Stainless steel investment casting is a method that many industries use for producing precision components. But why should you choose this process over others? This article will guide you through the intricacies of stainless steel investment casting and explain why it’s one of the top choices for high-performance, complex parts.

Stainless steel investment casting is an efficient way to create durable and precise parts. But how does it compare to traditional methods? We’ll answer this and more throughout this article.

If you’re considering stainless steel investment casting for your projects, you’re in the right place. The following sections will explain the process, its advantages, the materials used, and much more. Let’s dive in!

1. What is Stainless Steel Investment Casting?

Investment casting, also known as lost-wax casting, is a process used to create high-precision parts from stainless steel. But how does it work, and why should manufacturers consider it for their parts? Let’s explore the basics.

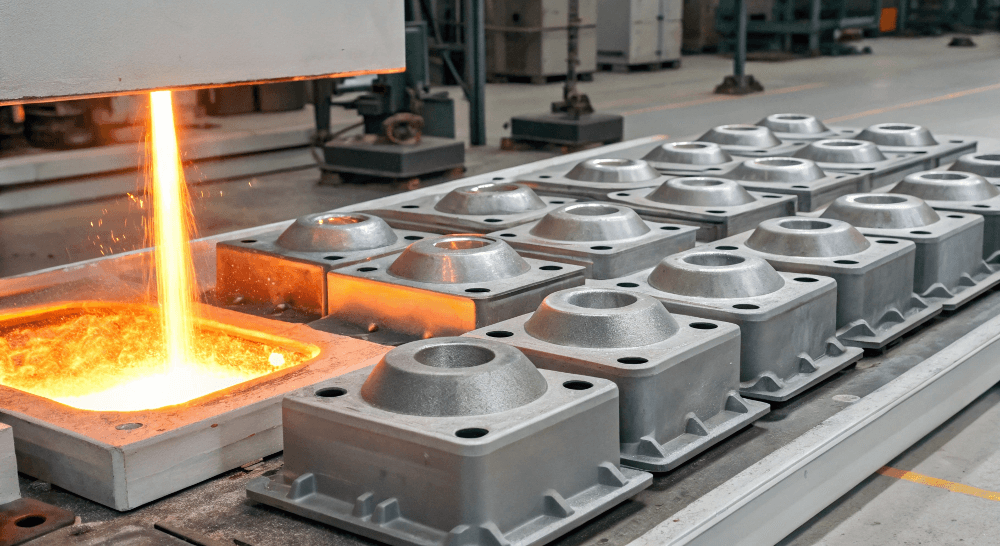

Investment casting works by using a mold created from a pattern of the desired part. This pattern is typically made of wax and is covered with a ceramic shell. After the wax is melted away, molten stainless steel is poured into the mold to create the final product.

In addition to being highly precise, stainless steel investment casting allows for complex shapes to be created, making it a go-to method for industries needing intricate parts. It’s perfect for components that demand high strength, durability, and resistance to corrosion.

Key Steps in Stainless Steel Investment Casting:

| Step | Description |

|---|---|

| Pattern Creation | Wax patterns are made using injection molding. |

| Shell Building | The pattern is coated with a ceramic shell. |

| Wax Removal | The mold is heated to melt and drain the wax. |

| Metal Pouring | Molten stainless steel is poured into the mold. |

| Finishing | The mold is removed, and parts are finished. |

2. Why Choose Stainless Steel Investment Casting?

Are you wondering why stainless steel investment casting is the preferred choice for manufacturers? This method offers numerous benefits, especially when compared to other casting processes. Here’s why it should be your top choice.

Stainless steel investment casting offers unmatched precision, allowing for the creation of parts with detailed features and smooth surfaces. Additionally, it’s an efficient process for low to medium-volume production, which reduces costs while maintaining product integrity.

What Makes Stainless Steel Investment Casting Stand Out?

| Feature | Advantage | Application Example |

|---|---|---|

| Precision | High accuracy, detailed features | Aerospace, medical devices |

| Cost Efficiency | Reduces need for post-production machining | Low to medium-volume runs |

| Material Flexibility | Custom alloys for specific needs | Automotive, industrial parts |

3. What are the Key Materials in Stainless Steel Investment Casting?

The material you choose for investment casting plays a huge role in the final product’s performance. But which types of stainless steel are typically used in this process? Let’s break it down.

There are several stainless steel alloys used in investment casting, each selected based on the part’s required properties. These alloys are known for their strength, corrosion resistance, and ability to withstand high temperatures.

Types of Stainless Steel Alloys:

| Alloy Type | Key Characteristics | Common Applications |

|---|---|---|

| 304 | Corrosion resistance, good weldability | Food processing, chemical equipment |

| 316 | High corrosion resistance to chlorides | Marine, pharmaceutical equipment |

| 17-4 PH | High strength, good hardness | Aerospace, industrial equipment |

4. How Does the Stainless Steel Investment Casting Process Work?

The stainless steel investment casting process is intricate, involving several key steps. But how does it all come together? Let’s take a closer look at each stage.

