Stainless steel casting is a vital part of many industries, yet understanding its nuances can be daunting. Are you looking to discover more about this versatile process? In this guide, I’ll walk you through everything you need to know about stainless steel casting.

Stainless steel casting is a critical process for creating high-quality, durable parts that meet demanding specifications. From industrial equipment to everyday products, its applications are vast and essential. This article will answer your questions about the process, materials, and best practices, helping you make informed decisions for your business.

Steel casting is one of the most reliable manufacturing techniques, but it’s often misunderstood or overlooked in favor of simpler processes. However, mastering this method is key to improving both your product quality and production efficiency. Keep reading to explore how stainless steel casting can benefit your operations and set you ahead of the competition.

1. What is Stainless Steel Casting?

Stainless steel casting is essential to industries that require precision and durability in their parts. From automotive parts to medical devices, casting stainless steel offers unique advantages that help businesses create high-performance products. But how exactly does this process work?

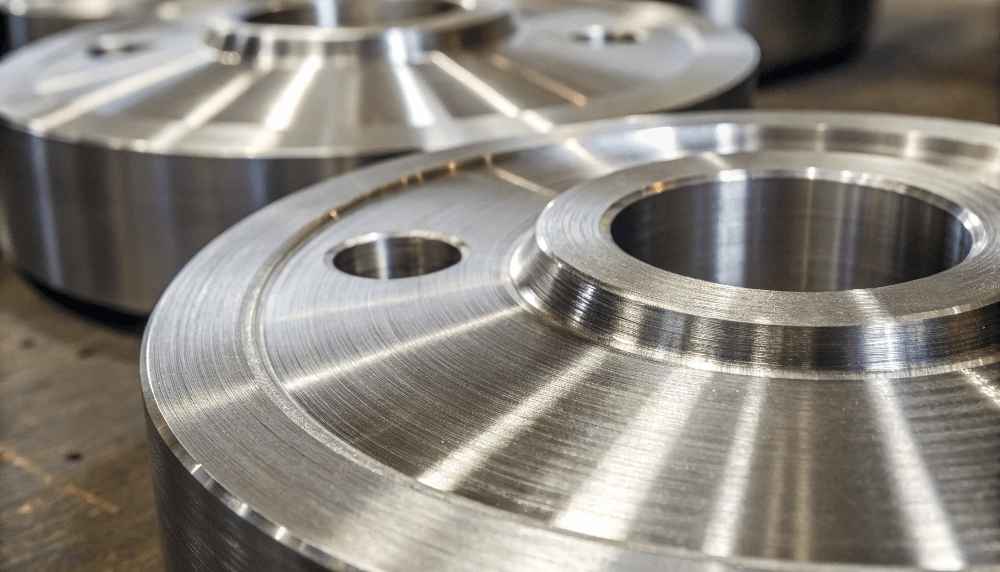

Stainless steel casting is the process of creating complex metal parts by pouring molten stainless steel into molds. This method allows for high precision and exceptional durability, making it ideal for parts that will face extreme conditions, like high pressure, high temperatures, or corrosive environments.

This process begins by melting stainless steel and pouring it into a mold that defines the shape of the final product. The molten steel cools and solidifies, taking on the form of the mold. Once cooled, the part is removed, and any excess material is cleaned up to reveal the finished casting.

Stainless steel castings are commonly used in industries that require high-strength, corrosion-resistant parts, including aerospace, automotive, and medical sectors. The precision offered by stainless steel casting enables manufacturers to create intricate, high-quality components that would be difficult or impossible to produce with other manufacturing techniques.

How is Stainless Steel Cast?

Stainless steel casting involves multiple steps:

- Pattern Making: A model is created to form the shape of the object being cast.

- Mold Making: The pattern is surrounded by a mold material that can withstand the heat of the molten steel.

- Melting and Pouring: Stainless steel is melted and poured into the mold.

- Cooling and Solidifying: The metal is left to cool and solidify into the final shape.

- Cleaning: The cast part is cleaned to remove any excess material or imperfections.

