Introduction

In the ever-evolving world of construction machinery, the demand for high-quality, durable, and efficient parts is paramount. One of the materials that has gained significant traction in this industry is carbon steel, particularly when used in precision casting. This method, known as carbon steel precision casting, has revolutionized the way machinery parts are manufactured, offering numerous advantages in terms of strength, cost-effectiveness, and versatility.

Carbon steel precision casting involves a detailed and meticulous process that allows for the creation of complex parts with high accuracy and minimal waste. When applied to construction machinery parts, it ensures that the components are not only robust but also perfectly suited to withstand the rigorous demands of construction environments.

This article delves into the various benefits of using carbon steel precision casting for construction machinery parts, exploring why this method and material combination is ideal for the industry. Whether you’re a general manager, technician, or procurement officer, understanding these benefits can help you make informed decisions about your machinery investments, ensuring optimal performance and longevity.

Understanding Carbon Steel Precision Casting

Before diving into the benefits, it’s important to understand what carbon steel precision casting is and why it’s becoming the go-to choice for construction machinery parts.

What is Precision Casting?

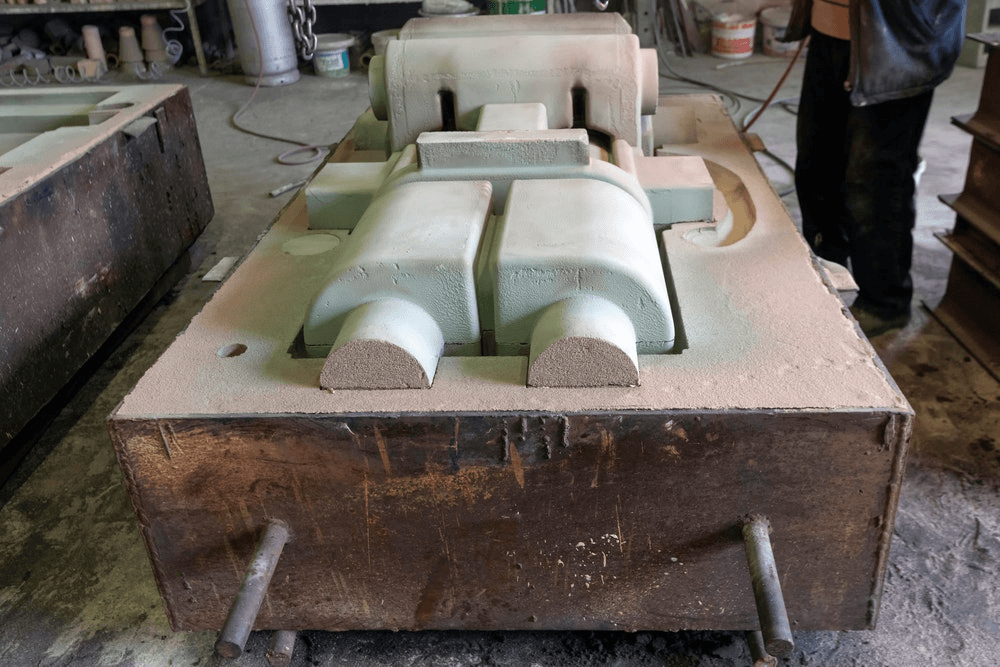

Precision casting, also known as investment casting or lost-wax casting, is a manufacturing process that creates intricate metal parts by pouring molten metal into a mold created from a wax model. The wax model is coated with a ceramic material, and once the ceramic hardens, the wax is melted away, leaving a hollow mold. Molten metal is then poured into this mold to create the final product. This process allows for high precision and the ability to cast complex shapes that would be difficult or impossible to achieve with other methods.

Compared to other casting methods such as sand casting or die casting, precision casting offers superior surface finish, dimensional accuracy, and material consistency. This makes it particularly advantageous for applications requiring tight tolerances and complex geometries, such as construction machinery parts.

Properties of Carbon Steel

Carbon steel is an alloy of iron and carbon, with the carbon content varying between 0.05% and 2.1% by weight. It is known for its strength, toughness, and wear resistance, making it a preferred material for heavy-duty applications. The different grades of carbon steel, such as low, medium, and high carbon steel, offer varying levels of hardness, ductility, and strength, allowing manufacturers to select the most suitable grade for specific applications.

In construction machinery, carbon steel is often chosen for parts that need to endure high stress, impact, and abrasion. Its ability to retain strength and integrity under extreme conditions makes it ideal for components like excavator arms, bulldozer blades, and crane booms, which are subject to intense use and wear.