The process begins with creating a wax pattern, followed by coating it with a ceramic shell. After the wax is removed, molten stainless steel is poured into the mold to form the final part. The process is completed with finishing steps such as machining or surface polishing.

Breakdown of the Stainless Steel Investment Casting Process:

| Process Step | Description | Tools/Equipment Used |

|---|---|---|

| Pattern Creation | Wax pattern is formed using injection molding. | Pattern injection machine |

| Shell Building | Ceramic shell is created around the pattern. | Shell building machine |

| Wax Removal | Mold is heated to remove the wax. | Furnace |

| Metal Pouring | Molten stainless steel fills the mold. | Pouring machine |

| Finishing | Parts are machined and polished as needed. | CNC machines, polishing tools |

5. What Equipment is Used in Stainless Steel Investment Casting?

High-quality investment casting requires precision equipment. But what tools and machines are involved in the process? Let’s explore.

From pattern production to the final casting, investment casting equipment plays a pivotal role in ensuring product quality. Specialized machinery helps maintain consistency and accuracy at every stage of the process.

Common Equipment Used:

| Equipment | Purpose |

|---|---|

| Pattern Injection Machine | Creates precise wax patterns for molding |

| Shell Building Machine | Coats the wax patterns with a ceramic shell |

| Furnace | Melts the wax and heats the mold |

| Pouring Machine | Pours molten metal into the mold |

6. How Does the Quality Control Process Affect Stainless Steel Investment Casting?

Quality control is an essential part of any manufacturing process. But what role does it play in stainless steel investment casting? Let’s examine the key factors involved.

Investment casting can produce parts with exceptional precision. However, to ensure the highest quality, strict quality control measures are in place throughout the process. These checks are crucial to detecting any defects before they become problematic.

Key Quality Control Steps:

| Quality Check | Purpose | Method |

|---|---|---|

| Pattern Inspection | Ensure the wax patterns are defect-free | Visual inspection, measurement |

| Shell Thickness Measurement | Ensure mold integrity | Micrometers, ultrasound |

| Post-Casting Inspection | Detect internal defects | X-ray, ultrasonic testing |

7. What Are the Challenges in Stainless Steel Investment Casting?

Despite the numerous benefits of stainless steel investment casting, it’s not without its challenges. So, what are some of the obstacles manufacturers face when utilizing this process?

Stainless steel investment casting requires attention to detail and expertise, but there are challenges to overcome. Issues such as casting distortion, the difficulty in handling complex shapes, and the energy demands of the process can complicate production.

Key Challenges in Stainless Steel Investment Casting:

| Challenge | Cause | Impact on Production |

|---|---|---|

| Shrinkage and Distortion | Metal cooling rates, mold design | Can lead to dimensional errors and rework |

| Complexity of Design | Intricate patterns or thin walls | Can increase production time and cost |

| High Energy Consumption | Required for melting and maintaining high temperatures | Increases operational costs |

8. How Can You Reduce Costs in Stainless Steel Investment Casting?

Cost reduction is crucial for staying competitive, but how can manufacturers minimize expenses while maintaining quality in stainless steel investment casting?

Reducing costs in investment casting involves optimizing the process, choosing the right materials, and utilizing automation where possible. This not only helps save on production costs but also improves efficiency.

Ways to Reduce Costs:

| Method | How It Helps |

|---|---|

| Optimizing Pattern Design | Reduces material waste and improves yield |

| Using Automation | Speeds up the process, lowers labor costs, and reduces human error |

| Material Selection | Choosing alloys that balance cost and performance can lower overall expenses |

9. What Are the Best Applications for Stainless Steel Investment Casting?

Are you wondering where stainless steel investment casting is used the most? This method is highly versatile, and here are the industries where it has the most significant impact.

Stainless steel investment casting is essential for industries that require durable, high-performance parts. It is used extensively in aerospace, automotive, medical, and defense sectors for creating precision parts that demand strength and resistance to extreme conditions.

Key Applications:

| Industry | Applications | Why Investment Casting Works Well |

|---|---|---|

| Aerospace | Engine components, structural parts | High precision and weight reduction |

| Automotive | Exhaust components, brackets, engine parts | Durability and strength under stress |

| Medical | Surgical instruments, implants | Sterility and corrosion resistance |

| Defense | Military equipment, structural parts | High strength and resistance to wear |

10. How Do Environmental Regulations Impact Stainless Steel Investment Casting?

Environmental regulations play a significant role in manufacturing, and investment casting is no exception. But how do these rules affect the process?

Manufacturers must comply with increasingly stringent environmental regulations regarding waste disposal, energy consumption, and emissions. By adopting green practices, the investment casting process can reduce its environmental footprint.

Environmental Considerations in Investment Casting:

| Regulation | Impact on Manufacturing | Solution |

|---|---|---|

| Emissions Standards | Limits on air pollution during metal pouring | Use of cleaner burning fuels and advanced filtration systems |

| Energy Efficiency | High energy consumption during heating and melting | Implement energy-efficient furnaces and recycling systems |

| Waste Management | Handling waste materials like wax and ceramic shell | Recycling of materials and better waste segregation practices |

11. What Are the Future Trends in Stainless Steel Investment Casting?

With advancements in technology and increasing demand for complex parts, the future of stainless steel investment casting looks promising. So, what does the future hold?