What Are the Key Benefits of Stainless Steel Casting?

Stainless steel casting has several advantages that make it a go-to method for manufacturers. One of the most notable benefits is its exceptional corrosion resistance, making it suitable for high-durability applications. Additionally, stainless steel castings can be made into complex shapes with high precision, which is essential for industries like aerospace and automotive.

2. Why is Stainless Steel Casting Important?

The importance of stainless steel casting goes beyond just its ability to create complex shapes. It also provides several practical benefits that can drastically improve the quality and efficiency of production. But why should businesses consider it?

Stainless steel casting is crucial for producing parts that need to withstand extreme conditions. It offers reliability and precision that other methods, like machining or forging, may struggle to provide. Its versatility in material selection and application makes it a valuable asset for industries that require high-quality, durable parts.

It’s particularly important in industries such as aerospace, automotive, and medical, where precision and durability are paramount. The casting process ensures that parts meet the highest standards for quality and performance.

The Role of Precision in Stainless Steel Casting

One of the defining features of stainless steel casting is its ability to create highly precise parts. When dealing with critical machinery and devices, small defects can lead to significant failures. The precision offered by stainless steel casting minimizes these risks and ensures that parts fit together correctly, reducing the chance of defects during operation.

Why Does Precision Matter in Stainless Steel Casting?

| Key Benefit | Why It Matters |

|---|---|

| Precision | Reduces defects, ensures proper fit, and maximizes product longevity. |

| Durability | Stainless steel is highly resistant to corrosion, ideal for harsh environments. |

| Complexity | Stainless steel casting can create intricate designs with high tolerance. |

In comparison to other casting methods, stainless steel offers exceptional reliability and accuracy, which are necessary for meeting the stringent requirements of industries like healthcare and aerospace.

3. How Does the Stainless Steel Casting Process Work?

The process of casting stainless steel is complex and involves various stages that need to be managed carefully for optimal results. How can you ensure that each step is performed correctly?

The stainless steel casting process is a precise and methodical operation. It involves several stages from pattern making to cleaning, each requiring meticulous attention to detail to ensure the best possible outcome.

Let’s dive into the details of each stage involved in stainless steel casting:

Pattern Making: Creating the Template

Pattern making is the first step in the process and involves creating a template of the part you wish to cast. This pattern is typically made from a material that can withstand the heat and pressure of molten metal.

Mold Making: Forming the Shape

Once the pattern is made, the next step is to create a mold around it. The mold must be able to endure high temperatures and pressure. The material used for the mold is often a mixture of sand and binder, which solidifies to hold the shape.

Melting and Pouring: Getting the Steel into Shape

The stainless steel is then melted in a furnace, reaching temperatures of up to 2,600°F (1,426°C). Once the steel is molten, it is poured into the mold to form the desired shape. The mold must be sturdy enough to hold the molten metal without cracking or deforming.

| Stage of Process | Material Used | Key Requirement |

|---|---|---|

| Pattern Making | Heat-resistant material | Accurate representation of the final product shape |

| Mold Making | Sand, binders | High-temperature resistance |

| Melting and Pouring | Stainless Steel | Consistent pouring into mold |

4. What Types of Stainless Steel Castings Exist?

Stainless steel casting offers different methods to produce the desired parts. Each method has its own benefits and ideal applications. But what are the most common types of stainless steel castings?

Stainless steel castings are divided into various types depending on the technique and material used. The most common types are investment casting, sand casting, permanent mold casting, and die casting. Each has its own strengths and is suitable for different applications, depending on the part’s complexity and required properties.

What Are the Different Types of Stainless Steel Castings?

