its superior strength-to-weight ratio, excellent resistance to fatigue, and ease of machining. However, when compared to cast iron or other steel alloys, it may have slightly higher costs, but the long-term benefits often outweigh this.

When choosing between materials, manufacturers must weigh the advantages of 4130 alloy steel against the specific requirements of their projects.

Comparison of 4130 Alloy Steel with Other Materials

| Material | Strength | Cost | Fatigue Resistance | Ease of Machining |

|---|---|---|---|---|

| 4130 Alloy Steel | High | Moderate | High | Good |

| Cast Iron | Moderate | Low | Low | Poor |

| Stainless Steel | Very High | High | Very High | Moderate |

| Carbon Steel | High | Moderate | Moderate | Good |

By considering these attributes, businesses can determine the most suitable material for their sand casting needs. 4130 alloy steel typically outperforms cast iron in strength and fatigue resistance, making it the preferred choice for demanding applications.

8. What is the Role of Sand in Sand Casting for 4130 Alloy Steel?

What role does sand play in the casting of 4130 alloy steel? Sand is an essential part of the sand casting process. It forms the mold in which the molten 4130 alloy steel is poured to create the final casting. The quality of the sand, as well as the design of the mold, directly affects the quality of the final casting. Therefore, selecting the right type of sand is crucial for achieving the desired casting properties.

The right sand helps in creating precise molds, resulting in high-quality 4130 alloy steel castings.

Types of Sand Used in Sand Casting

| Type of Sand | Properties | Use Case |

|---|---|---|

| Green Sand | Reusable, high permeability | Common for most castings |

| Resin Bonded Sand | High strength, fast setting | Used for precision castings |

| Silica Sand | High heat resistance, low cost | Used for large castings |

| Chromite Sand | High thermal conductivity | Used for high-performance castings |

Choosing the correct sand type based on your casting requirements can improve the overall quality of the casting, ensuring it meets the specified standards for 4130 alloy steel.

9. How Can You Improve the Sand Casting Process for 4130 Alloy Steel?

How can the sand casting process be improved when using 4130 alloy steel? Several methods can enhance the sand casting process to achieve better results when working with 4130 alloy steel. For example, adjusting the pouring temperature, improving the mold design, and using advanced technologies such as 3D printing molds can help reduce defects and improve accuracy.

Improvement efforts in the sand casting process can lead to higher precision and fewer defects, resulting in better quality and reduced waste.

Techniques for Improving Sand Casting

| Technique | Effect on Cast Quality | Implementation |

|---|---|---|

| Controlling Pouring Temperature | Reduces defects like porosity | Use temperature-controlled furnaces |

| Advanced Mold Design | Improves casting accuracy | Implement CAD designs for molds |

| 3D Printing Molds | Allows for more complex and precise shapes | Utilize 3D printing technology for molds |

Incorporating these techniques into your sand casting operations will help you enhance the quality of 4130 alloy steel castings and reduce the occurrence of defects.

10. What Are the Environmental Considerations in Sand Casting?

What environmental considerations should be taken into account when performing sand casting for 4130 alloy steel? Sand casting, while an efficient and cost-effective process, can have a significant environmental impact. The sand used in casting can contribute to landfill waste, and the energy required for melting and pouring metals can generate substantial carbon emissions.

Businesses must consider ways to minimize their environmental impact by using sustainable practices, recycling sand, and utilizing energy-efficient technologies.

Sustainable Practices in Sand Casting

| Practice | Benefit | Example |

|---|---|---|

| Recycling Sand | Reduces waste and the need for new sand | Use of reclaimed sand in molds |

| Using Energy-Efficient Furnaces | Lowers energy consumption and emissions | Implement electric furnaces |

| Reducing Mold Waste | Minimizes waste generated by mold materials | Use reusable molds and casting cores |

11. How Do You Perform Quality Control for 4130 Alloy Steel Sand Castings?

How can quality control be effectively performed for 4130 alloy steel sand castings? Quality control is essential in ensuring that 4130 alloy steel castings meet industry standards. This process involves inspecting the castings for defects such as cracks, porosity, and dimensional inaccuracies. Using advanced testing methods such as ultrasonic testing, x-ray inspection, and visual examination, manufacturers can ensure that only the highest-quality castings are delivered.

Quality control ensures that 4130 alloy steel castings are consistent, durable, and fit for use in high-performance applications.

Quality Control Methods for Sand Casting

| Method | Purpose | Use Case |

|---|---|---|

| Ultrasonic Testing | Detects internal defects like cracks | Checking for hidden porosity or cracks |

| X-ray Inspection | Inspects internal structures | Identifying cracks, voids, or defects inside the cast |

| Visual Inspection | Identifies surface imperfections | Checking for surface defects, like pitting |

| Dimensional Measurement | Ensures dimensional accuracy | Verifying the size and shape of cast parts |

Implementing these quality control measures ensures that every 4130 alloy steel sand casting is made to the highest standard, reducing defects and improving reliability.

12. How Does Heat Treatment Affect 4130 Alloy Steel Sand Castings?

How does heat treatment improve 4130 alloy steel sand castings? Heat treatment plays a crucial role in enhancing the mechanical properties of 4130 alloy steel. By undergoing processes such as quenching and tempering, the steel gains increased strength, toughness, and wear resistance. Heat treatment also helps in relieving stresses caused by the casting process, reducing the likelihood of defects such as cracking.