Why Use Carbon Steel in Construction Machinery?

The use of carbon steel in construction machinery is driven by its exceptional mechanical properties and cost-effectiveness. For parts that must perform reliably under heavy loads and harsh conditions, carbon steel provides the necessary strength and durability without the high cost associated with other materials like stainless steel or titanium.

Moreover, carbon steel’s versatility allows for customization in terms of alloy composition and heat treatment, enabling manufacturers to tailor the material properties to specific needs. This flexibility is crucial in the construction industry, where different projects and machinery types may require unique specifications.

In summary, carbon steel precision casting offers a perfect combination of precision, strength, and affordability, making it an ideal choice for construction machinery parts. As we explore the various benefits of this method and material, it becomes clear why it is increasingly being adopted by manufacturers and operators in the construction industry worldwide.

The Benefits of Carbon Steel Precision Casting for Construction Machinery Parts

1. Strength and Durability

Carbon steel is renowned for its exceptional strength and durability, two properties that are critically important for construction machinery parts. Construction equipment, such as excavators, bulldozers, and cranes, operates in harsh environments and often under heavy loads. Parts made from carbon steel can withstand these challenging conditions without degrading or failing.

The strength of carbon steel comes from its carbon content, which increases the hardness and tensile strength of the alloy. This makes it highly resistant to deformation and wear, ensuring that the parts retain their shape and functionality even under continuous stress. For example, an excavator arm made from carbon steel precision casting can repeatedly lift heavy loads and dig through tough materials without bending or breaking.

Moreover, carbon steel’s durability extends the lifespan of construction machinery parts, reducing the frequency of replacements and repairs. This not only minimizes downtime but also lowers the long-term operational costs for machinery operators, making carbon steel a cost-effective choice for heavy-duty applications.

2. Cost-Effectiveness

One of the primary advantages of carbon steel precision casting is its cost-effectiveness. Carbon steel is generally less expensive than other metals such as stainless steel or titanium, which makes it a more affordable option for manufacturing construction machinery parts. Additionally, the precision casting process itself is economical because it minimizes material waste and reduces the need for extensive machining after casting.

The efficiency of the precision casting process lies in its ability to produce near-net-shape parts, meaning that the components come out of the mold very close to their final dimensions. This reduces the amount of material that needs to be removed during finishing processes, saving both time and money. For manufacturers, this translates into lower production costs, which can be passed on to customers in the form of competitive pricing.

Furthermore, the durability of carbon steel parts means that they last longer and require less maintenance compared to parts made from other materials. This longevity results in further cost savings for machinery operators, as they can avoid frequent replacements and repairs. Over the lifespan of a piece of construction equipment, these savings can be substantial, reinforcing the value proposition of carbon steel precision casting.

3. Versatility and Customization

Carbon steel precision casting offers remarkable versatility and customization options, allowing manufacturers to produce parts that meet specific requirements for various construction machinery applications. This flexibility is particularly important in the construction industry, where different machines and projects demand different types of components.

The precision casting process enables the creation of complex shapes and intricate designs that would be difficult or impossible to achieve with other manufacturing methods. This capability allows for the production of custom parts tailored to unique machinery specifications, enhancing performance and compatibility. For instance, carbon steel castings can be used to produce specialized components for cranes, excavators, and loaders, each with distinct design requirements.

Additionally, the properties of carbon steel can be adjusted through alloying and heat treatment to achieve the desired balance of hardness, ductility, and strength. This means that parts can be optimized for specific applications, such as wear resistance for excavator buckets or impact resistance for crane booms. The ability to customize both the material properties and the part design makes carbon steel precision casting a highly adaptable solution for construction machinery parts.

4. Wear Resistance

In construction machinery, parts are often subjected to abrasive conditions that can cause significant wear over time. Carbon steel’s inherent wear resistance makes it an ideal material for these applications, as it can withstand the constant friction and abrasion that occurs during operation.

The wear resistance of carbon steel is primarily due to its hardness, which is enhanced by the carbon content in the alloy. This hardness allows carbon steel parts to resist surface damage and maintain their structural integrity even in the most demanding environments. For example, bulldozer blades made from carbon steel can endure continuous contact with rough terrain and debris without deteriorating quickly.