- Investment Casting:

Investment casting, also known as precision casting, is used for creating complex parts with intricate details. The process involves creating a wax model that is coated with a ceramic shell, then heated to remove the wax and cast molten metal into the mold. This method provides high precision and is ideal for parts like turbine blades or medical instruments. - Sand Casting:

Sand casting is one of the most commonly used methods. It involves creating a mold from a mixture of sand and binder. This casting method is excellent for large parts that do not require the same level of precision as investment casting. Sand casting is widely used in the automotive and construction industries. - Permanent Mold Casting:

In permanent mold casting, a metal mold is used multiple times to create the desired part. This method is ideal for mass production of parts that are similar in shape and require good surface finish and dimensional accuracy. - Die Casting:

Die casting uses high pressure to force molten stainless steel into molds. This process is often used for high-volume production of small parts with complex shapes. Die casting is typically employed in the automotive and electronics industries.

| Type of Casting | Best For | Advantages |

|---|---|---|

| Investment Casting | Complex, intricate parts | High precision, fine details |

| Sand Casting | Large parts, less precision required | Low cost, versatility |

| Permanent Mold Casting | Mass production of parts | Consistent quality, reusable molds |

| Die Casting | Small, intricate parts | High volume, fine details |

5. What Are the Key Benefits of Stainless Steel Casting?

Stainless steel casting is used for many reasons, but what makes it so popular in various industries?

Stainless steel casting offers several key benefits, including corrosion resistance, high mechanical properties, and design flexibility. These advantages make it an attractive option for industries that require durable and reliable parts.

One of the primary benefits of stainless steel casting is its corrosion resistance, which ensures parts can withstand exposure to harsh chemicals and environments without deteriorating. This makes stainless steel ideal for industries like healthcare, where parts need to stay sterile, or aerospace, where parts are exposed to extreme weather conditions.

What Makes Stainless Steel Castings Durable?

Stainless steel is inherently resistant to corrosion and oxidation, and its durability is one of the reasons why it’s so highly sought after in industries requiring high-performance components. Stainless steel castings also exhibit excellent mechanical properties, such as:

- Tensile strength: Stainless steel casting provides high tensile strength, which is essential for parts that must endure stress and pressure.

- Impact resistance: Stainless steel castings are resistant to damage from impact, making them ideal for heavy-duty applications.

- Heat resistance: Stainless steel performs well under extreme temperatures, which is why it’s widely used in industries like aerospace and automotive.

| Property | Stainless Steel Castings |

|---|---|

| Corrosion Resistance | High resistance to rust and oxidation |

| Tensile Strength | Strong ability to resist pulling forces |

| Impact Resistance | Resistant to breakage under stress |

| Heat Resistance | Performs well in extreme temperatures |

6. How Do You Choose the Right Stainless Steel for Casting?

Choosing the right type of stainless steel for casting is critical. With so many grades and types available, how can you determine which one is best for your application?

Choosing the right stainless steel grade for casting depends on factors like corrosion resistance, mechanical strength, and environmental conditions. Understanding the properties of various grades will help you select the one that fits your specific needs.

There are different types of stainless steel, each with distinct properties that make them suitable for different applications. The most commonly used grades for casting include:

- 304 Stainless Steel:

304 stainless steel is the most common and versatile grade used in stainless steel casting. It is highly resistant to corrosion, which makes it suitable for food processing, pharmaceuticals, and chemical industries. - 316 Stainless Steel:

Known for its superior corrosion resistance, 316 stainless steel is ideal for harsh environments such as marine or coastal areas. It also offers excellent resistance to pitting and crevice corrosion. - 17-4 PH Stainless Steel:

This is a precipitation-hardening stainless steel that offers a high strength-to-weight ratio, making it suitable for high-performance applications in the aerospace, nuclear, and chemical industries.

How to Choose the Right Stainless Steel for Your Project?

| Stainless Steel Grade | Ideal For | Advantages |

|---|---|---|

| 304 Stainless Steel | General use, food processing | Corrosion resistant, easy to form |

| 316 Stainless Steel | Marine environments, chemical industries | Superior corrosion resistance |

| 17-4 PH Stainless Steel | Aerospace, nuclear | High strength, high performance |

7. What Equipment is Needed for Stainless Steel Casting?

To effectively carry out stainless steel casting, certain equipment is necessary. But what tools and machinery should be in place to make the process work efficiently?