Technological innovations, such as the integration of 3D printing and advanced automation, are revolutionizing stainless steel investment casting. These developments aim to improve speed, reduce costs, and enhance the quality of the final products.

Future Trends in Stainless Steel Investment Casting:

| Trend | Description | Potential Benefits |

|---|---|---|

| 3D Printing Integration | Using 3D printing to create wax patterns | Allows for more complex designs with fewer limitations |

| Increased Automation | Automation in molding, pouring, and finishing | Faster production and reduced labor costs |

| Sustainable Practices | Adoption of green casting techniques | Reduced energy consumption and waste |

12. How Can You Ensure the Best Quality in Stainless Steel Investment Casting?

Ensuring the highest quality in stainless steel investment casting requires attention to detail at every step. But how can manufacturers maintain consistently high-quality outputs?

Quality in investment casting is maintained through a combination of precision in the initial stages, careful monitoring during production, and thorough inspections post-casting. A rigorous quality control system ensures that each part meets the required specifications.

Key Quality Control Best Practices:

| Practice | Description | Benefits |

|---|---|---|

| Design for Manufacturability | Ensuring the design is optimized for casting | Reduces defects and material wastage |

| Skilled Labor | Using highly trained personnel at every stage | Improved precision and fewer errors |

| Post-Casting Inspection | Using X-ray, ultrasonic tests, and visual checks | Identifies internal defects and surface issues |

13. What Are the Advantages of Stainless Steel Investment Casting for Complex Designs?

Can stainless steel investment casting handle complex designs? Absolutely. This method is ideal for creating intricate shapes and details. So, why is it so effective for complex designs?

Stainless steel investment casting provides excellent dimensional accuracy and the ability to create complex, thin-walled, and detailed parts. The process eliminates the need for additional machining, which reduces costs and time.

How Investment Casting Handles Complex Designs:

| Design Complexity | Advantage | Example Application |

|---|---|---|

| Intricate Geometries | Complex shapes can be formed without the need for additional machining | Aerospace brackets, turbine parts |

| Thin Walls and Small Parts | Precision allows for thin walls and small, detailed features | Medical devices, precision instruments |

| Detailed Surfaces | Smooth finishes and intricate surface details | Jewelry, fine mechanical components |

14. How Can Stainless Steel Investment Casting Benefit Your Manufacturing Business?

Is stainless steel investment casting the right choice for your business? It can be, especially if your operations involve high-volume, complex parts that need to meet strict performance requirements.

Stainless steel investment casting helps businesses improve production efficiency, reduce costs, and enhance the quality of their products. The ability to produce complex parts without excessive post-processing is a major advantage.

Benefits to Your Business:

| Benefit | Impact | Long-Term Gains |

|---|---|---|

| Reduced Post-Processing | Less need for additional machining | Lower operational costs and time savings |

| Improved Design Flexibility | Ability to create intricate parts | Offers competitive advantages in design |

| Lower Labor Costs | Automation reduces manual labor | Increased overall production efficiency |

15. What Are the Common Myths About Stainless Steel Investment Casting?

There are several misconceptions about stainless steel investment casting that can cause confusion. What are these myths, and what’s the truth behind them?

Many people believe investment casting is too costly or complicated, but this isn’t always the case. With proper planning and understanding, it can be a cost-effective solution for complex parts. Let’s debunk some of the most common myths.

Common Myths in Stainless Steel Investment Casting:

| Myth | Reality | Explanation |

|---|---|---|

| It’s too expensive | Investment casting can be cost-effective | Reduces the need for additional machining and labor |

| It’s only for simple parts | It’s ideal for complex, detailed designs | Investment casting excels at creating intricate shapes |

| Quality control is hard to manage | With proper techniques, quality control is easy | Rigorous inspections and skilled labor ensure high-quality output |

Conclusion

Stainless steel investment casting is a powerful method for producing high-precision parts. With its ability to create complex shapes with great accuracy, it remains one of the most popular manufacturing processes across multiple industries. By understanding the process, material choices, and benefits, you’ll be able to decide whether investment casting is the right choice for your next project.

FAQ

- Q1: What is stainless steel investment casting?

Stainless steel investment casting is a process that uses a wax pattern, covered in a ceramic shell, to create precise metal parts. Molten stainless steel is poured into the mold to form the part. - Q2: How does the stainless steel investment casting process work?

The process involves several stages: pattern creation, shell building, wax removal, metal pouring, and finishing. - Q3: What materials are used in stainless steel investment casting?

Common materials include alloys like 304, 316, and 17-4 PH, chosen based on factors like strength and corrosion resistance. - Q4: How do I choose the right supplier for stainless steel investment casting?

Look for suppliers with strong experience in precision casting and a commitment to quality control. Certifications like ISO can also help ensure reliability. - Q5: Can stainless steel investment casting be used for complex designs?

Yes, investment casting is ideal for producing intricate and complex designs with high accuracy, reducing the need for post-production machining.