Using wear-resistant materials like carbon steel not only extends the life of construction machinery parts but also improves the overall efficiency of the equipment. Parts that maintain their shape and functionality over time require less frequent maintenance and replacement, reducing downtime and operational costs. This makes carbon steel precision casting an excellent choice for parts that need to endure heavy use and harsh conditions.

5. Enhanced Machinability

Another significant benefit of carbon steel precision casting is its enhanced machinability. After casting, carbon steel parts are often subjected to additional machining processes, such as drilling, milling, and threading, to achieve the final specifications. Carbon steel’s favorable machinability makes these processes more efficient and cost-effective.

Machinability refers to the ease with which a material can be cut, shaped, and finished using various machining techniques. Carbon steel offers a good balance of hardness and ductility, which allows it to be machined without excessive tool wear or difficulty. This results in smoother finishes, tighter tolerances, and faster production times.

For construction machinery parts, this means that carbon steel castings can be quickly and accurately modified to meet precise specifications. This not only speeds up the manufacturing process but also ensures that the final parts are of the highest quality, with excellent dimensional accuracy and surface finish. Enhanced machinability also reduces the overall cost of production, making carbon steel precision casting an attractive option for manufacturers and machinery operators alike.

6. Corrosion Resistance

While carbon steel is not inherently as corrosion-resistant as stainless steel, certain grades and treatments can offer adequate protection against corrosion for many construction machinery applications. For example, adding elements like chromium or coating the parts with protective layers can enhance their resistance to rust and oxidation.

In environments where exposure to moisture, chemicals, or salt is a concern, using corrosion-resistant materials is crucial to prevent degradation and maintain the integrity of machinery parts. Carbon steel castings that have been treated for corrosion resistance can perform well in these conditions, providing a cost-effective alternative to more expensive alloys.

For construction machinery that operates outdoors or in challenging environments, corrosion-resistant carbon steel parts can offer a good balance of cost, performance, and durability. By selecting the appropriate grade and treatment, manufacturers can ensure that their components are protected against the elements, extending their lifespan and reliability.

7. Precision and Accuracy in Parts Manufacturing

Precision casting is highly valued for its ability to produce parts with exceptional accuracy and tight tolerances. This precision is particularly important for construction machinery parts, where even small deviations can impact performance and safety.

The precision casting process allows for the creation of parts that closely match the original design specifications, minimizing the need for extensive post-casting machining. This not only saves time and resources but also ensures that the final parts are dimensionally accurate and consistent.

For construction machinery, where precision is key to maintaining efficiency and safety, using carbon steel precision casting can lead to better-performing equipment with fewer issues related to part fit and function. Whether it’s a hydraulic cylinder, a gear, or a structural component, the ability to produce precise and accurate parts is essential for ensuring the reliability and performance of construction machinery.

8. Environmental and Sustainability Considerations

In today’s world, sustainability is a growing concern for many industries, including construction. Carbon steel precision casting offers several environmental benefits that make it an attractive option for manufacturers and operators looking to reduce their environmental footprint.

Firstly, the precision casting process generates less waste compared to other manufacturing methods. Because the parts are cast to near-net shape, there is minimal excess material that needs to be removed during finishing. This reduces material waste and lowers the overall environmental impact of the production process.

Secondly, carbon steel is highly recyclable, which aligns with sustainability goals. At the end of its life, carbon steel parts can be recycled and reused, reducing the need for virgin materials and minimizing waste. This recyclability makes carbon steel a more sustainable choice for construction machinery parts, contributing to a circular economy.

Lastly, the durability and longevity of carbon steel parts mean that they do not need to be replaced as frequently as parts made from less durable materials. This reduces the consumption of resources and energy associated with manufacturing new parts, further supporting sustainability efforts.

Key Applications of Carbon Steel Precision Casting in Construction Machinery

Carbon steel precision casting is used in a wide range of construction machinery applications due to its strength, durability, and versatility. Here are some of the key applications where carbon steel castings play a crucial role:

- Excavators and Loaders: Carbon steel castings are commonly used for parts such as buckets, arms, and linkage components. These parts need to withstand high levels of stress and impact, making carbon steel an ideal material choice.

- Cranes and Lifting Equipment: Load-bearing components and stability systems in cranes and lifting equipment are often made from carbon steel castings. The material’s strength and toughness are essential for ensuring the safety and reliability of these machines.

- Bulldozers and Graders: Bulldozer blades, ripper shanks, and undercarriage components are typically made from carbon steel due to its wear resistance and ability to withstand abrasive conditions.