Stainless steel casting requires specialized equipment that ensures the process is carried out with precision and safety. From melting furnaces to molds, having the right tools is crucial for success.

Key equipment involved in the stainless steel casting process includes:

- Melting Furnaces: These are used to melt the stainless steel at extremely high temperatures. Common types include electric arc furnaces and induction furnaces.

- Molds: High-quality molds made from materials that can withstand the molten metal’s heat are essential. These molds are usually made from sand or metal.

- Casting Machines: Depending on the method, casting machines may be required for processes like die casting or permanent mold casting. These machines help in filling the molds with molten stainless steel under pressure.

Essential Equipment for Stainless Steel Casting

| Equipment | Purpose |

|---|---|

| Melting Furnace | Melts stainless steel to a liquid state |

| Molds | Shapes the molten steel into the desired product |

| Casting Machine | Helps in filling molds under pressure |

8. What are the Challenges of Stainless Steel Casting?

While stainless steel casting is an excellent method for producing high-quality parts, it does come with some challenges. So, what are the obstacles manufacturers face, and how can they be addressed?

Stainless steel casting can present a few challenges, such as defects in the casting process, delays in production, and cost overruns. Understanding these challenges and knowing how to mitigate them is essential for successful casting.

Some common issues encountered in stainless steel casting include:

- Porosity:

This occurs when gas bubbles get trapped inside the molten metal during the casting process, leaving holes or voids in the final product. These voids can affect the integrity of the part and must be minimized through proper ventilation and controlled casting conditions. - Cracks:

Cracks can occur due to the rapid cooling of the molten metal or stress during cooling. Proper mold design and control of cooling rates can help reduce the risk of cracking. - Inconsistent Quality:

Variations in the quality of stainless steel or inconsistent casting methods can result in parts that do not meet specifications. Using high-quality materials and standardizing processes can reduce this issue.

Common Challenges in Stainless Steel Casting

| Challenge | Cause | Solution |

|---|---|---|

| Porosity | Trapped gas bubbles | Ensure proper mold ventilation |

| Cracks | Rapid cooling or stress during cooling | Control cooling rate, improve mold design |

| Inconsistent Quality | Variations in material or methods | Standardize processes, use high-quality materials |

9. What Industries Use Stainless Steel Castings?

Stainless steel castings are employed in various industries, each benefiting from the material’s durability, corrosion resistance, and strength. But which industries rely heavily on this versatile process?

Stainless steel castings play a critical role in industries that require high performance and durability. From aerospace to healthcare, the versatility of stainless steel ensures that it meets the diverse needs of manufacturers.

Key Industries Using Stainless Steel Castings

- Aerospace:

Aerospace components require precise, durable, and heat-resistant materials. Stainless steel castings are used for turbine blades, engine parts, and structural components that must withstand extreme conditions. - Automotive:

In the automotive industry, stainless steel castings are used for engine parts, exhaust systems, and other components that require strength and resistance to heat and wear. - Medical Devices:

Stainless steel is commonly used in medical devices such as surgical instruments, implants, and diagnostic equipment due to its biocompatibility and resistance to corrosion. - Construction and Architecture:

Stainless steel castings are often used in structural components, architectural elements, and facades due to their corrosion resistance and aesthetic appeal.

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, engine parts, structural components |

| Automotive | Engine components, exhaust systems, frame parts |

| Medical Devices | Surgical tools, implants, diagnostic instruments |

| Construction | Structural elements, facades, architectural features |

10. How Do You Maintain Stainless Steel Castings?

Maintaining stainless steel castings is essential for ensuring their longevity and performance. But how can you keep your stainless steel castings in top condition?

Proper maintenance of stainless steel castings ensures that they continue to function effectively, minimizing the risk of damage and extending their lifespan. Regular care and attention are necessary for parts exposed to harsh environments or frequent use.