Heat treatment is essential to optimize the performance and durability of 4130 alloy steel sand castings.

Heat Treatment Processes for 4130 Alloy Steel

| Process | Effect on 4130 Alloy Steel | Application |

|---|---|---|

| Quenching | Increases hardness and strength | Used for parts requiring high strength |

| Tempering | Relieves stress and improves toughness | Used to improve ductility and reduce brittleness |

| Annealing | Softens steel for better machinability | Used to prepare for further machining processes |

The right heat treatment process can dramatically improve the quality and durability of the final casting, ensuring it performs well in demanding applications.

13. What Are the Cost Considerations in Using 4130 Alloy Steel for Sand Casting?

What are the cost factors involved when using 4130 alloy steel for sand casting? Although 4130 alloy steel provides numerous benefits, it is important to consider the cost when choosing this material for sand casting. Factors such as raw material cost, energy consumption, mold design, and post-casting treatments all contribute to the final cost of production.

Cost analysis is key in determining whether 4130 alloy steel is the right material for your sand casting needs.

Breakdown of Cost Factors for 4130 Alloy Steel Sand Casting

| Cost Factor | Impact on Total Cost | Examples |

|---|---|---|

| Raw Material Cost | High due to alloying elements | 4130 alloy steel is more expensive than regular steel |

| Energy Consumption | High due to the need for melting | Energy-intensive furnaces |

| Mold Design | Custom molds increase cost | Complex molds cost more |

| Post-Casting Treatments | Additional costs for heat treatment | Tempering or quenching processes |

By understanding the various cost factors, companies can make more informed decisions and optimize their production processes to balance cost and quality.

14. What Are the Future Trends in Sand Casting with 4130 Alloy Steel?

What trends are emerging in the field of sand casting with 4130 alloy steel? As technology continues to evolve, so too does the process of sand casting. New innovations in materials, mold design, and automation are improving the efficiency and accuracy of sand casting for 4130 alloy steel. Additionally, increased focus on sustainability and environmental impact is driving the development of more eco-friendly practices in sand casting.

The future of sand casting with 4130 alloy steel looks promising, with advancements in both technology and sustainability.

Emerging Trends in Sand Casting for 4130 Alloy Steel

| Trend | Impact | Examples |

|---|---|---|

| 3D Printing of Molds | Allows for complex mold designs | Improves design flexibility and accuracy |

| Automation | Reduces labor costs and improves precision | Fully automated casting lines |

| Green Casting Practices | Reduces environmental impact | Use of recyclable materials, energy-efficient technologies |

These trends are expected to revolutionize the sand casting process, making it faster, more accurate, and more sustainable, while maintaining the high quality of 4130 alloy steel castings.

15. How Do You Choose the Right Foundry for 4130 Alloy Steel Sand Casting?

How do you select the right foundry for casting 4130 alloy steel? Choosing the right foundry for your 4130 alloy steel sand casting is essential to ensuring that the casting meets your requirements for quality, precision, and durability. Factors such as the foundry’s experience with 4130 alloy steel, the quality control measures in place, and the ability to meet your specific production needs all play a significant role in the decision.

Selecting the right foundry is crucial for ensuring that your 4130 alloy steel sand castings are produced efficiently and to the highest quality.

Factors to Consider When Choosing a Foundry

| Factor | Importance | Considerations |

|---|---|---|

| Foundry Experience | Ensures familiarity with 4130 alloy steel | Look for a foundry with proven experience in alloy steel casting |

| Quality Control | Ensures consistency and accuracy | Ask about their inspection methods and certifications |

| Production Capacity | Affects delivery times and flexibility | Ensure the foundry can handle the volume of castings you need |

| Technical Support | Provides ongoing assistance if issues arise | Choose a foundry with strong customer support and communication |

Conclusion

In conclusion, 4130 alloy steel sand casting offers a highly effective solution for industries seeking durable, high-quality metal components. With its favorable properties, versatility, and the ability to produce complex shapes at a low cost, 4130 alloy steel is an ideal choice for various manufacturing processes.

For businesses looking for a reliable material for casting, 4130 alloy steel provides an outstanding balance of performance and cost-effectiveness. Ensure that you choose the right materials and processes to achieve the best results for your next project.

FAQ Section

- Q1: What is 4130 alloy steel used for in sand casting?

4130 alloy steel is commonly used for manufacturing parts that require strength and toughness, such as aircraft components, automotive parts, and machinery. - Q2: How does sand casting work with 4130 alloy steel?

In sand casting, 4130 alloy steel is melted and poured into a sand mold to form desired shapes. The mold is then broken to remove the casting. - Q3: What are the key advantages of using 4130 alloy steel for sand casting?

4130 alloy steel offers high strength, good weldability, and resistance to wear, making it an excellent choice for applications in industries like aerospace and automotive. - Q4: What are common defects in 4130 alloy steel sand casting?

Common defects include shrinkage, porosity, and surface imperfections. Proper mold design and heat treatment can help reduce these issues. - Q5: How do heat treatment processes improve the quality of 4130 alloy steel castings?

Heat treatment processes like quenching and tempering enhance the strength, toughness, and ductility of 4130 alloy steel castings, making them suitable for demanding applications.