- Concrete and Asphalt Equipment: Mixers, pumps, and compactors benefit from carbon steel castings because of their durability and resistance to wear and corrosion.

- Drilling and Piling Machines: Drill bits, augers, and other heavy-wear parts are often made from carbon steel to ensure they can handle the demanding conditions of drilling and piling operations.

Comparing Carbon Steel Precision Casting to Other Materials

When choosing materials for construction machinery parts, it’s important to consider the advantages and disadvantages of different options. Here’s a comparison of carbon steel with other common materials:

- Aluminum and Stainless Steel: While aluminum is lighter than carbon steel, it does not offer the same level of strength and durability, making it less suitable for heavy-duty applications. Stainless steel is more corrosion-resistant but is also more expensive and harder to machine than carbon steel.

- Cast Iron: Cast iron is strong and has good wear resistance, but it is brittle and prone to cracking under impact. Carbon steel offers better toughness and impact resistance, making it a more reliable choice for construction machinery parts.

- Composite Materials: Composites can provide excellent strength-to-weight ratios, but they are often more expensive and less durable than carbon steel. Additionally, composites may not be suitable for applications requiring high wear resistance or machinability.

Challenges and Considerations in Using Carbon Steel Precision Casting

While carbon steel precision casting offers many benefits, there are also some challenges and considerations to keep in mind:

- Potential Limitations of Carbon Steel: Carbon steel can become brittle at low temperatures and may not be suitable for applications where extreme cold is a concern. Additionally, welding and joining carbon steel can be challenging, requiring specialized techniques to ensure strong and reliable connections.

- Quality Control in the Casting Process: To avoid defects and ensure the quality of carbon steel castings, stringent quality control measures must be in place throughout the casting process. Common issues like porosity, shrinkage, and inclusions can impact the performance of the final parts, so careful monitoring and inspection are essential.

- Maintaining Precision in High-Volume Production: When producing large quantities of parts, maintaining consistency and precision can be challenging. Manufacturers must use advanced casting technologies and quality control systems to ensure that each part meets the required specifications.

Future Trends in Precision Casting for Construction Machinery

The field of precision casting is constantly evolving, with new technologies and materials being developed to improve the process and expand its applications. Here are some of the future trends in precision casting for construction machinery:

- Advancements in Casting Technologies: Innovations like 3D printed molds and automated casting processes are making precision casting more efficient and accurate. These advancements are helping manufacturers produce high-quality parts with reduced lead times and lower costs.

- Material Developments: New alloys and treatments are being developed to enhance the properties of carbon steel, making it even more suitable for construction machinery applications. For example, advances in heat treatment and alloying can improve the strength, toughness, and corrosion resistance of carbon steel castings.

- Sustainability Trends: As the construction industry becomes more focused on sustainability, there is a growing interest in eco-friendly casting practices and materials. This includes using recycled materials, reducing energy consumption, and minimizing waste in the casting process.

- Impact of Industry 4.0: The integration of IoT, AI, and machine learning in precision casting is improving process control, quality assurance, and predictive maintenance. These technologies are helping manufacturers optimize their operations and deliver better products to customers.

Conclusion

Carbon steel precision casting offers numerous benefits for construction machinery parts, including strength, durability, cost-effectiveness, and versatility. By understanding the advantages of this method and material, manufacturers and operators can make informed decisions that enhance the performance and longevity of their equipment. As the industry continues to evolve, the use of carbon steel precision casting is likely to grow, driven by advancements in technology, materials, and sustainability.

Frequently Asked Questions (FAQs)

What are the most common carbon steel grades used in construction machinery?\

The most common carbon steel grades used in construction machinery include low, medium, and high carbon steels, each offering different levels of strength, hardness, and ductility to suit various applications.

How does precision casting improve the performance of machinery parts?\

Precision casting allows for the creation of parts with tight tolerances and complex geometries, ensuring accurate fit and function. This precision enhances the performance and reliability of machinery parts.

Can carbon steel precision castings be customized for specific applications?\

Yes, carbon steel precision castings can be customized in terms of design, shape, and material properties to meet the specific needs of different construction machinery applications.

What are the environmental benefits of using carbon steel over other materials?\

Carbon steel is highly recyclable and generates less waste during the casting process, making it a more sustainable choice for construction machinery parts.

How does the cost of carbon steel precision casting compare to other methods?\

Carbon steel precision casting is generally more cost-effective than other methods, such as stainless steel or titanium casting, due to lower material costs and reduced machining requirements.