Key Tips for Maintaining Stainless Steel Castings

- Regular Cleaning:

Clean stainless steel castings regularly to prevent the buildup of dirt, dust, and corrosive substances. Use mild detergents or specific stainless steel cleaners to avoid damaging the surface. - Prevent Rust and Corrosion:

Stainless steel is resistant to rust, but it’s not completely immune. In harsh environments, you should apply protective coatings or oils to prevent corrosion from saltwater or chemicals. - Proper Handling:

When transporting or installing stainless steel castings, ensure they are handled carefully to avoid dents or scratches that could lead to long-term damage. - Routine Inspections:

Regularly inspect the castings for any signs of wear or damage. Early detection of issues such as cracks or stress marks can prevent costly repairs or part failure.

| Maintenance Tip | Best Practice |

|---|---|

| Regular Cleaning | Use mild detergents or stainless steel cleaners |

| Prevent Rust | Apply protective coatings in harsh environments |

| Proper Handling | Handle carefully to avoid physical damage |

| Routine Inspections | Check for cracks, wear, and stress marks |

11. What is the Cost of Stainless Steel Casting?

The cost of stainless steel casting is influenced by a variety of factors. But how can you manage costs effectively without sacrificing quality?

The cost of stainless steel casting depends on several elements, including the type of casting method, the complexity of the part, and the quantity required. Understanding these factors will help businesses manage expenses while ensuring high-quality results.

Key Factors That Affect the Cost of Stainless Steel Casting

- Casting Method:

Different casting methods come with varying costs. For instance, investment casting is more expensive than sand casting due to the higher precision and more complex process. - Material Selection:

The grade of stainless steel chosen for casting can also affect the cost. High-end grades, such as 316 or 17-4 PH stainless steel, are more expensive than standard grades like 304. - Complexity of the Part:

Parts with intricate designs or tight tolerances require more time and labor to cast, which can drive up costs. - Quantity:

High-volume production runs often result in lower costs per unit, as the setup costs are spread across many parts. Small, custom orders may incur higher unit costs.

| Cost Factor | Influence on Price |

|---|---|

| Casting Method | Investment casting is more expensive than sand casting |

| Material Selection | Higher-grade stainless steel increases cost |

| Complexity of Part | Complex designs and high tolerances increase labor |

| Quantity | Larger production runs reduce cost per part |

12. How to Improve the Efficiency of Stainless Steel Casting?

Increasing the efficiency of stainless steel casting can help businesses reduce costs and improve turnaround times. But what steps can be taken to improve efficiency?

Improving the efficiency of stainless steel casting involves optimizing each step of the process, from pattern making to finishing. By making the process faster and more accurate, businesses can save time and money while maintaining high-quality results.

Key Strategies for Improving Efficiency in Stainless Steel Casting

- Invest in Automation:

Automated processes, such as robotic arms for pouring or handling, can speed up production and reduce human error. - Optimize Mold Design:

Streamlining the mold design to ensure that it fills efficiently with molten metal can reduce wasted time and material. The use of advanced mold materials can also help improve cycle times. - Use High-Quality Materials:

High-quality stainless steel reduces the likelihood of defects, meaning less time spent on repairs or rework. - Standardize Processes:

Implementing standardized procedures for each step of the casting process ensures consistency and reduces the chances of errors or delays.

| Strategy | Benefit |

|---|---|

| Automation | Reduces labor time and human error |

| Optimized Mold Design | Increases efficiency and reduces material waste |

| High-Quality Materials | Reduces defects and rework |

| Standardization | Ensures consistency and quality control |

13. What is the Future of Stainless Steel Casting?

Stainless steel casting is a time-tested manufacturing process, but how is it evolving to meet the needs of modern industries?

The future of stainless steel casting looks promising, with innovations in technology, materials, and processes driving improvements. As industries demand higher quality and precision, casting techniques are adapting to meet these challenges.

Emerging Trends in Stainless Steel Casting

- 3D Printing:

Additive manufacturing, or 3D printing, is being integrated with traditional casting methods. This combination allows for the rapid prototyping of complex parts and significantly reduces production times. - Sustainable Practices:

As sustainability becomes more important, the casting industry is exploring ways to minimize waste, reduce energy consumption, and recycle materials. - Automation and AI:

The introduction of AI and machine learning into casting processes is improving precision, reducing errors, and increasing the overall efficiency of production.

| Trend | Impact on Stainless Steel Casting |

|---|---|

| 3D Printing | Reduces production times, allows for complex designs |

| Sustainability | Minimizes waste, reduces environmental impact |

| Automation and AI | Improves precision, reduces errors, increases efficiency |

14. How Can I Find a Reliable Stainless Steel Casting Supplier?

Finding the right supplier is crucial to ensuring the success of your stainless steel casting project. But how can you choose a reliable and competent supplier?

Choosing a reliable stainless steel casting supplier requires careful research and understanding of their capabilities. A good supplier can ensure that your parts meet specifications, are produced on time, and delivered within budget.

What to Look for in a Stainless Steel Casting Supplier?

- Experience and Expertise:

Look for suppliers with a proven track record in stainless steel casting. Their expertise will ensure that they can handle your specific requirements. - Quality Control Systems:

A reliable supplier will have robust quality control systems in place to guarantee that each part meets industry standards and your specifications. - Capacity to Handle Orders:

Make sure the supplier can handle the scale of your order, whether you need small custom orders or large production runs.

| Criteria | What to Look for |

|---|---|

| Experience | Proven track record in stainless steel casting |

| Quality Control | Strong systems for ensuring high-quality products |

| Order Capacity | Ability to handle both small and large orders |

15. How Do Stainless Steel Castings Compare to Other Materials?

Stainless steel castings offer many advantages, but how do they compare to other materials like aluminum or carbon steel?

Stainless steel castings have distinct advantages over other materials, particularly when it comes to strength, corrosion resistance, and performance in extreme conditions. However, each material has its own strengths and is suited for different applications.

Stainless Steel vs. Other Materials

- Aluminum Casting:

Aluminum is lighter and more affordable, but it doesn’t offer the same level of strength or corrosion resistance as stainless steel. It’s ideal for parts that don’t face high temperatures or stress. - Carbon Steel Casting:

Carbon steel is stronger than aluminum but lacks the corrosion resistance of stainless steel. It’s ideal for parts that require durability but aren’t exposed to harsh environments.

| Material | Pros | Cons |

|---|---|---|

| Stainless Steel | High strength, corrosion resistance, heat resistance | Higher cost |

| Aluminum | Lightweight, cost-effective | Lower strength, poor corrosion resistance |

| Carbon Steel | Strong, cost-effective | Poor corrosion resistance |

Conclusion

Stainless steel casting is a crucial process for producing high-quality, durable parts. By understanding its importance, processes, and benefits, businesses can make more informed decisions when selecting manufacturing techniques for their products. Investing in stainless steel casting ensures precision, durability, and performance across a variety of industries, making it a valuable asset for any business.

FAQ Section

Q1: What is stainless steel casting?

Stainless steel casting is a process where molten stainless steel is poured into a mold to create a variety of components. It’s known for producing high-precision and durable parts used in industries like aerospace, automotive, and medical.

Q2: How does stainless steel casting work?

The process begins with creating a pattern, followed by mold making. Stainless steel is then melted and poured into the mold. The part is allowed to cool, and any excess material is cleaned up to reveal the finished casting.

Q3: What are the key benefits of stainless steel casting?

Stainless steel casting offers precision, corrosion resistance, and durability. It’s ideal for industries requiring parts that can withstand extreme conditions, making it a preferred choice for manufacturing critical components.

Q4: What types of industries use stainless steel casting?

Industries such as aerospace, automotive, and medical devices rely on stainless steel casting. The process provides the strength, precision, and durability necessary for manufacturing components that perform in demanding environments.

Q5: How do I maintain stainless steel castings?

Maintaining stainless steel castings involves regular cleaning to prevent rust and corrosion, careful handling to avoid physical damage, and routine inspections to ensure the part’s integrity over time.